Beruflich Dokumente

Kultur Dokumente

P-750 Control of Production and Service ProvisionNEW

Hochgeladen von

nice guyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

P-750 Control of Production and Service ProvisionNEW

Hochgeladen von

nice guyCopyright:

Verfügbare Formate

London Electronics Limited

MP-750

Control of Production and Service Provision

1.0 Purpose

1.1 This procedure describes the process used to provide controlled conditions

under which the key product realisation processes are performed.

2.0 Responsibilities

2.1 Trained personnel throughout the facility perform this procedure.

3.0 Definitions

3.1 Key product realisation processes: the processes that contribute or result in the

product being produced or the product being provided.

4.0 Equipment/Software

4.1 No additional equipment or software required.

5.0 Instructions

5.1 Product realisation processes are controlled and managed to achieve product

conformance and continual improvement.

5.2 Product realisation processes are planned or designed according to planning of

Product Realisation Processes, MP-824 or Design and Development, EP-730.

The design output or the planning form identifies the required controls for the

process.

5.3 Criteria for workmanship, expressed as product specifications or characteristics

are documented in the quality plan or specification sheet for the product.

5.4 Quality control measures that specify appropriate monitoring and control

guidelines and inspection and test requirements are documented in procedures

or work instructions.

5.4.1 The Measuring and Monitoring procedure identifies test points, process

monitoring requirements, tests performed, responsible person, and action

criteria.

5.5 Management approves all processes and equipment by approving all process

and equipment quality plans, procedures, or work instructions.

5.6 The written work instructions are presented in a clear and practical manner.

5.6.1 Illustrations, flowcharts, tables or other presentation tools are used, as

appropriate, to provide clear instructions.

5.7 All processes are performed using employees qualified according to the

Competence, Awareness and Training procedure.

5.8 Processes where resulting output cannot be verified by subsequent monitoring or

measurement are validated to demonstrate the ability of the process to achieve

Control of Production and Service Provision ISSUE A ISO9001: 2008

London Electronics Limited

MP-750

Control of Production and Service Provision

planned results.

5.9 The need for validation is identified during the Planning of Product Realisation

Processes. If the planning identifies the need for validation, responsibility is

assigned to a qualified employee, and performed according to the Process

Validation work instruction.

5.10 Product release criteria and/or product release authority are documented on the

new product inputs form F-FOP-001

5.11 Trained delivery personnel, following written work instructions and documented

customer delivery requirements, provide all delivery services provided by our

Company.

5.12 Post delivery activities include installation, activities relating to service contracts,

and warranty repairs. Post delivery activities are performed following

documented work instruction, prints or contracts.

6.0 Forms and Records

6.1 Relevant forms associated to the Processes found on the server in the Quality

Systems Forms folder.

7.0 Attachments

7.1 None

8.0 Related Documents

8.1 Product Realisation Procedures and Work Instructions

8.2 AP-622 Competence, Awareness and Training Procedure

8.3 Process Validation Work Instructions if needed

8.4 MP-824 Monitoring, Measuring and Analysis of Product and Realisation

Processes

8.5 MP-753 Identification and Traceability

8.6 SSD Static Sensitive Devices Procedure

8.7 Production Processes for Assembly, Inspection, Fabrication, Test, Configuration

and Repairs, Final Inspection and Dispatch.

9.0 References

9.1 None

Control of Production and Service Provision ISSUE A ISO9001: 2008

London Electronics Limited

MP-750

Control of Production and Service Provision

10.0 Revisions

REV. SECTION SUB-SEC. PARA. CHANGE REQUEST # DATE AUTHORISED BY

Control of Production and Service Provision ISSUE A ISO9001: 2008

Das könnte Ihnen auch gefallen

- KI Quality Manual Rev. D 12-28-2012Dokument35 SeitenKI Quality Manual Rev. D 12-28-2012kzl009Noch keine Bewertungen

- 1.validation of Processes For Production Service Provision ProcedureDokument4 Seiten1.validation of Processes For Production Service Provision ProcedureLora Jackson100% (1)

- ISO 9001-2015 Supplier Audit Checklist SAMPLEDokument2 SeitenISO 9001-2015 Supplier Audit Checklist SAMPLEFaisal0% (1)

- ISO 13485 Quality Management System A Complete Guide - 2021 EditionVon EverandISO 13485 Quality Management System A Complete Guide - 2021 EditionNoch keine Bewertungen

- AS9100 Rev D Procedure SampleDokument2 SeitenAS9100 Rev D Procedure SampleGiridhar PutchaNoch keine Bewertungen

- Quality Assurance Process A Complete Guide - 2020 EditionVon EverandQuality Assurance Process A Complete Guide - 2020 EditionNoch keine Bewertungen

- How to Establish a Document Control System for Compliance with ISO 9001:2015, ISO 13485:2016, and FDA Requirements: A Comprehensive Guide to Designing a Process-Based Document Control SystemVon EverandHow to Establish a Document Control System for Compliance with ISO 9001:2015, ISO 13485:2016, and FDA Requirements: A Comprehensive Guide to Designing a Process-Based Document Control SystemNoch keine Bewertungen

- Interface control document The Ultimate Step-By-Step GuideVon EverandInterface control document The Ultimate Step-By-Step GuideNoch keine Bewertungen

- Internal Quality Audit: Ogive Technology LLP Quality System ProcedureDokument2 SeitenInternal Quality Audit: Ogive Technology LLP Quality System Proceduretrivesh100% (1)

- Procedure For Design andDokument4 SeitenProcedure For Design andSharif KhanNoch keine Bewertungen

- Applying AS9100 Rev D: The Hassle-Free Approach to Implementing an Aerospace QMS for Small BusinessesVon EverandApplying AS9100 Rev D: The Hassle-Free Approach to Implementing an Aerospace QMS for Small BusinessesBewertung: 4 von 5 Sternen4/5 (2)

- Software Verification And Validation A Complete Guide - 2020 EditionVon EverandSoftware Verification And Validation A Complete Guide - 2020 EditionNoch keine Bewertungen

- Software Validation A Complete Guide - 2020 EditionVon EverandSoftware Validation A Complete Guide - 2020 EditionNoch keine Bewertungen

- Iso 9001 - 2015 Quality Manual - Trace InternationalDokument37 SeitenIso 9001 - 2015 Quality Manual - Trace Internationalchaminda nayanajithNoch keine Bewertungen

- Compare ISO 9001 AS9110 RevBDokument1 SeiteCompare ISO 9001 AS9110 RevBislam_shafik8820Noch keine Bewertungen

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Dokument35 Seiten4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNoch keine Bewertungen

- QSD111.07 Control of Nonconforming Material Policy - Rev112Dokument6 SeitenQSD111.07 Control of Nonconforming Material Policy - Rev112CTTONoch keine Bewertungen

- Star Ecn Form 2012Dokument4 SeitenStar Ecn Form 2012BERK YENİLMEZNoch keine Bewertungen

- P 400 Organizational ContextDokument4 SeitenP 400 Organizational ContextTamara Johnson-Pariag100% (1)

- Employee Training LogDokument1 SeiteEmployee Training Logjt2328Noch keine Bewertungen

- Audit Checklist 1Dokument2 SeitenAudit Checklist 1Jagi NikNoch keine Bewertungen

- Q2-760-01-Control of Monitoring and Measuring DevicesDokument5 SeitenQ2-760-01-Control of Monitoring and Measuring DevicesAlineNoch keine Bewertungen

- M09 Production and Service ProvisionDokument4 SeitenM09 Production and Service ProvisionMay Ann DuronNoch keine Bewertungen

- Safe System Of Work A Complete Guide - 2020 EditionVon EverandSafe System Of Work A Complete Guide - 2020 EditionNoch keine Bewertungen

- CalibrationDokument6 SeitenCalibrationMadhavan RamNoch keine Bewertungen

- As 9100 9110 QMDokument27 SeitenAs 9100 9110 QMAMINE ABASSINoch keine Bewertungen

- The AS9100C, AS9110, and AS9120 Handbook: Understanding Aviation, Space, and Defense Best PracticesVon EverandThe AS9100C, AS9110, and AS9120 Handbook: Understanding Aviation, Space, and Defense Best PracticesNoch keine Bewertungen

- SOP-03 (Employee Performance Monitoring)Dokument6 SeitenSOP-03 (Employee Performance Monitoring)FarhanNoch keine Bewertungen

- Advanced Quality ManualDokument17 SeitenAdvanced Quality ManualalexrferreiraNoch keine Bewertungen

- Qms MRM Input 2015Dokument1 SeiteQms MRM Input 2015venkatesanNoch keine Bewertungen

- QP11-100 E - Calibration - Control of Monitoring and Measuring Equipment PDFDokument12 SeitenQP11-100 E - Calibration - Control of Monitoring and Measuring Equipment PDFgranburyjohnstevensNoch keine Bewertungen

- AS9100D Internal Audit ToolDokument35 SeitenAS9100D Internal Audit ToolazzaNoch keine Bewertungen

- As9100d Inernal Audit ChecklistDokument90 SeitenAs9100d Inernal Audit ChecklistPANDIYANNoch keine Bewertungen

- Advanced Quality ManualDokument36 SeitenAdvanced Quality ManualYemi Victor AttehNoch keine Bewertungen

- MCI 01 Management ReviewDokument3 SeitenMCI 01 Management ReviewalexrferreiraNoch keine Bewertungen

- Form - Supplier Quality Survey - Rev 0Dokument3 SeitenForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonNoch keine Bewertungen

- Process Name: Process Owner: Instructions: Date: Risk Identification Risk Analysis Risk# Description Likelihood Impact Risk LevelDokument15 SeitenProcess Name: Process Owner: Instructions: Date: Risk Identification Risk Analysis Risk# Description Likelihood Impact Risk LevelJustformedia JustformediaNoch keine Bewertungen

- QMS 3Dokument11 SeitenQMS 3Ram MohanNoch keine Bewertungen

- Product Realization (Quality Control)Dokument16 SeitenProduct Realization (Quality Control)Khaled AbdelbakiNoch keine Bewertungen

- ISO PlanDokument12 SeitenISO PlanTamara Johnson-PariagNoch keine Bewertungen

- Supplier QMS Survey and Audit ExampleDokument7 SeitenSupplier QMS Survey and Audit ExampleHaleem Ur Rashid BangashNoch keine Bewertungen

- ISO 9001 - 2015 Organisational RequirementsDokument6 SeitenISO 9001 - 2015 Organisational RequirementsRommel BaesaNoch keine Bewertungen

- Supplier Assessment Checklist 110448Dokument45 SeitenSupplier Assessment Checklist 110448manno200100% (1)

- Document Change RequestDokument1 SeiteDocument Change Requestsuresh kumarNoch keine Bewertungen

- QAS P008 Control of Non-Conforming Processes, Services or Products ProcedureDokument2 SeitenQAS P008 Control of Non-Conforming Processes, Services or Products Proceduredanaka007Noch keine Bewertungen

- Q1 Procedure Required-1Dokument1 SeiteQ1 Procedure Required-1naveen yadav0% (1)

- Product Audit ChecklistDokument1 SeiteProduct Audit ChecklistRoy PhanNoch keine Bewertungen

- Control of Calibrated Equipment ProcedureDokument8 SeitenControl of Calibrated Equipment ProcedureShakti SharmaNoch keine Bewertungen

- As 9100 Rev D Internal Audit Checklist SampleDokument4 SeitenAs 9100 Rev D Internal Audit Checklist SampleHoang TanNoch keine Bewertungen

- ISO-Control of Non Conforming ProductsDokument3 SeitenISO-Control of Non Conforming Productsnoufal27100% (2)

- Loctite 3090: Large-Gap Filling 2-Component Instant AdhesiveDokument2 SeitenLoctite 3090: Large-Gap Filling 2-Component Instant Adhesivenice guyNoch keine Bewertungen

- ReadmeDokument1 SeiteReadmenice guyNoch keine Bewertungen

- He Beams PDFDokument8 SeitenHe Beams PDFnice guyNoch keine Bewertungen

- Pipe Sleeve Pipe: Description Dia (MM) Unit QTY Description Dia (MM) Unit QTYDokument2 SeitenPipe Sleeve Pipe: Description Dia (MM) Unit QTY Description Dia (MM) Unit QTYnice guyNoch keine Bewertungen

- THK60 Concrete Tile Non Slip Poceline TilesDokument2 SeitenTHK60 Concrete Tile Non Slip Poceline Tilesnice guyNoch keine Bewertungen

- VaishaliDokument2 SeitenVaishalinice guyNoch keine Bewertungen

- GRP & Hdpe MtoDokument11 SeitenGRP & Hdpe Mtonice guyNoch keine Bewertungen

- Inspection and Test Plans (ITP) - MUM-06 Pipework Installation ChecklistDokument3 SeitenInspection and Test Plans (ITP) - MUM-06 Pipework Installation Checklistnice guyNoch keine Bewertungen

- Reverse Osmosis Desalination: Our Global Expertise To Address Water ScarcityDokument16 SeitenReverse Osmosis Desalination: Our Global Expertise To Address Water Scarcitynice guyNoch keine Bewertungen

- Format For Submission of Expression of Interest (EOI) Under Notice No - 1 - PD - WBFBCP - 2012-13Dokument7 SeitenFormat For Submission of Expression of Interest (EOI) Under Notice No - 1 - PD - WBFBCP - 2012-13nice guyNoch keine Bewertungen

- Typical Project Quality Plan & ITP CPCDokument15 SeitenTypical Project Quality Plan & ITP CPCnice guy100% (1)

- Manual RO TheoryDokument9 SeitenManual RO TheoryElfirman SyafeiNoch keine Bewertungen

- TMS - Specialties Div.: Document Master ListDokument43 SeitenTMS - Specialties Div.: Document Master Listnice guyNoch keine Bewertungen

- 005 Plate PDFDokument22 Seiten005 Plate PDFnice guyNoch keine Bewertungen

- 7 1 PDFDokument3 Seiten7 1 PDFnice guyNoch keine Bewertungen

- 9 Hussein Amery WorkbookExpressionofInterestDokument2 Seiten9 Hussein Amery WorkbookExpressionofInterestnice guyNoch keine Bewertungen

- 20120502-47 De-Oiling Removal of Flammable Liquids From PipelinesDokument2 Seiten20120502-47 De-Oiling Removal of Flammable Liquids From Pipelinesnice guyNoch keine Bewertungen

- Scope Change Request Template: Overview & PurposeDokument2 SeitenScope Change Request Template: Overview & Purposenice guyNoch keine Bewertungen

- MasterRC Pile Cap DesignDokument4 SeitenMasterRC Pile Cap DesignAl-Ain HomesNoch keine Bewertungen

- DS ANT TNA352A33rDokument3 SeitenDS ANT TNA352A33rEdelNoch keine Bewertungen

- Iso 25964 2 201 PDFDokument19 SeitenIso 25964 2 201 PDFLetícia MirandaNoch keine Bewertungen

- Compress and Asme Viii-2Dokument21 SeitenCompress and Asme Viii-2cristinelbNoch keine Bewertungen

- BIO PROJECT MOBILE RADIATION 2 (Official Release)Dokument28 SeitenBIO PROJECT MOBILE RADIATION 2 (Official Release)Sarosij Sen Sarma67% (3)

- Q 10Dokument7 SeitenQ 10AndiniPermanaNoch keine Bewertungen

- AN296220 Bootstrap SupplyDokument4 SeitenAN296220 Bootstrap Supplya9841140155Noch keine Bewertungen

- 38smss4 Specification For Coupling Capacitor Voltage Transformer and or Carrier Coupler CapacitorDokument20 Seiten38smss4 Specification For Coupling Capacitor Voltage Transformer and or Carrier Coupler CapacitorengrandyNoch keine Bewertungen

- The Product & UX Design Roadmap 2023Dokument16 SeitenThe Product & UX Design Roadmap 2023shreya kaleNoch keine Bewertungen

- Embedded Web TechnologyDokument3 SeitenEmbedded Web TechnologySneha Nagaruru0% (1)

- Project Management Plan Training Plan For Plus Portal Management System Dauran Mcneil University of The West IndiesDokument25 SeitenProject Management Plan Training Plan For Plus Portal Management System Dauran Mcneil University of The West IndiesdauranNoch keine Bewertungen

- EMC Symmetrix Remote Data Facility (SRDF) : Connectivity GuideDokument150 SeitenEMC Symmetrix Remote Data Facility (SRDF) : Connectivity GuidepeymanNoch keine Bewertungen

- Valuation: Philippine Residential Broadband MarketDokument5 SeitenValuation: Philippine Residential Broadband MarketNico Angeles MenesesNoch keine Bewertungen

- Chapter Test Css g12Dokument30 SeitenChapter Test Css g12flash driveNoch keine Bewertungen

- Hardware Reference Guide: Small Form Factor Models Compaq Evo Desktop FamilyDokument63 SeitenHardware Reference Guide: Small Form Factor Models Compaq Evo Desktop FamilySébastien MunozNoch keine Bewertungen

- Guide: Overclocking FX-8350 To 4.8GHz On Crosshair V Formula-ZDokument7 SeitenGuide: Overclocking FX-8350 To 4.8GHz On Crosshair V Formula-ZBobapatatasNoch keine Bewertungen

- Samson 3277Dokument17 SeitenSamson 3277Anonymous 50FYYM2Noch keine Bewertungen

- ISAA HoA4 (Unit-5)Dokument10 SeitenISAA HoA4 (Unit-5)052 Deepak NaralaNoch keine Bewertungen

- A5 EXPERIMENT LVDT and RVDTDokument14 SeitenA5 EXPERIMENT LVDT and RVDTDuminduJayakodyNoch keine Bewertungen

- Eighty Eight 2.0 - User Guide - V1.0 - RPDokument22 SeitenEighty Eight 2.0 - User Guide - V1.0 - RPAnonymous W9sRv4iwNoch keine Bewertungen

- CIM For Enterprise Integration (IEC) 61968Dokument53 SeitenCIM For Enterprise Integration (IEC) 61968Igor SangulinNoch keine Bewertungen

- SANOG35 Tutorial Programming and Python For Network Engineers PDFDokument138 SeitenSANOG35 Tutorial Programming and Python For Network Engineers PDFPhuwanart PhiNoch keine Bewertungen

- Installation Procedure For Version 4.2.12.00 - Release 4.2Dokument54 SeitenInstallation Procedure For Version 4.2.12.00 - Release 4.2Talhaoui ZakariaNoch keine Bewertungen

- XYZ: PFD and P&ID Diagrams - PDF - Instrumentation - Control TheoryDokument15 SeitenXYZ: PFD and P&ID Diagrams - PDF - Instrumentation - Control TheoryAhmed Essam El-DinNoch keine Bewertungen

- Hydronic 300 Valve Setting Instructions - M04002enDokument14 SeitenHydronic 300 Valve Setting Instructions - M04002enbdgnsNoch keine Bewertungen

- Activity 6 - Two Station Motor Control With Emergency Stop (Non-Reversing)Dokument15 SeitenActivity 6 - Two Station Motor Control With Emergency Stop (Non-Reversing)AJ LunaNoch keine Bewertungen

- A5.28 and A5.18 - ER70S-GDokument10 SeitenA5.28 and A5.18 - ER70S-GSurat ButtarasriNoch keine Bewertungen

- Mastering Sap S4hana 1709Dokument617 SeitenMastering Sap S4hana 1709yakar55592% (38)

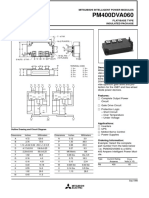

- PM400DVA060: Mitsubishi Intelligent Power ModulesDokument6 SeitenPM400DVA060: Mitsubishi Intelligent Power ModulesDiego GrisalesNoch keine Bewertungen

- Design For Test by Alfred L CrouchDokument117 SeitenDesign For Test by Alfred L CrouchEdwin Singh100% (1)