Beruflich Dokumente

Kultur Dokumente

Certificate of Analysis: National Institute of Standards & Technology

Hochgeladen von

MuhamadJaganurdinEl-SarawiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Certificate of Analysis: National Institute of Standards & Technology

Hochgeladen von

MuhamadJaganurdinEl-SarawiCopyright:

Verfügbare Formate

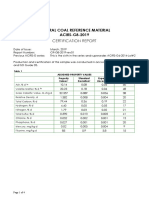

National Institute of Standards & Technology

Certificate of Analysis

Standard Reference Material 2710a

Montana I Soil

Highly Elevated Trace Element Concentrations

This Standard Reference Material (SRM) is intended primarily for use in the analysis of soils, sediments, or other

materials of a similar matrix. One unit of SRM 2710a consists of 50 g of the dried, powdered soil, blended with

lead oxide.

Certified Values: The certified concentrations for 22 elements, expressed as mass fractions [1] on a dry-mass

basis, are provided in Table 1. Certified values are based on results obtained from critically evaluated independent

analytical techniques. A NIST certified value is a value for which NIST has the highest confidence in its accuracy

in that all known or suspected sources of bias have been investigated or taken into account [2].

Reference Values: The reference values for 13 constituents, expressed as mass fractions on a dry-mass basis, are

provided in Table 2. Ten reference values are based on results obtained from a single NIST analytical method, and

three are based on results form two NIST analytical methods. Reference values are non-certified values that are the

best estimate of the true value; however, the values do not meet NIST criteria for certification and are provided with

associated uncertainties that may not include all sources of uncertainty [2].

Information Values: The values for 13 elements are provided in Table 3 for information purposes only. These are

non-certified values with no uncertainty assessed. The information values included in this certificate are based on

results obtained from one NIST method.

Expiration of Certification: The certification of SRM 2710a is valid, within the measurement uncertainties

specified, until 1 January 2019, provided the SRM is handled in accordance with the instructions given in this

certificate (see Instructions for Use). This certification is nullified if the SRM is damaged, contaminated, or

otherwise modified.

Maintenance of SRM Certification: NIST will monitor this SRM over the period of its certification. If

substantive technical changes occur that affect the certification before the expiration of this certificate, NIST will

notify the purchaser. Registration (see attached sheet) will facilitate notification.

E.A. Mackey and R.R. Greenberg of the NIST Analytical Chemistry Division were responsible for coordination of

the technical measurements leading to certification.

Statistical analyses were performed by J.H. Yen of the NIST Statistical Engineering Division.

Support aspects involved in the issuance of this SRM were coordinated through the NIST Measurement Services

Division.

Stephen A. Wise, Chief

Analytical Chemistry Division

Gaithersburg, MD 20899 Robert L. Watters, Jr., Chief

Certificate Issue Date: 7 April 2009 Measurement Services Division

SRM 2710a Page 1 of 7

INSTRUCTIONS FOR USE

Sampling: The SRM should be thoroughly mixed by repeatedly inverting and rotating the bottle horizontally

before removing a test portion for analysis. A minimum mass of 250 mg (dry mass - see Instructions for Drying)

should be used for analytical determinations to be related to the mass fraction values in this Certificate of Analysis.

To obtain the certified values, sample preparation procedures should be designed to effect complete dissolution. If

volatile elements (i.e., arsenic, mercury, selenium) will be determined, precautions should be taken in the

dissolution of SRM 2710a to avoid volatilization losses.

Drying: To relate measurements to the certified, reference, and information values that are expressed on a dry-mass

basis, users should determine a drying correction at the time of each analysis. The recommended drying procedure

is oven drying for 2 h at 110 C. Note that analytical determination of volatile elements (i.e., arsenic, mercury,

selenium) should be determined on samples as received; separate samples should be dried as previously described to

obtain a correction factor for moisture. Correction for moisture must be made to the data for volatile elements

before comparing to the certified values. This procedure ensures that these elements are not lost during drying. The

mass loss on drying for this material as bottled was approximately 2 %, but this value may change once the bottle is

opened and the soil is exposed to air.

SOURCE, PREPARATION, AND ANALYSIS

Source and Preparation of Material1: The U.S. Geological Survey (USGS), under contract to NIST, collected

and processed the material for SRM 2710a. The original collection site used for SRM 2710 was no longer available

due to remediation efforts by the Montana Department of Environmental Quality. An alternative nearby site,

located within the flood plain of the Silver Bow Creek, was selected. The site is approximately five miles west of

Butte, Montana. Soil for SRM 2710a was placed in 22 plastic-lined five-gallon buckets using a common garden

spade. The buckets were sealed and transferred to the USGS using a commercial freight carrier. At the USGS, the

SRM 2710a soil was dried at room temperature, disaggregated, and sieved to remove coarse material (2 mm). The

resulting soil was ball-milled in 50 kg portions together with an amount of lead oxide sufficient to achieve a mass

fraction of 0.55 % lead in the final product. The entire ball-milled batch of soil was transferred to a cross-flow

V-blender for mixing. The blended soil was radiation sterilized prior to bottling. In the final preparation step the

blended material was split into containers using a custom-designed spinning riffler, which was used to divide the

material into smaller batches, and then used to apportion approximately 50 g into each pre-cleaned bottle.

Every 100th bottle was set aside for chemical analyses designed to assess material homogeneity using X-ray

fluorescence spectrometry (XRF), inductively coupled plasma optical emission spectrometry (ICP-OES), and

inductively coupled plasma mass spectrometry (ICP-MS) at the USGS. Homogeneity assessments were performed

at NIST as well, and results indicated that additional processing was needed to achieve optimum homogeneity. The

material from all bottles was combined, and then ground in batches between stainless steel plates for a time

sufficient to produce a powder of which 95 %, by mass, passed through a 200 mesh (74 m) sieve. The resulting

powder was blended, and 50 g portions were dispensed into bottles using the spinning riffler. Results from

additional analyses indicated material homogeneity was acceptable (see below).

Analysis: The homogeneity was assessed for selected elements in the bottled material using X-ray fluorescence

spectrometry and instrumental neutron activation analysis (INAA). The estimated relative standard deviation for

material inhomogeneity is <1 % and no component for inhomogeneity was included in the expanded uncertainties of

the certified or reference values.

Analyses of this material were performed at NIST and at the USGS (Denver, CO). Results from NIST were used to

provide the certified, reference, and information values shown in Tables 1, 2, and 3 respectively. Results from the

USGS were used to confirm those values. The analytical techniques used for each element are listed in Table 4; the

analysts are listed in Tables 5 and 6.

1

Certain commercial equipment, instruments, or materials are identified in this certificate in order to specify

adequately the experimental procedure. Such identification does not imply recommendation or endorsement by the National

Institute of Standards and Technology, nor does it imply that the materials or equipment identified are necessarily the best

available for the purpose.

SRM 2710a Page 2 of 7

(a,b)

Table 1. Certified Values (Dry-Mass Basis) for Selected Elements in SRM 2710a

Element Mass Fraction Element Mass Fraction

(%) (mg/kg)

Aluminum 5.95 0.05 Antimony 52.5 1.6

Arsenic 0.154 0.010 Barium 792 36

Calcium 0.964 0.045 Cadmium 12.3 0.3

Copper 0.342 0.005 Cobalt 5.99 0.14

Iron 4.32 0.08 Lanthanum 30.6 1.2

Lead 0.552 0.003 Mercury 9.88 0.21

Magnesium 0.734 0.038 Strontium 255 7

Manganese 0.214 0.006 Uranium 9.11 0.30

Phosphorus 0.105 0.004

Potassium 2.17 0.13

Silicon 31.1 0.4

Sodium 0.894 0.019

Titanium 0.311 0.007

Zinc 0.418 0.015

(a)

Certified values for all elements except lead and mercury are the equally weighted means of results from two or

three analytical methods. The uncertainty listed with each value is an expanded uncertainty about the mean. The

expanded uncertainty is calculated as U = kuc, where uc is intended to represent, at the level of one standard

deviation, the combined effect of between-method and within-method components of uncertainty, following the ISO

Guide [3,4]. The coverage factor (k) is determined from the Student's t-distribution corresponding to the

appropriate associated degrees of freedom and approximately 95 % confidence for each analyte.

(b)

The certified values for lead and mercury are each results from a single NIST method (see Table 4) for which a

complete evaluation of all sources of uncertainty has been performed. The uncertainties for the certified values for

these elements represent expanded uncertainties with a coverage factor of 2, with uncertainty components combined

following the ISO Guide [4].

SRM 2710a Page 3 of 7

(a,b,c)

Table 2. Reference Values (Dry-Mass Basis) for Selected Elements in SRM 2710a

Element Mass Fraction (mg/kg)

Cesium 8.25 0.11

Chromium 23 6

Europium 0.82 0.01

Gadolinium 3.0 0.1

Lutetium 0.31 0.01

Neodymium 22 2

Nickel 8 1

Rubidium 117 3

Samarium 4.0 0.2

Scandium 9.9 0.1

Thallium 1.52 0.02

Thorium 18.1 0.3

Vanadium 82 9

(a)

Reference values for all elements except chromium, nickel, samarium, and vanadium are based on results

from one analytical method at NIST (see Table 4) and the uncertainties represent the expanded uncertainties,

which include the combined Type A and Type B with a coverage factor of 2, following the ISO Guide [4].

(b)

Reference values for nickel and samarium are the equally weighted means of results from two analytical

methods for nickel and two INAA experiments for samarium. The uncertainty listed with each value is an

expanded uncertainty about the mean. The expanded uncertainty is calculated as U = kuc, where uc is intended

to represent, at the level of one standard deviation, the combined effect of between-method and within-method

components of uncertainty, following the ISO Guide [3,4]. The coverage factor (k) is determined from the

Student's t-distribution corresponding to the appropriate associated degrees of freedom and approximately 95 %

confidence for each analyte.

(c)

Reference values for chromium and vanadium are based on a weighted mean calculated based on the

Dersimonian-Laird method [5], which incorporates an estimate of the between-method variance into the

weights. The expanded uncertainty listed with these values is calculated as U = kuc, where k = 2, and uc is

intended to represent, at the level of one standard deviation, the combined effect of between-method and

within-method components of uncertainty.

SRM 2710a Page 4 of 7

(a)

Table 3. Information Values (Dry-Mass Basis) for Selected Elements in SRM 2710a

Element Mass Fraction (mg/kg)

Boron 20

Cerium 60

Dysprosium 3

Gold 0.2

Hafnium 7

Indium 7

Selenium 1

Silver 40

Tantalum 0.9

Terbium 0.5

Tungsten 190

Ytterbium 2

Zirconium 200

(a)

Information values are based on results from one analytical method at NIST

SRM 2710a Page 5 of 7

Table 4. NIST Methods Used for the Analysis of SRM 2710a

Element Methods Element Methods

Ag INAA Na INAA; XRF

Al INAA; XRF Nd INAA

As CCT-ICP-MS; INAA; XRF Ni ICP-MS; ICP-OES

Au INAA P ICP-OES; XRF

B PGAA Pb ID-ICP-MS

Ba INAA: XRF Rb INAA

Ca INAA; XRF Sb ICP-MS; INAA

Cd ID-ICP-MS; PGAA Sc INAA

Ce INAA Se CCT-ICP-MS

Co INAA; ICP-OES Si PGAA; XRF

Cr INAA; XRF Sm INAA(a)

Cs INAA Sr ICP-OES; XRF

Cu INAA; XRF Ta INAA

Dy INAA Tb INAA

Eu INAA Th INAA

Fe INAA; PGAA; XRF Ti PGAA; XRF

Gd PGAA Tl ICP-MS

Hf INAA U ICP-MS; INAA

Hg CV-ID-ICPMS V INAA; XRF

K INAA; PGAA; XRF W INAA

La INAA(a) Yb INAA

Lu INAA Zn INAA; XRF

Mg INAA; XRF Zr XRF

Mn INAA; PGAA; XRF

NIST Methods of Analysis

CCT-ICP-MS Collision cell inductively coupled plasma mass spectrometry

CV-ID-ICP-MS Cold vapor isotope dilution inductively coupled plasma mass spectrometry

ICP-MS Inductively coupled plasma mass spectrometry

ICP-OES Inductively coupled plasma optical emission spectrometry

ID-ICP-MS Isotope dilution inductively coupled plasma mass spectrometry

INAA Instrumental neutron activation analysis

PGAA Prompt gamma-ray activation analysis

XRF X-ray fluorescence spectrometry

USGS Methods of Analysis(b)

WD-XRF-2 Wavelength dispersive X-ray fluorescence spectrometry at USGS

ICP-OES-2 Inductively coupled plasma optical emission spectrometry at USGS

ICP-MS-2 Inductively coupled plasma mass spectrometry at USGS

(a)

Two different INAA experiments, performed using different sub-samples and different analytical conditions, were

used to provide certified and reference values for lanthanum and samarium, respectively.

(b)

USGS Methods of Analysis were used to confirm results from certification methods.

SRM 2710a Page 6 of 7

Table 5. Participating NIST Analysts:

S.J. Christopher S.A. Rabb

R.D. Day J.R. Sieber

S.E. Long R.O. Spatz

E.A. Mackey R.S. Popelka-Filcoff

A.F. Marlow B.E. Tomlin

J.L. Molloy L.J. Wood

K.E. Murphy L.L. Yu

R.L. Paul R. Zeisler

Table 6. Participating USGS Laboratory and Analysts

Laboratory Analysts

U.S. Geological Survey M.G. Adams

Branch of Geochemistry Z.A. Brown

Denver, CO, USA P.L. Lamothe

J.E. Taggart

S.A. Wilson

REFERENCES

[1] Thompson, A.; Taylor, B.N.; Guide for the Use of the International System of Units (SI), NIST Special

Publication 811 (2008); available at http://www.physics.nist.gov/Pubs/contents.html.

[2] May, W.E.; Gills, T.E.; Parris, R.; Beck, II, C.M.; Fassett, J.D.; Gettings, R.J.; Greenberg, R.R.; Guenther,

F.R.; Kramer, G.; MacDonald, B.S.; Wise, S.A.; Definitions of Terms and Modes Used at NIST for Value-

Assignment of Reference Materials for Chemical Measurements, NIST Special Publication 260-136

(1999); available at http://www.cstl.nist.gov/nist839/NIST_special_publications.htm.

[3] Levenson, M.S.; Banks, D.L.; Eberhardt, K.R.; Gill, L.M.; Guthrie, W.F.; Liu, H.K.; Vangel, M.G.; Yen,

J.H.; Zhang, N.F.; J. Res. NIST 105, pp. 571-579 (2000).

[4] ISO; Guide to the Expression of Uncertainty in Measurement, ISBN 92-67-10188-9, 1st ed.; International

Organization for Standardization: Geneva, Switzerland (1993); see also Taylor, B.N.; Kuyatt, C.E.;

Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement Results, NIST Technical

Note 1297, U.S. Government Printing Office, Washington, DC (1994); available at

http://www.physics.nist.gov/Pubs/contents.html.

[5] DerSimonian, R.; Laird, N.; Controlled Clinical Trials 7, 177-188 (1986).

Users of this SRM should ensure that the certificate in their possession is current. This can be accomplished by

contacting the SRM Program at: telephone (301) 975-2200; fax (301) 926-4751; e-mail srminfo@nist.gov; or via

the Internet at http://www.nist.gov/srm.

SRM 2710a Page 7 of 7

Addendum to Certificate

Standard Reference Material 2710a

Montana I Soil

Highly Elevated Trace Element Concentrations

Leachable Concentrations Determined Using USEPA Methods 200.7 and 3050B

The mass fraction values contained in the NIST Certificate of Analysis for SRM 2710a represent the total element

content of the material. The measurement results used to provide the certified, reference or information values are

obtained from methods that require complete sample decomposition, or from nondestructive analytical methods

such as instrumental neutron activation analysis or prompt gamma-ray activation analysis. Where complete sample

decomposition is required, it can be accomplished by digestion with mixed acids or by fusion. For mixed-acid

decomposition, hydrofluoric acid must be included in the acid mixture used to totally decompose siliceous materials

such as soils and sediments.

In its monitoring programs, the U.S. Environmental Protection Agency (USEPA) has established a number of leach

methods for the preparation of soil samples for the determination of extractable elements. Six laboratories

participated, five of which used USEPA Method 200.7; the remaining laboratory used USEPA SW-846 Method

3050B for preparation of soil samples. All elements were determined in leachates by inductively coupled plasma

optical emission spectrometry. All laboratories provided individual results from duplicate portions, and these

results were averaged together to provide one result for each element from each participating laboratory. Results

rejected as outliers by the USEPA Contract Laboratory Program (CLP) officials were not included. Results are

summarized in Table A1. The ranges of mass fraction values, median values (to two significant figures), and the

number of results included for each are given for 23 elements. The percent recovery values based on the ratios of

the median values to the total element content (from the certified, reference, or information values in the Certificate

of Analysis) are listed in the last column of Table A1. Note that the certified values provided as total mass

fractions in the Certificate of Analysis are the best estimate of the true mass fraction values for this material.

This USEPA CLP Study was coordinated by Clifton Jones, Quality Assurance and Technical Support Program

(QATS), Shaw Environmental & Infrastructure Group, Las Vegas, NV, under the direction of John Nebelsick,

USEPA, Analytical Services Branch. The participating laboratories are listed in Table A2.

SRM 2710a Page 1 of 2

Table A1. Results from Laboratories Participating in the EPA Contract Laboratory Program Study.

Element n Range (mg/kg) Median (mg/kg) Recovery (%)

Aluminum 6 8200 - 12000 10000 17

Antimony 6 5.0 - 12 9.6 18

Arsenic 6 1300 - 1600 1400 92

Barium 6 490 - 540 510 65

Beryllium 6 0.24 - 0.51 0.48 --

Cadmium 5 9.6 - 12 11 86

Calcium 6 1700 - 2000 1800 19

Chromium 6 9.2 - 11 10 41

Cobalt 6 2.8 - 5.2 3.8 64

Copper 6 3100 - 3500 3300 95

Iron 6 30000 - 36000 34000 79

Lead 6 4700 - 5800 5100 93

Magnesium 6 3200 - 3600 3500 48

Manganese 6 1500 - 1800 1700 77

Mercury 6 9.3 - 11.7 10 104

Nickel 5 4.8 - 6.1 5.5 69

Potassium 6 3800 - 4700 4100 19

Selenium 2 1.5 - 2.6 2.0 200

Silver 6 31 - 39 36 91

Sodium 6 550 - 650 590 7

Thallium 3 1.3 - 3.6 3.2 213

Vanadium 6 35 - 43 38 48

Zinc 6 3300 - 4400 3800 90

Table A2. List of CLP and non-CLP Participating Laboratories

A4 Scientific, Inc.

Bonner Analytical Testing Co.

Chem Tech Consulting Group

Datachem Laboratories, Inc.

Liberty Analytical Corporation

SVL Analytical, Inc.

SRM 2710a Page 2 of 2

Das könnte Ihnen auch gefallen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument8 SeitenCertificate of Analysis: National Institute of Standards & TechnologySimone LinsNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument12 SeitenCertificate of Analysis: National Institute of Standards & TechnologyOrestes LenizNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument13 SeitenCertificate of Analysis: National Institute of Standards & TechnologyOrestes LenizNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument7 SeitenCertificate of Analysis: National Institute of Standards & TechnologyadrianaNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument4 SeitenCertificate of Analysis: National Institute of Standards & TechnologyVictorAndresMillaSalazarNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument3 SeitenCertificate of Analysis: National Institute of Standards & TechnologymoisesNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument4 SeitenCertificate of Analysis: National Institute of Standards & Technologymm mmNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument4 SeitenCertificate of Analysis: National Institute of Standards & TechnologyAfzal ImamNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument3 SeitenCertificate of Analysis: National Institute of Standards & Technologymm mmNoch keine Bewertungen

- Icpms2 PDFDokument24 SeitenIcpms2 PDFlabkpNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument7 SeitenCertificate of Analysis: National Institute of Standards & TechnologyCesar BarretoNoch keine Bewertungen

- Standard Reference Material 1882a Calcium Aluminate Cement: Ertificate of NalysisDokument5 SeitenStandard Reference Material 1882a Calcium Aluminate Cement: Ertificate of NalysisDerekNoch keine Bewertungen

- 1881 ADokument3 Seiten1881 Atatum29Noch keine Bewertungen

- AMIS0332 CertificateDokument8 SeitenAMIS0332 CertificatejemmacruzNoch keine Bewertungen

- AMIS0248 CertificateDokument8 SeitenAMIS0248 CertificatesynedNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards and TechnologyDokument5 SeitenCertificate of Analysis: National Institute of Standards and TechnologyJohn GiannakopoulosNoch keine Bewertungen

- ACIRS S2D TR 01 Technical ReportDokument4 SeitenACIRS S2D TR 01 Technical ReportJoe HartNoch keine Bewertungen

- 1885 ADokument3 Seiten1885 Atatum29Noch keine Bewertungen

- OREAS 991 CertificateDokument7 SeitenOREAS 991 CertificateVivianne PerezNoch keine Bewertungen

- 1889 ADokument3 Seiten1889 Atatum29Noch keine Bewertungen

- Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)Dokument9 SeitenMultielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)Luis Ernesto Marin JaimesNoch keine Bewertungen

- OREAS 401 CertificateDokument7 SeitenOREAS 401 Certificateflysch_ukNoch keine Bewertungen

- Nist Sucrose17fDokument4 SeitenNist Sucrose17fmaidenjukaNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument7 SeitenCertificate of Analysis: National Institute of Standards & TechnologyAchmad LatiefNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument2 SeitenCertificate of Analysis: National Institute of Standards & TechnologyNgân Hàng Ngô Mạnh TiếnNoch keine Bewertungen

- ACIRS G10 2022 CoA Rev01Dokument4 SeitenACIRS G10 2022 CoA Rev01Kase Family (Kei&Ken)Noch keine Bewertungen

- (Charslton) IV-STOCK-75 - S2-MEB713511Dokument4 Seiten(Charslton) IV-STOCK-75 - S2-MEB713511tamiaNoch keine Bewertungen

- Certificate of Analysis: National Institute of Standards & TechnologyDokument4 SeitenCertificate of Analysis: National Institute of Standards & TechnologySidneide Ferreira SantosNoch keine Bewertungen

- Certificate of Analysis: Value Beyond MeasureDokument1 SeiteCertificate of Analysis: Value Beyond MeasureFebri SandiNoch keine Bewertungen

- MRC Mix-Pesticidas 8270CDokument1 SeiteMRC Mix-Pesticidas 8270CmatheuscarlosebelNoch keine Bewertungen

- Astm D 5185 02 Icp PDFDokument7 SeitenAstm D 5185 02 Icp PDFReyzza AndiaNoch keine Bewertungen

- SN-QC-SAPP-106 Ebotux 2g InjDokument6 SeitenSN-QC-SAPP-106 Ebotux 2g Injdaizhussain004Noch keine Bewertungen

- ASTM D5185-18-ICP-L-Bpn (29-01-2019)Dokument9 SeitenASTM D5185-18-ICP-L-Bpn (29-01-2019)I Wayan Arief Pradana Putra100% (3)

- BCS-CRM 177 - 2 Aug2012Dokument2 SeitenBCS-CRM 177 - 2 Aug2012Ishmael WoolooNoch keine Bewertungen

- QC3077 Lrac4478Dokument2 SeitenQC3077 Lrac4478Exata MetrologiaNoch keine Bewertungen

- C1111-10 (Reapproved 2015)Dokument6 SeitenC1111-10 (Reapproved 2015)Mohamad ZandiNoch keine Bewertungen

- Lrac3125Dokument2 SeitenLrac3125egpharma1Noch keine Bewertungen

- CR G8 2019 Rev1Dokument4 SeitenCR G8 2019 Rev1Andhika Manggal Putra PNoch keine Bewertungen

- 1880 BDokument5 Seiten1880 Btatum29Noch keine Bewertungen

- Determination of Nickel, Vanadium, Iron, and Sodium in Crude Oils and Residual Fuels by Flame Atomic Absorption SpectrometryDokument7 SeitenDetermination of Nickel, Vanadium, Iron, and Sodium in Crude Oils and Residual Fuels by Flame Atomic Absorption SpectrometryammarNoch keine Bewertungen

- E 246 - 10 (2015)Dokument9 SeitenE 246 - 10 (2015)ruben carcamoNoch keine Bewertungen

- ACIRS-G9-2021 Certificate of Analysis: General Coal Reference MaterialDokument4 SeitenACIRS-G9-2021 Certificate of Analysis: General Coal Reference MaterialShintya FebrizaNoch keine Bewertungen

- Certificate: National Institute of Standards & TechnologyDokument5 SeitenCertificate: National Institute of Standards & Technologymusic onlyNoch keine Bewertungen

- E-CLD-0031 - Alkali Carbonate ReactivityDokument5 SeitenE-CLD-0031 - Alkali Carbonate ReactivityclaudiaortizlozaNoch keine Bewertungen

- Boldenone UndDokument2 SeitenBoldenone UndAhmedNoch keine Bewertungen

- POTASIO 918bDokument3 SeitenPOTASIO 918bpatricia.mprpNoch keine Bewertungen

- Nist Dicromato de PotasioDokument2 SeitenNist Dicromato de PotasioSandra Lara LaraNoch keine Bewertungen

- Determination of Zinc in Zinc Ores and Concentrates by Complexometric TitrimetryDokument4 SeitenDetermination of Zinc in Zinc Ores and Concentrates by Complexometric TitrimetryROHITNoch keine Bewertungen

- GBMS304 2Dokument1 SeiteGBMS304 2Dave AdamsNoch keine Bewertungen

- 5990-8685en Appnote 4100mp-Aes FoodsDokument6 Seiten5990-8685en Appnote 4100mp-Aes FoodsMackinder LijarzaNoch keine Bewertungen

- PKI - 2011 - AN - The Determination of Minerals in Vitamins by FAAS With PinAAcle 900Dokument3 SeitenPKI - 2011 - AN - The Determination of Minerals in Vitamins by FAAS With PinAAcle 900Adelitza StrubingerNoch keine Bewertungen

- Certificate of Analysis : CertificationDokument2 SeitenCertificate of Analysis : CertificationKunam JayaNoch keine Bewertungen

- MRC - Mix Ftalatos 27 10 23Dokument2 SeitenMRC - Mix Ftalatos 27 10 23matheuscarlosebelNoch keine Bewertungen

- SN-QC-SAPP-027 Monaz 5mg TabletDokument7 SeitenSN-QC-SAPP-027 Monaz 5mg Tabletdaizhussain004Noch keine Bewertungen

- Samarthethephonepaper2016 PDFDokument7 SeitenSamarthethephonepaper2016 PDFIlham KurniawanNoch keine Bewertungen

- Astm D5863Dokument2 SeitenAstm D5863Sylab InstrumentsNoch keine Bewertungen

- Iron, Dissolved: Chemkey 1,10-Phenanthroline Method Method 10281 0.05 To 3.00 MG/L As Fe Chemkey ReagentsDokument4 SeitenIron, Dissolved: Chemkey 1,10-Phenanthroline Method Method 10281 0.05 To 3.00 MG/L As Fe Chemkey ReagentsDavid Cruz ZamoraNoch keine Bewertungen

- ISO 14000 Environmental Management Standards: Engineering and Financial AspectsVon EverandISO 14000 Environmental Management Standards: Engineering and Financial AspectsNoch keine Bewertungen

- BS Iso 11352-2012Dokument38 SeitenBS Iso 11352-2012Shady Ismail100% (2)

- ICP Stanndard Solution IV 1113550100 - HC90682355 - SU - ENDokument2 SeitenICP Stanndard Solution IV 1113550100 - HC90682355 - SU - ENZulfahmi Al UsuiNoch keine Bewertungen

- ASTM D7778-15 Planificación InterlaboratorioDokument11 SeitenASTM D7778-15 Planificación InterlaboratorioDoina Marquez100% (1)

- HP Certified ProfessionalDokument3 SeitenHP Certified ProfessionalIrfan100% (2)

- A2LA Policy On Measurement TraceabilityDokument9 SeitenA2LA Policy On Measurement Traceabilityjrlr65Noch keine Bewertungen

- Human Control Seronorm Control NormalDokument6 SeitenHuman Control Seronorm Control Normaloscarleandro69Noch keine Bewertungen

- CANNON Viscosity & Flash Point Standards BrochureDokument12 SeitenCANNON Viscosity & Flash Point Standards BrochureLuis Xarlos GutierrezNoch keine Bewertungen

- MapanDokument8 SeitenMapanbochraNoch keine Bewertungen

- Certificate of Analysis: (Batch G) Certified Reference Material InformationDokument4 SeitenCertificate of Analysis: (Batch G) Certified Reference Material InformationrahulNoch keine Bewertungen

- Method VerificationDokument61 SeitenMethod VerificationWaqarAhmedButt100% (1)

- G123 - Guidance For Accreditation of Cannabis Testing Laboratories-5616-8Dokument6 SeitenG123 - Guidance For Accreditation of Cannabis Testing Laboratories-5616-8walterNoch keine Bewertungen

- Türki̇yede Referans Malzeme Üreti̇mi̇ PDFDokument4 SeitenTürki̇yede Referans Malzeme Üreti̇mi̇ PDFttugce29Noch keine Bewertungen

- Conductivity Standard ThomasDokument1 SeiteConductivity Standard ThomasJulio David Vilca PizarroNoch keine Bewertungen

- CRM PPC BlainesDokument2 SeitenCRM PPC BlainesVara Prasad PaluriNoch keine Bewertungen

- Total Mercury in Coal and Coal Combustion Residues by Acid Extraction or Wet Oxidation/Cold Vapor Atomic AbsorptionDokument7 SeitenTotal Mercury in Coal and Coal Combustion Residues by Acid Extraction or Wet Oxidation/Cold Vapor Atomic AbsorptionahmedNoch keine Bewertungen

- استمارة تدقيقDokument29 Seitenاستمارة تدقيقdr.alwahar1Noch keine Bewertungen

- Nordtest TR 537 (2011-11) MNDokument54 SeitenNordtest TR 537 (2011-11) MNMatea Malovrh100% (1)

- Marssim Chapter7 PDFDokument28 SeitenMarssim Chapter7 PDFFranz CulagbangNoch keine Bewertungen

- NT Technical Report Nordtest Report TR 569Dokument52 SeitenNT Technical Report Nordtest Report TR 569Fabianus Galih Ari WigunaNoch keine Bewertungen

- Technical Guide: UV/Vis Spectrophotometer Calibration ProceduresDokument7 SeitenTechnical Guide: UV/Vis Spectrophotometer Calibration Procedureslong100% (1)

- Metrological TraceabilityDokument45 SeitenMetrological TraceabilityAlex Flores PardoNoch keine Bewertungen

- Catálogo EraDokument8 SeitenCatálogo EraFRANCO HUACANJULCA GARCIANoch keine Bewertungen

- Ilac G2 1994Dokument53 SeitenIlac G2 1994boborg8792Noch keine Bewertungen

- WHO TRS 961 (2011) Annex 2. Good Microbiology LaboratoryDokument25 SeitenWHO TRS 961 (2011) Annex 2. Good Microbiology LaboratoryQAD ImedcoNoch keine Bewertungen

- L1050096 IPV Kit Users GuideDokument10 SeitenL1050096 IPV Kit Users GuideAndy CowlandNoch keine Bewertungen

- Astm D4084-12Dokument7 SeitenAstm D4084-12Sergey KichenkoNoch keine Bewertungen

- Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission SpectrometryDokument11 SeitenAnalysis of Carbon and Low-Alloy Steel by Spark Atomic Emission SpectrometryIbtisam AbudNoch keine Bewertungen

- EUA Qorvo Omina LetterDokument9 SeitenEUA Qorvo Omina LetterSanjayaNoch keine Bewertungen

- Method Statement For I&C Calibration and LaboratoryDokument20 SeitenMethod Statement For I&C Calibration and LaboratoryUtku Can Kılıç100% (1)

- D 859 - 16Dokument5 SeitenD 859 - 16Joselito Cortes100% (1)