Beruflich Dokumente

Kultur Dokumente

Instandhaltung Anleitung en

Hochgeladen von

Jason MaldonadoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Instandhaltung Anleitung en

Hochgeladen von

Jason MaldonadoCopyright:

Verfügbare Formate

Machine maintenance

Regular care and inspection of your STUDER cylindrical grinding machine is important to keep it running. Here

you will find a list of important maintenance and inspection points which should be regularly checked for your

STUDER universal cylindrical grinding machines. The points are itemized according to operating hours.

The list is by no means exhaustive, but is a useful reminder which you can affix to your STUDER machine. Chap-

ter 7 in your STUDER operating manual provides further information on the subject of machine maintenance.

After 8 operating hours After 200 operating hours

Lubricate the seatings Check extraction unit filter

STUDER recommends drying and lubricating the Check number of drops of pneumatic service unit

table during single-shift operation and at the Check lubricating system of internal grinding

weekend. The sliding doors should be comple- spindle

tely opened, so that high humidity levels in the Operate air lifts

machine can escape.

Check oil condition in hydraulic system

Tipp: Remove the anti-corrosive protection at the

Check operating pressure

start of grinding, so that the function of the grinding

oil is not impaired. Check cooling-lubricating unit

After 40 operating hours After 1000 operating hours

Clean the machine Check bellows

Check the incoming compressed air Check tightness of telescopic devices

Check the oil level of the pneumatic service unit Check that barrel runs smoothly

Clean bellows and telescopic devices

Check oil level of tailstock After 2000 operating hours

Check barrel seal

Check coolant level Replace filter mat of extraction unit

High frequency spindle: check oil flow Replace buffer batteries

Notes

1) You can find further information in your instruction manual or via your HelpLine.

2) Fritz Studer AG excludes all liability arising from incorrect operation or use.

3) Our General Terms and Conditions apply. These can be downloaded from www.studer.com.

1

www.studer.com

Das könnte Ihnen auch gefallen

- Business Statistics: Fourth Canadian EditionDokument41 SeitenBusiness Statistics: Fourth Canadian EditionTaron AhsanNoch keine Bewertungen

- 3512 Industrial Engine-Maintenance IntervalsDokument40 Seiten3512 Industrial Engine-Maintenance Intervalssiul789493% (15)

- Wärtsilä 32 Engine Instruction Manual 04. Maintenance ScheduleDokument12 SeitenWärtsilä 32 Engine Instruction Manual 04. Maintenance ScheduleSalman Kapoor100% (1)

- Sebu7687-08 BDokument4 SeitenSebu7687-08 Bkevin jeyson merma aragon0% (1)

- JCB 3DX Maintenance ManualDokument12 SeitenJCB 3DX Maintenance ManualDavid Palash100% (2)

- CLG418 Operation &maintainance ManualDokument66 SeitenCLG418 Operation &maintainance ManualLYCANTROPOFAGO89% (9)

- Compressor ChecklistDokument4 SeitenCompressor ChecklistEber.CV100% (1)

- Major Process Equipment Maintenance and RepairVon EverandMajor Process Equipment Maintenance and RepairBewertung: 4 von 5 Sternen4/5 (4)

- Tutorial: MSBA7003 Quantitative Analysis MethodsDokument29 SeitenTutorial: MSBA7003 Quantitative Analysis MethodsAmanda WangNoch keine Bewertungen

- Antes Da Operação 777F Ing.Dokument10 SeitenAntes Da Operação 777F Ing.Jardel Fernandes de MoraesNoch keine Bewertungen

- CS76 Before OperationDokument4 SeitenCS76 Before OperationJosé Carlos CarvalhoNoch keine Bewertungen

- Before Operation: Operation and Maintenance Manual ExcerptDokument4 SeitenBefore Operation: Operation and Maintenance Manual Excerptanon_828943220Noch keine Bewertungen

- Hydro Power MaintenanceDokument26 SeitenHydro Power Maintenancetrxrhcp50% (4)

- Grúa Tadano Faun ATF 130 G5Dokument67 SeitenGrúa Tadano Faun ATF 130 G5Reinaldo ZorrillaNoch keine Bewertungen

- 16M Motor Grader - Before OperationDokument7 Seiten16M Motor Grader - Before Operationmamaqita100% (1)

- Before Operation: Operation and Maintenance Manual ExcerptDokument5 SeitenBefore Operation: Operation and Maintenance Manual Excerptalice_dickson523Noch keine Bewertungen

- Before Operation: Operation and Maintenance Manual ExcerptDokument4 SeitenBefore Operation: Operation and Maintenance Manual ExcerptPercyLeonNoch keine Bewertungen

- Skt-Maintenance of Electro-Mechanicl Equipment of SHPDokument51 SeitenSkt-Maintenance of Electro-Mechanicl Equipment of SHPsktyagi_iitr6102Noch keine Bewertungen

- Use and Maintenance of Gear UnitDokument4 SeitenUse and Maintenance of Gear UnitRaphael LinoNoch keine Bewertungen

- Chapter 3. Procedures Before Starting Section 1. Safety Safety Instructions Emergency ExitDokument18 SeitenChapter 3. Procedures Before Starting Section 1. Safety Safety Instructions Emergency ExitPeetNoch keine Bewertungen

- Before Operation: Operation and Maintenance Manual ExcerptDokument4 SeitenBefore Operation: Operation and Maintenance Manual ExcerptHernan Sanchez100% (1)

- Before Operation 320C PDFDokument5 SeitenBefore Operation 320C PDFFabian Ariza ArizaNoch keine Bewertungen

- Sebu7763-03 BDokument4 SeitenSebu7763-03 BHernan SanchezNoch keine Bewertungen

- Superior Technology in Aeronautical MechanicsDokument17 SeitenSuperior Technology in Aeronautical Mechanicsarlette caizaNoch keine Bewertungen

- Before Operation: Operation and Maintenance Manual ExcerptDokument4 SeitenBefore Operation: Operation and Maintenance Manual Excerptgeorgejr8950% (2)

- CAT Antes de Usar TH460BDokument4 SeitenCAT Antes de Usar TH460Bmiguel0% (1)

- Sebu7709-05 BDokument4 SeitenSebu7709-05 BJaime SuaNoch keine Bewertungen

- R05323-M-079-X009-233 - Manual Blower D600-31Dokument12 SeitenR05323-M-079-X009-233 - Manual Blower D600-31Walter Efrain Armas SeguraNoch keine Bewertungen

- Maintenance Activities of Farm FacilitiesDokument13 SeitenMaintenance Activities of Farm FacilitiesRnDome CliKNoch keine Bewertungen

- 9 Chapter 6 Machine Maintenance-UPDATE in 20190823Dokument24 Seiten9 Chapter 6 Machine Maintenance-UPDATE in 20190823EduGómezCamposNoch keine Bewertungen

- Capstan - Shin Myung Tech - SMCAPDokument19 SeitenCapstan - Shin Myung Tech - SMCAPjohn smith0% (1)

- Compressor ChecklistDokument5 SeitenCompressor ChecklistJuanPabloAlvarezNoch keine Bewertungen

- Boiler Operation General Safety and SAFETY ValvesDokument4 SeitenBoiler Operation General Safety and SAFETY ValvesherlyasNoch keine Bewertungen

- IT62G Integrated Toolcarrier and 950G and 962G Wheel Loaders-Before OperationDokument7 SeitenIT62G Integrated Toolcarrier and 950G and 962G Wheel Loaders-Before OperationRODOLFO ESTEBAN VARGAS TORONoch keine Bewertungen

- Ass. 2Dokument18 SeitenAss. 2Ramez RaymonNoch keine Bewertungen

- General Information: Section 1Dokument22 SeitenGeneral Information: Section 1cunNoch keine Bewertungen

- Before Operation: Operation and Maintenance Manual ExcerptDokument4 SeitenBefore Operation: Operation and Maintenance Manual ExcerptAnthony PozoNoch keine Bewertungen

- Before Operation: Operation and Maintenance Manual ExcerptDokument4 SeitenBefore Operation: Operation and Maintenance Manual ExcerptAnthony PozoNoch keine Bewertungen

- Grúa Tadano Faun ATF 130 G5Dokument93 SeitenGrúa Tadano Faun ATF 130 G5Reinaldo ZorrillaNoch keine Bewertungen

- G. Maintenance Schedule: ServiceDokument38 SeitenG. Maintenance Schedule: ServiceAdam100% (1)

- AAEDR-F-005 Rev 1 (Extended Storage PA)Dokument6 SeitenAAEDR-F-005 Rev 1 (Extended Storage PA)Jose G LopezNoch keine Bewertungen

- Mooney M20 100 Hour Annual 2007Dokument2 SeitenMooney M20 100 Hour Annual 2007flyokie100% (1)

- Session - 16 - Eliminator - Oil - Filter (Compatibility Mode)Dokument42 SeitenSession - 16 - Eliminator - Oil - Filter (Compatibility Mode)agvass100% (1)

- Maintenance & Repair WorkDokument29 SeitenMaintenance & Repair WorkAhmed Hassan Abo Asem100% (3)

- Operation and Maintenance of Hydropower Stations PDFDokument26 SeitenOperation and Maintenance of Hydropower Stations PDFtranhuutuongNoch keine Bewertungen

- V8051 335 Instruction Manual 88aceDokument7 SeitenV8051 335 Instruction Manual 88acecarlNoch keine Bewertungen

- Mantenimineto Caterpillar Antes de OperarDokument4 SeitenMantenimineto Caterpillar Antes de OperarTeofilo Flores100% (1)

- Messrs. SM Cyclo de Chile Ltda.: Orden Interna Sumitomo CHD1A064 Orden Interna Weir Minerals 189316Dokument36 SeitenMessrs. SM Cyclo de Chile Ltda.: Orden Interna Sumitomo CHD1A064 Orden Interna Weir Minerals 189316Leonardo SilvaNoch keine Bewertungen

- 6D105 Series O&M ManualDokument49 Seiten6D105 Series O&M Manualjobin joyNoch keine Bewertungen

- SHE73 LubricaciónDokument48 SeitenSHE73 Lubricacióngonzalo valderramaNoch keine Bewertungen

- Reciprocating Compressor MaintenanceDokument5 SeitenReciprocating Compressor MaintenanceshimaNoch keine Bewertungen

- Zabatt Compressor MaintenanceDokument5 SeitenZabatt Compressor MaintenanceMuhammad ArslaanNoch keine Bewertungen

- Mooney M20 100hour PDFDokument2 SeitenMooney M20 100hour PDFsplyn100% (1)

- SS TLS T40140-T40180 S3a-B1ct-B33g-EnDokument2 SeitenSS TLS T40140-T40180 S3a-B1ct-B33g-EnAhmed El-AdawyNoch keine Bewertungen

- Regular Maintenance 3: 3 ServiceDokument24 SeitenRegular Maintenance 3: 3 ServiceMiguel MartínezNoch keine Bewertungen

- 320C U Excavator-Before OperationDokument4 Seiten320C U Excavator-Before OperationPedro BarriosNoch keine Bewertungen

- Unit Iv Classification of Jet Engine ComponentsDokument81 SeitenUnit Iv Classification of Jet Engine Componentsraj6062Noch keine Bewertungen

- Maintenance and LubricationDokument34 SeitenMaintenance and Lubricationtoppen_76100% (1)

- MotorDokument4 SeitenMotorjoaofelippejsaNoch keine Bewertungen

- 307C Excavator - Before StartingDokument4 Seiten307C Excavator - Before StartingNanang RizalNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

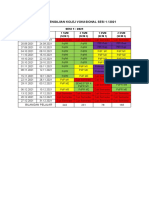

- Takwim Pengajian Kolej Vokasional Sesi 1Dokument1 SeiteTakwim Pengajian Kolej Vokasional Sesi 1Jason MaldonadoNoch keine Bewertungen

- Maintenance Schedule Checklist For GE PC Motors PDFDokument54 SeitenMaintenance Schedule Checklist For GE PC Motors PDFrama jenaNoch keine Bewertungen

- Students Today Are Surrounded by Technology and Gadgets Such As LaptopsDokument1 SeiteStudents Today Are Surrounded by Technology and Gadgets Such As LaptopsJason MaldonadoNoch keine Bewertungen

- Bengkel Program Teknologi Automotif: Preventive Maintenance Checklist Petrol EngineDokument1 SeiteBengkel Program Teknologi Automotif: Preventive Maintenance Checklist Petrol EngineJason MaldonadoNoch keine Bewertungen

- Medical Repricing 95925429Dokument10 SeitenMedical Repricing 95925429Jason MaldonadoNoch keine Bewertungen

- Kelas Tambahan 2 SVM 2021Dokument2 SeitenKelas Tambahan 2 SVM 2021Jason MaldonadoNoch keine Bewertungen

- Electronic Power Steering SystemDokument69 SeitenElectronic Power Steering SystemJason MaldonadoNoch keine Bewertungen

- Syllabus 9) DMD 3213 - Engine Management System (2020)Dokument8 SeitenSyllabus 9) DMD 3213 - Engine Management System (2020)Jason MaldonadoNoch keine Bewertungen

- 08 ChargingDokument32 Seiten08 ChargingJason MaldonadoNoch keine Bewertungen

- 2 Starters ADokument30 Seiten2 Starters AJason MaldonadoNoch keine Bewertungen

- Electronic Ignition (EI) SystemsDokument22 SeitenElectronic Ignition (EI) SystemsJason MaldonadoNoch keine Bewertungen

- 08 ChargingDokument32 Seiten08 ChargingJason MaldonadoNoch keine Bewertungen

- Electronic Ignition (EI) SystemsDokument22 SeitenElectronic Ignition (EI) SystemsJason MaldonadoNoch keine Bewertungen

- 1 BatteriesDokument27 Seiten1 BatteriesJason MaldonadoNoch keine Bewertungen

- Nota Kuliah 2Dokument17 SeitenNota Kuliah 2Jason Maldonado100% (1)

- 2 Starters ADokument30 Seiten2 Starters AJason MaldonadoNoch keine Bewertungen

- Ignition 161226174624Dokument57 SeitenIgnition 161226174624Jason MaldonadoNoch keine Bewertungen

- Mpi 3014 - CNC Milling Machine ApplicationDokument15 SeitenMpi 3014 - CNC Milling Machine ApplicationJason MaldonadoNoch keine Bewertungen

- Education 4.0 ... The Future of Learning Will Be Dramatically DifferentDokument9 SeitenEducation 4.0 ... The Future of Learning Will Be Dramatically DifferentJason MaldonadoNoch keine Bewertungen

- Ignitionsystemsppt1 160818114501Dokument24 SeitenIgnitionsystemsppt1 160818114501Jason MaldonadoNoch keine Bewertungen

- Surat Mohon Sumbangan Pibg - 1Dokument1 SeiteSurat Mohon Sumbangan Pibg - 1Jason MaldonadoNoch keine Bewertungen

- HttpsDokument1 SeiteHttpsJason MaldonadoNoch keine Bewertungen

- Vertical Timeline Infographics PGo 4 3Dokument3 SeitenVertical Timeline Infographics PGo 4 3Rola Mesrani SimbolonNoch keine Bewertungen

- Jadual Sidang Pa Pelajar Sem 4 Diploma Mta8013Dokument1 SeiteJadual Sidang Pa Pelajar Sem 4 Diploma Mta8013Jason MaldonadoNoch keine Bewertungen

- Equipment / Machinery Checklist: BlankDokument4 SeitenEquipment / Machinery Checklist: BlankJason Maldonado0% (1)

- Nota 6 Fundamental of CNC Milling ProgramDokument17 SeitenNota 6 Fundamental of CNC Milling ProgramJason MaldonadoNoch keine Bewertungen

- Nota 6 Fundamental of CNC Milling ProgramDokument17 SeitenNota 6 Fundamental of CNC Milling ProgramJason MaldonadoNoch keine Bewertungen

- Resume Infografik NanonDokument1 SeiteResume Infografik NanonJason MaldonadoNoch keine Bewertungen

- NOTA 7 - CNC Milling Programming IIDokument26 SeitenNOTA 7 - CNC Milling Programming IIJason MaldonadoNoch keine Bewertungen

- (2.01) Complete! ChaexDokument15 Seiten(2.01) Complete! ChaexJason MaldonadoNoch keine Bewertungen

- Introducing Eventstorming-4Dokument1 SeiteIntroducing Eventstorming-4Alex TrujilloNoch keine Bewertungen

- Technical Test 03Dokument13 SeitenTechnical Test 03KartikNoch keine Bewertungen

- Assistant Bookkeeper Resume Sample - Best Format - Great Sample ResumeDokument4 SeitenAssistant Bookkeeper Resume Sample - Best Format - Great Sample ResumedrustagiNoch keine Bewertungen

- Certified Vendors As of 9 24 21Dokument19 SeitenCertified Vendors As of 9 24 21Micheal StormNoch keine Bewertungen

- FS-C8025MFP Release NotesDokument22 SeitenFS-C8025MFP Release NotesFirmware SM-SHNoch keine Bewertungen

- Lic Nach MandateDokument1 SeiteLic Nach Mandatefibiro9231Noch keine Bewertungen

- 05-11 Trainer Interview QuestionsDokument8 Seiten05-11 Trainer Interview QuestionsqulaityNoch keine Bewertungen

- Module 2 DIPDokument33 SeitenModule 2 DIPdigital loveNoch keine Bewertungen

- The Neuroscience of Helmholtz and The Theories of Johannes Muèller Part 2: Sensation and PerceptionDokument22 SeitenThe Neuroscience of Helmholtz and The Theories of Johannes Muèller Part 2: Sensation and PerceptionCrystal JenningsNoch keine Bewertungen

- Bio 104 Lab Manual 2010Dokument236 SeitenBio 104 Lab Manual 2010Querrynithen100% (1)

- Guia Instalacion APP Huawei Fusion HmeDokument4 SeitenGuia Instalacion APP Huawei Fusion Hmecalinp72Noch keine Bewertungen

- Information Brochure: (Special Rounds)Dokument35 SeitenInformation Brochure: (Special Rounds)Praveen KumarNoch keine Bewertungen

- DLP - CO#1-for PandemicDokument4 SeitenDLP - CO#1-for PandemicEvelyn CanoneraNoch keine Bewertungen

- Lab Final SolutionDokument18 SeitenLab Final SolutionZeeNoch keine Bewertungen

- FmatterDokument12 SeitenFmatterNabilAlshawish0% (2)

- Libro INGLÉS BÁSICO IDokument85 SeitenLibro INGLÉS BÁSICO IRandalHoyos100% (1)

- Chen 2021Dokument13 SeitenChen 2021Aitor UzkudunNoch keine Bewertungen

- Placa 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Dokument39 SeitenPlaca 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Sergio GalliNoch keine Bewertungen

- Operations and Service ManualDokument311 SeitenOperations and Service ManualELARD GUILLENNoch keine Bewertungen

- Class I Water Well: DescriptionDokument10 SeitenClass I Water Well: DescriptionJavier Andrés Acevedo GarcíaNoch keine Bewertungen

- Dady - Piernas LargasDokument12 SeitenDady - Piernas LargasSarha NietoNoch keine Bewertungen

- Electric PotentialDokument26 SeitenElectric PotentialGlitchNoch keine Bewertungen

- Rules and Fallacies For Categorical SyllogismsDokument5 SeitenRules and Fallacies For Categorical SyllogismsFatima Ismael PortacioNoch keine Bewertungen

- Exp - P7 - UPCTDokument11 SeitenExp - P7 - UPCTSiddesh PatilNoch keine Bewertungen

- SeparexgeneralbrochureDokument4 SeitenSeparexgeneralbrochurewwl1981Noch keine Bewertungen

- AT ChapIDokument48 SeitenAT ChapIvigneshwaranbeNoch keine Bewertungen

- Selecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationDokument35 SeitenSelecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationJhenn Mhen Yhon100% (1)

- Graduate Macro Theory II: The Real Business Cycle Model: Eric Sims University of Notre Dame Spring 2017Dokument25 SeitenGraduate Macro Theory II: The Real Business Cycle Model: Eric Sims University of Notre Dame Spring 2017Joab Dan Valdivia CoriaNoch keine Bewertungen