Beruflich Dokumente

Kultur Dokumente

PD190 BPV Code, Section IX: Welding, Brazing, and Fusing Qualifications Day One

Hochgeladen von

Charles JacobOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PD190 BPV Code, Section IX: Welding, Brazing, and Fusing Qualifications Day One

Hochgeladen von

Charles JacobCopyright:

Verfügbare Formate

PD190

BPV Code, Section IX: Welding, Brazing, and Fusing Qualifications

Day One

Historical perspective of welding and code development

The relationship of Section IX to other codes

The secret to using Section IX efficiently

Review of the welding processes: fuel gas, shielded metal arc, gas tungsten arc,

gas metal arc, submerged arc, plasma arc, electroslag, electrogas, beam, stud,

friction, resistance, explosion, diffusion, and hybrid

In-depth review of SMAW (shield-metal arc welding) variables

P-numbers, S-numbers and non-code metals, steel metallurgy;

hardenability; preheat and postweld heat treatment

Filler metal specifications including F-numbers; A numbers; SFA

specifications; non SFA filler metals

Variables for other common processes

Day Two

Practical Aspects

Basic welding metallurgy for steels

Approaches to writing the welding procedure specification

Addressing customer requirements

Providing direction to the welder

Sources of information for preparing intelligent and meaningful welding

procedure specifications

Selecting, preparing, and welding the test coupon

Selection of the test coupon materials for maximum cost-effectiveness

Recording both necessary and worthwhile data and demonstrating code

compliance

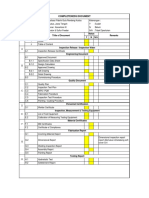

Practical session: Approaches to writing the WPSs (welder procedure

specifications):

Samples of the good, the bad and the ugly

Section IX form; other formats; checklists

Revisions to records and procedures

Take-home test

BPV Code, Section IX: Welding, Brazing, and Fusing Qualifications

PD190

Updated August 2013 1

Day Three

Welder and welding operator qualifications

Responsibility for testing welders and welding operators

Performance qualification Variables - Welders vs. Operators

Selecting test coupons and testing completed welds

Maintaining qualifications over time

Impact Tested Qualifications

Learn how welding influences toughness and how construction codes

deal with toughness

Upgrading WPSs for impact tested applications

Supplementary essential variables and documenting them during

welding

Measuring and recording heat input data and translating heat input data

into useful directions for a welder

Brazing Qualifications

Review of Brazing processes and variables

Differences between the QW (welding)and QB (brazing) sections

Qualification of the brazing procedure and brazers

Differences in testing between welding and brazing

Fusing Qualifications

Review of plastic fusing processes and variables

Qualification of the fusing procedure and fusing operators

BPV Code, Section IX: Welding, Brazing, and Fusing Qualifications

PD190

Updated August 2013 2

Das könnte Ihnen auch gefallen

- 2 Storey House PlanDokument4 Seiten2 Storey House PlanVinluan Erika AnnNoch keine Bewertungen

- Inspector Course OutlineDokument23 SeitenInspector Course Outlinebhingmeh yotalNoch keine Bewertungen

- Asme Sec - IxDokument132 SeitenAsme Sec - IxBoran YelkenciogluNoch keine Bewertungen

- WPS& WQRDokument132 SeitenWPS& WQRAby Jacob Mathews100% (3)

- Presentation Asme Sec Ix Wps PQR WPQDokument177 SeitenPresentation Asme Sec Ix Wps PQR WPQM A67% (3)

- Section IX WeldingDokument6 SeitenSection IX WeldingAhmedNoch keine Bewertungen

- 5 - Module 5Dokument47 Seiten5 - Module 5Ahmed Shaban Kotb100% (1)

- Plumbing SymbolsDokument17 SeitenPlumbing SymbolsdonprofaghatiseNoch keine Bewertungen

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Presentation Asme Sec-Ix Wps PQR Wpq..Dokument176 SeitenPresentation Asme Sec-Ix Wps PQR Wpq..Utkarsh GautamNoch keine Bewertungen

- Asme IxDokument132 SeitenAsme IxAhmed Shaban Kotb100% (1)

- Quick Guide To Welding Procedure Qualification (WPS & PQR)Dokument5 SeitenQuick Guide To Welding Procedure Qualification (WPS & PQR)Annamalai Ram JGCNoch keine Bewertungen

- Wit T 2008PVDokument6 SeitenWit T 2008PVCharles JacobNoch keine Bewertungen

- California Building CodeDokument21 SeitenCalifornia Building Codez15tea33% (3)

- Method of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Dokument17 SeitenMethod of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Sherief Abd El Baky83% (12)

- Production Engineering: Jig and Tool DesignVon EverandProduction Engineering: Jig and Tool DesignBewertung: 4 von 5 Sternen4/5 (9)

- QC Welding Inspector ImtiazDokument3 SeitenQC Welding Inspector ImtiazImtiyaz MirzaNoch keine Bewertungen

- Lloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Dokument30 SeitenLloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Navneet Singh100% (2)

- Design of Press Tool With Its DefectsDokument22 SeitenDesign of Press Tool With Its DefectsDean Dattha100% (4)

- LR Weld Certification Guide v1.3 SubscribeDokument24 SeitenLR Weld Certification Guide v1.3 SubscribeSergio Jesus SanjurjoNoch keine Bewertungen

- Presentation Asme Sec Ix Wps PQR WPQDokument177 SeitenPresentation Asme Sec Ix Wps PQR WPQsiva92% (26)

- Fab 04 WPS, WPQR, Welder Qualification, Welding Positions, Defect - Repair WeldingDokument39 SeitenFab 04 WPS, WPQR, Welder Qualification, Welding Positions, Defect - Repair WeldingRaghu vamshiNoch keine Bewertungen

- BS IndexDokument11 SeitenBS IndexShirleyLiuNoch keine Bewertungen

- Lloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457 PDFDokument30 SeitenLloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457 PDFjos22231Noch keine Bewertungen

- Spun Concrete Piles Product LeafletDokument4 SeitenSpun Concrete Piles Product LeafletDieka Meidilla AnanzaNoch keine Bewertungen

- !indx PipDokument18 Seiten!indx PipCharles JacobNoch keine Bewertungen

- Welding Inspector May 2021Dokument8 SeitenWelding Inspector May 2021SUNIL BABURAO GAVADENoch keine Bewertungen

- Asme Sec Ix - Short Notes ReferenceDokument29 SeitenAsme Sec Ix - Short Notes Referencekart_rl0% (1)

- CV FormateDokument8 SeitenCV Formatetariq_hussain_20Noch keine Bewertungen

- Asme Section IX - NewDokument70 SeitenAsme Section IX - NewAnaswarps100% (2)

- Welder and Procedure QualificationDokument25 SeitenWelder and Procedure QualificationRamón G. Pacheco100% (3)

- Drop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsVon EverandDrop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsBewertung: 5 von 5 Sternen5/5 (1)

- Shortcut To A WPSDokument18 SeitenShortcut To A WPSCepi Sindang Kamulan100% (1)

- Anilkumar Gopinathan Nair: Phone: +91-6380325363Dokument2 SeitenAnilkumar Gopinathan Nair: Phone: +91-6380325363Anilkumar GNoch keine Bewertungen

- WpsDokument39 SeitenWpsAkhilesh Kumar100% (1)

- Asme Sec Ix - Short NotesDokument20 SeitenAsme Sec Ix - Short NotesParvee K NakwalNoch keine Bewertungen

- Heat ExchangerDokument36 SeitenHeat ExchangerUsman MansuriNoch keine Bewertungen

- Presentation Asme Sec Ix Wps PQR WPQ PDFDokument177 SeitenPresentation Asme Sec Ix Wps PQR WPQ PDFemrullah100% (1)

- WPS ManualDokument5 SeitenWPS Manualarif maulanafNoch keine Bewertungen

- EN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyDokument13 SeitenEN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyMad Max100% (1)

- 08CLecture - Welding Codes StandardsDokument15 Seiten08CLecture - Welding Codes StandardsDavid HuamanNoch keine Bewertungen

- Welding Procedures and DocumentationDokument17 SeitenWelding Procedures and DocumentationVamsikrishna Chowdary MarthaNoch keine Bewertungen

- MS - Sikadur-732 (Application of Epoxy Bonding Agent) (Ver.01)Dokument4 SeitenMS - Sikadur-732 (Application of Epoxy Bonding Agent) (Ver.01)Jerome Li100% (2)

- ExhibitorList 2018Dokument68 SeitenExhibitorList 2018Charles JacobNoch keine Bewertungen

- Resume of Mohd Illias Uddin (SR Welding-Mech QC)Dokument7 SeitenResume of Mohd Illias Uddin (SR Welding-Mech QC)Mohammed IlliasuddinNoch keine Bewertungen

- Section IX CourseDokument1 SeiteSection IX Coursehareesh13hNoch keine Bewertungen

- PD645 BPV Code, Section IX: Welding, Brazing, and Fusing Qualifications Day OneDokument2 SeitenPD645 BPV Code, Section IX: Welding, Brazing, and Fusing Qualifications Day Onesivagnanam sNoch keine Bewertungen

- Ravishekh CVDokument3 SeitenRavishekh CVraj kumar SinghNoch keine Bewertungen

- Welding EngineerDokument7 SeitenWelding Engineercreative video logicNoch keine Bewertungen

- Yavar Shadab CVDokument4 SeitenYavar Shadab CVMuhammed ThanzeelNoch keine Bewertungen

- Edison Aliagan Walit: Registered Mechanical Engineer Abu Dhabi United Arab Emirates Mobile # (+971) 504481492 E-MailDokument8 SeitenEdison Aliagan Walit: Registered Mechanical Engineer Abu Dhabi United Arab Emirates Mobile # (+971) 504481492 E-MailEdison WalitNoch keine Bewertungen

- Fiche Programme Doc Asme IxDokument5 SeitenFiche Programme Doc Asme IxSalah JallaliNoch keine Bewertungen

- Edison Aliagan Walit: Mechanical Engineer Abu Dhabi United Arab Emirates Mobile # (+971) 504481492 E-MailDokument8 SeitenEdison Aliagan Walit: Mechanical Engineer Abu Dhabi United Arab Emirates Mobile # (+971) 504481492 E-MailEdison WalitNoch keine Bewertungen

- Naukri VISHALRAJARAMINGALE (6y 9m)Dokument4 SeitenNaukri VISHALRAJARAMINGALE (6y 9m)3asNoch keine Bewertungen

- Bio-Data: Name: Zain Yousaf Aramco Approved QCI WELDING Iqama # 2460058569 Driving License - Saudi ArabiaDokument6 SeitenBio-Data: Name: Zain Yousaf Aramco Approved QCI WELDING Iqama # 2460058569 Driving License - Saudi ArabiaMd SogibNoch keine Bewertungen

- Welding EngineerDokument1 SeiteWelding EngineerMERVINNoch keine Bewertungen

- Binoy O MathewDokument5 SeitenBinoy O MathewAneez AbdulJaleelNoch keine Bewertungen

- Edison Aliagan WalitDokument7 SeitenEdison Aliagan WalitEdison WalitNoch keine Bewertungen

- Rasheed K H - CVDokument5 SeitenRasheed K H - CVKshama RaiNoch keine Bewertungen

- Resume - Chantu SasiDokument8 SeitenResume - Chantu SasiDhanush NairNoch keine Bewertungen

- Name Bijinlal AT: Current Position Engineer-Inspection QC Call +91 9497109600 MailDokument4 SeitenName Bijinlal AT: Current Position Engineer-Inspection QC Call +91 9497109600 MailUdayan JadavNoch keine Bewertungen

- Baraneedharan Raju CV UpdatedDokument7 SeitenBaraneedharan Raju CV UpdatedBaraneedharanNoch keine Bewertungen

- The Propose of Training Program For Welding Inspectors 2021Dokument5 SeitenThe Propose of Training Program For Welding Inspectors 2021adelNoch keine Bewertungen

- Module 7 - Summary: 7A - ASME Section IX Weld Procedure Qualification 7B - ASME Section IX Welder QualificationDokument42 SeitenModule 7 - Summary: 7A - ASME Section IX Weld Procedure Qualification 7B - ASME Section IX Welder Qualificationkapster KannourNoch keine Bewertungen

- Guideline - Review - of - Supplier - Welding - Docs (18.08)Dokument32 SeitenGuideline - Review - of - Supplier - Welding - Docs (18.08)Jodan AsiborNoch keine Bewertungen

- Training Plan For Each Work PackageDokument10 SeitenTraining Plan For Each Work PackageDalia PrinceNoch keine Bewertungen

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Principles of Mining: Valuation, Organization and AdministrationVon EverandPrinciples of Mining: Valuation, Organization and AdministrationNoch keine Bewertungen

- Spot Welding Interview Success: An Introduction to Spot WeldingVon EverandSpot Welding Interview Success: An Introduction to Spot WeldingNoch keine Bewertungen

- 00 ContentsDokument56 Seiten00 ContentsCharles JacobNoch keine Bewertungen

- RL 396 17 StateDokument7 SeitenRL 396 17 StateCharles JacobNoch keine Bewertungen

- About The Knowledge TestDokument4 SeitenAbout The Knowledge TestCharles JacobNoch keine Bewertungen

- Pallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportDokument1 SeitePallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportCharles JacobNoch keine Bewertungen

- The Hare-Clarke Controversy Over The Invention of The Improved Gas BlowpipeDokument6 SeitenThe Hare-Clarke Controversy Over The Invention of The Improved Gas BlowpipeCharles JacobNoch keine Bewertungen

- THE ALL-NEW XL666 BrochureDokument15 SeitenTHE ALL-NEW XL666 BrochureCharles JacobNoch keine Bewertungen

- Question Paper and Answer Key: Mathematics (MA)Dokument25 SeitenQuestion Paper and Answer Key: Mathematics (MA)Charles JacobNoch keine Bewertungen

- Henri Sainte-Claire DevilleDokument8 SeitenHenri Sainte-Claire DevilleCharles JacobNoch keine Bewertungen

- Web Work PDFDokument39 SeitenWeb Work PDFCharles JacobNoch keine Bewertungen

- Team-BHP PDI Checklist PDFDokument3 SeitenTeam-BHP PDI Checklist PDFCharles JacobNoch keine Bewertungen

- 2020 Price List: Certification ProgramsDokument2 Seiten2020 Price List: Certification ProgramsCharles JacobNoch keine Bewertungen

- Excon 2019 - Visitor RegistrationDokument2 SeitenExcon 2019 - Visitor RegistrationCharles JacobNoch keine Bewertungen

- New Welding Gas Innovation: How To Signifi Cantly Reduce Your Welding Costs WhileDokument2 SeitenNew Welding Gas Innovation: How To Signifi Cantly Reduce Your Welding Costs WhileCharles JacobNoch keine Bewertungen

- EnveloperyDokument11 SeitenEnveloperyCharles JacobNoch keine Bewertungen

- Railways Tourism, Retiring Rooms, Holidays Customized Tours, LTC Tours, Maharajas, MahaparinirvanDokument2 SeitenRailways Tourism, Retiring Rooms, Holidays Customized Tours, LTC Tours, Maharajas, MahaparinirvanCharles JacobNoch keine Bewertungen

- 820 PDFDokument19 Seiten820 PDFCharles JacobNoch keine Bewertungen

- AUTOMIG FC 110T5-K4 : (Formerly Known As Advani-Oerlikon LTD.)Dokument1 SeiteAUTOMIG FC 110T5-K4 : (Formerly Known As Advani-Oerlikon LTD.)Charles JacobNoch keine Bewertungen

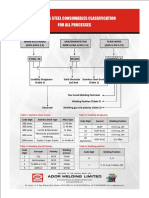

- Stainless Steel Consumables ClassificationDokument1 SeiteStainless Steel Consumables ClassificationCharles JacobNoch keine Bewertungen

- Automig FC 91T1-B3 : (Formerly Known As Advani-Oerlikon LTD.)Dokument1 SeiteAutomig FC 91T1-B3 : (Formerly Known As Advani-Oerlikon LTD.)Charles JacobNoch keine Bewertungen

- Automig FC 71t 1 ModDokument1 SeiteAutomig FC 71t 1 ModCharles JacobNoch keine Bewertungen

- Automig FC 90T5-K2 : (Formerly Known As Advani-Oerlikon LTD.)Dokument1 SeiteAutomig FC 90T5-K2 : (Formerly Known As Advani-Oerlikon LTD.)Charles JacobNoch keine Bewertungen

- Automig FC 560: (Formerly Known As Advani-Oerlikon LTD.)Dokument1 SeiteAutomig FC 560: (Formerly Known As Advani-Oerlikon LTD.)Charles JacobNoch keine Bewertungen

- M 3 D1.1 2015 FormDokument1 SeiteM 3 D1.1 2015 FormĐỗ Văn ChinhNoch keine Bewertungen

- Automig FC 71T-5 : (Formerly Known As Advani-Oerlikon LTD.)Dokument1 SeiteAutomig FC 71T-5 : (Formerly Known As Advani-Oerlikon LTD.)Charles JacobNoch keine Bewertungen

- SpecificationDokument1 SeiteSpecificationdanielsu87Noch keine Bewertungen

- May 2014-1Dokument412 SeitenMay 2014-1Andi DumayNoch keine Bewertungen

- Metal Matrix Composites (MMC) : Presented By:-Nikhil Dixit (16MMF0010)Dokument27 SeitenMetal Matrix Composites (MMC) : Presented By:-Nikhil Dixit (16MMF0010)trishulNoch keine Bewertungen

- Fire Departement Connection (Siames Connection)Dokument1 SeiteFire Departement Connection (Siames Connection)Mohamed HassanNoch keine Bewertungen

- Piping Design InfoDokument273 SeitenPiping Design InfoFerry SiswantoNoch keine Bewertungen

- OMC-6050 Chain InclinometerDokument2 SeitenOMC-6050 Chain InclinometerJavier VillasmilNoch keine Bewertungen

- BN - 20038 Hexalobular Socket Pan Head Machine Screws Fully Threaded (A4)Dokument3 SeitenBN - 20038 Hexalobular Socket Pan Head Machine Screws Fully Threaded (A4)MSD ENGRNoch keine Bewertungen

- Marshall Mix DesignDokument2 SeitenMarshall Mix DesignTakdir Satria NandaNoch keine Bewertungen

- An Exploratory Study of GFRP Rebar With Ribs Containing Milled Glass FibersDokument9 SeitenAn Exploratory Study of GFRP Rebar With Ribs Containing Milled Glass FibersShoban Senapathi MNoch keine Bewertungen

- WPC Bruchure Revised Price List November 7 2020Dokument10 SeitenWPC Bruchure Revised Price List November 7 2020Michael FutolNoch keine Bewertungen

- Hemadri Cements Production ReportDokument7 SeitenHemadri Cements Production ReportJCSNoch keine Bewertungen

- Tabla de MetradoDokument6 SeitenTabla de MetradodiogenesNoch keine Bewertungen

- Review Dokumen PG. RendengDokument10 SeitenReview Dokumen PG. RendengFarhan PutraNoch keine Bewertungen

- 2 Construction WorkDokument53 Seiten2 Construction WorkShuvam AdhikariNoch keine Bewertungen

- Working With The Cold Box ProcessDokument21 SeitenWorking With The Cold Box ProcessAnonymous iztPUhIiNoch keine Bewertungen

- X ENP Data Sheet Technical Information ASSET DOC 2591592Dokument9 SeitenX ENP Data Sheet Technical Information ASSET DOC 2591592Milos VukobratNoch keine Bewertungen

- 02112015000000B - Boehler FOX DCMS Ti - CeDokument1 Seite02112015000000B - Boehler FOX DCMS Ti - CeparbinaNoch keine Bewertungen

- TDS - TR144 - Astm (Eng)Dokument2 SeitenTDS - TR144 - Astm (Eng)Darwin Lenin Iza PradoNoch keine Bewertungen

- 3.7.11 PTS E-101sl - 170522 (Web)Dokument4 Seiten3.7.11 PTS E-101sl - 170522 (Web)betoaranoNoch keine Bewertungen

- Inspection & Testing Requirements Scope:: Test and Inspection PerDokument2 SeitenInspection & Testing Requirements Scope:: Test and Inspection PerWael ChouchaniNoch keine Bewertungen

- Owens Corning - Fiberglass InsulationDokument4 SeitenOwens Corning - Fiberglass InsulationdenisnonameNoch keine Bewertungen