Beruflich Dokumente

Kultur Dokumente

PressureReliefValves Specs

Hochgeladen von

nmosilvaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PressureReliefValves Specs

Hochgeladen von

nmosilvaCopyright:

Verfügbare Formate

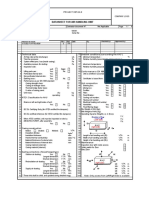

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-7501/1 & 2 Other Specify: Specify:

3. Service, Line, Equip. No: TK-7501 8. Comply with API 526: Yes X No

4. Number Required: 2 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN 20 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 13.800 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: 6 barG 59. Other Specify:

43. Set pressure and units: 10 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: 40 C C Sizing and Selection

47. Relieving Temperature: 65 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-7502 Other Specify: Specify:

3. Service, Line, Equip. No: HE-7501/1 8. Comply with API 526: Yes X No

4. Number Required: 1 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN 50 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 5.770 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: 6 barG 59. Other Specify:

43. Set pressure and units: 10 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: 40 C C Sizing and Selection

47. Relieving Temperature: 65 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-7503 Other Specify: Specify:

3. Service, Line, Equip. No: HE-7501/2 8. Comply with API 526: Yes X No

4. Number Required: 1 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN 50 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 5.770 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: 6 barG 59. Other Specify:

43. Set pressure and units: 10 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: 40 C C Sizing and Selection

47. Relieving Temperature: 65 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-7504 Other Specify: Specify:

3. Service, Line, Equip. No: HE-7502 8. Comply with API 526: Yes X No

4. Number Required: 1 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN 50 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 3.280 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: 6 barG 59. Other Specify:

43. Set pressure and units: 10 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: 40 C C Sizing and Selection

47. Relieving Temperature: 65 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-7501/1 & 2 Other Specify: Specify:

3. Service, Line, Equip. No: TK-7301/3 8. Comply with API 526: Yes X No

4. Number Required: 2 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN 80 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 44.000 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: barG 59. Other Specify:

43. Set pressure and units: 6 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: C Sizing and Selection

47. Relieving Temperature: 46 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-3208/1&2 Other Specify: Specify:

3. Service, Line, Equip. No: PL-3201/1 8. Comply with API 526: Yes X No

4. Number Required: 2 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN15 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 58.800 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: barG 59. Other Specify:

43. Set pressure and units: 11 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: C Sizing and Selection

47. Relieving Temperature: 70 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-3209/1&2 Other Specify: Specify:

3. Service, Line, Equip. No: PL-3201/2 8. Comply with API 526: Yes X No

4. Number Required: 2 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN 80 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 58.800 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: barG 59. Other Specify:

43. Set pressure and units: 11 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: C Sizing and Selection

47. Relieving Temperature: 70 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-3210/1&2 Other Specify: Specify:

3. Service, Line, Equip. No: PL-3201/3 8. Comply with API 526: Yes X No

4. Number Required: 2 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN15 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 58.800 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: barG 59. Other Specify:

43. Set pressure and units: 11 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: C Sizing and Selection

47. Relieving Temperature: 70 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-3211/1&2 Other Specify: Specify:

3. Service, Line, Equip. No: PL-3201/4 8. Comply with API 526: Yes X No

4. Number Required: 2 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN15 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 58.800 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: barG 59. Other Specify:

43. Set pressure and units: 11 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: C Sizing and Selection

47. Relieving Temperature: 70 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-7505/1&2 Other Specify: Specify:

3. Service, Line, Equip. No: TK-7510 8. Comply with API 526: Yes X No

4. Number Required: 2 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN 15 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 6.200 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: 6 barG 59. Other Specify:

43. Set pressure and units: 10 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: 40 C C Sizing and Selection

47. Relieving Temperature: 65 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

PRESSURE RELIEF VALVE

General Basis of Selection

1. Item Number: 7. Code: ASME Sec. VIII Yes X No Stamp?: Yes No X

2. Tag Number: PSV-1201/1&2 Other Specify: Specify:

3. Service, Line, Equip. No: TK-1201 8. Comply with API 526: Yes X No

4. Number Required: 2 9. Fire Specify:

5. 10. Rupture disk: Yes X No

6. 11. Diverter Valve Yes X No

Valve Design Materials

12. Design Type: Safety Relief 23. Body: CS

Conventional X Bellows X Balanced Piston 24. Bonnet: CS

13. Nozzle type: Full X Semi 25. Seat (Nozzle): SS

Other. Specify: 26. Resilient Seat: Acording to manufactuer

14. Bonnet type: Open Closed X 27. Guide: Acording to manufactuer

15. Seat type: Metal-to-metal X Resilient 28. Adjusting Ring Acording to manufactuer

16. Seat Type: API 527 Seat 29. Spring Acording to manufactuer

Other. Specify: 30. Bellows: Acording to manufactuer

Connections 31. Balanced piston: N/A

17. Equipment inlet dimension: DN 100 32. Comply with NACE MR0175: Yes No X

18. Equipment outlet dimension: 33. Other Specify:

19. Equipment Inlet / outletsize standard: EN 1092 - type 11 34.

20. Valvet inlet dimension: Acc. Manufacturer 35.

21. Valve outlet dimension: Acc. Manufacturer 36.

22. Equipment Inlet / outletsize standard: EN 1092 - type 11 37.

Service condition Accessories

38. Fluid and State: VCM (Vinyl Chlorine Monomer) 55. Cap: Screwed Bolted X

39. Required Capacity: 20.540 kg/h 56. Lifting Lever: Plain Packed: None X

40. Molecular Weight or Specific Gravity: 62.5 g/mol 57. Test tag: Yes X No

41. Viscosity at Flowing Temperature : 58. Bug Screen Yes No X

42. Operating Pressure & Units: 6 barG 59. Other Specify:

43. Set pressure and units: 14 barG 60.

44. Blowdown: 61.

45. Specific heat coefficient: 334.1((lbm.lbmol.R))/(lbf.hr) 62.

46. Operating Temperature: 40 C C Sizing and Selection

47. Relieving Temperature: 80 C C 63. Calculated Orifice Area (square inches):

48. Built-up Back Pressure: Atm 64. Selected Orifice Area (square inches):

49. Superimposed Back Pressures: 65. Orifice Designation (letter):

50. Cold differential Test Pressure: 66. Manufacturer:

51. Allowable Overpressure in Percent or Units: 67. Model Number:

52. Compressibility Factor, Z: 0.84 68. Vendor Calculations Required: Yes X No

53. Ratio of Specific Heats: 1.183 69.

54. Density at Flowing Temperature: 800 kg / m^3 70.

Das könnte Ihnen auch gefallen

- Strength BiasDokument11 SeitenStrength BiasnmosilvaNoch keine Bewertungen

- Supercritical Fluid Technology For Drug Product Development (2004)Dokument688 SeitenSupercritical Fluid Technology For Drug Product Development (2004)Regiani Almeida Rezende100% (1)

- Mech. Design CalculationDokument182 SeitenMech. Design CalculationSajad AbdulNoch keine Bewertungen

- Characterization of Gaskets Flange ConnectionsDokument18 SeitenCharacterization of Gaskets Flange ConnectionsnmosilvaNoch keine Bewertungen

- Jovanovic - Comparison Between The New European Risk-Based Inspection (RBI) Standard EN16991 2018Dokument65 SeitenJovanovic - Comparison Between The New European Risk-Based Inspection (RBI) Standard EN16991 2018nmosilvaNoch keine Bewertungen

- Technical Data Sheets - Centrifugal Pumps ANSIDokument6 SeitenTechnical Data Sheets - Centrifugal Pumps ANSIAdit NugrahaNoch keine Bewertungen

- ACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgDokument2 SeitenACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgbaccour bilelNoch keine Bewertungen

- 03 Blending PowerpointDokument70 Seiten03 Blending PowerpointNinhHoàngHải100% (4)

- (Solutions Chapter) Introduction To Plasma Physics and Controlled Fusion Plasma Physics - Francis F. ChenDokument47 Seiten(Solutions Chapter) Introduction To Plasma Physics and Controlled Fusion Plasma Physics - Francis F. ChenLu Young80% (5)

- Triathlon Strength Training GuideDokument5 SeitenTriathlon Strength Training Guidenmosilva100% (1)

- NHT-P51-00032 04MDokument937 SeitenNHT-P51-00032 04MnmosilvaNoch keine Bewertungen

- 5060 Piping and ValvesDokument9 Seiten5060 Piping and Valvesnmosilva100% (1)

- Journal: Scaling: How Less Can Be MoreDokument8 SeitenJournal: Scaling: How Less Can Be MorenmosilvaNoch keine Bewertungen

- Api 1120Dokument17 SeitenApi 1120nmosilva100% (2)

- TWI Current Practice For Welding P92 PDFDokument13 SeitenTWI Current Practice For Welding P92 PDFpipedown456100% (1)

- Data Sheet For PSVDokument1 SeiteData Sheet For PSVBABILIN VNoch keine Bewertungen

- PVVDokument10 SeitenPVVJorge Arturo Rodríguez HerreraNoch keine Bewertungen

- CK-E61 H - Generator Set Onan-Cummins Generic2Dokument5 SeitenCK-E61 H - Generator Set Onan-Cummins Generic2Edward SchenkNoch keine Bewertungen

- Instructions For The Use of Allied Valve Control Valve Spec SheetDokument4 SeitenInstructions For The Use of Allied Valve Control Valve Spec Sheetmainur mechanical engineerNoch keine Bewertungen

- MFV MasterChoke 2013Dokument8 SeitenMFV MasterChoke 2013claudio godinezNoch keine Bewertungen

- Project NoDokument1 SeiteProject Nokoraina2015Noch keine Bewertungen

- AHU Datasheet Sample Detailed Page 1 of 6 1635440149Dokument1 SeiteAHU Datasheet Sample Detailed Page 1 of 6 1635440149alim khanNoch keine Bewertungen

- PSV-Scrapper TrapDokument1 SeitePSV-Scrapper TrapUmer KhanNoch keine Bewertungen

- CK-E73 H - Generator Set Detroit Diesel - Series 71 In-Line2Dokument5 SeitenCK-E73 H - Generator Set Detroit Diesel - Series 71 In-Line2Edward SchenkNoch keine Bewertungen

- Relief 5Dokument5 SeitenRelief 5Mo ZeroNoch keine Bewertungen

- PSV WordDokument1 SeitePSV WordL KISHORE REDDYNoch keine Bewertungen

- CK-E55 H - Generator Set Caterpillar2Dokument6 SeitenCK-E55 H - Generator Set Caterpillar2Edward SchenkNoch keine Bewertungen

- BPCL Technical-DataSheet-a8a979Dokument13 SeitenBPCL Technical-DataSheet-a8a979cnrk777inNoch keine Bewertungen

- SPC/PNSDP-LPG/1/2012: of 3 Barg Req. When 50% Closed at 6,270 L/min FlowDokument1 SeiteSPC/PNSDP-LPG/1/2012: of 3 Barg Req. When 50% Closed at 6,270 L/min Flowkoraina2015Noch keine Bewertungen

- Pressure Reducing-Relief Valves Hydraulics-Rexroth Series ZDRDokument12 SeitenPressure Reducing-Relief Valves Hydraulics-Rexroth Series ZDRJORGE ALBERTO PEREZ RAMIREZNoch keine Bewertungen

- ECP Jo Colombia 3102124385 Quote Number:: Pressure Relief Valve Sizing & Selection ReportDokument6 SeitenECP Jo Colombia 3102124385 Quote Number:: Pressure Relief Valve Sizing & Selection ReportJorge LemusNoch keine Bewertungen

- Extracted Pages From NAFD-CPFXXX-ECME-DSME-0042-AB - Data Sheet For Pressurized Deaerator (v-13550)Dokument3 SeitenExtracted Pages From NAFD-CPFXXX-ECME-DSME-0042-AB - Data Sheet For Pressurized Deaerator (v-13550)Mo OsNoch keine Bewertungen

- Data Sheet Centrifugal Pump: Client: Location: Service: Plant: Supplier MFR.: Equipment No.Dokument4 SeitenData Sheet Centrifugal Pump: Client: Location: Service: Plant: Supplier MFR.: Equipment No.zvlcar nainNoch keine Bewertungen

- DESIGNDokument211 SeitenDESIGNAbinNoch keine Bewertungen

- PSV Preliminary Documents - Oxidizer BurnerDokument8 SeitenPSV Preliminary Documents - Oxidizer BurnerEsneyNoch keine Bewertungen

- 1 Pieza PSV-3X4Dokument4 Seiten1 Pieza PSV-3X4jose ocanaNoch keine Bewertungen

- PRV SizingDokument28 SeitenPRV Sizingjithin.rjn4055Noch keine Bewertungen

- 00000-JDS-015 (ERV Manhole) Rev 0Dokument10 Seiten00000-JDS-015 (ERV Manhole) Rev 0sithulibraNoch keine Bewertungen

- PSV Bombas AcpilodosDokument1 SeitePSV Bombas AcpilodosJulian Camilo Segura BermudezNoch keine Bewertungen

- Forged Cast Trunnion Ball Valves PDFDokument24 SeitenForged Cast Trunnion Ball Valves PDFAnggi SujiwoNoch keine Bewertungen

- GeneralDokument6 SeitenGeneralmilton1987Noch keine Bewertungen

- Zeus Energy SAC Peru +51949827888 Quote Number:: Pressure Relief Valve Sizing & Selection ReportDokument5 SeitenZeus Energy SAC Peru +51949827888 Quote Number:: Pressure Relief Valve Sizing & Selection ReportJorge Rodriguez HerreraNoch keine Bewertungen

- Packaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorDokument6 SeitenPackaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorNuzul FurqonyNoch keine Bewertungen

- Centrifugal Pump Data SheetDokument8 SeitenCentrifugal Pump Data SheetCarlos GomezNoch keine Bewertungen

- Valvula wh6Dokument16 SeitenValvula wh6Willam Hugo Luna PonteNoch keine Bewertungen

- 100 PSV 001 AZ Safety Pressure Valve (Design)Dokument2 Seiten100 PSV 001 AZ Safety Pressure Valve (Design)magdy salehNoch keine Bewertungen

- Submittals ChillersDokument17 SeitenSubmittals ChillersCastañeda JoanNoch keine Bewertungen

- Israel Flores Valvula 2Dokument2 SeitenIsrael Flores Valvula 2Israel Flores MamaniNoch keine Bewertungen

- BE-WI-248-01-F19 Datasheet Breather ValveDokument3 SeitenBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNoch keine Bewertungen

- LCV 105Dokument1 SeiteLCV 105Juan Krloz CastañedaNoch keine Bewertungen

- Control Valve Specification SheetDokument1 SeiteControl Valve Specification SheetJuan Krloz CastañedaNoch keine Bewertungen

- 07-PSV-07 Folha de Dados ValbracDokument1 Seite07-PSV-07 Folha de Dados ValbracRODRIGO CARDOSONoch keine Bewertungen

- Valvula de Seguridad Patin Auxiliar TerniumDokument1 SeiteValvula de Seguridad Patin Auxiliar TerniumSearch45Noch keine Bewertungen

- Asme Strength Calculation ManualDokument37 SeitenAsme Strength Calculation ManualPrakashNoch keine Bewertungen

- Essence Mixing Tank Technical Bid Evaluation: Kg/batch Bar (G) Bar (G) °C °CDokument3 SeitenEssence Mixing Tank Technical Bid Evaluation: Kg/batch Bar (G) Bar (G) °C °CHaries Bugarin GarciaNoch keine Bewertungen

- FCV 103Dokument1 SeiteFCV 103Juan Krloz CastañedaNoch keine Bewertungen

- ValvulaDokument1 SeiteValvulaSergio Jhordan Garcia ClarosNoch keine Bewertungen

- Alejandra PDFDokument1 SeiteAlejandra PDFCristian Melendres OrellanaNoch keine Bewertungen

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDokument1 SeiteL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77Noch keine Bewertungen

- SimSolid 2019 VerificationManual-1Dokument114 SeitenSimSolid 2019 VerificationManual-1André Ricardo MoschenNoch keine Bewertungen

- EMI Marco Antonio Serrano Bazán Bolivia 6945986 Quote NumberDokument1 SeiteEMI Marco Antonio Serrano Bazán Bolivia 6945986 Quote NumberMarcoAntonioSerranoBazanNoch keine Bewertungen

- Opal Wwts - Tender Doc - Part 3 1411817364 14Dokument1 SeiteOpal Wwts - Tender Doc - Part 3 1411817364 14SHIVAJINoch keine Bewertungen

- Indicação de Pessoas No Caso de Urgencia e Emergencia.Dokument80 SeitenIndicação de Pessoas No Caso de Urgencia e Emergencia.nathan lucasNoch keine Bewertungen

- 01.data SheetDokument1 Seite01.data SheetBhargav PatelNoch keine Bewertungen

- SBD 0631 ValveDokument3 SeitenSBD 0631 ValvewodrNoch keine Bewertungen

- Rotary Pump Data SheetDokument6 SeitenRotary Pump Data SheetCarlos GomezNoch keine Bewertungen

- Data Sheet of High Pressure PumpDokument2 SeitenData Sheet of High Pressure Pumpsajeesh5113699Noch keine Bewertungen

- Emerson Automation Solutions 3950 Greenbriar Stafford TX, 77477 United States (281) 274-4400 Quote NumberDokument1 SeiteEmerson Automation Solutions 3950 Greenbriar Stafford TX, 77477 United States (281) 274-4400 Quote NumberYamil Castro FernandezNoch keine Bewertungen

- Control Valve Specification SheetDokument1 SeiteControl Valve Specification SheetJuan Krloz CastañedaNoch keine Bewertungen

- Technical Manual: Split Unit Air Conditioner Wall Mounted C Series - Cooling Only (50Hz)Dokument31 SeitenTechnical Manual: Split Unit Air Conditioner Wall Mounted C Series - Cooling Only (50Hz)Wai Lwin KoNoch keine Bewertungen

- 0ZVPULS051 Sump Pit LS S-W Data SheetDokument1 Seite0ZVPULS051 Sump Pit LS S-W Data Sheetjean-marie BOGUYNoch keine Bewertungen

- Criticality Analysis For Assets Priority Setting of Abadan Oil Refinery Using AHP and DelphiDokument7 SeitenCriticality Analysis For Assets Priority Setting of Abadan Oil Refinery Using AHP and DelphinmosilvaNoch keine Bewertungen

- D2Z Angled Armrest Wedges Key InformationDokument4 SeitenD2Z Angled Armrest Wedges Key InformationnmosilvaNoch keine Bewertungen

- Garlock Gasketing GYLON Standard Style 3501-E 2.0mm DIN EN13555 Datasheet Rev.3 KU25318 en EU LRDokument3 SeitenGarlock Gasketing GYLON Standard Style 3501-E 2.0mm DIN EN13555 Datasheet Rev.3 KU25318 en EU LRnmosilvaNoch keine Bewertungen

- Ageing of Hazardous InstallationsDokument34 SeitenAgeing of Hazardous InstallationsnmosilvaNoch keine Bewertungen

- Iaea Safety Standards and Other Publications For Ageing Maanagement and Long Term Operation of Nuclear Power PlantsDokument12 SeitenIaea Safety Standards and Other Publications For Ageing Maanagement and Long Term Operation of Nuclear Power PlantsnmosilvaNoch keine Bewertungen

- Csni r2002 26Dokument32 SeitenCsni r2002 26nmosilvaNoch keine Bewertungen

- TK18 Madone Whitepaper en-GBDokument30 SeitenTK18 Madone Whitepaper en-GBnmosilvaNoch keine Bewertungen

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDokument1 SeiteGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaNoch keine Bewertungen

- Official Crossfit Warm-Up Warm Up DDokument1 SeiteOfficial Crossfit Warm-Up Warm Up DnmosilvaNoch keine Bewertungen

- The All-New Speed Concept: The Fastest Bike Just Got FasterDokument40 SeitenThe All-New Speed Concept: The Fastest Bike Just Got FasternmosilvaNoch keine Bewertungen

- Trek-Seed PconceptDokument36 SeitenTrek-Seed PconceptnmosilvaNoch keine Bewertungen

- Ppcon Additional Technical RequirementsDokument13 SeitenPpcon Additional Technical RequirementsnmosilvaNoch keine Bewertungen

- 4621 Rev 01Dokument11 Seiten4621 Rev 01nmosilvaNoch keine Bewertungen

- Angus Thermospray NozzleDokument1 SeiteAngus Thermospray NozzlenmosilvaNoch keine Bewertungen

- Project Report AdsorptionDokument9 SeitenProject Report AdsorptionKajal panchalNoch keine Bewertungen

- Aspen Plus - Cetic Anhyhdrate ReactorsDokument6 SeitenAspen Plus - Cetic Anhyhdrate ReactorsGyan PrameswaraNoch keine Bewertungen

- Materials and Processes For Agricultural and Biosystems EngineeringDokument17 SeitenMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioNoch keine Bewertungen

- MSDS BenzeneDokument3 SeitenMSDS BenzeneUmair JavedNoch keine Bewertungen

- Agar Desalter Control Sys3 Appl 3Dokument2 SeitenAgar Desalter Control Sys3 Appl 3JADNoch keine Bewertungen

- S Start of Lesson E End of Lesson Grading 1-5: Learning Outcomes Progress ArrowDokument30 SeitenS Start of Lesson E End of Lesson Grading 1-5: Learning Outcomes Progress ArrowYu Seung KimNoch keine Bewertungen

- Design of FRP-Profiles & All-FRP-Structures (2009) - Presentation PDFDokument67 SeitenDesign of FRP-Profiles & All-FRP-Structures (2009) - Presentation PDFJulio Humberto Díaz RondánNoch keine Bewertungen

- Fish Processing HandoutDokument1 SeiteFish Processing HandoutGre ChieNoch keine Bewertungen

- Light-Exposure Test Method by Xenon-Arc Lamp For Automotive InteriorDokument20 SeitenLight-Exposure Test Method by Xenon-Arc Lamp For Automotive InteriorMahmood KhanNoch keine Bewertungen

- Potent Antimutagenic Activity of White Tea in Comparison With Green Tea in The Salmonella AssayDokument15 SeitenPotent Antimutagenic Activity of White Tea in Comparison With Green Tea in The Salmonella AssayPhan Anh TrịnhNoch keine Bewertungen

- CHAPTER 3c MOLECULAR DIFFUSION IN SOLIDSDokument18 SeitenCHAPTER 3c MOLECULAR DIFFUSION IN SOLIDSkiran367Noch keine Bewertungen

- Acid SlurryDokument8 SeitenAcid SlurryVinod GoelNoch keine Bewertungen

- Nanoformulation of Curcuma Longa Root Extract and Evaluation of Its Dissolution PotentialDokument9 SeitenNanoformulation of Curcuma Longa Root Extract and Evaluation of Its Dissolution Potentialmuhammad adnan ayubNoch keine Bewertungen

- Florgard Epu SL - TDSDokument3 SeitenFlorgard Epu SL - TDSGabriel GabeNoch keine Bewertungen

- Lai BinglinDokument22 SeitenLai BinglinNicholas Chin Yong LekNoch keine Bewertungen

- Energetics QuestionsDokument72 SeitenEnergetics QuestionsSahaj SinghNoch keine Bewertungen

- UV VIS CaffeineDokument15 SeitenUV VIS CaffeineTinuviele EsguerraNoch keine Bewertungen

- Cover Lab ReportDokument5 SeitenCover Lab ReportadlenaNoch keine Bewertungen

- Assignment 1 - Mass and Energy Balance March 2020Dokument2 SeitenAssignment 1 - Mass and Energy Balance March 2020Porkkodi SugumaranNoch keine Bewertungen

- Acid Bases and SaltsDokument1 SeiteAcid Bases and SaltsSherida GibbsNoch keine Bewertungen

- Continuous Winemaking Fermentation Using Quince-Immobilized Yeast at Room and Low TemperaturesDokument6 SeitenContinuous Winemaking Fermentation Using Quince-Immobilized Yeast at Room and Low TemperaturesLoc VotuongNoch keine Bewertungen

- Brosur Multi Block Retaining Wall SystemDokument7 SeitenBrosur Multi Block Retaining Wall SystemIsparmoNoch keine Bewertungen

- Stem Gc11cb Iid G 70Dokument3 SeitenStem Gc11cb Iid G 70jeffrey yumang100% (1)

- Basic Laboratory Glassware and EquipmentDokument11 SeitenBasic Laboratory Glassware and EquipmentSheila Mae BaranganNoch keine Bewertungen

- Papercrete4 PDFDokument9 SeitenPapercrete4 PDFPrasad TekadeNoch keine Bewertungen

- Biological and Physicochemical Indicators of Water Quality in Libreville and Its SurroundingsDokument7 SeitenBiological and Physicochemical Indicators of Water Quality in Libreville and Its SurroundingsInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen