Beruflich Dokumente

Kultur Dokumente

IATF 16949 Documen

Hochgeladen von

punitg_20 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

296 Ansichten1 SeiteThe document lists IATF 16949 requirements for various documentation topics including:

- Required documentation topics such as responsibility and authority, quality management system documentation, and customer notification.

- Required records topics such as risk analysis, calibration and verification, and internal auditing.

- Required documented processes topics covering areas like product safety, design and development, supplier selection, and problem solving.

Originalbeschreibung:

SZCZ

Copyright

© © All Rights Reserved

Verfügbare Formate

XLSX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document lists IATF 16949 requirements for various documentation topics including:

- Required documentation topics such as responsibility and authority, quality management system documentation, and customer notification.

- Required records topics such as risk analysis, calibration and verification, and internal auditing.

- Required documented processes topics covering areas like product safety, design and development, supplier selection, and problem solving.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

296 Ansichten1 SeiteIATF 16949 Documen

Hochgeladen von

punitg_2The document lists IATF 16949 requirements for various documentation topics including:

- Required documentation topics such as responsibility and authority, quality management system documentation, and customer notification.

- Required records topics such as risk analysis, calibration and verification, and internal auditing.

- Required documented processes topics covering areas like product safety, design and development, supplier selection, and problem solving.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

IATF 16949 Documentation Requirements

Required Documentation Topic

5.3.1 Responsibility and Authority

7.3.1 Awareness

7.5.1.1 QMS Documentation

7.5.3.2.1 Record Retention

8.3.3.3 Special Characteristics

8.5.1.2 Standardized Work

8.5.6.1.1 Temporary Changes to Process Controls

8.6.1 Release of Products and Services

8.7.1.6 Customer Notification

9.3.3.1 Management Review Outputs

Required Records Topic

6.1.2.1 Risk Analysis

6.1.2.2 Preventative Action

6.1.2.3 Contingency Plans

7.1.5.1.1 Measurement System Analysis

7.1.5.2.1 Calibration and Verification

7.1.5.3.1 Internal Laboratory

7.2.3 Internal Auditor Competency

7.5.3.2.2 Engineering Specifications

8.2.3.1.1 Review of Requirements

8.3.2.3 Imbedded Software

8.3.6.1 Design and Development Changes

8.4.2.4.1 Second Party Audits

8.5.1.3 Verification of Job Set-up

8.5.6.1 Control of Changes

8.7.1.1 Customer Authorization

8.7.1.4 Reworked Product

8.7.1.5 Repaired Product

9.1.1.1 Monitoring and Measurement of Manufacturing Processes

Required Documented Processes Topic

4.4.1.2 Product Safety

7.1.5.2.1 Calibration and Verification

7.1..5.3.1 Internal Laboratory

7.2.1 Competence

7.2.3 Internal Auditor Competency

7.3.2 Employee Motivation and Empowerment

7.5.3.2.2 Engineering Specifications

8.3.1.1 Design and Development

8.3.3.2 Manufacturing Process Design Input

8.3.5.2 Manufacturing Process Design Output

8.4.1.2 Supplier Selection

Required Documented Processes (cont'd) Topic

8.4.2.1 Type and Extent of Control

8.4.2.2 Statutory and Regulatory Requirements

8.4.2.4 Supplier Monitoring

8.5.1.5 Total Productive Maintenance

8.5.6.1 Control of Changes

8.7.1.4 Control of Reworked Product

8.7.1.5 Control of Repaired Product

8.7.1.7 Nonconforming Product Disposition

9.2.2.1 Internal Audit

10.2.3 Problem Solving

10.2.4 Error Proofing

10.3.1 Continual Improvement

Das könnte Ihnen auch gefallen

- APQP ProcedureDokument9 SeitenAPQP ProcedurePk Nimiwal100% (4)

- 14-QSP - 59 Procedure For Temporary Change of Process Controls PDFDokument1 Seite14-QSP - 59 Procedure For Temporary Change of Process Controls PDFsahyadri engineersNoch keine Bewertungen

- APQP Timing Plan TemplateDokument9 SeitenAPQP Timing Plan TemplatemuthuselvanNoch keine Bewertungen

- Checklist of Documentation As Per IATF 16949:2016Dokument10 SeitenChecklist of Documentation As Per IATF 16949:2016Arun Kumar Sharma100% (2)

- Work Instruction: Action's Responsibility Change Parameters & CriteriaDokument2 SeitenWork Instruction: Action's Responsibility Change Parameters & CriteriaSameer Saxena100% (2)

- Clause Matrix Iatf 16949Dokument10 SeitenClause Matrix Iatf 16949ikesh mNoch keine Bewertungen

- AIAG & VDA PFMEA FormatDokument1 SeiteAIAG & VDA PFMEA Formatmahesh KhatalNoch keine Bewertungen

- ApqpDokument72 SeitenApqpsaby aroraNoch keine Bewertungen

- AIAG-VDA PFMEA Template For Activity - (Delegate)Dokument38 SeitenAIAG-VDA PFMEA Template For Activity - (Delegate)nadia_naaz90Noch keine Bewertungen

- PFMEA AIAG VDA Heading Hints PDFDokument1 SeitePFMEA AIAG VDA Heading Hints PDFRamdas PaithankarNoch keine Bewertungen

- APQP Timing Plan SampleDokument3 SeitenAPQP Timing Plan SampleDhananjay Patil75% (4)

- Guideline 4M Change MatrixDokument3 SeitenGuideline 4M Change MatrixAman JasujaNoch keine Bewertungen

- APQP Supplier ProcedureDokument20 SeitenAPQP Supplier ProcedurepharmatonNoch keine Bewertungen

- List of Documents IATF 16949 Documentation Toolkit EN PDFDokument4 SeitenList of Documents IATF 16949 Documentation Toolkit EN PDFRahul SharmaNoch keine Bewertungen

- NPD Check SheetDokument6 SeitenNPD Check Sheets.charlie0% (1)

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDokument9 SeitenGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNoch keine Bewertungen

- P13-Process For APQPDokument6 SeitenP13-Process For APQPBangali Singh100% (1)

- Supplier APQP Requirements Matrix: D & C These Items To Be Included On Gap Analysis Sheet With ActionsDokument4 SeitenSupplier APQP Requirements Matrix: D & C These Items To Be Included On Gap Analysis Sheet With ActionsOmkar waghuleNoch keine Bewertungen

- Manufacturing Process AuditDokument1 SeiteManufacturing Process AuditSachin Kumbhar100% (1)

- Supplier APQP Training SupplementDokument78 SeitenSupplier APQP Training SupplementjcperezNoch keine Bewertungen

- Attribute MSA 4th EditionDokument4 SeitenAttribute MSA 4th EditionSachin RamdurgNoch keine Bewertungen

- MSIL Audit Cheklist 16Dokument22 SeitenMSIL Audit Cheklist 16Pravin Balasaheb GunjalNoch keine Bewertungen

- Product Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDokument8 SeitenProduct Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDavid MorenoNoch keine Bewertungen

- Iatf UpgradingDokument6 SeitenIatf UpgradingAhmad AzrilNoch keine Bewertungen

- GM Machining CP REV 03Dokument17 SeitenGM Machining CP REV 03Suraj RawatNoch keine Bewertungen

- Sop On Apqp & Ppap WRT Iatf 16949-2016Dokument1 SeiteSop On Apqp & Ppap WRT Iatf 16949-2016balakumar rajaram100% (1)

- AIAG PPAP Cover SheetDokument1 SeiteAIAG PPAP Cover SheetSCHOPENHAUERNoch keine Bewertungen

- 5M CHANGE ProcedureDokument8 Seiten5M CHANGE ProcedurePk Nimiwal100% (1)

- 01 Procedure For Structural SteelDokument9 Seiten01 Procedure For Structural Steelpunitg_2Noch keine Bewertungen

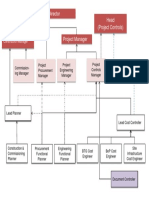

- Project Director Head (Project Controls) Project ManagerDokument1 SeiteProject Director Head (Project Controls) Project Managerpunitg_2Noch keine Bewertungen

- Process Map - Unitwise Process LinkagesDokument1 SeiteProcess Map - Unitwise Process LinkagesSachin RamdurgNoch keine Bewertungen

- HF-0467 - Product Audit Report - C - 2015-08-06Dokument44 SeitenHF-0467 - Product Audit Report - C - 2015-08-06Enis SirbegovicNoch keine Bewertungen

- Procedure: Measurement System Analysis ExecutionDokument1 SeiteProcedure: Measurement System Analysis Executionaslam100% (1)

- List of Mandatory Documents Required by IATF 16949-2016Dokument3 SeitenList of Mandatory Documents Required by IATF 16949-2016Oscar Solis MartirNoch keine Bewertungen

- Wi SPCDokument4 SeitenWi SPCSujeet Kumar100% (1)

- Error Proofing QSP-37 REV 00Dokument3 SeitenError Proofing QSP-37 REV 00BRPLNoch keine Bewertungen

- Automotive Quality Management System Manual: Century Metal Recycling LimitedDokument7 SeitenAutomotive Quality Management System Manual: Century Metal Recycling LimitedsunilNoch keine Bewertungen

- Required Documents For IATF - 16949Dokument5 SeitenRequired Documents For IATF - 16949Rajesh Sahasrabuddhe0% (1)

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Dokument5 SeitenClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhaneNoch keine Bewertungen

- Iatf ActivitiesDokument6 SeitenIatf ActivitiesWizard tube and Engineered componentNoch keine Bewertungen

- PPAP ChecklistDokument4 SeitenPPAP ChecklistHirbod HirmandNoch keine Bewertungen

- IATF 16949 List of Mandatory DocumentsDokument2 SeitenIATF 16949 List of Mandatory DocumentsLuis Alejandro67% (6)

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Dokument11 SeitenLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011punitg_2Noch keine Bewertungen

- APQP Sample FormatDokument32 SeitenAPQP Sample FormatManigandan RNoch keine Bewertungen

- Layered Audit ChecklistDokument4 SeitenLayered Audit ChecklistNavnath TamhaneNoch keine Bewertungen

- Quality Manual: Subject: Procedure For PFMEADokument3 SeitenQuality Manual: Subject: Procedure For PFMEAPk Nimiwal100% (3)

- Required Doc For IATFDokument3 SeitenRequired Doc For IATFAbhayNoch keine Bewertungen

- Sop SeDokument60 SeitenSop SemanttupandeyNoch keine Bewertungen

- 1 ApqpDokument30 Seiten1 ApqpVIPIN YADAVNoch keine Bewertungen

- Fmea Vda AiagDokument63 SeitenFmea Vda AiagfquysxlahyytpxpwgqNoch keine Bewertungen

- New Org Chart - LNT PowerDokument1 SeiteNew Org Chart - LNT Powerpunitg_2Noch keine Bewertungen

- Iatf Process Audit Check Sheet FormatDokument14 SeitenIatf Process Audit Check Sheet FormatPuspavathi S Rama NaiduNoch keine Bewertungen

- Product Audit Check SheetDokument3 SeitenProduct Audit Check SheetLakshmanan Venkatesan100% (1)

- IATF 16949 2016 Mandatory ProcedureDokument1 SeiteIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- IATF IA CHecklistDokument2 SeitenIATF IA CHecklistDamodaran RajanayagamNoch keine Bewertungen

- IATF 16949 Transition Audit - Off Site Document Review WorksheetDokument5 SeitenIATF 16949 Transition Audit - Off Site Document Review WorksheetDuho ConsultoresNoch keine Bewertungen

- Ref Flow Charts Layout InspectionDokument1 SeiteRef Flow Charts Layout Inspectionrajesh.bNoch keine Bewertungen

- Contents:: Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) ProjectDokument3 SeitenContents:: Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Projectpunitg_2Noch keine Bewertungen

- 4M Change Management DefinitionDokument4 Seiten4M Change Management DefinitionManasi shindeNoch keine Bewertungen

- Sr. No. Requirements: Ppap Check ListDokument3 SeitenSr. No. Requirements: Ppap Check Listkamlesh kuchekarNoch keine Bewertungen

- IATF 16949 Training PDFDokument23 SeitenIATF 16949 Training PDFRajeshLS100% (1)

- Clausul IATFDokument8 SeitenClausul IATFAhmad ZainuddinNoch keine Bewertungen

- 31 1 Static Equipment Vertical ErectionDokument2 Seiten31 1 Static Equipment Vertical Erectionpunitg_2Noch keine Bewertungen

- 30 1 Static Equipment Horizontal ErectionDokument2 Seiten30 1 Static Equipment Horizontal Erectionpunitg_2Noch keine Bewertungen

- 02 Lista de Documentos Mandatorios IATF 2016Dokument2 Seiten02 Lista de Documentos Mandatorios IATF 2016Luis AlejandroNoch keine Bewertungen

- 11 TradeDokument3 Seiten11 Tradepunitg_2Noch keine Bewertungen

- Project Director: Construction Manager EHS Manager Qa/Qc ManagerDokument1 SeiteProject Director: Construction Manager EHS Manager Qa/Qc Managerpunitg_2Noch keine Bewertungen

- Trading Account - ChargesDokument6 SeitenTrading Account - Chargespunitg_2Noch keine Bewertungen

- About Kotak Gold ETF (KGETF) Scheme FactsDokument3 SeitenAbout Kotak Gold ETF (KGETF) Scheme Factspunitg_2Noch keine Bewertungen

- The Overview of Gold Etfs and Its Various Positive Features: Mohdsaleem Matloobullah KhanDokument11 SeitenThe Overview of Gold Etfs and Its Various Positive Features: Mohdsaleem Matloobullah Khanpunitg_2Noch keine Bewertungen

- 1 Procedure For Radiography TestingDokument9 Seiten1 Procedure For Radiography Testingpunitg_2Noch keine Bewertungen

- GEOJIT Equity Trading - Call and Trade Services - Free Online Trading ServicesDokument2 SeitenGEOJIT Equity Trading - Call and Trade Services - Free Online Trading Servicespunitg_2Noch keine Bewertungen

- Trading Holidays For The Calendar Year 2014Dokument1 SeiteTrading Holidays For The Calendar Year 2014punitg_2Noch keine Bewertungen

- Securities Transaction Tax11234Dokument2 SeitenSecurities Transaction Tax11234punitg_2Noch keine Bewertungen

- Procedure For Installation Static Equipment For MSQ Upgradation UnitDokument7 SeitenProcedure For Installation Static Equipment For MSQ Upgradation Unitpunitg_2Noch keine Bewertungen

- Larsen & Toubro Limited MSQ (Epcc 1) Up Gradation: LT/MSQ/P/DPT//007Dokument4 SeitenLarsen & Toubro Limited MSQ (Epcc 1) Up Gradation: LT/MSQ/P/DPT//007punitg_2Noch keine Bewertungen

- Larsen & Toubro Limited MSQ (Epcc-1) Upgadation Project: ContentsDokument5 SeitenLarsen & Toubro Limited MSQ (Epcc-1) Upgadation Project: Contentspunitg_2Noch keine Bewertungen

- NC 306 29JUL2010Dokument1 SeiteNC 306 29JUL2010punitg_2Noch keine Bewertungen

- Udhakar Chchasare: Total Experience:-THREE YEAR & ONE MONTH Experience in QA/QC & NDTDokument4 SeitenUdhakar Chchasare: Total Experience:-THREE YEAR & ONE MONTH Experience in QA/QC & NDTpunitg_2Noch keine Bewertungen

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: Procedure For Joint NumberingDokument3 SeitenLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: Procedure For Joint Numberingpunitg_2Noch keine Bewertungen

- FRM-OHS-HOT - WORK - PERMIT - Permit & GuidelinesDokument2 SeitenFRM-OHS-HOT - WORK - PERMIT - Permit & Guidelinespunitg_2Noch keine Bewertungen

- PROC-OHS-INCIDENT-REPORTING - Procedure and Corrective ActionDokument6 SeitenPROC-OHS-INCIDENT-REPORTING - Procedure and Corrective Actionpunitg_2Noch keine Bewertungen

- ABRO Company ProfileDokument7 SeitenABRO Company Profilepunitg_2Noch keine Bewertungen