Beruflich Dokumente

Kultur Dokumente

Aftercoolers PDF

Hochgeladen von

Jose Castañeda SurcoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aftercoolers PDF

Hochgeladen von

Jose Castañeda SurcoCopyright:

Verfügbare Formate

A range of effective after-coolers

and water separators to match your compressor

4 4 Water-cooled HD after-coolers

Atlas Copco offers a range of after-coolers Atlas Copco HD water-cooled after-coolers are designed to

and water separators, which combines minimal air combine a high level of cooling with economic water consumption.

pressure drop with high cooling efficiency and The air leaving the compressor is cooled in a bundle of stainless

low energy consumption. steel tubes, with the cooling water and the compressed air flowing in

opposite directions. A water separator is provided with the cooler

After-coolers are supplied complete with all as standard.

necessary parts. They are compact, simple

to install and easy to dismantle for cleaning. The cooling tubes are reeled inside to

The negligible pressure drop effected by the create turbulence for more rapid cooling

after-coolers means virtually no loss of power of the compressed air. To increase the cooling

to compressed air-driven tools, machines and effect, the water is deflected by baffles.

pneumatic devices. Thus no extra demand is

placed on the compressor and no additional energy

or maintenance costs are incurred.

In addition, the Atlas Copco solution provides a

number of important advantages:

4 special, highly efficient separation by cyclone

4 minimum maintenance

4 totally rustproof material

4 the assembly of the connection flanges is easy

4 Air-cooled TD after-coolers

Atlas Copco after-coolers, whether cooled

by air or water, are reliable, require minimum

maintenance and provide trouble-free Atlas Copco TD air-cooled after-coolers have an aluminium

protection against the costly effects of water block cooling element. An electrically driven fan, shielded by

in your system. Both types of after-cooler a protector for user safety, forces cooling air between the fins.

deliver air into the air-net at a temperature High cooling efficiency is combined with low energy consumption.

suitable for most types of air dryers.

The after-cooler is mounted on a sturdy frame. A water separator

is delivered as standard with the TD25-650 coolers. The TD 08,

is delivered with wall mounting brackets and incorporates

a drain collector with manual drain.

Aftercoolers brochure_20110816.indd 1 16/08/11 17:09

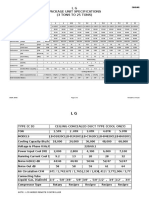

Technical data after-coolers

4 HD water-cooled after-cooler

Maximum working t above

Nominal flow * pressure cooling water * Water consumption

Type

l/s cfm bar(e) psi C F l/s m3/h USgal/min

HD 4 67 142 20 290 7 13 0.17 0.61 2.7

HD 8 133 282 20 290 7 13 0.34 1.22 5.4

HD 11 183 388 20 290 6 11 0.46 1.66 7.3

HD 16 267 566 10.5 152 8 14 0.67 2.41 10.6

HD 32 533 1129 10.5 152 8 14 1.33 4.79 21.1

HD 48 800 1694 10.5 152 8 14 2.00 7.20 31.7

HD 67 1067 2260 10.5 152 8 14 2.67 9.61 42.3

HD 96 1600 3389 10.5 152 8 14 4.00 14.40 63.4

* HD water-cooled after-cooler

Cooling

Air inlet / outlet Dimensions water

Weight N of

Type connections cooler

Height Width Length inlet cores

inlet outlet mm inch mm inch mm inch kg lbs outlet

HD 4 G 1 G 1 1840 72.4 170 5.1 344 13.5 37 121 G 1

HD 8 G 2 G 2 1973 77.7 215 6.3 474 18.7 78 172 G 1

HD 11 G 2 G 2 1975 77.8 230 9.1 483 19.0 85 187 G 1

HD 16 DN 100 DN 80 2083 82.0 500 19.7 645 25.4 180 396 G 1

HD 32 DN 100 DN 80 2083 82.0 500 19.7 635 25.0 210 463 G 1 1

HD 48 DN 150 DN 80 2112 83.2 490 19.3 1032 40.6 380 838 G 1 2

HD 67 DN 150 DN 80 2112 83.2 490 19.3 1032 40.6 410 904 G 1 2

HD 96 DN 175 DN 80 2139 83.2 490 19.3 1412 55.6 610 1345 G 1 3

4 TD air-cooled after-cooler

Maximum working t above *

Nominal flow * Fan motor power

Type pressure ambient temperature

l/s cfm bar(e) psi C F kW hp

TD 08 8 17 20 290 10 18 0.05 0.07

TD 25 25 53 20 290 10 18 0.12 0.16

TD 50 50 106 20 290 10 18 0.18 0.24

TD 150 150 318 20 290 10 18 0.75 1.01

TD 300 300 363 20 290 10 18 0.75 1.01

TD 650 650 1377 20 290 10 18 2.20 2.95

TD 650 650 1377 10.5 152 10 18 2.20 2.95

* Referred to absolute pressure of 1 bar and temperature of 20 C. Compressed air in at 160 C.

Air inlet / outlet Dimensions

Weight N of

Type connections cooler

Height Width Length

cores

inlet outlet mm inch mm inch mm inch kg lbs

TD 08 G G 188 7.4 130 5.1 270 10.6 6 13 1

TD 25 G1 G1 658 25.9 402 15.8 588 23.1 19 42 1

TD 50 G 1 G 1 735 28.9 412 16.2 664 26.1 23 51 1

TD 150 G 2 G 2 1160 45.6 435 17.1 920 36.2 53 117 1

TD 300 G 2 G 2 1280 50.3 466 18.3 1140 44.8 73 161 1

TD 650 DN 80 DN 100 1525 60.0 716 28.1 1780 70.0 185 408 1

Aftercoolers brochure_20110816.indd 4 16/08/11 17:10

Das könnte Ihnen auch gefallen

- YORK PackageDokument28 SeitenYORK PackageSreekumarNoch keine Bewertungen

- BOSS™ Pressurisation Units and Expansion Vessels PDFDokument16 SeitenBOSS™ Pressurisation Units and Expansion Vessels PDFRIFASNoch keine Bewertungen

- Functional Safety Switch Amplifier KFD2-SR2-Ex .W (.LB) : ManualDokument24 SeitenFunctional Safety Switch Amplifier KFD2-SR2-Ex .W (.LB) : ManualPaul Ramos CarcaustoNoch keine Bewertungen

- Design Properties and Calculations for FRP Lining PanelsDokument5 SeitenDesign Properties and Calculations for FRP Lining PanelsSubin AnandanNoch keine Bewertungen

- Technical data sheet for 200x150 CNHA 5 45 pumpDokument5 SeitenTechnical data sheet for 200x150 CNHA 5 45 pumpسمير البسيونىNoch keine Bewertungen

- Application Guide Sludge Mixers en Rev 1Dokument8 SeitenApplication Guide Sludge Mixers en Rev 1gazwang478Noch keine Bewertungen

- Quality NBR Insulation Thickness Guide for Condensation ControlDokument8 SeitenQuality NBR Insulation Thickness Guide for Condensation ControlSam Wing HongNoch keine Bewertungen

- Aqua FluxDokument8 SeitenAqua FluxavikbhaiNoch keine Bewertungen

- (SR5-13) Tee, 45 Degree Entry Branch, Diverging (Brooks 1993)Dokument1 Seite(SR5-13) Tee, 45 Degree Entry Branch, Diverging (Brooks 1993)manoNoch keine Bewertungen

- FT 10 Indicator Manual enDokument100 SeitenFT 10 Indicator Manual enM Syahrul Gunawan100% (1)

- TS-01 Air - Washer UnitsDokument27 SeitenTS-01 Air - Washer UnitsPraveen KumarNoch keine Bewertungen

- Refrigerant Dryer CatalogDokument4 SeitenRefrigerant Dryer CatalogManny MendozaNoch keine Bewertungen

- Pressure Relief Valve Data Sheet-Rev01Dokument1 SeitePressure Relief Valve Data Sheet-Rev01thawdarNoch keine Bewertungen

- F 1090 - 87 R97 - Rjewota - PDFDokument4 SeitenF 1090 - 87 R97 - Rjewota - PDFFreddy AlmeidaNoch keine Bewertungen

- TERZ 94OMManualRev0107 PDFDokument66 SeitenTERZ 94OMManualRev0107 PDFRoberto Andres Vasquez Campusano75% (4)

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationDokument3 SeitenGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarNoch keine Bewertungen

- Non Circular Pipe FrictionDokument3 SeitenNon Circular Pipe Frictionravi_radanNoch keine Bewertungen

- BETE 110metric Catalog PDFDokument128 SeitenBETE 110metric Catalog PDFSung Woong MoonNoch keine Bewertungen

- Beko Drypoint Ra123 - ManualDokument36 SeitenBeko Drypoint Ra123 - Manualfgomes100Noch keine Bewertungen

- Programmable 15A Automatic Voltage RegulatorDokument2 SeitenProgrammable 15A Automatic Voltage RegulatorduaNoch keine Bewertungen

- General-Service Packaged Air Compressors and ReceiversDokument11 SeitenGeneral-Service Packaged Air Compressors and ReceiversElie HajjNoch keine Bewertungen

- Easyheat s27 - 02 SarcoDokument8 SeitenEasyheat s27 - 02 SarcoMarcelo ResckNoch keine Bewertungen

- Eil Spec For Architechture-6-75-0051 - Rev 0Dokument14 SeitenEil Spec For Architechture-6-75-0051 - Rev 0innovativekarthiNoch keine Bewertungen

- Oil Free Scroll Compressors 2 30 KW Brochure NADokument8 SeitenOil Free Scroll Compressors 2 30 KW Brochure NAKervin CoronadoNoch keine Bewertungen

- DV DVW Series - Catalog - For 2015Dokument39 SeitenDV DVW Series - Catalog - For 2015adeel_akhtarNoch keine Bewertungen

- Pressure Volume Calculator 02Dokument6 SeitenPressure Volume Calculator 02Jenny Cecilia Ureña ZuriNoch keine Bewertungen

- Forbes Marshall Consultancy specifications for compressed air accessoriesDokument2 SeitenForbes Marshall Consultancy specifications for compressed air accessoriessppatilNoch keine Bewertungen

- H23A383DBEADokument1 SeiteH23A383DBEABruno MonteiroNoch keine Bewertungen

- 2749 - Carrier 30 GH 095Dokument16 Seiten2749 - Carrier 30 GH 095Mohammad Amer100% (2)

- Clarke 100e Mig WelderDokument18 SeitenClarke 100e Mig WelderplainmanNoch keine Bewertungen

- Capillary Tube Inst-Tubing PDFDokument4 SeitenCapillary Tube Inst-Tubing PDFEduardoNoch keine Bewertungen

- 57-606.9 Eclipse Model 706 Hart Io 1 PDFDokument108 Seiten57-606.9 Eclipse Model 706 Hart Io 1 PDFAbdul Shaharlal ENoch keine Bewertungen

- General Specification For Air-Conditioning, Refrigeration, Ventilation and Central Monitoring & Control SystemDokument3 SeitenGeneral Specification For Air-Conditioning, Refrigeration, Ventilation and Central Monitoring & Control SystemjackwpsoNoch keine Bewertungen

- N2 Generator CalculationDokument9 SeitenN2 Generator CalculationBagus PrambudiNoch keine Bewertungen

- Manufacturer's Warranty and Limitation of ClaimsDokument2 SeitenManufacturer's Warranty and Limitation of ClaimsBrandon TrocNoch keine Bewertungen

- Brentwood CT HTP25 Ex Spec 2014 enDokument1 SeiteBrentwood CT HTP25 Ex Spec 2014 enTubagus Dimas AditiarachmanNoch keine Bewertungen

- 01-01-1865-D ELDS Technical Manual Iss13Dokument221 Seiten01-01-1865-D ELDS Technical Manual Iss13Alberyt099Noch keine Bewertungen

- LMF-GP LX15-8 - 10 - 13Dokument2 SeitenLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- 7MF0300 Highlighted PDFDokument81 Seiten7MF0300 Highlighted PDFmajmor-1Noch keine Bewertungen

- Residential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationDokument7 SeitenResidential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationPedro JonesNoch keine Bewertungen

- HDPE Manual: LamasatDokument51 SeitenHDPE Manual: LamasatMalay Kar0% (1)

- Pressure Vacuum Relief Valve Flame Arrester 102Dokument3 SeitenPressure Vacuum Relief Valve Flame Arrester 102vikramNoch keine Bewertungen

- Dresser 3 Way ValveDokument24 SeitenDresser 3 Way ValveAmjath Pallas100% (1)

- Self-priming side channel pump PN 40 technical descriptionDokument8 SeitenSelf-priming side channel pump PN 40 technical descriptionsdafas dfNoch keine Bewertungen

- Boge Cyclone Separator Z 20N To Z 375Dokument2 SeitenBoge Cyclone Separator Z 20N To Z 375Air Repair, LLCNoch keine Bewertungen

- PARTS LITS Air Cooled Packaged Water ChillersDokument11 SeitenPARTS LITS Air Cooled Packaged Water ChillersOng MatNoch keine Bewertungen

- Data Teknis WILO 100lps @40mDokument4 SeitenData Teknis WILO 100lps @40mAnonymous dr93RjfPEY100% (1)

- KITZ ProductDokument44 SeitenKITZ Productkingathur26681Noch keine Bewertungen

- Fire Pump InstallationDokument4 SeitenFire Pump InstallationFrancis Owusu100% (1)

- LV Fuse Holders BS Type SelectionDokument2 SeitenLV Fuse Holders BS Type Selectionavishai04Noch keine Bewertungen

- LG Package Unit Specifications GuideDokument5 SeitenLG Package Unit Specifications GuideShaikhMazharAhmed100% (1)

- Parker Substrate 4250-InTRAFLOW Dec 2003Dokument12 SeitenParker Substrate 4250-InTRAFLOW Dec 2003Laurence MalanumNoch keine Bewertungen

- Wilo Pump Catloug 24-4-017 (Wilo Booster PumpsDokument20 SeitenWilo Pump Catloug 24-4-017 (Wilo Booster Pumpsglobalpumps0% (1)

- Snowkey Quotation F50A SN20191209 PE 01Dokument3 SeitenSnowkey Quotation F50A SN20191209 PE 01hugo renzo chavez bernuyNoch keine Bewertungen

- Airwasher PDFDokument12 SeitenAirwasher PDFGanesh HotkarNoch keine Bewertungen

- PE PipeDokument54 SeitenPE PipeMuhammad SalmanNoch keine Bewertungen

- Solar Optical Materials: Applications & Performance of Coatings & Materials in Buildings & Solar Energy SystemsVon EverandSolar Optical Materials: Applications & Performance of Coatings & Materials in Buildings & Solar Energy SystemsM. G. HutchinsNoch keine Bewertungen

- Atlas Copco after-coolers and water separators keep compressed air dryDokument6 SeitenAtlas Copco after-coolers and water separators keep compressed air dryAdalberto CastroNoch keine Bewertungen

- CondensateManangement Antwerp Leaflet EN 2935083846Dokument12 SeitenCondensateManangement Antwerp Leaflet EN 2935083846Max LimNoch keine Bewertungen

- Shear Angle Calculation Based On Chip Thickness Ratio:: T R T T AB T AB T AB R T AB R RDokument3 SeitenShear Angle Calculation Based On Chip Thickness Ratio:: T R T T AB T AB T AB R T AB R RJohn TLNoch keine Bewertungen

- Possible Outcomes in The Short TermDokument1 SeitePossible Outcomes in The Short TermJohn TLNoch keine Bewertungen

- Problem 1 Part D Code:: For ForDokument2 SeitenProblem 1 Part D Code:: For ForJohn TLNoch keine Bewertungen

- Tpo Toefl ExampleDokument11 SeitenTpo Toefl ExampleJohn TLNoch keine Bewertungen

- Prove PDFDokument1 SeiteProve PDFJohn TLNoch keine Bewertungen

- Homework Module1Dokument1 SeiteHomework Module1John TLNoch keine Bewertungen

- Disuccion 2 GGDokument3 SeitenDisuccion 2 GGJohn TLNoch keine Bewertungen

- Writing Toefl ExampleDokument1 SeiteWriting Toefl ExampleJohn TLNoch keine Bewertungen

- Disuccion2gg PDFDokument2 SeitenDisuccion2gg PDFJohn TLNoch keine Bewertungen

- Toefl Tpo 3 WritingDokument2 SeitenToefl Tpo 3 WritingJohn TLNoch keine Bewertungen

- 2019 GKS-G Application Guidelines (English)Dokument45 Seiten2019 GKS-G Application Guidelines (English)Noelia Sandoval Zambrano100% (2)

- Ggplot2 CheatsheetDokument2 SeitenGgplot2 Cheatsheetwroin1Noch keine Bewertungen

- General Informaion Box PackingsDokument8 SeitenGeneral Informaion Box PackingsJohn TLNoch keine Bewertungen

- EquipmentDokument1 SeiteEquipmentJohn TLNoch keine Bewertungen

- Sir Iber Per 2015 HeDokument7 SeitenSir Iber Per 2015 HeJohn TLNoch keine Bewertungen

- Pratt Fixedconevalve f13265 v5Dokument8 SeitenPratt Fixedconevalve f13265 v5John TLNoch keine Bewertungen

- 7300 enDokument76 Seiten7300 enJohn TLNoch keine Bewertungen

- EquipmentDokument1 SeiteEquipmentJohn TLNoch keine Bewertungen

- Howell and Bunger's 1934 patented valve designDokument6 SeitenHowell and Bunger's 1934 patented valve designJohn TLNoch keine Bewertungen

- Especificaciones Tecnicas de Una RepresaDokument14 SeitenEspecificaciones Tecnicas de Una RepresaJohn TLNoch keine Bewertungen

- MN3060 Dogde 7 Pulg y 12 PulgDokument12 SeitenMN3060 Dogde 7 Pulg y 12 PulgJohn TL100% (1)

- Writing Samples Oa Ac1-3 - Ac1-8Dokument13 SeitenWriting Samples Oa Ac1-3 - Ac1-8mariuxi_bruzza2513Noch keine Bewertungen

- Weight Fixed Cone ValveDokument9 SeitenWeight Fixed Cone ValveJohn TLNoch keine Bewertungen

- APA DOC No. 3050Dokument17 SeitenAPA DOC No. 3050John TLNoch keine Bewertungen

- W1J1 e 00 PDFDokument578 SeitenW1J1 e 00 PDFcherif67% (3)

- Generac Power SystemsDokument68 SeitenGenerac Power Systemsprinter6Noch keine Bewertungen

- Anti Surge ControlDokument33 SeitenAnti Surge Controlgopinath87100% (1)

- Gas TurbineDokument24 SeitenGas Turbineluvonosoji100% (2)

- KKS ProcedureDokument33 SeitenKKS Procedurepmvelilla100% (1)

- 5 Gas Exchange Processes - UpdatedDokument24 Seiten5 Gas Exchange Processes - UpdatedShahzaib Anwar OffNoch keine Bewertungen

- Mepc.365 (79) 2022Dokument24 SeitenMepc.365 (79) 2022yucai.chenNoch keine Bewertungen

- Kitchen Improvised FertilizerDokument68 SeitenKitchen Improvised Fertilizerjohn smith100% (1)

- Mathematical Model of SOFC (Solid Oxide Fuel Cell) For Power Plant SimulationsDokument7 SeitenMathematical Model of SOFC (Solid Oxide Fuel Cell) For Power Plant SimulationsErwin Zavalla OchoaNoch keine Bewertungen

- Enerator: Alternators (As They Are Usually Called)Dokument15 SeitenEnerator: Alternators (As They Are Usually Called)raviNoch keine Bewertungen

- M.T. Energy R: Type: Delivered: Class: TonnageDokument2 SeitenM.T. Energy R: Type: Delivered: Class: TonnageHergheligiu VasileNoch keine Bewertungen

- Disco 3 WiringDokument241 SeitenDisco 3 WiringRichard Andrianjaka Lucky100% (5)

- Service Manual: Group IndexDokument522 SeitenService Manual: Group Indexpepecalienes2052Noch keine Bewertungen

- 3ZB-20 10.5 SpecificationDokument5 Seiten3ZB-20 10.5 Specificationsigma Petroleum services CoNoch keine Bewertungen

- Bilge Ballast and SystemsDokument72 SeitenBilge Ballast and SystemsRENGANATHAN P100% (7)

- Exhaust GasDokument6 SeitenExhaust Gaschinnasamy76Noch keine Bewertungen

- Craftsman Mower ManualDokument31 SeitenCraftsman Mower ManualDayton Mickens100% (1)

- MD6420 - Procedimiento de Cambio de Compresor - Manual de Servicio (EM005781)Dokument16 SeitenMD6420 - Procedimiento de Cambio de Compresor - Manual de Servicio (EM005781)Victor ArceNoch keine Bewertungen

- Reciprocating Internal Combustion Engines: Prof. Rolf D. Reitz Engine Research Center University of Wisconsin-MadisonDokument40 SeitenReciprocating Internal Combustion Engines: Prof. Rolf D. Reitz Engine Research Center University of Wisconsin-MadisonmoaedNoch keine Bewertungen

- Service Parts List: Diesel EngineDokument44 SeitenService Parts List: Diesel Enginepedro perezNoch keine Bewertungen

- 160W Workshop Manuel PDFDokument715 Seiten160W Workshop Manuel PDFSahba Kiyanoush100% (1)

- 2900 EbzDokument2 Seiten2900 EbzRalf MaurerNoch keine Bewertungen

- Belt Technical DataDokument40 SeitenBelt Technical Dataอาทิตย์ เพ็ชรคงNoch keine Bewertungen

- DYG ChinaDokument8 SeitenDYG ChinaNurfandy DewantoNoch keine Bewertungen

- E55 6990093 enUS SM 11-16 - DecryptedDokument6 SeitenE55 6990093 enUS SM 11-16 - DecryptedNacer Nacer0% (1)

- Ge Small Scale Liquefied Natural Gas Plants GuideDokument8 SeitenGe Small Scale Liquefied Natural Gas Plants GuideMuhamad Apriyudi Syafputra100% (1)

- Series Parts CatalogDokument24 SeitenSeries Parts Catalogcochran04Noch keine Bewertungen

- Presentation On CFBC Technology by Cethar Vessels (P) LTDDokument21 SeitenPresentation On CFBC Technology by Cethar Vessels (P) LTDRavi Chandar100% (3)

- Mitsubishi GB180LE 215Dokument34 SeitenMitsubishi GB180LE 215Yew LimNoch keine Bewertungen

- Coal Analysis LabDokument35 SeitenCoal Analysis LabAhsan Habib0% (1)