Beruflich Dokumente

Kultur Dokumente

Artículo Técnico Contraction Coefficients For Borda Mouthpieces

Hochgeladen von

AndresCanoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Artículo Técnico Contraction Coefficients For Borda Mouthpieces

Hochgeladen von

AndresCanoCopyright:

Verfügbare Formate

Contraction Coefficients for Borda Mouthpieces Good Cc data for the Borda mouthpiece are very hard to

find. The values of 0.5149 (Borda), 0.5547 (Bidone), and

Wei-guo Dong1 and John H. Lienhard1 0.5324 (Weisbach) quoted in [1] - without references and

without giving the dimensions o r proportions of the tube - ap-

pear to be the bases upon which textbooks normally quote

Nomenclature values between 0.52 and 0.54. It is customary to rationalize a

a = distance from a point at value of Cc>0.50 using equation (1) with a n assumed C, be-

which D j is measured to the tween 0.98 and 0.96.

point above it, at which we While the shortage of Cc data clearly reflects the limited

want to know Dj,ae,ual practical importance of the Borda mouthpiece, two issues in

C, C , = arbitrary constants this matter d o merit our attention. One is that of questioning

Cc = coefficient of contraction, the validity of the routinely-taught momentum balance. The

(jet area)/(aperture area) other is that of checking the common implication that

C, = coefficient of discharge, CcCu substantial mechanical energy is dissipated in conventional

C, = coefficient of velocity, orifices.

(jet velocity)/* In 1984 Lienhard V and Lienhard (IV) [2] showed that C,

D, Dj = diameter of a Borda for a sharp-edged orifice is s o close to unity that we can prac-

mouthpiece, diameter of the tically forget about any energy dissipation in such discharges.

jet from a Borda mouthpiece They also noted that, although they did not calculate the

g = acceleration of gravity dissipation in a Borda mouthpiece, it would certainly be even

h = head above a Borda less than in a sharp edged orifice. Consequently one must look

mouthpiece elsewhere than to C, for the explanation of C,'s greater than

M = 4([2L/DI2 + 1) 1/2.

L = length of a Borda mouthpiece The other place where people often look for the cause of the

p = pressure in the liquid higher value of Cc is in manufacturing imperfections in the lip

Re = Reynolds number, of the mouthpiece. However, one is hard pressed to see how

p~/(viscosity) minor alternations of the lip could affect the momentum

r = radial coordinate around the balance calculation in any way2.

axis of the Borda mouthpiece We therefore ask how the momentum balance argument

u = liquid velocity itself could fail. A key assumption in the argument is that the

We = Weber number, pD(2gh)/a liquid is stagnant on the support wall (see Fig. 1.). However, it

p = liquid density is clear that there is some liquid movement o n the wall, and

a = surface tension that it must decrease as the length, L, of the mouthpiece is in-

creased. Liquid motion reduces the pressure o n the wall; con-

sequently the jet momentum must increase to compensate for

Introduction it. Since the velocity is constant, it is the area of the jet that

Figure 1, which is half sketch and half photograph, shows must increase.

liquid emerging from a Borda mouthpiece; and it establishes Our objective is thus to measure Cc as a function of the

some nomenclature. It is well-known that an elementary ratio L/D. The result should verify or deny two matters that

momentum balance specifies the coefficient of contraction, we have suggested above. 1) If liquid movement parallel with

C,, (the ratio of the cross-sectional area of the jet to that of the support wall affects C,, then Cc should decrease toward an

the hole) in the following way: asymptote as L / D becomes large. 2) If C, is virtually unity,

then that asymptote should be 1/2.

cC= 1/(2cU2) (1)

where C, is the "coefficient of velocity" or the ratio of the jet Experiment

velocity to a. Experimental Design. Figure 1 shows the Borda

mouthpiece we designed t o measure C,. The apparatus was

'Heat Transfer/Phase-Change Laboratory, Mechanical Engineering Depart- manufactured entirely from plexiglass. The support wall

ment. University of Houston. Houston, Texas 77004. Mr. Wei-guo Dong is a shown in the figure forms the bottom of 154 cm vertical sup-

Visiting Scientist on leave from the Thermal Power Engineering Research In- ply tube with a 15.2 cm inside diameter, which is not shown.

. Reoublic of China. Professor Lienhard is a Fellow

stitute. Xi-an.. Peo~les'

ASME.

Contributed by the Fluids Engineering Division of THEAMERICAN SOCIETY OF 'we are indebted to A. Degani who triggered this inquiry by questioning the

MECHANICAL ENGINEERS. Manuscript received by the Fluids Engineering Divi- machining argument on this basis, when it was offered in a fluid mechanics

sion, July 9, 1985. class.

Journal of Fluids Engineering SEPTEMBER 1986, Vol. 1081377

In the second experiment, the loss of liquid from the supply

/ tube was observed as a function of time during draining, and

the discharge coefficient, C,, was obtained from these data.

The supply tube was drained from an initial head, t o each of

about five lower values of head, for each mouthpiece. Each of

these 25 points was replicated about 10 times. The probable er-

ror of these measurements averaged 0.83 percent.

We made most of these measurements without letting the

water stand for hours. But when we did let it stand, C, was

the same within 0.4 percent o r less. Nevertheless, these are

time-averaged data a n d , during part of the time in all cases,

the jets exhibited imperfections. Therefore these data are less

trustworthy than the C, observations even though their

probable error is less.

The velocity coefficients, C,,= C,/C,, obtained from the

data did not deviate significantly o r consistently from unity,

which bears out the assertion that C,.= 1 , made in [2].W e

therefore take C, and C,, d a t a as being equivalent.

The ranges of Reynolds and Weber numbers in these tests

were:

23,000 < R e < 62,000 and 800 < W e < 4000

These ranges, which arose entirely from the variability of h ,

had no discernable influence o n C,, o r C,.

Corrections. T h e following corrections were applied to the

observed jet diameters:

1 ) Gravity Correction. Combining the increase of jet

velocity resulting from gravity with the continuity equation we

obtain for the jet diameter uninfluenced by gravity, D,:

D, =(1 +a/2h)"D,,,,,,,,,, (2)

where "a" is the distance from the position at which the

measurement was made to the ~ o s i t o n at which the iet

Fig. 1 Borda mouthpiece configuration used in the experiments, and a

originated, and h is the head above the mouthpiece. Jets that

typical experimental photograph did not match equation (2)within the experimental error, over

their length in the photographs, were deemed to be deformed

and were rejected.

The five Borda mouthpieces-each of a different

length - were separate inserts as shown. Each had a nominal 2) The Location of the Origin of the Jet. When a

outside diameter of 1.27 cm. Since plexiglass expands by mouthpiece of finite size is located in a gravity field, the for-

about 0.2 percent when it is wet, actual data are based o n the mation of the jet is smeared over a variable head region.

measured outside diameter of the wet mouthpieces. The lip of Where the effective origin of the jet is located is not clear;

each mouthpiece was examined under a powerful magnifying however it should lie between the lip of the mouthpiece and

glass before it was used, and found t o be free of perceptible the support wall.

defects. The gravity correction gave the most consistent results

T a p water was supplied through an overhead tray at the top among the various heads when zero head was taken t o lie one

of the supply tube. All of the jets filled the Borda tube under third of the way from the lip to the support wall. W e therefore

normal conditions. The separated jet flow pattern had to be refer the head to this point in each case. T h e variation of the

initiated by blowing compressed air into the lip region through value of C,, as the zero head point for the correction was

a small straw3. varied from the lip to the support wall, remained well within

Two kinds of experiment were made. In one, contraction the probable error.

coefficients were obtained from still photographs of the 3 ) Surface Tension. W e are indebted to T. B. Benjamin

discharging jets, by comparing the jet diameter in the picture who made the calculation in the Appendix for us. It shows

with a 1.27 cm marker (which can be seen in the photographic that the jet dilates slightly under the influence of surface ten-

portion of Fig. 1.) All photographs were made after allowing sion. The observed values of C, had to be reduced between 0.4

the water several hours of stilling to get rid of air bubbles. W e and 2 percent, on the average, on the basis of this correction.

discovered that air bubbles coming out of solution would cling

to the lip of the mouthpiece and deform the jets. Stilling the

water eliminated most of these bubbles and yielded a higher Results and Discussion

fraction of perfectly shaped jets. The fully corrected C, and C, data re plotted against L / D

About 20 photos were made for each mouthpiece. Just over in Fig. 2. (Since they are corrected for surface tension, these

half o f these had t o be rejected because of deformities in the data represent the high W e limit.) They show that C, exceeds

jet. The probable error of C, was 1.3 percent. The standard 0.5 when L / D is small, and that it falls off asymptotically

error of the repeated measurements varied slightly, since data toward 0.5 as L / D is increased. The sharp-edged orifice C,, is

were obtained at different heads in each case; but it averaged included a t L/D=O. (This is Medaugh-Johnson's [ 3 ] value of

1.2 percent which is, predictably, almost the same. 0.595 for large We and Re.)

--

A very simple analytical model serves t o illuminate this

' w e are grateful to Prof. T. B. Benjamin for drawing our attention to this behavior. We approximate the flow on the support wall by im-

technique, which is needed to operare a Borda mouthpiece. agining symmetrical sinks located at a distance, L from the

3781 Vol. 108, SEPTEMBER 1986 Transactions of the ASME

4) The sharp-edged orifice is not the appropriate limit for a

Medaugh-Johnson [3] C D for a s h a r p - very short Borda mouthpiece.

e d g e d orifice a t high R e a n d W e 5) The influence of surface tension on C,. for a Borda jet is

0.58

4 CD Cc from draining t e s t s

I

1 error b a r s -

-

References

I Encyclopaedia Brilannica, l l th ed., Encylopaedia Britannica Inc., New

York, 191 I, Article on "Hydraul~cs." pp. 38-56.

m

k

, 2 Lienhard, J. H., V and Lienhard, J . H . , (IV), "Velocity Coefficients of

Free Jets from Sharp-Edged Orifices," ASME JOURNAL

INC, V01. 106. NO. I , 1984, pp. 13-17.

OF FLUIDSENGINPER-

? - 3 Medaugh, F. W . , and Johnson, G. D., "lnvestigalion of [he Discharge

.- Coefficients o f Small Circular Orifices," Ciuil Engr., Vol. 7 , No. 7. 1940. pp.

5J -

422-4.

A P P E N D I X

Influence of Surface Tension o n C , for a Borda Mouthpiece

0.48

0

I 1

Approximate prediction,

equation ( 6 )

I

1.o

I l l 1

2.0

i A Calculation by

T . B. Benjamin, Sedleian Prof. of Natural History

Mathematical Institute

Oxford University

LID

Fig. 2 Experimental results shown the influence of the mouthpiece The Bernoulli equation between the stagnant liquid at gauge

configuration on contraction pressure, pgh, in the supply tube and the liquid in the jet, is:

pgh = p + pu2/2 ('41)

where the static gauge pressure in the jet is given by the

wall on the jet centerline- that is, where the liquid enters the Laplace relation as:

tube, and at its mirror image below. The velocity, u, parallel

with the wall is then:

C

u=- (4) Neglecting fluid motion o n the support wall as being of

(L' + r2) second order in importance, we write the following momen-

where r is the radius in the plane of the wall and C is a con- tum balance:

stant. Then the pressure gradient on the wall is:

Force o n static fluid = momentum of jet

surface force on the lip

-

s u r f a c e force o n the jet.

where C , must be pghC;D4/16 t o make the velocity consistent

with the discharge rate. or:

We obtain C, from equation (5) in the following way: W e

first integrate it t o estimate the pressure force o n a large cir-

cular segment of the support wall surrounding the hole of

diameter, D . W e then add the jet momentum force,

- T~GDU

aDa - (A3)

C,(*D/4)~(2gh), t o get the total force t o the left. This must Substituting equation (A2) in (A[), solving for pu2, and using

be balanced by the opposing pressure within the static liquid, theresult in equation (A3), we get a quadratic equation in

Solving the result for C, , we obtain: x'C, . Its positive root yields:

c,;:M-(fl -ME (6)

where M = 4([2L/DI2 + I).

Equation (6) is included in Fig. 2. It is suprisingly close to after we neglect terms of higher than first degree in (l/We).

the data, considering what a simplistic model it is. It makes it This result is accordingly limited t o W e greater than the order

very clear that fluid movement on the wall is indeed the reason of 100. It is also limited t o such We's by the fact that the cor-

that observed values of C, are above 1/2. rection is assumed small enough t o be superposed additively

It is also important to note that neither this simple theory, o n the ideal flow.

nor the data, approach the sharp-edged orifice data point at

the L = O limit. Once the tube is removed entirely, the

transverse velocity component at r = D / 2 discontinuously goes Prediction of Stack Plume Downwash

t o J 2 g h . But for any finite Borda tube, it will be less than this

value.

Conclusions Introduction

1) ~ l ~ imotion

d on the support wall influences the Downwash in the wake of smokestacks and cooling towers

magnitude of C, for a finite Borda mouthpiece. has been a subject of investigation for more than 50 years [ I ] .

2) C, for a ~~~d~ mouthpiece approaches asymp- The phenomenon occurs when the emerging positively

totically as the length of the mouthpiece is increased. For

a very short Borda mouthpiece' Cc is a little above 0.54' Engtneering Analysis, Inc., Hun~sville,Ala. 35801

Contributed by the Flulds Engineering Divirion o f . T ~ AMERICAN

c SOCIFTY OF

3, The coefficient is a BOrda MECHANICAL ENGINEERS. Mauscript received by the Fluidr Engineering Division

mouthpiece, just as it is for a sharp-edged orifice. A U ~ U S15,

~ 1985.

Journal of Fluids Engineering SEPTEMBER 1986, Vol. 108 1379

Das könnte Ihnen auch gefallen

- CB 8512 Hydronic Solutions BrochureDokument8 SeitenCB 8512 Hydronic Solutions BrochureAndresCanoNoch keine Bewertungen

- Lección 123456789 PDFDokument4 SeitenLección 123456789 PDFAndresCanoNoch keine Bewertungen

- Catálogo Boiler Book CBEX Elite 100-800Dokument20 SeitenCatálogo Boiler Book CBEX Elite 100-800AndresCanoNoch keine Bewertungen

- Module 1: Quantum Mechanics Chapter 1: Prelude To Quantum TheoryDokument4 SeitenModule 1: Quantum Mechanics Chapter 1: Prelude To Quantum TheoryAndresCanoNoch keine Bewertungen

- Lec2 PDFDokument24 SeitenLec2 PDFAndresCanoNoch keine Bewertungen

- Lec1 PDFDokument30 SeitenLec1 PDFAndresCanoNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- COBIT Checklist and ReviewDokument20 SeitenCOBIT Checklist and ReviewMike0% (1)

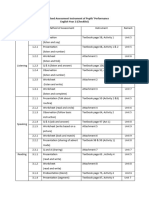

- Penyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Dokument2 SeitenPenyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Hui YingNoch keine Bewertungen

- Wisdom Blog - Sri Sri Ravi Shankar Art of LivingDokument3 SeitenWisdom Blog - Sri Sri Ravi Shankar Art of LivingShrikrishna PotdarNoch keine Bewertungen

- Senior Instrument Engineer Resume - AhammadDokument5 SeitenSenior Instrument Engineer Resume - AhammadSayed Ahammad100% (1)

- Penguatan Industri Kreatif Batik Semarang Di Kampung Alam Malon Kecamatan Gunung Pati SemarangDokument10 SeitenPenguatan Industri Kreatif Batik Semarang Di Kampung Alam Malon Kecamatan Gunung Pati SemarangAllo YeNoch keine Bewertungen

- Oracle OTL Timecard Layout CustomicationDokument138 SeitenOracle OTL Timecard Layout CustomicationFoolIshNoch keine Bewertungen

- Appendix F FormatDokument4 SeitenAppendix F FormatGeNoch keine Bewertungen

- What Is Engineering SurveyingDokument5 SeitenWhat Is Engineering SurveyingHui EdroxNoch keine Bewertungen

- Ca1 Pu 12Dokument100 SeitenCa1 Pu 12Shabbeer ZafarNoch keine Bewertungen

- Port of Spain Case StudyDokument18 SeitenPort of Spain Case StudyThe Cropper Foundation83% (6)

- Cooling TowerDokument63 SeitenCooling TowerApsara Katugaha100% (1)

- The Alchemist - Book ReviewDokument10 SeitenThe Alchemist - Book ReviewNETFLIX ORIGINALSNoch keine Bewertungen

- Aniket CV NewDokument2 SeitenAniket CV NewRajreddy ChamawarNoch keine Bewertungen

- Wcee2012 4133Dokument10 SeitenWcee2012 4133toyi kamiNoch keine Bewertungen

- Humanities Social Sciences DistinctionsDokument3 SeitenHumanities Social Sciences DistinctionsDavid0% (1)

- Unit 29 Sentence Structure in EnglishDokument11 SeitenUnit 29 Sentence Structure in Englishj pcNoch keine Bewertungen

- Master of Business Administration - MBA Semester 3 ProjectDokument2 SeitenMaster of Business Administration - MBA Semester 3 ProjectAnkur SharmaNoch keine Bewertungen

- NadiAstrologyAndTransitspart 2Dokument7 SeitenNadiAstrologyAndTransitspart 2Jhon Jairo Mosquera RodasNoch keine Bewertungen

- South Coast LIDAR Project, 2008 - Delivery 1 QC AnalysisDokument15 SeitenSouth Coast LIDAR Project, 2008 - Delivery 1 QC AnalysisariesugmNoch keine Bewertungen

- Statistics in Experimental Research: Mark Anthony F. Casimiro Marikina Science High School-JHSDokument32 SeitenStatistics in Experimental Research: Mark Anthony F. Casimiro Marikina Science High School-JHSJeanne Emerose TalabuconNoch keine Bewertungen

- Karatina University: University Examinations 2018/2019 ACADEMIC YEARDokument5 SeitenKaratina University: University Examinations 2018/2019 ACADEMIC YEARtimNoch keine Bewertungen

- Riya Mary Cherian: Specialization: Human ResourceDokument4 SeitenRiya Mary Cherian: Specialization: Human ResourceNikhil KhobragadeNoch keine Bewertungen

- Preparation of Instructional MaterialsDokument28 SeitenPreparation of Instructional MaterialsMara Quila-Verzo86% (7)

- Samcef RotorDokument4 SeitenSamcef RotorChihiya Fitria NurhayatiNoch keine Bewertungen

- Safe City in Malaysia's ContextDokument8 SeitenSafe City in Malaysia's Contextuyunaman100% (1)

- Ethnic Groups and RacismDokument21 SeitenEthnic Groups and RacismNichaella BiscochoNoch keine Bewertungen

- Educational Planning (Felipe)Dokument102 SeitenEducational Planning (Felipe)Felipe Beranio Sullera Jr.100% (4)

- Jean Piaget ProjectDokument13 SeitenJean Piaget ProjectRoland Aparece100% (1)

- Lesson 2: IGSS System Overview: Interactive Graphical SCADA SystemDokument7 SeitenLesson 2: IGSS System Overview: Interactive Graphical SCADA SystemRoberto CarrascoNoch keine Bewertungen

- Grade 8 Science Unit 1 Force, Motion and EnergyDokument68 SeitenGrade 8 Science Unit 1 Force, Motion and EnergyKeil Morada73% (26)