Beruflich Dokumente

Kultur Dokumente

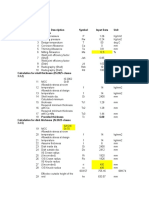

S.No Description Symbol Input Data Unit Design Data

Hochgeladen von

Thiru Ananth0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

24 Ansichten2 SeitenOriginaltitel

design of vessel.docx

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

24 Ansichten2 SeitenS.No Description Symbol Input Data Unit Design Data

Hochgeladen von

Thiru AnanthCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

S.

NO Description Symbol Input Data Unit

DESIGN DATA

1 Design pressure P 1.26 Kg/cm2

2 Working pressure Pw 0.24 Kg/cm2

3 Design temperature T 50 deg.C

4 Corrosion Allowance Ca 0 mm

5 Thinning Allowance Ta 0.8 mm

6 Milling Allowance Ma 12.5 %

Weld joint efficiency factor

7 (Shell) Jsh 0.85

Weld joint efficiency factor

8 (Dish) Jd 1.00

9 Radiography (Shell) Rsh 10 %

10 Radiography (Dish) Rd 100 %

Calculation for shell thichness (IS:2825-clause

3.3.2)

IS 2062

11 MOC Gr.B

Allowable stress at room

12 temperature f 14 kg/mm2

Allowable stress at design

13 temperature f 14 kg/mm2

14 Shell inside dia. Di 2400 mm

Calculated minimum

15 thickness Tc1 1.28 mm

Required minimum thickness

16 with Ca Tc2 1.28 mm

Required minimum thickness

17 with Ca+Ma Tc3 1.44 mm

18 Provided thickness Tc 6.00 mm

Calculation for dish thichness (IS:2825-clause

3.4.5)

SA 516

19 MOC Gr.70

Allowable stress at room

20 temperature f 14 kg/mm2

Allowable stress at design

21 temperature f 14 kg/mm2

22 Assume thickness t 6 mm

23 Dish inside dia. Di 2400 mm

24 Dish outside dia. Do 2412 mm

I/S Crown radius

25 (Uncorroded) Ri 1920 mm

26 O/S Crown radius Ro 1926 mm

I/S Knucle radius

27 (Uncorroded) ri 400 mm

28 O/S Knucle radius ro 406 mm

633.57 755.16 699.74

Effective outside height of the

29 end he 633.57 mm

30 Factor 1 he/Do 0.263

31 Factor 2 t/Do 0.0025

32 Shape factor C 1.25

Calculated minimum

33 thickness Tc1 1.4 mm

Required minimum thickness

34 with Ca Tc2 1.36 mm

Required minimum thickness

35 with Ca+Ta Tc3 2.16 mm

Required minimum thickness

36 with Ca+Ta+Ma Tc4 2.43 mm

37 Provided thickness Tc 6.00 mm

Minimum thickness after

38 forming Tc 5.20 mm

Das könnte Ihnen auch gefallen

- S.No Description Symbol Input Data Unit Design DataDokument2 SeitenS.No Description Symbol Input Data Unit Design DataThiru AnanthNoch keine Bewertungen

- S.No Description Symbol Input Data Unit Design DataDokument2 SeitenS.No Description Symbol Input Data Unit Design DataThiru AnanthNoch keine Bewertungen

- S.No Description Symbol Input Data Unit Design DataDokument2 SeitenS.No Description Symbol Input Data Unit Design DataThiru AnanthNoch keine Bewertungen

- S.No Description Symbol Input Data Unit Design DataDokument1 SeiteS.No Description Symbol Input Data Unit Design DataThiru AnanthNoch keine Bewertungen

- HDD Calculation - CH 15Dokument23 SeitenHDD Calculation - CH 15Binay Kumar100% (1)

- Steel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectDokument1 SeiteSteel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectCaspian DattaNoch keine Bewertungen

- Calc' Diesel Fuel (Rev)Dokument10 SeitenCalc' Diesel Fuel (Rev)joko_tm02Noch keine Bewertungen

- Combined Footing-2 (Cf2)Dokument2 SeitenCombined Footing-2 (Cf2)harish gowdaNoch keine Bewertungen

- Design Calculations Sheet - 12.75": SL .No. Symbol Value UnitDokument6 SeitenDesign Calculations Sheet - 12.75": SL .No. Symbol Value UnitASHOK SWAMINoch keine Bewertungen

- Tank Thickness Calculation: Is 2825 S.No Description Unit Value InputDokument10 SeitenTank Thickness Calculation: Is 2825 S.No Description Unit Value InputdineshNoch keine Bewertungen

- Concrete Grade (M) Steel Grade (Fe) Assume Depth: Design Balcony Cantilever SlabDokument1 SeiteConcrete Grade (M) Steel Grade (Fe) Assume Depth: Design Balcony Cantilever SlabAhmad MasoodNoch keine Bewertungen

- Design of Corbels, Brackets and NibsDokument3 SeitenDesign of Corbels, Brackets and NibsBrij AkabariNoch keine Bewertungen

- Spreader Beam Calculations: JOB NO:09025-01, Item no:K84-F-473/573 (STEAM GENERATOR)Dokument2 SeitenSpreader Beam Calculations: JOB NO:09025-01, Item no:K84-F-473/573 (STEAM GENERATOR)Senthil KumarNoch keine Bewertungen

- Beams TB1Dokument3 SeitenBeams TB1mangeshNoch keine Bewertungen

- OPGW GTP of Various VendorsDokument19 SeitenOPGW GTP of Various VendorsRamphani Nunna100% (1)

- Memoria ASME-Pressure-Vessel-DesignDokument143 SeitenMemoria ASME-Pressure-Vessel-DesignJuan MendozaNoch keine Bewertungen

- Builtup SectionDokument4 SeitenBuiltup SectionSuhas MangaloreNoch keine Bewertungen

- VSL CalDokument50 SeitenVSL CalEmrahCayboyluNoch keine Bewertungen

- Shell&Tube TEMAsheet 1Dokument1 SeiteShell&Tube TEMAsheet 1Rikiya FebriyanNoch keine Bewertungen

- Allowable Stress SA 285 GR CDokument4 SeitenAllowable Stress SA 285 GR Cdianita nurnandaNoch keine Bewertungen

- Design ExamplesDokument42 SeitenDesign ExamplesARSENoch keine Bewertungen

- CS-74 - MAND RIVER HDD Design CalculationDokument6 SeitenCS-74 - MAND RIVER HDD Design CalculationG. BalamuruganNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument1 SeiteF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Ujol PraNoch keine Bewertungen

- Load CalculationDokument31 SeitenLoad CalculationrahulNoch keine Bewertungen

- Flange DesignDokument4 SeitenFlange DesignAshish SharmaNoch keine Bewertungen

- ASME Pressure Vessel Design-ADokument190 SeitenASME Pressure Vessel Design-AWidyAdityaNoch keine Bewertungen

- BS5400-R-C-Design-With-Crack-Width SampleDokument1 SeiteBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNoch keine Bewertungen

- Nozzle With Reinforcement Pad: Date: 13/6/21 Client: IecDokument1 SeiteNozzle With Reinforcement Pad: Date: 13/6/21 Client: Iecגרבר פליקסNoch keine Bewertungen

- Bracing NewDokument1 SeiteBracing NewKQC CONSULTING AND ENGINEERSNoch keine Bewertungen

- Part-Uhx (U-Tube) .Dokument5 SeitenPart-Uhx (U-Tube) .AKSHAY BHATKARNoch keine Bewertungen

- Mechanical Design CalculationsDokument15 SeitenMechanical Design CalculationsJomhel Callueng100% (1)

- InputDokument4 SeitenInputAmit KananiNoch keine Bewertungen

- Bolted Truss Column Connections - xlsx-29!14!2020Dokument34 SeitenBolted Truss Column Connections - xlsx-29!14!2020Vineetha KrishnanNoch keine Bewertungen

- VG 320 Oil CoolerDokument32 SeitenVG 320 Oil CoolergsdaundhNoch keine Bewertungen

- Design Data Sheet For Air ReceiverDokument3 SeitenDesign Data Sheet For Air ReceivergksakthiNoch keine Bewertungen

- Design CalculationDokument6 SeitenDesign Calculationbinay kumar100% (1)

- Design Calculation PDFDokument6 SeitenDesign Calculation PDFJWC Sales & Services :Noch keine Bewertungen

- RCC DesignDokument39 SeitenRCC DesignMariappan .PNoch keine Bewertungen

- DNO Pred 4 23.03.2018Dokument14 SeitenDNO Pred 4 23.03.2018nemanja micicNoch keine Bewertungen

- RCC94 Two-Way Slabs (Tables)Dokument5 SeitenRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3Noch keine Bewertungen

- Shell ReinDokument2 SeitenShell ReinLatipKumar SharmaNoch keine Bewertungen

- Sudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Dokument7 SeitenSudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Hgagselim SelimNoch keine Bewertungen

- Shell CalculationsDokument3 SeitenShell CalculationsBaher Elsheikh100% (7)

- 1.FB - Balkhu - Star Design With Break - 36m Edit Opt 2 - Copy (2) OldDokument32 Seiten1.FB - Balkhu - Star Design With Break - 36m Edit Opt 2 - Copy (2) OldTriChandra MaharjanNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument4 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNoch keine Bewertungen

- Thickness Calculation AsmeDokument2 SeitenThickness Calculation AsmeSushil WadiyeNoch keine Bewertungen

- Cs-74 - Mand River HDD Design CalculationDokument9 SeitenCs-74 - Mand River HDD Design CalculationG. Balamurugan100% (1)

- Steel Beam SpreadsheetDokument27 SeitenSteel Beam SpreadsheetHugh McGilveray100% (1)

- WT Calculation - Pipelines With CRA CladDokument6 SeitenWT Calculation - Pipelines With CRA CladShankar VadivelNoch keine Bewertungen

- Design of Deckslab IRC 112Dokument24 SeitenDesign of Deckslab IRC 112Structural SpreadsheetsNoch keine Bewertungen

- Etd44 PDFDokument5 SeitenEtd44 PDFChAmirShokatGujjarNoch keine Bewertungen

- Strip Footing (Exterior)Dokument4 SeitenStrip Footing (Exterior)Kelvin MutetiNoch keine Bewertungen

- Frame ConnectionsDokument14 SeitenFrame ConnectionsShawkat Ali KhanNoch keine Bewertungen

- NDC Analytique Ot3439Dokument3 SeitenNDC Analytique Ot3439Ben Abdallah BecemNoch keine Bewertungen

- ASME B31.4-Wall Thickness CalDokument2 SeitenASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Larsen & Toubro Limited: 1. Sectional PropertiesDokument8 SeitenLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNoch keine Bewertungen

- Beam DesignDokument8 SeitenBeam DesignSelva kumarNoch keine Bewertungen

- FFB4Dokument8 SeitenFFB4prajjwal patidarNoch keine Bewertungen

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- Compressed Air Type Surge Vessels: Data Unit DetailsDokument2 SeitenCompressed Air Type Surge Vessels: Data Unit DetailsThiru AnanthNoch keine Bewertungen

- Appendix-A2 (Piping Design Data)Dokument2 SeitenAppendix-A2 (Piping Design Data)Thiru AnanthNoch keine Bewertungen

- GRE Piping Design Data - 10 InchDokument2 SeitenGRE Piping Design Data - 10 InchThiru AnanthNoch keine Bewertungen

- Power Plant-Part - 2 of 1Dokument10 SeitenPower Plant-Part - 2 of 1Thiru AnanthNoch keine Bewertungen

- Fire SystemsDokument5 SeitenFire SystemsThiru AnanthNoch keine Bewertungen

- Specification For Injection QuillDokument4 SeitenSpecification For Injection QuillThiru AnanthNoch keine Bewertungen

- Specification For Fire Water HydrantDokument5 SeitenSpecification For Fire Water HydrantThiru AnanthNoch keine Bewertungen

- Specification For Fire Water MonitorsDokument6 SeitenSpecification For Fire Water MonitorsThiru AnanthNoch keine Bewertungen

- Fire Pump SpecificationDokument5 SeitenFire Pump SpecificationThiru AnanthNoch keine Bewertungen

- Chilled Water Distribution SystemDokument5 SeitenChilled Water Distribution SystemThiru AnanthNoch keine Bewertungen

- Sump DesignDokument4 SeitenSump DesignThiru AnanthNoch keine Bewertungen

- Hazen-Williams EquationDokument1 SeiteHazen-Williams EquationThiru AnanthNoch keine Bewertungen

- Eaton 120641 FAZ C10 2 NA DC en - GBDokument2 SeitenEaton 120641 FAZ C10 2 NA DC en - GBCarlos Garcia Jacome DarkerNoch keine Bewertungen

- Carbon-Carbon Composites A Summary of Recent Developments and ApplicationsDokument5 SeitenCarbon-Carbon Composites A Summary of Recent Developments and Applicationsdroessaert_stijn100% (1)

- Surface PlateDokument3 SeitenSurface PlateSaket OraonNoch keine Bewertungen

- Gel ElectrophoresisDokument13 SeitenGel ElectrophoresisVishnu Reddy Vardhan PulimiNoch keine Bewertungen

- A Detailed Lesson Plan in Science 10Dokument9 SeitenA Detailed Lesson Plan in Science 10Maricae NathanielNoch keine Bewertungen

- RMA4 Users Guide 09-27-2011Dokument187 SeitenRMA4 Users Guide 09-27-2011Athanasius Kurniawan Prasetyo AdiNoch keine Bewertungen

- ME 534 - 02 Modeling I (Rev. 1.5)Dokument13 SeitenME 534 - 02 Modeling I (Rev. 1.5)Michael PalmerNoch keine Bewertungen

- Práctica GrafcetDokument11 SeitenPráctica GrafcetJaimeNoch keine Bewertungen

- BismuthDokument16 SeitenBismuthlostgrailNoch keine Bewertungen

- Underground Wiring InstallationDokument6 SeitenUnderground Wiring InstallationCarbelyn BarteNoch keine Bewertungen

- SOM NotesDokument88 SeitenSOM NotesThiru Moorthy100% (1)

- Section 7Dokument17 SeitenSection 7xmanian90Noch keine Bewertungen

- Franc3D V6 Nastran TutorialDokument52 SeitenFranc3D V6 Nastran TutorialSandeep BhatiaNoch keine Bewertungen

- Investment CastingDokument43 SeitenInvestment Castingshiva9113Noch keine Bewertungen

- Pet PhotographyDokument28 SeitenPet PhotographyAnonymous Wyb8Y1Noch keine Bewertungen

- The Pipeline-Steels X100 and X120Dokument24 SeitenThe Pipeline-Steels X100 and X120thepleguyNoch keine Bewertungen

- NgspicemanualDokument517 SeitenNgspicemanualronakmehta31Noch keine Bewertungen

- Solid Solution StrengtheningDokument23 SeitenSolid Solution StrengtheningAdivadewanggaNoch keine Bewertungen

- Manual CTI Technical Manual PDFDokument39 SeitenManual CTI Technical Manual PDFaricomen43% (7)

- CERBERITE Hollow Glass Speciality Contact MaterialDokument5 SeitenCERBERITE Hollow Glass Speciality Contact MaterialPramendraSinghNoch keine Bewertungen

- Pengaruh Kecepatan Pemotongan Dan Ketebalan Bahan Terhadap Kekerasan Dan Kekasaran Permukaan Baja Aisi 1045 Menggunakan CNC Plasma Arc CuttingDokument6 SeitenPengaruh Kecepatan Pemotongan Dan Ketebalan Bahan Terhadap Kekerasan Dan Kekasaran Permukaan Baja Aisi 1045 Menggunakan CNC Plasma Arc CuttingRamjay BudiartoNoch keine Bewertungen

- A S C D W V S: Pplication OF Tatistical Oncepts IN THE Etermination OF Eight Ariation IN AmplesDokument7 SeitenA S C D W V S: Pplication OF Tatistical Oncepts IN THE Etermination OF Eight Ariation IN AmplesElaine Nicole CanebaNoch keine Bewertungen

- Stream, Streak, PathlinesDokument4 SeitenStream, Streak, PathlineschauguleNoch keine Bewertungen

- PVD Design ReportDokument61 SeitenPVD Design ReportCEG BangladeshNoch keine Bewertungen

- 110 MBRSDokument4 Seiten110 MBRSknsvel20005966Noch keine Bewertungen

- Road To The Stars AbstractDokument218 SeitenRoad To The Stars AbstractgrradoNoch keine Bewertungen

- XR-EBSD 203110007 13thfebDokument12 SeitenXR-EBSD 203110007 13thfebVikram ChavanNoch keine Bewertungen

- Chapter 17 Electromagnetic Induction Notes Answers PDFDokument2 SeitenChapter 17 Electromagnetic Induction Notes Answers PDFabdul halimNoch keine Bewertungen

- Sci 202 - Course GuideDokument8 SeitenSci 202 - Course GuideRicardo VelozNoch keine Bewertungen

- 11th - STD - Physics - Volume II - EM - WWW - Tntextbooks.in PDFDokument328 Seiten11th - STD - Physics - Volume II - EM - WWW - Tntextbooks.in PDFTheresaNoch keine Bewertungen