Beruflich Dokumente

Kultur Dokumente

Allied Maturity Matrix 14 Reliability Centered Lubrication PDF

Hochgeladen von

HosseinOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Allied Maturity Matrix 14 Reliability Centered Lubrication PDF

Hochgeladen von

HosseinCopyright:

Verfügbare Formate

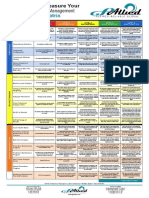

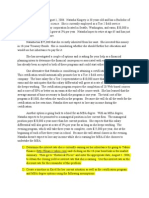

Ways to Measure Your

Reliability Centered Lubrication (RCL)

Maturity Matrix

LEVEL 11

LEVEL LEVEL 22

LEVEL LEVEL 3 LEVEL 44

LEVEL LEVEL 55

LEVEL

Elements NOT

NOT ENGAGED

ENGAGED EXPERIMENTING

EXPERIMENTING ENLIGHTENED GOOD

GOOD PRACTICE

PRACTICE BEST

BEST PRACTICE

PRACTICE

No functional hierarchy exists. Plant utilizes a smart CMMS Plant has a hierarchy down Hierarchy exists down to the

Plant has a hierarchy down to the

Plant uses the asset list from identification number for to the system level. Some component and/or lube point

machine level. Some components

level. List is very consistent across

Hierarchy accounting. No understanding hierarchy purposes. Machines, machines exist on their own exist on their own indenture level.

different areas and +95% accurate.

of the difference between asset components, and parts exist on indenture level. No real List is fairly consistent and at least

Data is validated on a frequent and

and equipment. the same indenture levels. consistency. List not accurate. 70% accurate.

regular interval.

Comprehensive library exists,

inclusive of all lubrication-related

Component attribute data contains Level 4 considerations + All

attributes. Level 3 + lube types,

Some component attributes basic lubrication information only. component attributes databased.

equipment modifications for lube

Information necessary for basic

Asset Catalog No Component Attribute Library. recorded for a few pieces of lubrication design (component

tasks, breathers, filtration, etc. Records are under document

critical equipment. Suitable for complete equipment control. Data validated on

mfg/model, size, speed, temp,

BOM. Records can only be changed regular and frequent intervals.

environmental considerations, etc).

by Planner. Data validated on an

as-needed basis.

RCL Program Elements

Formally designed program inclusive

Formally designed program that of Levels 3 and 4, with lubrication

Formally designed program

Basic program design; looks at looks at specific operating and routes and visual inspection

Current Lubrication inclusive of Level 3 with tasks

No formal program. manufacturer recommendations environmental characteristics data collection. Rounds logging

Program Design grouped into lubrication routes application in place with integrated

and basic component attributes. to determine required tasks,

by area, task, and interval. task management and reporting

intervals, and volumes.

capabilities.

Comprehensive systems set

Lubrication included in generic Some specific reporting for targets, monitor consumption, Level 4 capabilities + Integrated

Monitoring, Tracking,

No accounting for lubrication. maintenance reporting with lubrication with specific data identify defects, quantify platform for monitoring and

and Reporting

generic data and targets. sources and targets. savings, and provide budget reporting capabilities.

tracking.

Marketing the value of

Informal contacts used to Formal methods (email campaigns) Program in place for staff lubrication program and the

No promotion of lubrication

Internal Marketing promote lubrication program and to promote lubrication awareness to awareness and regular publicity performance of lubrication

program. lubrication and maintenance staff.

lubrication-related gains. campaign. management both within and

outside the organization.

Monies dedicated for the

Only low-cost measures or Investment decisions based on New asset investments required to

modification of existing facility

No investment in developing long-term paybacks for increased be designed/equipped for the proper

Investment short-term payback criteria assets for the maintenance of in use

lubrication program. reliability; methodical implementation

lubricants and proper storage of new

maintenance and handling of new

considered. focused on criticality. and used lubricants.

lubricants.

Lubrication function in place Detailed lubrication RASCIs

Lubrication Program and managed at lower levels List of lubrication responsibilities exist and are comprehensive

No evidence of assignment of Unwritten set of lubrication

Management of organization to include oil and their assignment exists for and regularly reviewed.

lubrication tasks and duties. responsibility assignments.

Responsibilities analysis, regrease, and visual key lubrication staff. Dedicated staff for Lubrication

inspection. Program.

Ad hoc training provided through Lubrication Awareness Training Fundamental lubrication and Lubrication technicians have

received training and are certified

Lubrication Training and lubricant or other service available to management oil analysis training provided

No lubrication training provided. as MLT and/or MLA; Lubrication

Awareness providers; product and process and involved staff; focus on to those involved in lubrication Awareness Training is available to

specific. lubrication fundamentals. program. all personnel involved in operations.

Routine reporting takes into account

equipment criticality, failure modes

and symptoms, primary and

Reports only issued if prompted Occasional reporting, verbal or secondary detection techniques. All

Routine reporting within CMMS

Reporting Procedures No reporting. by a business need, or when hard copy, informal with timeline equipment considered. Integrated

on a structured timeline. Asset Health reporting system in

problem exists. variability.

place inclusive of all applied CBM

technologies as well as lubrication

tasks.

Some equipment may have Critical equipment components Critical equipment components

Equipment modifications

manufacturer-installed components are modified with hardware are modified to include desiccant Lubricated components are

Existing Plant and to minimize downtime for

such as visual level gauges or to ease the burden of task breathers, level gauges, sample modified based on criticality,

Equipment Modification lubrication servicing has not sample valves, but additional completion (desiccant breathers, valves, quick connects, grease sump size, operating conditions.

been considered. modifications are not considered. level gauges, grease lines). lines, etc.

Equipment is well maintained Level 4 + Equipment modifications

Equipment is not maintained;

Equipment is given basic care Basic preventive maintenance and functional. Preventive and have been made to support

Status of Existing Plant leaks are observed and not

to keep it running until failure or on calendar basis and repair as condition based maintenance

Technical Elements

associated lubrication tasks.

and Equipment repaired; strictly Run-to-Failure Equipment is clean and labeled /

plant shutdown. needed. is performed. Repairs are

mentality. lube positions identified.

performed as needed.

Equipment is selected to be the

Equipment is selected to be the

most appropriate to the application

Equipment is replaced with most appropriate to the application

Equipment is replaced with and is modified with appropriate

with appropriate lubrication

Plant and Equipment No consideration for ease of similarly designed components; lubrication hardware prior to being

similar components; sealed hardware installed by manufacturer.

Replacement lubrication in selection process. aftermarket modifications are installed. Equipment utilizes

Equipment utilizes lubricants that are

bearings may be considered. lubricants that are already included

made. already included in the lubrication

in the lubrication program with

program.

minimal exceptions.

Procedures cover partial/critical Procedures cover all lubricated Procedures cover all lubricated

Procedures cover parts of components with routine task

No regular inspections or plant with routine task details components with routine

Lubrication / plant and/or basic information details. Component condition

lubrication maintenance carried (machine, lubrication, points, task details. Remedial action

Maintenance Procedures available (machine and lubricant information is documented and

out. lubricant grade(s), frequency, undertaken for most defects remedial action undertaken for all

type).

amount, etc.). identified. defects identified.

Continued on back...

Helping companies build wealth and competitive advantage through world-class reliability

across a global manufacturing network.

4200 Faber Place Drive Charleston, SC 29405 www.alliedreliability.com

Ways to Measure Your

Reliability Centered Lubrication (RCL)

Maturity Matrix

LEVEL 11

LEVEL LEVEL 22

LEVEL LEVEL 3 LEVEL 44

LEVEL LEVEL 55

LEVEL

Elements NOT

NOT ENGAGED

ENGAGED EXPERIMENTING

EXPERIMENTING ENLIGHTENED GOOD

GOOD PRACTICE

PRACTICE BEST

BEST PRACTICE

PRACTICE

Lubrication-related tasks are

When appropriate, all

completed while equipment is Equipment directly involved

No consideration is given to Critical equipment is modified lubrication-related tasks are

operating for assets that are with the production process is

Operational Knowledge completing lubrication-related so lubrication tasks can be completed while equipment

accessible during operation. modified so lubrication tasks can

for Task Completion tasks while equipment is completed while component is is running. Appropriate

Inaccessible assets are be completed while component

operating. running. modifications are made to

maintained while equipment is is running.

components to facilitate this.

down.

Available standards and Documents are comprehensive Documents are comprehensive

Some specific documents

documentation are generic or and cover most common and cover all common tasks and

Program Documentation None available. written; relevant documents are

poorly written. Difficult to apply tasks; relevant documents are scenarios; relevant documents

referenced on all tasks.

as written. referenced on all tasks. are provided with all tasks.

Level 4 + Dedicated lubrication

Dedicated lubrication storage storage room, dedicated bulk

Centralized storage available.

present. May not be centralized. Level 3 + Well organized, storage with filtration, desiccant

No dedicated lubrication storage Adequately sized and located.

Lubrication Storage Inadequately sized or located. clean, and tidy. Lubricants breather, pressurized, climate

in place. Poorly ventilated or lit. Dirty,

Technical Elements

Poorly ventilated or lit. Dirty, consolidated and well labeled. control, bulk lubrication storage

badly organized, or untidy.

badly organized, or untidy. includes filtration with dedicated

dispensing.

Filtration included at some Filtered at a single delivery Filtered at the delivery point.

Level 4 + Established

point in the handling/dispensing point. Meets target cleanliness Meets target cleanliness

procedures developed and

Lubrication Dispensing No filtration or testing of new oil. process. Not tested or prior to dispensing. Proper prior to dispensing. Proper

adhered to for proper lubrication

not meeting cleanliness transportation methods or transportation methods and

handling practices.

requirements. containers not considered. containers utilized.

Available lubricants are based

Current lubricants are based on

Supplier-developed lubricant Available lubricants are based on an engineered approach that

a combination of manufacturer

list based on general needs on an engineered approach that takes into account operating

Lubrication Selection / No formal documentation of recommendations, lubricants

throughout the plant, some takes into account operating and environmental variables for

Type / Application required lubricants. that have always been used,

consolidation in order to fit need and environmental variables for all equipment and the available

and the suppliers flavor of the

to available product. critical equipment only. number optimized to meet

month.

specific needs.

Analysis strategy takes into account

equipment criticality, failure modes

No consistent analysis Routine testing of critical Plant-wide routine testing. Some and symptoms, primary and

secondary detection techniques,

Oil Analysis Program Oil analysis currently not used. performed, only utilized when compartments only (no regards tailoring of frequency and test and test effectiveness. All equipment

there is a problem. for compartment size). slate to meet equipment needs. considered. Integrated Asset Health

program management and reporting

capabilities.

Lubrication tasks tracked within

integrated condition monitoring

Lubrication tasks tracked within Lubrication tasks tracked reporting system, scheduling,

Lubrication tasks tracked on

Lubrication Program No identifiable lubrication aspect spreadsheet, includes date within scheduling or work order follow-up work etc. is tracked, as

paper, includes date completed

Tracking tracked. completed, new due date, and system, follow-up tasks are well as Asset Health and component

and next due date. condition assessed based on

past due alert. scheduled as required.

applied lubrication tasks and

physical inspections.

Oil analysis results for critical Oil analysis results are migrated Visual inspection data, including

components are tracked in into CMMS system; completed top off volumes, and quantified

Data is available in paper format component conditions are collected

No measurements taken and no standalone system; completed task/inspection information

Data Sources for completed tasks/inspections/ during inspection tasks and stored

records kept. task/inspection information is available in paper format in condition monitoring system, Oil

oil analysis.

available in paper format or or other database (possibly

Results / Scorecard Elements

analysis results are also included in

other database. migrated into CMMS). the CBM database.

Lubricant usage monitored with

Lubricant usage is monitored respect to lubricant type and

Lubricant usage is tracked as with respect to lubricant type component, amount of lubricant

Lubricant usage analysis by type

Lubricant Usage No lubricant usage analysis a running total for all lubricants and component type, amount purchased is compared to running

is monitored based on amount

Tracking prepared. with limited identification of purchased is compared total of amount dispensed by

added/subtracted from inventory. specific component. Dispensed

individual products. to running total of amount

dispensed by component type. amounts are also compared to total

waste oil disposed of.

Reports prepared and provided

Reports prepared and provided Reports prepared and provided

Reports prepared and provided to managers in a concise form,

to managers incorporating both to managers in a concise form,

to managers incorporating both allowing both technical and

No management reports technical and financial data allowing both technical and financial

Report Outputs technical and financial data financial data to be effectively

prepared. together with deviations from data to be effectively utilized. Data

when prompted by business utilized, with deviations from normalized for ease of comparison.

budget and comparisons with

need or when problem exists. budget and comparisons with Impact of any uncertainties defined.

previous period.

previous period.

Suite of KPIs covering all Suite of KPIs covering all facets

facets of lubrication that are of lubrication that are regularly

regularly reviewed and updated reviewed and updated (Work

Lubrication included in generic Basic lubrication KPIs (Work Management, Plant Performance,

KPIs No lubrication KPIs. (Work Management, Plant

maintenance KPIs. Management, QA/QC). QA/QC, Storage and Handling,

Performance, QA/QC, Storage Health, Safety and Environment).

and Handling, Health, Safety KPIs communicated and understood

and Environment). by all stakeholders.

Helping companies build wealth and competitive advantage through world-class reliability

across a global manufacturing network.

4200 Faber Place Drive Charleston, SC 29405 www.alliedreliability.com

Das könnte Ihnen auch gefallen

- 5 Ways To Measure Your Asset Health ManagementDokument2 Seiten5 Ways To Measure Your Asset Health ManagementChávez Ordoñez RemyNoch keine Bewertungen

- 3 - Pillar Two-20170102Dokument26 Seiten3 - Pillar Two-20170102AhmadNoch keine Bewertungen

- How To Write A Lubrication ProcedureDokument5 SeitenHow To Write A Lubrication ProceduremawooaNoch keine Bewertungen

- Empowering Reliability Through Lubrication Program Development (LPD) Udey DhirDokument28 SeitenEmpowering Reliability Through Lubrication Program Development (LPD) Udey DhirEXECUTIVE ENGINEEER BOILER MAINTENANCENoch keine Bewertungen

- Plant Study Lube Assessment SOPDokument11 SeitenPlant Study Lube Assessment SOPHaitham Youssef100% (1)

- CMMS StrategyDokument12 SeitenCMMS StrategyDia Putranto HarmayNoch keine Bewertungen

- Machinery Lubrication March April 2019 PDFDokument86 SeitenMachinery Lubrication March April 2019 PDFJorge Cuadros BlasNoch keine Bewertungen

- Aladon Reliability-Mgmt E-Brochure 062116Dokument4 SeitenAladon Reliability-Mgmt E-Brochure 062116HugoCabanillasNoch keine Bewertungen

- Automatic Grease Lubricators White PaperDokument5 SeitenAutomatic Grease Lubricators White PaperPaul RuckNoch keine Bewertungen

- How To Select Machines For Oil AnalysisDokument3 SeitenHow To Select Machines For Oil AnalysisHari PurwadiNoch keine Bewertungen

- Creating An Effective Plant Lubrication ProgramDokument6 SeitenCreating An Effective Plant Lubrication Programocto widodo100% (1)

- 4 - Pillar Three-20170305Dokument129 Seiten4 - Pillar Three-20170305Ahmad100% (1)

- Presentation On GreaseDokument29 SeitenPresentation On GreaseAshishNoch keine Bewertungen

- 1 - Overview Rev-20170225Dokument11 Seiten1 - Overview Rev-20170225AhmadNoch keine Bewertungen

- Proactive MaintenanceDokument242 SeitenProactive MaintenancesatfasNoch keine Bewertungen

- 7 A New Look at Criticality Analisys For Machinery LubricationDokument8 Seiten7 A New Look at Criticality Analisys For Machinery LubricationGoakof100% (1)

- RSA Reliability and Maintenance Newsletter Vault Collection Supplementary Series on World Class Maintenance Management - The 12 Disciplines: 1, #8Von EverandRSA Reliability and Maintenance Newsletter Vault Collection Supplementary Series on World Class Maintenance Management - The 12 Disciplines: 1, #8Noch keine Bewertungen

- The Rights and Wrongs of Greasing From Selection To ApplicationDokument6 SeitenThe Rights and Wrongs of Greasing From Selection To ApplicationCeciliagorra100% (2)

- Signum Oil Analysis Condition Monitoring Fundamentals English UkDokument20 SeitenSignum Oil Analysis Condition Monitoring Fundamentals English UkHim SatiNoch keine Bewertungen

- Finding The Root Causes of Oil DegradationDokument12 SeitenFinding The Root Causes of Oil Degradationtehnicar1Noch keine Bewertungen

- Machinery Lubrication March April 2017Dokument89 SeitenMachinery Lubrication March April 2017EduardoChuchulloNoch keine Bewertungen

- SMRP Metric 5.5.38 Storeroom Maintenance Material CostDokument5 SeitenSMRP Metric 5.5.38 Storeroom Maintenance Material CostJorge FracaroNoch keine Bewertungen

- CBP Current Best Practices For Reliability and MaintenanceDokument8 SeitenCBP Current Best Practices For Reliability and MaintenancepkbijuNoch keine Bewertungen

- CMMS Software Work Order CodingDokument4 SeitenCMMS Software Work Order CodingKara JohnstonNoch keine Bewertungen

- Lubrication School: Training and Capability DevelopmentDokument20 SeitenLubrication School: Training and Capability DevelopmentFraz AhmadNoch keine Bewertungen

- Reliabilityweb Uptime 20121011Dokument69 SeitenReliabilityweb Uptime 20121011catraioNoch keine Bewertungen

- Machinery Lubrication MagazineDokument82 SeitenMachinery Lubrication Magazined_ansari26Noch keine Bewertungen

- Problems and Solutions on MRO Spare Parts and Storeroom 6th Discipline of World Class Maintenance Management: 1, #5Von EverandProblems and Solutions on MRO Spare Parts and Storeroom 6th Discipline of World Class Maintenance Management: 1, #5Noch keine Bewertungen

- Condition Monitoring EssentialsDokument44 SeitenCondition Monitoring Essentials4358213100% (2)

- SMRP Metric 5.5.8 Overtime Maintenance HoursDokument6 SeitenSMRP Metric 5.5.8 Overtime Maintenance HoursJorge FracaroNoch keine Bewertungen

- Machinery Lubrication Level IIDokument6 SeitenMachinery Lubrication Level IILot SalasNoch keine Bewertungen

- Lubricating OilsDokument22 SeitenLubricating OilsShweta PatilNoch keine Bewertungen

- Maintenance Indices - Meaningful Measures of Equipment Performance: 1, #10Von EverandMaintenance Indices - Meaningful Measures of Equipment Performance: 1, #10Noch keine Bewertungen

- Flushing and The Voice Within Your OilDokument4 SeitenFlushing and The Voice Within Your OilHunab379Noch keine Bewertungen

- Machinery Lubrication: Level 1 - 2Dokument12 SeitenMachinery Lubrication: Level 1 - 2JairNoch keine Bewertungen

- Step-by-Step Grease SelectionDokument10 SeitenStep-by-Step Grease SelectionSounak SasmalNoch keine Bewertungen

- (Whitepaper) Essential Tips For Optimizing Your Preventive MaintenanceDokument11 Seiten(Whitepaper) Essential Tips For Optimizing Your Preventive MaintenanceNazar Alrodainy100% (1)

- RCM Benchmarking SoftwareDokument8 SeitenRCM Benchmarking SoftwareAndres Felipe Torres100% (1)

- Technical Topic - Lubrication Program ManagementDokument2 SeitenTechnical Topic - Lubrication Program Managementdhavit wijayantoNoch keine Bewertungen

- Reliability Centered Maintenance Rcm A Complete Guide - 2019 EditionVon EverandReliability Centered Maintenance Rcm A Complete Guide - 2019 EditionNoch keine Bewertungen

- 5 - Shell LubAnalystDokument18 Seiten5 - Shell LubAnalystRicardo VillegasNoch keine Bewertungen

- Anatomy of An Oil Analysis ReportDokument8 SeitenAnatomy of An Oil Analysis ReportRuben_3115Noch keine Bewertungen

- Acoustic Lubrication Handbook 2018 Web PDFDokument20 SeitenAcoustic Lubrication Handbook 2018 Web PDFEswin Paico de la CruzNoch keine Bewertungen

- Noria Training CatalogDokument28 SeitenNoria Training Catalogaal_shurafaNoch keine Bewertungen

- Failure Codes For Power PlantsDokument80 SeitenFailure Codes For Power PlantsMohammed Aslam100% (3)

- RCMDokument2 SeitenRCMMohd Idris MohiuddinNoch keine Bewertungen

- Why Are We So Bad at Maintenance ManagementDokument16 SeitenWhy Are We So Bad at Maintenance ManagementMasoud AmirzadehfardNoch keine Bewertungen

- Decoding Reliability-Centered Maintenance Process for Manufacturing Industries 10th Discipline of World Class Maintenance Management: 1, #7Von EverandDecoding Reliability-Centered Maintenance Process for Manufacturing Industries 10th Discipline of World Class Maintenance Management: 1, #7Noch keine Bewertungen

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityVon EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityBewertung: 3 von 5 Sternen3/5 (4)

- Understanding Lubrication From The BearingDokument22 SeitenUnderstanding Lubrication From The BearingengrsurifNoch keine Bewertungen

- Determining Spare Parts RequirementsDokument4 SeitenDetermining Spare Parts RequirementsbijishvmNoch keine Bewertungen

- Mechanical Engineering Failures The Role of ReliabilityDokument15 SeitenMechanical Engineering Failures The Role of ReliabilityAbdulrahman AlkhowaiterNoch keine Bewertungen

- Best Maintenance Repair PracticesDokument4 SeitenBest Maintenance Repair PracticesMahaveer SinghNoch keine Bewertungen

- RCM Process RCM ProcessDokument58 SeitenRCM Process RCM Processgoldu18100% (2)

- Signum Technical GuideDokument30 SeitenSignum Technical Guiderbdubey2020Noch keine Bewertungen

- Reliability Centered MaintenanceDokument33 SeitenReliability Centered MaintenanceJeflonh Labu100% (2)

- SMRP Metric 1.5 Total Maintenance Cost As A Percent of Replacement Asset ValueDokument6 SeitenSMRP Metric 1.5 Total Maintenance Cost As A Percent of Replacement Asset Valueeigersumarly100% (2)

- Noria FML Training Brochure With ICML Certification ExamDokument7 SeitenNoria FML Training Brochure With ICML Certification Examediwski100% (1)

- Grammar On The Go!Dokument14 SeitenGrammar On The Go!HosseinNoch keine Bewertungen

- GrammarDokument87 SeitenGrammarMoralesRodrigoNoch keine Bewertungen

- Grammar On The Go!Dokument40 SeitenGrammar On The Go!HosseinNoch keine Bewertungen

- Steering The CourseDokument73 SeitenSteering The CourseHosseinNoch keine Bewertungen

- Parts of Speech PDFDokument104 SeitenParts of Speech PDFTia Sella IsnainiNoch keine Bewertungen

- Constructing SentencesDokument78 SeitenConstructing SentencesHosseinNoch keine Bewertungen

- PunctuationDokument68 SeitenPunctuationIvan Cortes50% (2)

- PunctuationDokument68 SeitenPunctuationIvan Cortes50% (2)

- English Tenses ChartDokument6 SeitenEnglish Tenses ChartHosseinNoch keine Bewertungen

- Constructing SentencesDokument78 SeitenConstructing SentencesHosseinNoch keine Bewertungen

- Writing Style and ProcessDokument30 SeitenWriting Style and ProcessHosseinNoch keine Bewertungen

- SP UP - SP Out UnitDokument66 SeitenSP UP - SP Out UnitHosseinNoch keine Bewertungen

- English Verbs + Prepositions DictionaryDokument19 SeitenEnglish Verbs + Prepositions DictionaryShayna - Espresso English89% (9)

- Useful Notes FromDokument14 SeitenUseful Notes FromHosseinNoch keine Bewertungen

- Tesnses TablesDokument2 SeitenTesnses TablesHosseinNoch keine Bewertungen

- Word Work & Spelling, Graphic Organizers & Mini-Lessons - 2008Dokument48 SeitenWord Work & Spelling, Graphic Organizers & Mini-Lessons - 2008HosseinNoch keine Bewertungen

- A Simple Guide To Practicing English With Native Speakers PDFDokument8 SeitenA Simple Guide To Practicing English With Native Speakers PDFChris MorgensternNoch keine Bewertungen

- 56 of The Most Useful Phrasal PDFDokument6 Seiten56 of The Most Useful Phrasal PDFbijayrNoch keine Bewertungen

- List of Connectors PDFDokument3 SeitenList of Connectors PDFYojan Sebastian MastropieroNoch keine Bewertungen

- Reliabilityweb How Failure OccursDokument1 SeiteReliabilityweb How Failure Occursleonardq1100% (1)

- Logical RelationshipsDokument13 SeitenLogical RelationshipsAndres Giovanny MeloNoch keine Bewertungen

- Improve Your Writing skill-IELTSDokument21 SeitenImprove Your Writing skill-IELTSfgousiosNoch keine Bewertungen

- Bearing FailuresDokument7 SeitenBearing FailuresdwdobbsNoch keine Bewertungen

- Alumax - ProActive Maintenance ModelDokument7 SeitenAlumax - ProActive Maintenance ModelHosseinNoch keine Bewertungen

- Defect EliminationDokument4 SeitenDefect EliminationHossein100% (1)

- How To Analyze Gear FailuresDokument6 SeitenHow To Analyze Gear FailuresHossein100% (1)

- Understanding The Importance of Bearing ClearanceDokument4 SeitenUnderstanding The Importance of Bearing ClearanceHosseinNoch keine Bewertungen

- Crazy Sentences and Suggested ReadingDokument7 SeitenCrazy Sentences and Suggested ReadingHosseinNoch keine Bewertungen

- Crazy Sentences and Suggested ReadingDokument9 SeitenCrazy Sentences and Suggested ReadingDeea MaanthNoch keine Bewertungen

- Sudhir Anand and Amartya SenDokument34 SeitenSudhir Anand and Amartya SenAnkur SinghNoch keine Bewertungen

- Business Environment and Strategic ManagementDokument40 SeitenBusiness Environment and Strategic Managementsmithanil100% (1)

- Ambit - CDSL - Initiation - Best Play On Equitisation - 05sept2023Dokument54 SeitenAmbit - CDSL - Initiation - Best Play On Equitisation - 05sept2023Naushil Shah100% (1)

- VolatilityDokument5 SeitenVolatilityTaxation Tax100% (1)

- Globalisation BrochureDokument43 SeitenGlobalisation Brochurerobertod2003Noch keine Bewertungen

- FIL 124 - Final TestDokument16 SeitenFIL 124 - Final TestChavey Jean V. RenidoNoch keine Bewertungen

- Roll No Time Allowed: 3 Hours Maximum Marks: 100 Total Number of Questions: 8 Total Number of Printed Pages: 11Dokument11 SeitenRoll No Time Allowed: 3 Hours Maximum Marks: 100 Total Number of Questions: 8 Total Number of Printed Pages: 11Jesse SandersNoch keine Bewertungen

- The Asian Financial Crisis of 1997 1998 Revisited Causes Recovery and The Path Going ForwardDokument10 SeitenThe Asian Financial Crisis of 1997 1998 Revisited Causes Recovery and The Path Going Forwardgreenam 14Noch keine Bewertungen

- Digital Transformation Is The Process of Using Digital Technologies To Create New - or Modify ExistingDokument4 SeitenDigital Transformation Is The Process of Using Digital Technologies To Create New - or Modify ExistingZaw Myo HeinNoch keine Bewertungen

- National Income: Click To Edit Master Subtitle StyleDokument26 SeitenNational Income: Click To Edit Master Subtitle StyleashpakkhatikNoch keine Bewertungen

- Financial LiteracyDokument4 SeitenFinancial LiteracyLester AcupidoNoch keine Bewertungen

- The Effect of The Global Financial Crisis and On Emerging and Developing EconomiesDokument16 SeitenThe Effect of The Global Financial Crisis and On Emerging and Developing EconomiesIPPRNoch keine Bewertungen

- Impact of US Subprime Crisis On Indian Fnancial SectorDokument60 SeitenImpact of US Subprime Crisis On Indian Fnancial SectorShashi Dev PandeyNoch keine Bewertungen

- WK 4 Paper Finance - Doc - 35K - Student of FortuneDokument5 SeitenWK 4 Paper Finance - Doc - 35K - Student of FortuneOlaru LorenaNoch keine Bewertungen

- Solution Manual For Advanced Accounting, 11th Edition - HoyleDokument27 SeitenSolution Manual For Advanced Accounting, 11th Edition - HoyleAlmoosawi100% (1)

- NEF Funding-Application-FormsDokument8 SeitenNEF Funding-Application-FormssylvesterNoch keine Bewertungen

- Ratio Analysis FormulaeDokument3 SeitenRatio Analysis FormulaeErica DsouzaNoch keine Bewertungen

- SAP R3 SD Senior and Certified SAP CRM ConsultantDokument714 SeitenSAP R3 SD Senior and Certified SAP CRM ConsultantJana MeinertNoch keine Bewertungen

- Introduction To Financial Modelling - Varsity by ZerodhaDokument8 SeitenIntroduction To Financial Modelling - Varsity by ZerodhaBenudhar SahooNoch keine Bewertungen

- Global In-House Center (GIC) Landscape in Costa Rica and Trends in Offshore GIC MarketDokument14 SeitenGlobal In-House Center (GIC) Landscape in Costa Rica and Trends in Offshore GIC MarketeverestgrpNoch keine Bewertungen

- PDFDokument19 SeitenPDFVINOD MEHTANoch keine Bewertungen

- Celeste Han Enbloc SurveyDokument6 SeitenCeleste Han Enbloc SurveydrminorityNoch keine Bewertungen

- Id Fas Brochure Noexp PDFDokument24 SeitenId Fas Brochure Noexp PDFDaniel PandapotanNoch keine Bewertungen

- FurnitureDokument72 SeitenFurnitureSamuel Davis100% (3)

- Lakshwiz - D Street - AVARTAN 2022Dokument7 SeitenLakshwiz - D Street - AVARTAN 2022Jenil RitaNoch keine Bewertungen

- Chapter 6: Government Influence On Exchange Rate Exchange Rate System Fixed Exchange Rate SystemDokument5 SeitenChapter 6: Government Influence On Exchange Rate Exchange Rate System Fixed Exchange Rate SystemMayliya Alfi NurritaNoch keine Bewertungen

- Presentation On Topic: HDFC Bank AND Models of ManagementDokument42 SeitenPresentation On Topic: HDFC Bank AND Models of Managementsonu238909Noch keine Bewertungen

- Ppt. On Current ScenarioDokument14 SeitenPpt. On Current Scenariovnahata87Noch keine Bewertungen

- Compliance Portal - Non-Filing of Return - User Guide - V2.0Dokument94 SeitenCompliance Portal - Non-Filing of Return - User Guide - V2.0Videesh Kakarla0% (1)

- Hotel Industry Terror ImpactDokument8 SeitenHotel Industry Terror ImpactTidusVelatNoch keine Bewertungen