Beruflich Dokumente

Kultur Dokumente

Hebel Floor Plus

Hochgeladen von

AbuCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hebel Floor Plus

Hochgeladen von

AbuCopyright:

Verfügbare Formate

Technical Sheet

and Installation Guide

Autoclaved Aerated Concrete

Properties

Characteristic Unit Strength Class

AAC-6

Compressive Strength (faac) psi 870

Nominal Density pcf 37

Design Weight pcf 45

Drying Shrinkage % 0.02

Thermal Expansion Coefficient K-1 8 x 10-6

2 0

Thermal Conductivity BTU-in/ft h F 0.9811

Water Vapor Permeability ng/Pa.s.m 0.226

Fig. 1: Hebel Slab Panel.

Modulus of Elasticity psi 377,000

1 Technical Modulus of Rupture (MOR) psi 142

Sheet

Allowable Bearnig Stress psi 523

Table 1: Physical and design properties.

1.1 Hebel Slab Panel

Thermal Conductivity

General Features Class

Hebel Autoclaved Aerated Thermal Conductivity

Concrete (AAC) Floor and Roof AAC-6

Steady-State

Slab Panels are lightweight, fire 0.9811 BTU-in/ft2-h-0F

resistant, fast and easy to install

and provide lifelong superior Unit: BTU = british thermal unit , in = inches, ft = foot, h = hour, F = fahrenheit

thermal insulation. Hebel Slab Table 2: Hebel Slab Panel thermal conductivity.

Panels are steel reinforced (Grade

70) Autoclaved Aerated Concrete

elements. The interior steel wire Fire Performance

Thickness Fire Ratings UL Design

reinforcement is covered with an Hebel Slab Panel (Inch) (Hours) Number

anti-corrosion coating. Hebel Slab 4 1 K909

Panel is produced in an ASTM C Reinforced Slab Panel AAC-6

P932

1452 strength class: AAC-6. ->5 4

Note: Testing performed at Underwriters Laboratories, Inc., Northbrook, IL under ASTM E119

(UL/ANSI 263) Fire Tests of Building Construction and Materials.

Uses

Hebel Slab Panels are used as Table 3: Hebel Slab Panel fire rating.

floor and roof simply-supported

slabs on Hebel Masonry Maximum Allowable Service Load - Hebel Slab Panel AAC-6

Components or CMU load-bearing Uniform Load [psf]

walls, wood, concrete or steel AAC Roof Panels AAC Floor Panels

beams. These panels are used in Panel Thickness [in] Panel Thickness [in]

Length

residential, multi-family housing, [ft]

4 6 7 8 4 6 7 8

Selfweight [psf] Selfweight [psf]

hotels, offices and industrial 14.8 22.1 25.8 29.5 14.8 22.1 25.8 29.5

buildings. Hebel AAC meets the

6.6 149 --- --- --- 154 --- --- ---

diverse demands better than any

8.2 115 --- For superimposed 88 --- For superimposed

other material due to the loads over 150 psf loads over 150 psf

numerous advantages of its 9.8 65 151 contact Xella Texas. 45 156 contact Xella Texas.

physical, mechanical, energy 11.5 36 126 149 --- 128 155 ---

efficiency and safety properties. 13.1 19 108 127 148 --- 79 133 154

14.8 --- 72 111 128 --- 49 98 135

Dimensions 16.4 --- 47 95 113 --- --- 65 106

Length: (2) Up to 20 ft 18.0 --- 30 65 102 --- --- 42 73

20.0 --- 16 41 70 --- --- --- 45

Width: 24 in.

Note: Panel Class AAC-6 and 24 in width. Superimposed uniform loads were calculated in accordance

Nominal Thickness: (1)(3) 4, 5, 6, 7, 8, 10 and 12 in. to ACI-523 design methodology. All roof panels meet or exceed L/240 live load and L/180 total load

vertical deflections at the allowable loads indicated. All floor panels meet or exceed L/360 live load

Class: AAC-6 and L/240 total load vertical deflations at the allowable loads indicated. Superimposed dead load

of 12.2 psf (roof panels) or 30.7 psf (floor panels) and the compression reinforcement contribution

(1) Tolerance + + 3/16,

_ 1/8, (2) Tolerance _ for long term deflection were considered.

(3) Nominal. Manufactured according to ASTM C1452. Table 4: Allowable service loads for AAC Slab Panels.

2 Hebel Aerated Concrete

OSHA trainer for rigging or

2 Design other safety considerations.

Insure adherence to Leading

Considerations Edge Support OSHA Guidelines.

- Carefully unload panels using

2.1 General pallet forks (forklift, nylon straps,

Considerations slings or pallet fork on a crane

cable). Place pallets over wood

Hebel Autoclaved Aerated blocks (panels must not be in

Concrete (AAC) Slab Panels can contact with ground).

be used as floor or roof systems

and shall be designed in order to - Storage areas should be Fig. 2: Hebel Slab Panel Pallets.

comply with strength and accessible to delivery trucks and

serviceability requirements as convenient to staging areas. If

specified by ACI-523.4R-09 possible, drop-deliver the surface areas may be repaired

material right to the material using a compatible AAC patching

The Slab Panel thickness and staging areas. compound.

the span will determine the

allowable service load (see Table - Material should always be - All panels that have surface or

4). The load (dead and live) must stored away from other minor cracks are usable. Contact

comply with the Local and Regional construction activities on a flat- an authorized AAC representative

Building Code. grade area that is not susceptible when a crack is extended

to standing water, erosion or completely through the panel.

Floor and roof panels can be settling.

supported by AAC Masonry Walls, 3. Check existing steel

reinforced concrete, concrete 2. Check material and installation accessories (not supplied by Xella

masonry walls (CMU), wood or logistic AAC Texas).

steel beams.

- Verify dimensions, positions - Steel accessories for holes

AAC Slab Panels are reinforced and quantity of the panels (ducts) -1 or 2 panels width- in

with two layers of high strength according to Hebel shop floor and roofs.

smooth bars (Fy = 70,000 psi) which drawings. - Steel plate for connecting Slab

are protected with an anti- Panels to steel structure.

corrosive coat. - Define sequence of panel

installation according to Hebel 4. Check support structure

The longitudinal bars develop shop drawings. To help speed

their tensile stress using installation, place the panels - All support elements (load-

mechanical anchorage provided with the groove side at the bearing walls, concrete or steel

by cross bars . beginning and continue. beams, etc) must be already

finished before receiving floor

- Define type of installation and roof panels.

equipment (crane or similar).

3 Installation - Evaluate quantity of personnel

- Check layout and top of

supporting structure. AAC top

Guide required for installation ( 4 to 5

assistants for panel installation

block adjustments must not be

less than 2 in height, or else

plus crane operator). cement-sand mortar (1:4) must

Before installation be used (see Fig. 12-A).

of Hebel Slab Panels - Keep the material covered and

banded until ready for

installation. Excessive handling

3.1 General Installation may cause damage. Set delivery Project Number

Guidelines schedule to match the erection

sequence. 91593 P02 A01

1. Clear the unloading and

provisional storage area - Chips and spalls can be Panel position

repaired. If any reinforcing is Panel type / area

E: Floor panel

- Consult an appropriate safety visible, contact an authorized A: Roof panel

professional or knowledgeable AAC representative. All damaged

Fig. 3: Panel identification.

Hebel Aerated Concrete 3

Support Elements Minimum Bearing Length (in)

Hebel Masonry Ld/80 or 2 (min)

Concrete or

Ld/80 or 2.0 (min)

Reinforced Concrete

Wood Ld/80 or 2.0 (min)

Steel Beams Ld/80 or 1.5 (min)

Note: Ld = Effective span length, Le = Clear span, where Ld = Le + 3 inches.

Table 5: Minimum bearing length for Slab Panels.

3.2 Installation Equipment:

- Hebel Slab Panel Lifting Gear

Requirements or Clamp (optional).

Fig. 4: Storage area close to job site. - Telescopic Crane or similar.

The actual list of tools, equipment - Circular Saw (8 diam min)

and other materials will depend on with metal cutting blade or

type of project and workforce. Gasoline-Powered Circular

Saws ( 12 min).

Tools: - Power Drill / Stirrer.

- Hammer-Ax. - Router / Bits.

- Rubber Mallet. - Hebel Hand Saw

- Scrub Brush. - Hebel Turners (2 pc).

- Hebel Sanding Float. - Safety Equipment (Hard hat,

- Hebel Plastic Bucket. face-shield, goggles, dust

- Chasing Tools. mask, ear plugs, gloves, safety

- Spatula. shoes, etc.).

- Chalk-Line.

- Tape Measure. Other materials:

- Finishing Trowels. - Hebel Thin Bed Mortar and

- Ripping Bar (36). Rapair Mortar.

- Hebel Rebar Spacers.

- Anticorrosive Paint.

- Fiberglass Mesh

- 4x4 in. Wood Block (2 ft long).

Fig. 5: Slab Panel supported by steel elements. - Rebar #3, #4

- Cement-Sand Mortar.

- Bearing lengths for AAC floor - Concrete (3.000 psi).

and roof panels should comply - Steel Plates.

with Table 5. - Hebel Stucco, Base-Coats,

Textures, etc.

- Mark guidelines on top of the Fig. 6: Panel lifting gear T800.

- Anchors & Hebel Nails.

supporting elements according

to bearing lengths in Hebel shop

drawings. Note: Mayor equipment / tools are listed

but not limited to items noted above to

complete the installation.

- For non-load-bearing

elements, put a layer of a

compressible material

(polystyrene or similar) on top.

Fig. 7: Panel lifting gear T1400.

Precaution: Always wear proper personal protection

equipment when using a circular saw, band saw or

an angle grinder, including goggles, face-shield,

hearing protection and dust mask.

4 Hebel Aerated Concrete

3.3 Installation of Hebel IMPORTANT:

Slab Panels Handle panels with care to

a. Identify Hebel Panels to be avoid damage.

installed according to previous Make chases needed prior

logistics (see section 3.1 (2) and to installation.

Fig. 3). It is strictly forbidden at any

time for people to be under

b. Carefully unpack panels using

scissors or a hammer ax. Verify the load during lifting.

that panels are in a stable Never put hands, arms, feet

position prior to cutting the or legs between the jaws

banding. of the clamp.

The load must always be

c. Over 4x4 wood blocks, rotate

hoisted; it may not dragged

Slab Panel 90 or until tongue

and groove profiles are facing along the ground.

up. Mark center of panel -Panel Avoid sudden movement to

Fig. 9

length/2- (see Fig. 8). prevent accidental release

of the load.

d. Clean the tongue and groove

surface using a sanding float,

hammer and a brush.

e. Place lifting gear at center of f. Using the pulleys, close

panel (see Fig. 8). clamps, clipping the tongue and

groove sides of the panel.

g. Fasten safety chains avoiding

excessive tightening, lower the

locking lever (unlock position)

and indicate to crane operator

to lift the panel (see Fig. 9).

h. Two people will lead the panel

to place it on the support

(masonry, steel beams, etc).

i. Remove safety chains

Fig. 10

(see Fig. 10).

j. Place the panel on the

guidelines previously traced.

Verify minimum bearing length

(see Fig. 11).

k. Once the panel is placed, open

the clamps, raise the locking

lever (lock position) and remove

the lifting gear.

l. This procedure should be

Fig. 8

followed for each successive

panel.

Fig. 11

Hebel Aerated Concrete 5

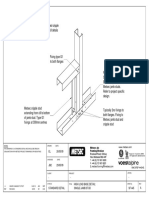

Ring beam

longitudinal joint

(Reinforced)

Transversal joint

(Non-Reinforced)

B

B

Ring beam

Panel position

Cantiliver panel

anchorage

1/3

Cantiliver panel

Hebel rebar

spacer

(2 per panel) A A

SLAB PANEL

2 3/4

Longitudinal Lateral

minimum

reinforcement overlap

along panel Hebel Slab panel Hebel Slab panel

joint

Groove

Panel thickness

Ring beam: Panel thickness

concrete fc= 3Ksi

2#4 (along) and Ring beam

1#3@16 all around

the perimeter

Hebel Masonry

wall (Non load-bearing)

Hebel Masonry

wall (Load-bearing)

SECTION A-A SECTION B-B

Fig. 12: Hebel Slab panels over masonry.

6 Hebel Aerated Concrete

3.4 Cast and Cement-sand mortar (1:4)

Reinforcement of Groove joint

1#3 Rebar Tongue

Smooth finish

longitudinal joints and joint

ring beams Panel

thickness

Fiberglass mesh

After panel installation, place steel Reinforcement

reinforcement in longitudinal joints

(see Fig. 12 to 15 and 17) and ring

Fig. 13: Slab panel cross-section view.

beams surrounding panels (see

Fig. 14 and 17). Forms must be

placed in perimetral ring beams.

One #3 rebar is required in Hebel Slab panel

longitudinal joints (shear joints),

wedged with rebar spacers (2 per

panel), and filled with cement-sand Ring beam

Longitudinal

(2#4 and #3@16)

mortar (1:4) - see Fig. 14. Moist concrete fc= 3Ksi joint between

panels (1#3 and

Panel joints before application. cement-sand mortar)

Ring beams require 2#4 rebars

(along) and a #3 every 16

6

(diagonal) and filled with regular

concrete fc= 3 ksi. The maximum

size of coarse aggregate is 3/8

and 5 to 6 of slump. Ring beam 8 8

and form surfaces must be moist

before concrete casting.

Masonry

Fig. 14: Longitudinal joint and ring beam.

Rebar Conduit

Slab

panel

2 1/4

min.

Cut using 2 3/4 2 3/4 Fiberglass mesh

a small angle

grinder

Rebar

Galv. wire

Slab

panel

Ceiling outlet box

Fig. 15: Five-story hotel built with AAC (floor panels). Fig. 16: Conduit and ceiling fixtures.

Hebel Aerated Concrete 7

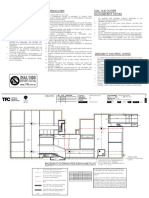

Longitudinal joint Ring beam

(Reinforced)

Transversal joint

(Non reinforced)

1 1

Steel plates

(every 2 joints,

1 1 alternated)

1

1

Groove

Hebel Slab Panel

Installation sequence

1 1

1 1 Panel

position

Tongue

1 1

Load-bearing element

1 1

Hebel rebar 1 1

spacer

(2 per panel)

1 1

See joint and steel plate detail

SLAB PANEL

Transversal joint 1#3 + cement-sand

A Load-bearing Plate

(non reinforced) mortar

element (1/4 thickness)

thickness

Panel

Variable

Load bearing element

Hebel

Slab Panel

SECTION A-A

A 2

1 1/2

1/2

5/8

Panel thickness

minus 3/8

1 1/8

1/8

Longitudinal

joint (1#3

continuous

+ cement-sand

mortar) Variable

Steel plates Load bearing element

(every 2 joints,

alternated)

JOINT DETAIL PLATE DETAIL

Fig. 17:

17 Hebel Slab panel over steel structure.

8 Hebel Aerated Concrete

Slab

Panel

1#3

Steel plate

Supporting element

(joist)

Fig. 20: Steel plate connection.

Fig. 18: Filling longitudinal joint with cement-sand mortar.

Minimum

Longitudinal bearing

reinforcement length

(1#3 +

Cement-sand cement-sand Hebel Slab

Steel plate panel

(cut panel at site) mortar mortar)

thickness

Ring

Panel

beam

Steel

plate

Hebel Slab panel Steel

beam

1#3 Rebar

along longitudinal joint Longitudinal

reinforcement

Steel beam

1/8

Steel

Fig. 19: Cantiliver panel anchorage. plate thickness

Panel

When Hebel Panels are installed

on a steel structure, steel plates Slab panel

must be welded (every 2 Steel

longitudinal joints, alternated) to beam

the structure for connection (see

Fig. 17 to 21). Place steel plates

after panel installation to ensure

correct location.

Fig. 21: Steel plate details.

Hebel Aerated Concrete 9

3.6 Panels Cutting d. For longitudinal cuts, wood

pieces must be placed at every 6

According to shop drawings, ft. (max) for 6 to 12 in thick panels

identify Hebel Slab Panels to be and every 4 ft for panels 4 to 5 in

cut. Permissible cutting length is thick.

indicated on shop drawings,

otherwise contact Xella Technical e. Check for full contact between

Department. Along its length, wood pieces and panel. Wedge if

Hebel Slab Panel can be cut 1/3 necessary.

the width.

f. Place a ruler as a guide and

trace the cut dimensions.

Cutting equipment options

Fig. 22: Sanitary utilities.

g. Proceed with panel cutting,

Electric Circular Saw (8 blade

verifying that cutting dimensions

3.5 Utilities Installation diameter).

comply with specifications.

Transversal and longitudinal cuts

Openings Power Cutter (gasoline-

must be made with panel in

powered) 12 blade or greater

horizontal position; if full

Openings in floor and roofs for A/C (see Fig. 23).

thickness is to be cut, perform

ducts, staircases, roof windows, cut from both sides.

air exhausters, etc. are built using Cutting procedures

steel support. For more h. Apply anticorrosive paint at

information, please call Xella a. Prepare a flat surface for reinforced bar tips.

Technical Department. cutting site.

Electrical conduits b. Check dimensions of cuts to

be made. Caution: Wear

protective helmet

Electrical conduits with a diameter

-1 can be lodged through

< c. For transversal cuts, wood & visor, goggles,

longitudinal joints on top or bottom pieces must be placed along the hearing and

of the panels. For electrical sides of the cut and at the edges respiratory protection. Read

conduits >1 or several electrical of the panel.

equipment instruction manual.

conduits, longitudinal joints can be

Inhalation of concrete dust

widened to lodge them. It is not

recommended to chase on top and above recommended exposure

across the panel width -transversal levels may be harmful. Wet

chase- (see Fig. 16). sawing is recommended.

Please consult the Xella

It is possible to define cut surfaces Material Safety Data Sheet for

in Panels regarding installations.

For more information, please call further details.

Xella Technical Department. Fig. 23: Power cutter.

Piping lines incorrect

6

When required, PVC and other 6 correct

piping lines can pass through

holes in the panels. The maximum

6

hole diameter permitted in one Hebel Slab

panel

panel is 6 or 12 in a joint between

panels (6 each panel). If more than Aligned

one hole is required, they must be 6

aligned along the length of the 6

panel. Only two longitudinal

rebar in the bottom reinforcement

6

of the panel can be cut (see Fig. 22 6

and 24).

Fig. 24: Maximum dimensions of holes through slab panel.

10 Hebel Aerated Concrete

4 Renders

and Finishes

4.1 Products

Surface patching

Use Hebel Repair Mortar to patch

chips, breaks and other

imperfections on surfaces of Hebel

Slab Panels.

Hebel Repair Mortar is prepared Fig. 25: Industrial and commercial projects.

in a plastic bucket, adding water

and mortar from the bag (see

instructions on the bag) and mixed

with a stirrer using a power drill

or by manual means (depending

on quantity to be used). It is applied

using a spatula.

Fiberglass Mesh

Fiberglass mesh, 6 minimum

width, should be installed directly

over one layer of render (without

nails) en every inferior joint

between panels (see Fig. 13) and

in places according to construction

details. Fiberglass mesh is not

required in case of suspended or

false ceilings.

Render and Finishes

Fig. 26: Housing projects.

Underneath Hebel Slab Panels can

be finish with Hebel Stucco,

gypsum plaster, acrylic texture

coat, elastomeric finishes, cement

based finishes; on floor panels

ceramic or clay tiles, laminated

stone, concrete pieces, carpet, etc.

can be used (see Fig. 27).

Roof panels can be finished using

membrane systems (SBS, APP,

etc), elastomeric roof coatings,

concrete or ceramic roof tiles,

asphalt roof shingles.

For more information and

technical assistance, please Fig. 27: Floor finish (marble).

contact AAC Texas.

Fig. 28: Multi-story building.

Hebel Aerated Concrete 11

December 2009. Printed and Made in Mexico.

Xella Mexicana, S.A. de C.V.

Ro Amacuzac 1201 Ote.

Col. Valle Oriente

Garza Garca, NL 66269

Mxico

Tels +52 (81) 8399 2424, 64 y 62

Fax +52 (81) 8399 2420 y 30

01 800 00 XELLA (93552)

ventasmexico@xella.com

Manufacturing Facility:

Carretera a Dulces Nombres Km 9.1

Pesquera, NL 66650

Mxico

Tel +52 (81) 8369 1515

Fax +52 (81) 8369 1520

Xella AAC Texas, Inc.

San Antonio Office:

900 Schneider Dr.

Cibolo, TX 78108

USA

Tel (210) 402 3223

Fax (210) 402 6390

1 888 SA XELLA (72 93552)

xellatexas@xella.com

Xella and Hebel are registered trademarks of Xella Group.

Rio Grande Valley Office:

700 East Expressway 83

San Juan, TX 78589

USA

Tel (956) 782 9065

Fax (956) 782 9068

xellatexas-rgv@xella.com

www.hebel.mx

www.xellatexas.com

Das könnte Ihnen auch gefallen

- Hebel MC v09.11Dokument12 SeitenHebel MC v09.11subhaschandraNoch keine Bewertungen

- Analysis For Schedule-2009 PDFDokument2.393 SeitenAnalysis For Schedule-2009 PDFVikrant Narayan VasudevaNoch keine Bewertungen

- Previews ANSI BHMA A156.4 2013 PreDokument5 SeitenPreviews ANSI BHMA A156.4 2013 PreNatalia Diaz100% (1)

- Upcoming Changes To Aisc 341 - Seismic Provisions For Structural Steel BuildingsDokument6 SeitenUpcoming Changes To Aisc 341 - Seismic Provisions For Structural Steel BuildingsFranco SerafiniNoch keine Bewertungen

- Pocs. Also Please Contact The Pocs WithDokument65 SeitenPocs. Also Please Contact The Pocs Withrize1159100% (1)

- TSC21-214 Apartments - 14 Prowse Street WEST PERTH - Structural - 2021-05-26Dokument38 SeitenTSC21-214 Apartments - 14 Prowse Street WEST PERTH - Structural - 2021-05-26Carent AyuNoch keine Bewertungen

- Structural For TenderDokument18 SeitenStructural For Tenderrimshabatoool72Noch keine Bewertungen

- Load Tables ASD K-SeriesDokument77 SeitenLoad Tables ASD K-SeriesEnrique Olvera LaraNoch keine Bewertungen

- 20160401b33d44-Scyon Axon Installation Manual May 2015 v2 FADokument8 Seiten20160401b33d44-Scyon Axon Installation Manual May 2015 v2 FAarhivojkanNoch keine Bewertungen

- Gypwall 3.2: General Purpose Metal Stud Partition SystemDokument20 SeitenGypwall 3.2: General Purpose Metal Stud Partition SystemA CNoch keine Bewertungen

- AacDokument3 SeitenAacbubunrintuNoch keine Bewertungen

- AWC Beam FormulasDokument26 SeitenAWC Beam FormulasR ASTUSNoch keine Bewertungen

- UFC 3-490-06 - 2018.06 - ElevatorsDokument48 SeitenUFC 3-490-06 - 2018.06 - ElevatorsMofasa ENoch keine Bewertungen

- As 4459.1-1999 Methods of Sampling and Testing Ceramic Tiles Sampling and Basis For AcceptanceDokument2 SeitenAs 4459.1-1999 Methods of Sampling and Testing Ceramic Tiles Sampling and Basis For AcceptanceSAI Global - APACNoch keine Bewertungen

- The Al Bahr Towers Enhancing SustainabilityDokument8 SeitenThe Al Bahr Towers Enhancing SustainabilityOlumide OkuneyeNoch keine Bewertungen

- Isolite: Technical Data ManualDokument15 SeitenIsolite: Technical Data Manualchillerz69Noch keine Bewertungen

- 4.8 Procedures For Nonstructural Components: CommentaryDokument20 Seiten4.8 Procedures For Nonstructural Components: CommentarymanohargudNoch keine Bewertungen

- Ronan Point Apartment Tower Collapse and Its Effect On Building CDokument7 SeitenRonan Point Apartment Tower Collapse and Its Effect On Building CAman 'kebe' KebedeNoch keine Bewertungen

- Building Envelope CorrosionDokument12 SeitenBuilding Envelope CorrosionJohnNoch keine Bewertungen

- Brief Ytong Advertising Jan 2011Dokument46 SeitenBrief Ytong Advertising Jan 2011Alexandra PascuNoch keine Bewertungen

- NFPA 285 Fire Testing For Exterior Walls: Code Requirements and Design ChallengesDokument1 SeiteNFPA 285 Fire Testing For Exterior Walls: Code Requirements and Design ChallengesaialosangelesNoch keine Bewertungen

- Galvalume Brochure Web2Dokument24 SeitenGalvalume Brochure Web2amitNoch keine Bewertungen

- Technical Data: Carbofol HDPE 406 1,0 S/s Smooth / Smooth OITDokument1 SeiteTechnical Data: Carbofol HDPE 406 1,0 S/s Smooth / Smooth OITAlex Lie100% (1)

- Masterseal 620 TdsDokument3 SeitenMasterseal 620 TdsNadeem Khan SelaniNoch keine Bewertungen

- Metsec Framing Detail sf445 PDFDokument1 SeiteMetsec Framing Detail sf445 PDFBanditAkosNoch keine Bewertungen

- False CeilingDokument23 SeitenFalse CeilingZhwan Anwar100% (1)

- TemperedGlassBible PDFDokument698 SeitenTemperedGlassBible PDFengineering masatalsahraaNoch keine Bewertungen

- 2008 Dahon User Manual enDokument32 Seiten2008 Dahon User Manual eninoblivionNoch keine Bewertungen

- Alubond Tech - Brochure PDFDokument8 SeitenAlubond Tech - Brochure PDFLjubisa TopicNoch keine Bewertungen

- Fortress Timber & Metal SDS Screws 2017 WebDokument36 SeitenFortress Timber & Metal SDS Screws 2017 WebGabriel MacedoNoch keine Bewertungen

- 4 Dygal ST, Mona Vale - Stormwater DrawingDokument8 Seiten4 Dygal ST, Mona Vale - Stormwater DrawingRohan Dutt SharmaNoch keine Bewertungen

- Soetens 2008Dokument37 SeitenSoetens 2008jvs11021102Noch keine Bewertungen

- Branz Advisory Trower PartitionsDokument6 SeitenBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- Safe Load TablesDokument12 SeitenSafe Load TablesdeviationzNoch keine Bewertungen

- Anchors Fundamentals - Hilti PDFDokument24 SeitenAnchors Fundamentals - Hilti PDFIho1Noch keine Bewertungen

- Rolltec Coupler BrochureDokument4 SeitenRolltec Coupler BrochureMohammad Aasimuddin100% (1)

- Sikatherm® Foam 45 IN: Product Data SheetDokument4 SeitenSikatherm® Foam 45 IN: Product Data SheetTarun KumarNoch keine Bewertungen

- Connection Details: 264 Reynoldsdale Road, Bedford, PA 15522-7401 Phone: 814-623-8125Dokument7 SeitenConnection Details: 264 Reynoldsdale Road, Bedford, PA 15522-7401 Phone: 814-623-8125Cancio FlorezNoch keine Bewertungen

- SALUMCO Pre QualificationDokument135 SeitenSALUMCO Pre QualificationNayeemuddin KhajaNoch keine Bewertungen

- Star Building Systems - 2 - 1Dokument27 SeitenStar Building Systems - 2 - 1NiranjanAryanNoch keine Bewertungen

- Hebel Tech Manual 3Dokument79 SeitenHebel Tech Manual 3subhaschandraNoch keine Bewertungen

- S0104 ENG Double Portal Frame Hanger Open FarmDokument23 SeitenS0104 ENG Double Portal Frame Hanger Open Farmrimshabatoool72Noch keine Bewertungen

- Apton Partitioning Brochure 2018 19 2 PDFDokument48 SeitenApton Partitioning Brochure 2018 19 2 PDFMarcelo CariatiNoch keine Bewertungen

- HDG Datasheet 4b A Guide To Hot Dip Galvanizing To Standard BS en ISO 1461 Low Res LDokument2 SeitenHDG Datasheet 4b A Guide To Hot Dip Galvanizing To Standard BS en ISO 1461 Low Res LMehman NasibovNoch keine Bewertungen

- Hambro Joist Typical DetailsDokument27 SeitenHambro Joist Typical DetailsjgjgNoch keine Bewertungen

- Glass CorrosionDokument8 SeitenGlass CorrosionCan Yigit DincNoch keine Bewertungen

- Counter Top SpecsDokument12 SeitenCounter Top Specsapi-3797031100% (3)

- Wood ScrewsDokument178 SeitenWood ScrewsOmar AL-jazairiNoch keine Bewertungen

- 55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Dokument2 Seiten55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Syed Raja AdeelNoch keine Bewertungen

- Armaseam Technical BrochureDokument24 SeitenArmaseam Technical BrochureMuraleedharanNoch keine Bewertungen

- 16 10 25 Epd 7 Reynaers Curtain Wall CW 50 r01Dokument14 Seiten16 10 25 Epd 7 Reynaers Curtain Wall CW 50 r01supadiNoch keine Bewertungen

- Ramp AreaDokument1 SeiteRamp AreaAhmed KowaiderNoch keine Bewertungen

- Trimdek: Design and Installation GuideDokument6 SeitenTrimdek: Design and Installation GuideHarold SanaresNoch keine Bewertungen

- White Book C04 S11 Partitions Non Loadbearing Timber StudDokument17 SeitenWhite Book C04 S11 Partitions Non Loadbearing Timber StudPavaloaie Marian ConstantinNoch keine Bewertungen

- 2-2 Building Construction MethodsDokument36 Seiten2-2 Building Construction MethodsVũ Thị Hà TrangNoch keine Bewertungen

- Intumescent Adhesion StudyDokument58 SeitenIntumescent Adhesion StudyPeter ThomsonNoch keine Bewertungen

- In-Plant Testing Guidelines For Manufacturers and Independent Laboratories AAMA 205-01Dokument4 SeitenIn-Plant Testing Guidelines For Manufacturers and Independent Laboratories AAMA 205-01DavidNoch keine Bewertungen

- UFC 1-200-01 General Building Requirements, With Change 1 (11!27!2007)Dokument14 SeitenUFC 1-200-01 General Building Requirements, With Change 1 (11!27!2007)Bob Vines100% (1)

- Astm C-1178-1 PDFDokument3 SeitenAstm C-1178-1 PDFibrahim0% (1)

- Hebel MC v09.11Dokument12 SeitenHebel MC v09.11Majed NabeelNoch keine Bewertungen

- Riyad Metro DWGDokument15 SeitenRiyad Metro DWGAbu100% (1)

- Bolts (Al Rashed Fastners) PDFDokument71 SeitenBolts (Al Rashed Fastners) PDFAbuNoch keine Bewertungen

- Hilti 2011 Anchor Fastening Technical Guide B25981 PDFDokument389 SeitenHilti 2011 Anchor Fastening Technical Guide B25981 PDFChristian D. OrbeNoch keine Bewertungen

- Mac Alloy TensionDokument16 SeitenMac Alloy TensionAbuNoch keine Bewertungen

- Bolts (Al Rashed Fastners) PDFDokument71 SeitenBolts (Al Rashed Fastners) PDFAbu100% (1)

- Design of Square Footing (With or Without Moment)Dokument13 SeitenDesign of Square Footing (With or Without Moment)Ella Clent moralesNoch keine Bewertungen

- CE3155-1-Introduction 2011Dokument47 SeitenCE3155-1-Introduction 2011huiting loy100% (1)

- Nib CalculationDokument1 SeiteNib CalculationKen LuuNoch keine Bewertungen

- 12 Propeller CavitationDokument24 Seiten12 Propeller CavitationAbdelrahman Atef ElbashNoch keine Bewertungen

- Otech 1998234255-275Dokument21 SeitenOtech 1998234255-275Arun PatelNoch keine Bewertungen

- Design Concrete SleepersDokument16 SeitenDesign Concrete SleepersOky Andytya Pratama100% (1)

- Water and Fabric RelationshipDokument3 SeitenWater and Fabric RelationshipibrahimNoch keine Bewertungen

- Filtration ExampleDokument17 SeitenFiltration ExampleAbelNoch keine Bewertungen

- Stainles Steel Transformation PDFDokument22 SeitenStainles Steel Transformation PDFAyush MishraNoch keine Bewertungen

- Numéro de Repère: Date: 06/05/2016 87 PSV-23: Relief Device Calculation SheetDokument1 SeiteNuméro de Repère: Date: 06/05/2016 87 PSV-23: Relief Device Calculation SheetDiby AlainNoch keine Bewertungen

- Geotechnical Engineering ReportDokument31 SeitenGeotechnical Engineering ReportNadir Khattak Jr.Noch keine Bewertungen

- Sub: Price Structure For 80mm and 100mm Interlock PaversDokument1 SeiteSub: Price Structure For 80mm and 100mm Interlock PaversDeepNoch keine Bewertungen

- 20 Ton Crane Weight & Wheel Load CalculationDokument2 Seiten20 Ton Crane Weight & Wheel Load CalculationAdeeb ShahzadaNoch keine Bewertungen

- Design of Intake Stoplog R0Dokument25 SeitenDesign of Intake Stoplog R0Sujeet Kumar50% (2)

- Cross Flow Part 1Dokument5 SeitenCross Flow Part 1mohmmad othmanNoch keine Bewertungen

- S8 - Pile Driving Analyzer (PDA) and CAPWAP Proven Pile Testing Technology Principles and Recent Advances - LTC2013Dokument46 SeitenS8 - Pile Driving Analyzer (PDA) and CAPWAP Proven Pile Testing Technology Principles and Recent Advances - LTC2013walaywan100% (3)

- AD 288 Discontinuous Columns in Simple Construction Beam-Column ConnectionDokument3 SeitenAD 288 Discontinuous Columns in Simple Construction Beam-Column ConnectionMarco GomesNoch keine Bewertungen

- Adobe Scan 15-Dec-2022Dokument12 SeitenAdobe Scan 15-Dec-2022zoro roronoaNoch keine Bewertungen

- List of Unauthorized Construction of Building Department-I, South Zone 01.06.2018 To 30.09.2018Dokument10 SeitenList of Unauthorized Construction of Building Department-I, South Zone 01.06.2018 To 30.09.2018BALAJI ASSOCIATESNoch keine Bewertungen

- FM Mod4@Azdocuments - inDokument17 SeitenFM Mod4@Azdocuments - inVivek Thakur Sujanian100% (1)

- Mathcad - 2Dokument4 SeitenMathcad - 2Desejo SozinandoNoch keine Bewertungen

- 5.determination of Shrinkage Limit of SoilDokument3 Seiten5.determination of Shrinkage Limit of Soilashrithareddy yeddula19Noch keine Bewertungen

- SOR Civil Works - Assam PWD Schedule - 2013-14Dokument176 SeitenSOR Civil Works - Assam PWD Schedule - 2013-14Anamika Tiwary78% (169)

- Composite Floor - FlavsDokument5 SeitenComposite Floor - FlavszewilkNoch keine Bewertungen

- CEE 110 Lecture 1Dokument29 SeitenCEE 110 Lecture 1Tousif RahmanNoch keine Bewertungen

- EuroCode - Wind Load Calculation - Part 2Dokument5 SeitenEuroCode - Wind Load Calculation - Part 2RigonDECNoch keine Bewertungen

- Crystalline Waterproofing TechnologyDokument8 SeitenCrystalline Waterproofing TechnologyKiran Kumar JhaNoch keine Bewertungen

- Design Analysis and Optimization of Offshore ModuleDokument116 SeitenDesign Analysis and Optimization of Offshore ModuleMirceaNoch keine Bewertungen

- Hardinge Bridge To Padma BridgeDokument23 SeitenHardinge Bridge To Padma BridgeBridge WingNoch keine Bewertungen

- Advanced Construction MaterialsDokument16 SeitenAdvanced Construction MaterialsEsakki RajaNoch keine Bewertungen

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansBewertung: 4.5 von 5 Sternen4.5/5 (21)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Von EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Noch keine Bewertungen

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresVon EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresBewertung: 1 von 5 Sternen1/5 (2)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetVon EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetBewertung: 4.5 von 5 Sternen4.5/5 (10)

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (138)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeVon EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeBewertung: 4.5 von 5 Sternen4.5/5 (59)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsVon EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNoch keine Bewertungen

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyVon EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Advanced Modelling Techniques in Structural DesignVon EverandAdvanced Modelling Techniques in Structural DesignBewertung: 5 von 5 Sternen5/5 (3)

- Troubleshooting and Repair of Diesel EnginesVon EverandTroubleshooting and Repair of Diesel EnginesBewertung: 1.5 von 5 Sternen1.5/5 (2)

- Piping Engineering Leadership for Process Plant ProjectsVon EverandPiping Engineering Leadership for Process Plant ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesVon EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownVon EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownNoch keine Bewertungen

- Introduction To Civil EngineeringVon EverandIntroduction To Civil EngineeringBewertung: 3.5 von 5 Sternen3.5/5 (5)

- Summary of Taiichi Ohno's Taiichi Ohno's Workplace ManagementVon EverandSummary of Taiichi Ohno's Taiichi Ohno's Workplace ManagementNoch keine Bewertungen

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesVon EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNoch keine Bewertungen

- Structural Cross Sections: Analysis and DesignVon EverandStructural Cross Sections: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (19)