Beruflich Dokumente

Kultur Dokumente

As 4100 1998 SteelStruct

Hochgeladen von

sivakumar100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

898 Ansichten200 SeitenAS 4100 1998 Steel Structures

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAS 4100 1998 Steel Structures

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

898 Ansichten200 SeitenAs 4100 1998 SteelStruct

Hochgeladen von

sivakumarAS 4100 1998 Steel Structures

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 200

AS 4100—19¢8

®

Australian Standard™

Steel structures

ae oct Gaendanine a

‘This Ausaian Standard was prepaced by Commits BD/, Steel Sucre. Te wat

{pproved on bea of the Coun of Stars Aus en 17 Api 1998 snd published

on Tone (998

‘The flloing interests ae represented on Commitee BDV

Assocation of Costing Eaglners Aus

‘Auslin Coaseucion Services

Auscllan Insitute of Steel Contution

AUSTROADS

Building Management Authority, WA.

Bureau of Stel Manufacturers of Ava {

t

CSIRO, Division of Bung, Constction and Engineering

Confederation of Auslian Instry

Inston of Engines, Attala I

Mea Tay certo Asa we ©).

Now Zen Heavy Engneing Research Asocaon o ?

Pb Works Deparment NS r

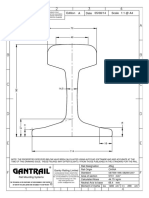

Railay Aas Commitee |

nie of New South aes |

Urine of Qrentnd

Unie 0 Syey #

‘Welding Technology Ist of Avsalia

ef arn Smt, og ces rp nny. ao dg ti

‘phe uted ac os fone he eee

‘soot naman oe sah ye eg a sean a

Coen IR ha fe pe no

pied ieee yey oy na una Sedo see ma wt

Tiny ner ce mabe cated a arate a

Sooaslmvamscmen

a Perper

Sees ae eae oe emo

[Risky pment Raped Polen al inkemuo on mea shee ace lB fn te Head Oc

Sp ae ret ce mime eee pp oy

cpt aa tnt ee te Sn tat ol oe eS ioe

‘Rete ten nema wong tre ropes ol emer wi ye ie

MSpace el Suan cana

AS 4100—1998

Australian Standard ™

»

Steel structures

® umuiskeo ey spnoanos ausraAia

(RIMS STORES AUSTEN

PRRERESSERTASOESUST ATEN

enema eal

€@

PREFACE,

This Standard was prepared by the Standards Australia Commitee BDYI, Stel Structures, to

supersede AS 41001990,

‘The objective of this Standard isto provide designers of tel strates with specifiestios for sel

structural members used for lad-canying purposes in uilngs and cher structures

This new edition of the Standard incorporates Amendments No, 1—-1992, No, 2—1993,

No.31998 and drafl Amendment No. issued for public comment as DR 9737. Draft

Amendment No.4 was nt published separately agree slip,

Amendment No, 11992 lds he lowing male changes

(0) Seng tls copying wit AS 1163 and ASINZS 159, (abe 2.1)

(0) Shearling apy fr steed we, (Clase 5.152)

(©) Desig heking cpa (Clase 3.134) oo

Amendnen No 2-199 cada fing jr cane: ee

(a) Stear an bending inerton meio. (Case 5123)

(©) Minimum ares forthe design ofntrmediate ransvere web sitfeners, (Clause 5.15.3)

(©) Scetioncapaciy of members subject o combined actions, (Cause 8:3.)

(©) Strength assessment ofa but weld, (Clause 9.7.2.7)

(@) Fatigue. (Section 11)

Amendment No, 31993 inludes the following major changes:

(@)_ Compressive bearing ction on the edge ofa web. (Clause 5.13)

(©) Section capacity of members subject o combined actions. (Cause 83.)

(©) Inplane and out-of-plane capacity of compression members. (Causes 84.2.2 and 8.441.)

(8) Sengih assessment ofa butt weld, (Clase 9.2.7)

(©) athqoake (Section 13)

‘Amendment No.4 incdes the fllowing major changes:

Strengths of steels complying with ASINZS 3678, AS/NZS 3679.1 and ASINZS 3679.2.

(asie21),

(©) Mummum edge distance of fasteners. (Clause 9.62) |

(©) Permissible service temperatures secordng to ste ype and thickness (Table 104.1.)

(6) Steeltype relationship to sel grade, (Table 10.8.4.)

(©) Welding of concentrically braced frames for structures of earthquake Design Category D

and E (Clause 133.42)

‘The tems ‘nomative" and ‘informatve" have heen wd inthis Standard to define the application of

"he appendix o which they apply. A “normative” appendix i an intl pat of Standard wheres 80

“infomative’ appendix is only for information and guidance,

c@

Cc»

CD

(®

CONTENTS:

Poge

SECTION | SCOPE AND GENERAL

LL SCOPE AND APPLICATION *

12 REFERENCED DOCUMENTS '

13 DEFINITIONS '

14 NOTATION see

1.5. USE OF ALTERNATIVE MATERIALS OR METHODS 2

16 DESIGN 21

17 CONSTRUCTION... n

SECTION2 MATERIALS

2.1 YIELD STRESS AND TENSILE STRENGTII USED IN DESIGN a

22 STRUCTURAL STEFL, 2

23. FASTENERS . 2

24 STEEL CASTINGS a

SECTIONS GENERAL DESIGN REQUIREMENTS

Bi DESIGN 2

32 LOADS AND OTHER ACTIONS 3

33. STABILITY LIMITSTATE .... - »

34 STRENGTH LIMIT STATE

35. SERVICEABILITY LIMIT STATE 3

36 STRENGTH AND SERVICEABILITY LIMIT STATES BY LOAD

TESTING... a

3 BRITTLE FRACTURE «00.00.00. . 3

38 FATIGUE 3

39° FIRE : vvceeennneneeee ee

3:10 EARTHQUAKE =

3.11 OTHER DESIGN REQUIREMENTS =

3

SECTION 4 METHODS OF STRUCTURAL ANALYSIS

4a

42

43

44

45

46

a

‘METHODS OF DETERMINING ACTION EFFECTS

[FORMS OF CONSTRUCTION ASSUMED FOR STRUCTURAL

ANALYSIS : 3

[ASSUMPTIONS FOR ANALYSIS M

BLASTIC ANALYSIS. Py

PLASTIC ANALYSIS... %

MEMBER BUCKLING ANALYSIS 4

FRAME BUCKLING ANALYSIS = :a

SECTIONS MEMBERS SUBJECT TO BENDING

sa

s2

33

34

55

36

st

ss

39

510

sn

512

513

sad

34s

516

DESIGN FOR BENDING MOMENT

SECTION MOMENT CAPACITY FOR BENDING ABOUT

A PRINCIPAL AXIS

MEMBER CAPACITY OF SEGMENTS WITH FULL LATERAL

RESTRAINT

RESTRAINTS

CRITICAL FLANGE

[MEMBER CAPACITY OF SEGMENTS WITHOUT FULL LATERAL,

RESTRAINT

BENDING IN A NON-PRINCIPAL PLANE

SEPARATORS AND DIAPHRAGMS

DESIGN OF WEBS

ARRANGEMENT OF WEBS

SHEAR CAPACITY OF ERS

INTERACTION OF SHEAR AND BENDING

COMPRESSIVE BEARING ACTION ON THE EDGE OF A WEB.

DESIGN OF LOAD BEARING STIFFENERS.

DESIGN OF INTERMEDIATE TRANSVERSE WEB STIFFENERS

DESIGN OF LONGITUDINAL WEB STIFFENERS

SECTION 6 MEMBERS SUBJECT TO AXIAL COMPRESSION

64

62

63

6a

65

66

DESIGN FOR AXIAL COMPRESSION

NOMINAL SECTION CAPACITY

[NOMINAL MEMBER CAPACITY

LACED AND BATTENED COMPRESSION MEMBERS

COMPRESSION MEMBERS BACK TO BACK

RESTRAINTS

SECTION? MEMBERS SUBJECT TO AXIAL TENSION

1

2

13

14

1s

DESIGN FOR AXIAL TENSION

NOMINAL SECTION CAPACITY

DISTRIBUTION OF FORCES

TENSION MEMBERS WITH TWO OR MORE MAIN

COMPONENTS,

MEMBERS WITH PIN CONNECTIONS

SECTION 8 MEMBERS SUBJECT TO COMBINED ACTIONS

&L

82

83

8s

GENERAL

DBSIGN ACTIONS

SECTION CAPACITY

MEMBER CAPACITY

45

4s

»

Ss

3

39

B

eesaze

Py

4

a

- 8s

‘@

SECTION9 CONNECTIONS

94

92

93

94

9s

96

97

98

99

SECTION 10. BRITTL

01

02

m3

oa

ms

GENERAL

DEFINITIONS

DESIGN OF BOLTS

[ASSESSMENT OF THE STRENGTH OF A BOLT GROUP.

DESIGN OF A PIN CONNECTION

DESIGN DETAILS FOR BOLTS AND PINS

DESIGN OF WELDS

[ASSESSMENT OF THE STRENGTH OF A WELD GROUP

PACKING IN CONSTRUCTION

FRACTURE

METHODS

NOTCH-DUCTILE RANGE METHOD

DESIGN SERVICE TEMPERATURE

‘MATERIAL SELECTION

[FRACTURE ASSESSMENT

SECTION Il FATIGUE

Ma

na

us

na

us

6

nz

us

ng

GENERAL,

FATIGUE LOADING

DESIGN SPECTRUM

EXEMPTION FROM ASSESSMENT

DETAIL CATEGORY

FATIGUE STRENGTH

EXEMPTION FROM FURTHER ASSESSMENT

FATIGUE ASSESSMENT

PUNCHING LIMITATION

SECTION 12 FIRE

a

2

123

ns

ns

126

ny

ns

REQUIREMENTS

DEFINITIONS

DETERMINATION OF PERIOD OF STRUCTURAL ADEQUACY

VARIATION OF MECHANICAL PROPERTIES OF STEEL WITH

‘TEMPERATURE...

DETERMINATION OF LIMITING STEEL TEMPERATURE

DETERMINATION OF TIME AT WHICH LIMITING TEMPERATURE IS

ATTAINED FOR PROTECTED MEMBERS

DETERMINATION OF TIME AT WHICH LIMITING TEMPERATURE IS

ATTAINED FOR UNPROTECTED MEMBERS

DETERMINATION OF PSA FROM A SINGLE TEST

Page

95

98

102

1m

13

104

13

M4

us

us

13

us

18

19

m1

m1

12

13.

1

16

16

16,

7

a

ro

Bs

Bs

19

1

ey

Page

129 THREE-SIDED FIRE EXPOSURE CONDITION 1a

12.10 SPECIAL CONSIDERATIONS 1

SECTION 13 EARTHQUAKE

1 GENERAL . us

132 DEFINITIONS «0... us

133. DESIGN AND DETAILING REQUIREMENTS «0.0... us

134. DESIGN REQUIREMENTS FOR NON.BUILDING STRUCTURES wr

SECTION 14 FABRICATION

141 GENERAL

142 MATERIAL

M3. FABRICATION PROCEDURES

144 TOLERANCES

SECTION 1S ERECTION

1S... GENERAL 136

152. ERECTION PROCEDURES . 156

183 TOLERANCES. oe 139

154 INSPECTION OF BOLTED CONNECTIONS 163

185. GROUTING AT SUPPORTS . 163

SECTION 16 MODIFICATION OF EXISTING STRUCTURES,

161 GENERAL sees IGE

162. MATERIALS . ee ie

163 CLEANING . ’ cove 1H

1644 SPECIAL PROVISIONS ........ . 168

@

|

SECTION 7 TESTING OF STRUCTURES OR ELEMENTS

wn ces = vs

fia eRAMONS = es

173 Test REQUIREMENTS : ws

M4 ROOP TESTING. ws

MS PROTOTYPE TESTING... Cw

Pn6 REWORTORTESTS oo CEs

arexrces

{A REFERENCED DOCUMENTS ..ujcses neat a

SUGGESTED DEFLECTION LIMITS... 169

‘CORROSION PROTECTION ceo 170

ADVANCED STRUCTURAL ANALYSIS a

‘SECOND ORDER ELASTIC ANALYSIS Sin

‘MOMENT AMPLIFICATION FOR A SWAY MEMBER... cere TA

amooe

® : —-

Page

G__ BRACED MEMBER BUCKLING IN FRAMES

H__ ELASTIC RESISTANCE TO LATERAL BUCKLING

1 STRENGTH OF STIFFENED WEB PANELS UNDER COMBINED

ACTIONS : mm

J. STANDARD TEST FOR EVALUATION OF SLIP FACTOR cosas TBA

K_ INSPECTION OF BOLT TENSION USING A TORQUE WRENCH 188

INDEX

ns

eI

19

STANDARDS AUSTRALIA

‘Australian Standard

Steel structures

SECTION 1 SCOPEAND GENERAL

LL SCOPE AND APPLICATION |

4.1.1 Scope This Standard sets out minimum requirements fo the design fabrication, erection,

sd modification of stcel work in stucteres in accordance with the int states design method

‘This Standard plies ro buildings, tractus and ranes constructed of te, @

y

‘This Standard is intended wo apply also to roadway, railway, and pedestrian bridges. However, he

requirements given in his Standard may not always be sufficient for bridge applications Th these

sSteumstances, the specifications ofthe relevant Authority shall be used,

‘This Standard does not apply to the following structures and materials: 1

Sa

Te ert cc at ie

1.12 Application This Standard wll be referenced inthe Bulding Code of Australi by way of|

[BCA Amendment No.3 o be published by | July 1998, thereby superseding the previous eition,

‘AS 4100—1900, which wil be withrawn 12 moms from the date of publication of this edition

1.2 REFERENCED DOCUMENTS The documents refered to inthis Standard ar stein

Appendix A.

13 DEFINITIONS For the purpose of this Standard the definitions below apply. Definitions

peculiar toa particular Cause or Section are also given in that Clause or Section

‘Action—the cause of sesso deformations in a uct

“Action effect or load effect—the itera force or bending moment det tons or loads

Athority—a body having tarutory powers to contol the design and erection of struct

‘Bearing-type connection—connecton effected sing iter sng tight ols, or high-strength bots

Vightened to induce a specified minimum bol tension, i which the design ston is transfered by

shear inthe bolts and bearing onthe connected parte a the stengt iit state

Bearing-wall system-—see AS 11704,

Brace frame—see AS 1170,

Braced member—one for which the tansverse displacement of on end ofthe member relative othe

‘other is effectively prevented

Building frame stem—see AS 1170.

Capacity factor—a factor use 10 mally the nominal capacity to obtain the desi capaci,

Compete peneration butt weld—a but weld in which fusion exists betwen she weld and parent

metal throughout the complete depth ofthe jin.

Concentric braced frame—see AS 1170

Consiant sess range faigue limit—ghest constant sues range fo each dtl category a which

fatigue cracks are not expected to propagate (see Figure II.)

Cuff tnit—for exch det category, the highest variable stress range which doesnot reuire

‘consideration when canying ou camlative damage caleulstion (see Figures 11.6.1 and 11.62),

Design ation effec or design load efect—the action ola effect computed fom the design acons

‘or design lous.

Design ation or design load the combination of the nominal actions o lauds and the load factor,

1 specified in AS 1170.1, AS 11702, AS 1170.3 or AS 1170.4,

Desig capacty—the product ofthe nominal apacity andthe capacity factor,

Design ife—period over which a stuctueor structural element is required o perform its function

without repair

Design vesiszance efecr—the ressance effect computed fom the loads and design capact

‘contig toward the stably Timi stat esistance,

Desig spectrat—som ofthe stress spect rom al ofthe nominal oading events expected during

the design ie

Detail category designation given oa paticlar etl once which of the SN curvesist> be

sed in the fatigue assessment

iscominuity—an absence of mats

Drifsee AS 1170

Dual system—see AS 11704,

Ductliy—see AS 117044

arthquae design eategory—see AS 11704,

artquake resisting sstem—see AS 1704,

Eccentric braced frame—see AS 1704,

Exposed surface area 1 mass raio—the ratio of the surface area expose tothe ie othe mass of|

‘sl

‘Forgue—damage cased by repeated hstustos of res leading to gral racking of strata

element

Fatigue foading—set of nominal loading events deseribed by the dsributon of the loads. their

‘magnitudes and the numbers of applications of cach nominal loaing event,

-arigue soength—the sess range defied in Clause 11.6 fr each detail category (se Figures 1.6.1

and 1.62) varying wih the numberof sues ecls,

Fire exposure condition —

(8) tree-sided fire exposure condtionsteel member incorporated in or in contact wih &

concrete or masenry Noor or wal,

(©) foursided fre exposwe conditions sel member exposed to fire on al sides.

Fire protection sstem—the fire protection material and its method of attchmeat to the sel

member.

Fiperesiiance level (FRL}~te fire-esistance grading period for structural adequacy only, ia

‘minutes, whic required tobe atned inthe standard ie tes

Friction ype comecionconnection effected using high-strength bolts tightened to induce &

specified minimum bot tension such thatthe resultant clamping ation trates the desin shear

forees atthe serviceability limit tate acting in the plan ofthe common contact surfaces bythe

fiction developed between the contact surfaces,

Fail ensioning-a mao of nstaling td tensioning a bolt in accordance with Clauses 15.2.4 and

1525.

Geometrical stenderessrario—he geomesical senderess ratio I), taken a th elective length

Uo, specified in Clause 6:32, divide by the radu of gyration (7) computed fr the gross section

about he relevant axis

Incomplete penetration but weld but wed in which the depth of penetration is less than the

complete depth ofthe joint.

‘plan tading—loading fr which the design force and being moments ae in he plane ofthe

‘connection, so hat the design action effects induced inthe connection components ae shea ores

only.

Imermediate moment resisting fame see AS 11708.

“Length (ofa compression member)—tne eta eth (0) ofan axially loaded compression member,

taken asthe length centre-to-cetre of intersections with supporting members, othe canvered

length inthe ease of a re-staning member.

“init state—any iting condition beyond which he stuctare ceases ofits intended function

Load—an exernlly applied force,

Miner’ summarion—curulative damage clelation based onthe Palmgren-Minr sunmtion oF

equivalent

Moment resisting frame system—see AS 1170

‘Namina aeton or foad—an action or load, a specified in Clause 32.1 or 3.2.2.

‘Nominal capacizy—ihe capacity of a member or connection computed using the parameters

specified inthis Standard

Nominal lading event—the long sequence fo the structure or structural element,

Non-ip fasteners—fasteners which donot allow sip to occur between connected plats or members

atthe serviceabily limit stat 0 that the orginal alignment and relative positions are maintine,

Ondinary moment resisting frame—see AS 170A,

(Out plane loadng-toading for which the design forces or bending moments result in design

‘etn fects nama othe plane ofthe connection

Period of structural adequacy (PSA) (fire) time (in inate, forthe member orate Limit

state of structural adequacy inte standard fete.

Pinan undeaded fastener manufactured out of round bas

Plastic hinge—a yeding zone with signiieant inelastic rotation which forms ina member whe the

plastic moments reached.

Prequalified weld preparations join preparation prequalified in terms of AS/NZS 1854.

Proof resting—the application of et loads to a structure, sb-srature, member or connection to

cera the suuctral characterises of only that one unt under test

Prototype (fire)—a est specimen represeting ste member and it fire proection system which is

subjected tothe standard fire tes

Prosoype resting—the application of est load o one or more srctures,sub-stroctures, members ot

‘connections to ascertain the strcturl characteristics ofthat class of structures sub-srutues,

‘members or connections which are nominally identical Yo the nie tested,

———e

rain orce—adsiiona tensile force developed a rest ofthe fetng ofa convetion component

in a connection subjected ro rene force. Extemal tension force reduces the contact presse

between the component andthe bse, and bending in pat ofthe component develops a yin free

nea the edge ofthe connection component

Segment (na member subjected obending)~Ibe length beeen adjacent cross-sections whichare

Fully opr restsined or he length between an unrestined end andthe ajacent cross secton

whic s flyer paiallyresrane,

Servceabitiry limi stare—a limit sate of acceptable in-service condition,

‘Shear wall—a wall designed to resist lateral eres parallel to the plane ofthe wal,

5:9 curve—curve defining the iting relationship between the amber of stress cycles and tess

range fra detail category.

‘Sg ight—tetghines of abot acieved by afew impacts fan impact wrench or by the ll eet

ofa person using a standard poser spanner

Sys fone 8 704

DS essing mea A 1704

Stabilny tit state—a limit sae comesponding othe loss of static equilibrium of a stuctre

considered rigid body.

‘Standard fire rest—the fie-esitance test specified in AS 1530.4.

| Sckabit—the ably ofthe fie protection sytem remain in plas asthe member deflects unler

oad daring fire tes.

| Strength tint stare—a iit sate of collapse or loss of starlings.

Siress cycle one eycl of tess defined by stress cycle counting

Siress cele counting method —any rational method sed to ety individual tress cls from the

sires story.

‘Siessrange—algebrac difference beween two extemes of ste,

Sires pectrun-—histogram ofthe sess eels produced bya nominal lading event

Structural adequacy fire)—the sity ofthe member exposed tothe saad fir test teary he est

oad specified n AS 15304,

|

a Sway member—ove for which be wansverse displacement of one end ofthe member eative ose

|

|

ceri not effestively prevented

Tensile strengeh—the minimum ultimate strength ia tension specified for the grade of seein he

appropriate Australian Standard.

eld siress—the minimum ye stress in tension speed for the grade of tee inthe appropriate

‘Austin Standard.

14 NOTATION Symbols use in this Standard ae listed below.

‘Where non-dimensional ratios ae invelved, both the mmertor and denominator are expesse in

‘detcal units.

‘The dimensional wits for length and sess in all expressions or equations are to be taken as

millimetres (num) an megapascals (MPa respectively, unless specially noted wtherwise-

‘A superscripted “placed after symbol denotes a design ation effec to the design lad for the

strength Limi state

A = area of erosesection

a = minor diameter area of abot, as defined in AS 1275

A etve area ofa eos seton: or

1 ea enclosed by allow section

corvacit

Aw

Me

Ain

aay

a5

Po Pas Bn Bo

fa

m

be

o

re

a

be

baba

3.4.

o

= ea ofan end pate

Nang area at vial evoss- section

4098 are of ange

‘ange are a minimum croee-scton; or

lesser ofthe ange effective srs

= net area ofa flange

= gross area ofa crost-secton

et area of a cross-section or

= sum ofthe net areas ofthe flanges and the gross area ofthe web

= plain shank atea of a bole

«cross-sectional area ofa pin

tensile ses area ofa bolt as defined in AS 1275; or

ea of asifener or stiffeners in contact with flange; or

sed of an intermediate web tifener

sro sectional ares of web oF

= effective shear area ofa pug or sot weld

‘minimum distance from the edge ofa hole othe edge ofa ply measerein he

staggered pitch of bots

steel temperature in degrees Celsius

= limiting steel emperature in degrees Celsius

thickness or

thickness of hiner pat joined

wall thikness ofa circular hollow section or

Ahickness ofan ange section or

thickness ofa fangs or

thickness ofthe erie flange

thickness of ply: or

1 thickness of thinner ply connected or

= thickness ofa plate

thickness of stiffener

design dat thickness ofa weld

thickness of awed

size ofa filet weld

nominal bearing capacity of ply oF pin; or

nominal shear buckling espacity ofa web

nominal shear capacity of a olt or pin—strength limit state

= nominal shear capacity ofa bol—serviceabily limit tte

= measured slip-oad atthe ith bot

comme

~e-

A

ve

ve

VE

‘= nominal shea apacity of a web with a wniform shear stress dstbuion

nominal shear capacity of a web

= nominal wel shear capacity in the presenoe of bending moment

nominal shear ysl capacity of a wel or

nominal shear capacity ofa plug or le weld

design shear force or

esign horizontal sre shear ore at lower column ends or

design transverse shea force

» ls oo

oorplate 450.15 < o

Ie, | cen | ao 0

oe | meee | mo

ae ten | wo =

TABLE 21 (continued)

Tike

sietsuntrs | Form | stpmte | “amt” nares | see neh

_ ersm0 380, | 80,

eo ren wo |”

sezn | wo 0

pm, | crew | a 0

eee 0

25015, fs “o

EA sen | x0 |

[a0 |

pe | ere | a “0

aus | wasuo | no 0

so acrzm | 20 a0

0 ven [a =

‘coi

ccoPrescir

TABLE 21. (contimed)

Sel Standard

Viet sree

Tee stent

SINE 31

90

sous

000

soos

ere

sons

x0

ind gece

10

0

‘eoninedh

TABLE 24 (continued)

Sto Sta Form | Siestgrade | materi

Tease eng

ot soereim

ous

poy ream

tous

a

sao ocr 100

0 sem

“0

0.0 socrewo

2sitis

10

20

Woled racine capling wih ASRS 5672 we mucin fom baad peal el er

Emig wih ASI SOR.

owes:

1 Fer ign pps, da ee sents aprocinate thse of src Grae HAZOD. For sic

Ines moe he nee

2 Cle 1.1 snot pei bey ss) sen desen excel 40 a

corvaci

SECTION 3 GENERAL DESIGN REQUIREMENTS

3M DESIGN

JAL Alm The aim of strucural design isto provide a structure which is stable, has adequate

Serength, serviceable and durable nd which satisfies the bjectves such as economy and ease of

‘A suture is table if it doesnot overt, ik or slide shroushout its intended life

A sructre has adequate strength andi sevceble if the probabilities of ruta file and of ss

of serviceability thoughout intended Iie are accepably low.

‘A srr is doable iit withstands te expected Wear and deterioration vhroughowt its intended fe

‘wither the need fr undue maintenance.

3412 Requirements. The souctre and its component members and connections sll sity the

‘espn requirement for stability. stent, serviceabil, bile Fracture, fate, ir and eartuake

In accordance with the procedures piven inthis Standard, as appropri

32 LOADS AND OTHER ACTIONS

321. Loads “The design of srctre forthe stably strength and serviceability limit tts call

account for the action effects diety arising from the following toads

(@) Dead, lve, wind, snow and eanbguake loads specified in AS 1170.1, AS 11702, AS 11703

and AS 11704,

(©) For the design of cranes, any relevant lads specified in AS 1418,

(©) For the design of fixed platforms, walkways, sthrways and ladders, any relevant loa

specified in AS 1657

(©) Forte design ofits, any relevant loads specified in AS-1735,

©) Oder speife loads, a8 require,

NoTES:

1 Porth design of brides, loads specified in SAA HBTT.2 or SAA HB. 2 pliable, shouldbe

‘sed

2 Formltstoy bung erst, ato Case 3.24

322 Other actions Any action which may significantly affect the stabil, strength or

‘ervicabley ofthe tract, including the fllwig sll be ake a ws

(@) Foundation movements,

(©) Temperature changes and graens,

(@) Axial shorening.

(@ Dynamic effes.

(2) Consrtion loading.

32.3 Design load combinations The design load combination for the stability, strength and

Services limit tats shall be those specified in AS 117.1

[NOTE: For the dsipn of tides, lad combitins specified in SAA HR77.2 or SAA HBT? 8

applicable shoul bused.

‘324 Notional horlontal forces For multi-storey building structures only, notional horizons

Forces, each equal 10 0.002 times the total design venical load applied st floor level, hall 6

ppied at that Noor lve. These otonl horizontal forces shall be considered to atin conjunction

with ony the design dead and live loads fom AS 11701 forthe stength and serviceability lini

tae, These notional horizontal forces hall ot be included forte stability imi state

33 STABILITY LIMIT STATE. The seven aa whole (and any pir of) shal be designed to

Prevent intbility due to overtring, uplift or sing as follows

(@} The loads detemined in accordance with Clause 3.2 shal be subvided ino the components

tending to cause instability and the component tending to ress instability.

(©) The design action effets") sal be clelated from the component ofthe loads tending 0

‘cause instability, combined in accordance with the load combinations for the strength lint

State specified in AS11704

(©) The design resistance effect shal be calculated as 8 tines the par ofthe dead load tending to

resist the instability plus che design capacity (QR) of any elements coarbutng awards

‘sisting the instability, where is capacity factor which shall not exceed the approprite

value given in Table 3.4

(@) ‘The whole or par ofthe structure shal be proportioned so thatthe design resistance effets

ot les than the design action eect.

34 STRENGTH LIMIT STATE. The sructure and its component members and connections

Shall be designe for he strength limit state s fellows

(@) Theloads and actions shal be determined in acondance with Causes 3.2.1 and 3.2.2, andthe

‘sreath mit state design loads shal be determined in accordance with Clauses 3:23 and

324,

(©) The design action effects (S") resting from the strength limit state design loads shall be

determined by an analysis in acordance with Section 4

(©) The design capacity () shal be deterined from the nominal capacity (R,) determined

fiom Sections § 10 9, a8 appropriate, where the capacity factor (9) shall not exceed the

sppropriate valve given in Table 3

(@) Allmemters and connections al be roprtined so that the design capacity (DR) is ot ess

than the design action effect 5"), Le

Ss hy

TABLE 34

CAPACITY FACTORS (6) FOR STRENGTH LIMIT STATES,

Desig captor Conse Copa ar)

fa el epee ss28ss a0

regnent vito fl el pe 51856 a

sie Jsu.sasesis 090

‘Mente jet al conpesion

Senter acy 1863 ry

Member eet oa son nae72 090,

Meer eject combined sons

emer iaty a 050

onic)

‘coPraan

TABLE 34 (continued)

a Capac to)

rita shear oaaa a

tate combine sera in 323 ow

—yintece aaa 0%

Soho ea a0

| sroneasa [cP cusse

comple pects a wel po27 020 ow

logit fi dn RS

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- MTS Extent-1Dokument36 SeitenMTS Extent-1sivakumarNoch keine Bewertungen

- Countersunk Hollowbolt CECertEnglish852Dokument2 SeitenCountersunk Hollowbolt CECertEnglish852sivakumarNoch keine Bewertungen

- Multipurpose Tug FendersDokument44 SeitenMultipurpose Tug FenderssivakumarNoch keine Bewertungen

- PERI Formwork Load Calculator ResultsDokument3 SeitenPERI Formwork Load Calculator ResultssivakumarNoch keine Bewertungen

- Asdo Tie Bar Design Capacities: Product DataDokument2 SeitenAsdo Tie Bar Design Capacities: Product DatasivakumarNoch keine Bewertungen

- ECIA Guidelines 2018 Terrestrial Freshwater Coastal and Marine V1.2 April 22 CompressedDokument44 SeitenECIA Guidelines 2018 Terrestrial Freshwater Coastal and Marine V1.2 April 22 CompressedsivakumarNoch keine Bewertungen

- ABG BBA Findrains 567 To SHW F18 DRAWINGDokument1 SeiteABG BBA Findrains 567 To SHW F18 DRAWINGsivakumarNoch keine Bewertungen

- PD 6698-2009 PDFDokument30 SeitenPD 6698-2009 PDFsivakumarNoch keine Bewertungen

- Sono WZ Concrete Sensor Product BrochureDokument8 SeitenSono WZ Concrete Sensor Product BrochuresivakumarNoch keine Bewertungen

- FRP GRP Gratings Load Table 03Dokument1 SeiteFRP GRP Gratings Load Table 03sivakumarNoch keine Bewertungen

- ASCE 7-16 Supplement 1Dokument16 SeitenASCE 7-16 Supplement 1sivakumarNoch keine Bewertungen

- Jun19 1E QPDokument32 SeitenJun19 1E QPsivakumarNoch keine Bewertungen

- Forwarding Letter and GuidelinesDokument31 SeitenForwarding Letter and Guidelinesye yint100% (1)

- Critical Lift Plan For Pile Load Test-2Dokument14 SeitenCritical Lift Plan For Pile Load Test-2sivakumarNoch keine Bewertungen

- Trelleborg MV Fenders PDFDokument16 SeitenTrelleborg MV Fenders PDFsivakumarNoch keine Bewertungen

- Trelleborg Seapile & SeatimberDokument6 SeitenTrelleborg Seapile & SeatimbersivakumarNoch keine Bewertungen

- A 05/08/14 1:1 at A4 Edition Date ScaleDokument1 SeiteA 05/08/14 1:1 at A4 Edition Date ScalesivakumarNoch keine Bewertungen

- Marine & Offshore Catalog Channel Tray SystemsDokument34 SeitenMarine & Offshore Catalog Channel Tray SystemssivakumarNoch keine Bewertungen

- TECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelDokument3 SeitenTECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelRaed Naim Khammash100% (1)

- Multi-Purpose Fenders: Trelleborg Marine SystemsDokument7 SeitenMulti-Purpose Fenders: Trelleborg Marine SystemssivakumarNoch keine Bewertungen

- Foundation Design As Per ACI & BowlesDokument17 SeitenFoundation Design As Per ACI & BowlessivakumarNoch keine Bewertungen

- Trelleborg MV FendersDokument16 SeitenTrelleborg MV FenderssivakumarNoch keine Bewertungen

- 4651 3 PDFDokument27 Seiten4651 3 PDFsivakumarNoch keine Bewertungen

- Eurocode and Superseded BSDokument2 SeitenEurocode and Superseded BSsivakumar100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)