Beruflich Dokumente

Kultur Dokumente

Influence of Softening Test and Light Activation Protocols On Resin Composite Polymer Structure

Hochgeladen von

Aini Dwi HandiniOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Influence of Softening Test and Light Activation Protocols On Resin Composite Polymer Structure

Hochgeladen von

Aini Dwi HandiniCopyright:

Verfügbare Formate

[Downloaded free from http://www.eurjdent.com on Thursday, February 11, 2016, IP: 36.83.94.

120]

Original Article

Influence of softening test and lightactivation

protocols on resin composite polymer structure

Maria Ceclia Caldas Giorgi1, Dbora Alves Nunes Leite Lima1, Giselle Maria Marchi1,

Glucia Maria Ambrosano2, Flvio Henrique Baggio Aguiar1

1

Department of Restorative Dentistry Piracicaba Dental

School, University of Campinas, PiracicabaSP, Brazil,

Correspondence: Dr. Maria Ceclia Caldas Giorgi 2

Department of Social Dentistry, Piracicaba Dental

Email: cecilia.giorgi@yahoo.com School, University of Campinas, PiracicabaSP, Brazil

ABSTRACT

Objective: This study analyzed the influences of the lightactivation protocol and softening test on the degree of conversion(DC)

and Knoop Hardness (KHN) of a microhybrid resin composite. Materials and Methods: Filtek Z250 (3M ESPE) was

lightactivated with a thirdgeneration lightemitting diode(Valo Ultradent) by three protocolsstandard, high power, and

plasma emulationor with a quartztungsten halogen XL 3000(3M ESPE) in conventional mode. All modes were set to deliver

19 J/cm2. The DC(N=20) was determined by Fourier transform infrared spectrometry on the top(T) and bottom(B) surfaces.

For the KHN test, samples were subdivided in four groups(n=5 each) according to the storage media: absolute ethanol,

75% ethanol, distilled water, and air(control group). The KHN values were evaluated on T and B before and 24 h after immersion

in the storage media. Data were analyzed by splitplot analysis of variance(ANOVA; for DC) or repeatedmeasures splitplot

ANOVA(for KHN), followed by Tukeys test( = 0.05). Results: For the DC, the lightactivation protocol did not influence

the results and there was no difference between T and B. For the KHN test, the lightactivation protocol did not influence the

results and T showed higher microhardness values than B for all experimental conditions. There were significant differences in

KHN depending on the storage media. Samples immersed in absolute ethanol generally presented lower KHN values, with no

differences compared to samples in 75% ethanol. Conclusion: The storage media affected the outcomes of the softening test.

Key words: Dental lightcuring, ethanol, hardness, polymerization

INTRODUCTION The conversion of a monomer into a polymer, known

as the degree of conversion(DC), is related to the

Lightactivated resin composites are widely used in performance of resin composite materials. When

dentistry. Since their introduction into the market, higher DCs are obtained, improved mechanical

lightcuring units(LCUs) have become a key properties are achieved. Indeed, the monomer DC

equipment in dental offices.[1] The polymerization of photoactivated resin composites will increase

over several hours, until vitrification hinders the

reaction begins when light at the correct wavelength

further propagation of growing chains.[3] Therefore,

reaches the resin composite. This reaction involves the monomer DC is never complete, and the formed

the rupture of carboncarbon double bonds(C=C) of polymer contains considerable quantities of unreacted

dimethacrylate monomers into primary carboncarbon C=C. This condition may lead to reduced mechanical

single(CC) covalent bonds, with a reduction in the properties, and may allow the free monomer to be

intermolecular distances.[2] eluted from the resin composite.[4]

How to cite this article: Giorgi MC, Lima DN, Marchi GM, Ambrosano GM, Aguiar FB. Influence of softening test and light-activation protocols on

resin composite polymer structure. Eur J Dent 2014;8:9-14.

Copyright 2014 Dental Investigations Society. DOI: 10.4103/1305-7456.126233

European Journal of Dentistry, Vol 8 / Issue 1 / Jan-Mar 2014 9

[Downloaded free from http://www.eurjdent.com on Thursday, February 11, 2016, IP: 36.83.94.120]

Giorgi, etal.: Resincomposite polymer structure

Fourier transform infrared(FTIR) spectroscopy can After light activation, the sample was removed from

be used to evaluate the DC of a resin composite the Teflon mold and submitted to the DC test on the

directly. Nevertheless, when taken alone, this T and B surfaces. For Knoop Hardness(KHN), the

information does not fully characterize the polymer samples were subdivided into four groups(n=5 each)

structure. The DC is an average measure that does according to the storage media: 1) absolute ethanol,

not account for the heterogeneity of the material.[4] 2) 75% ethanol, 3) distilled water, and 4) air. The KHN

Polymers that differ in linearity and, therefore, have test was performed before and after 24h immersion

different crosslink densities(CLDs) may have in storage medium at 37C.

similar DCs. Acrosslink forms when the radical

reacts with a pendant C=C on a different kinetic Degree of conversion

chain. Systems with very low crosslinking tend The DC measurements were recorded in absorbance

to be weak and flexible, whereas polymers with mode with an FTIR spectrometer(Spectrum 100 FTIR;

high degrees of crosslinking are hard, inflexible, PerkinElmer, Waltham, MA, USA) coupled to a zinc

and more heat resistant. The monomer structure selenide multiple (six) reflection attenuated total

influences a polymers ultimate physical properties.[5] reflection(ATR) accessory, with a refraction index of

The polymer CLD may be assessed by measuring 2.4 at 1000 cm1(Pick Technologies, Madison, WI, USA).

the glass transition temperature[5,6] and by softening Apreliminary reading for the nonpolymerized resin

tests.[7,8] The softening test is easy to conduct and is composite was taken under the following conditions:

based on repeated measurements before and after 1665-1580 cm1 frequency range, 4 cm1 resolution,

immersion of the samples in organic solvents.[8] and HappGenzel apodization in absorbance mode.

Additional FTIR spectra were obtained immediately

The aim of this study was to evaluate the influence of after light activation performed according to the

different softening storage media and lightactivation experimental groups.

protocols on the DC and CLD of a composite resin. The

working hypotheses were: 1) different combinations of The percentage of unreacted C=C bonds was

power density and exposure duration may affect the DC, determined from the ratio of absorbance intensities

microhardness, and CLD and 2) different storage media of aliphatic C=C bonds(peak at 1638 cm1) against

may show different capabilities for evaluating CLD. the internal standard(aromatic C=C bonds, peak at

1608 cm1). The DC was determined by the following

MATERIALS AND METHODS formula:

A microhybrid resin composite(Filtek Z50; 3M ESPE, DC(%) =100*[1Rpolymerized/Rnonpolymerized],

St Paul, MN, USA) of A3 shade was selected for this study.

The lightactivation protocols were: Third lightemitting where R is the ratio of the band height at 1638 cm1

diode(LED) generation Valo(Ultradent Products, South to the band height at 1608 cm1. Data were submitted

Jordan, UT, USA) in three modesstandard(1000 to splitplot analysis of variance(ANOVA), followed

mW/cm2, 19 s), high power(1400 mW/cm2, 14 s), by Tukeys test( =0.05).

and plasma emulation(3200 mW/cm2, 6 s); and

quartztungsten halogen XL 3000(3M ESPE, Grafenau, Microhardness test and cross-link densitie

Germany) in conventional mode(500 mW/cm2, 38 s)all evaluations

set up to deliver approximately 19 J/cm2. The hardness at the bottom and top of each sample was

obtained with a digital microhardness tester(HMV2T

Eighty cylindrical specimens(N=20) were prepared E; Shimadzu Corporation, Tokyo, Japan) under a load

in Teflon mold(5 mm in diameter, 2 mm thick). of 10 g for 10 s. Five hardness measurements were

Atransparent polyester strip was positioned on the taken for the surface, and the KHN was recorded as

bottom(B) of the mold. The cavity was filled in one the average of the five indentations. The hardness

increment. The top(T) was covered with another was determined before(KHNb) and after(KHNa)

polyester strip to provide a flat surface and to remove immersion in the storage media.

a possible oxygeninhibited layer, and the strip was

covered with a glass plate. After that, the glass plate The CLD was estimated by the softening effect

was removed, and the sample was polymerized promoted by the storage media, that is, by the decrease

according to the lightactivation protocols described in hardness. Data were submitted to repeatedmeasures

above. splitplot ANOVA, followed by Tukeys test( =0.05).

10 European Journal of Dentistry, Vol 8 / Issue 1 / Jan-Mar 2014

[Downloaded free from http://www.eurjdent.com on Thursday, February 11, 2016, IP: 36.83.94.120]

Giorgi, etal.: Resincomposite polymer structure

RESULTS Table 2: Contd...

Absolute 40.51(8.49) 24.28(4.68)

Degree of conversion ethanol Aa Bc

The DC results are displayed in Table1. There were 100

Air 33.34(9.58) 37.76(6.52)

no statistically significant differences among the Aa Aa

lightactivation protocol(P=0.0759) or surface VALO T Distilled *39.99(6.95) *33.09(5.80)

factors(P=0.295). standard water Aa Bb

75% *38.38(10.34) *25.83(10.14)

Microhardness test and CLD evaluations Ethanol Aa Bbc

The ANOVA showed a significant main effect for the Absolute *32.92(6.90) *24.84(7.16)

surface and an interaction between storage media and ethanol Aa Bc

100

microhardness[Table2]. The T surfaces showed higher

Air *39.72(5.06) *40.18(13.57)

microhardness values than the B surfaces, independent Aa Aa

of the lightactivation protocol or storage media before or B Distilled 34.02(5.68) 33.32(5.15)

after immersion. The KHNb values were higher than the water Aa Bb

KHNa values, irrespective of the storage media[Table2], 75% 34.74(9.05) 21.48(6.57)

Ethanol Aa Bbc

except for the groups stored in air(control groups). In

Absolute 34.81(5.62) 19.10(5.50)

the softening test, there were no significant differences ethanol Aa Bc

in microhardness before immersion. After storage, the 100

highest microhardness values were obtained when the Air 38.42(6.64) 40.35(4.30)

Aa Aa

samples were stored in air. Absolute ethanol showed

VALO high T Distilled *39.55(10.20) *34.00(12.40)

higher or equal decreases in microhardness compared to power water Aa Bb

75% *36.52(10.92) *28.46(7.05)

Ethanol Aa Bbc

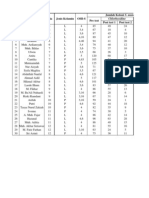

Table1: Results for degree of conversion(SD) Absolute *39.11(7.47) *26.72(4.28)

Lightactivation Surface DC ethanol Aa Bc

protocol 100

XL 3000 conventional T 55.58(2.92) A Air *42.45(4.22) *43.40(7.22)

Aa Aa

B 55.79(2.28) A

B Distilled 38.83(9.55) 33.09(10.47)

VALO standard T 56.3(4.72) A water Aa Bb

B 55.89(4.31) A 75% 37.09(5.82) 24.85(4.11)

VALO high power T 56.80(3.01) A Ethanol Aa Bbc

B 57.25(3.55) A Absolute 37.07(8.55) 22.09(7.68)

VALO plasma emulation mode T 56.81(3.49) A ethanol Aa Bc

B 55.68(3.44) A 100

DC: Degree of conversion, SD: Standard deviation, Lolute A provide prefix. Air 38.98(6.75) 39.81(4.27)

Mean values with the same letter were not statistically different(P<0.05) Aa Aa

VALO plasma T Distilled *36.58(7.89) *33.58(6.79)

emulation water Aa Bb

Table2: Results for microhardness test and 75% *35.88(7.96) *30.17(8.90)

crosslink density evaluation Ethanol Aa Bbc

Light Surface Storage Microhardness Absolute *37.96(9.66) *26.47(8.19)

activation media ethanol Aa Bc

protocol KHNb(SD) KHNa(SD) 100

XL 3000 T Distilled *37.24(9.93) *29.90(9.45) Air *34.29(2.10) *35.01(9.36)

conventional water Aa Bb Aa Aa

75% *39.16(8.59) *32.19(3.24) B Distilled 35.79(11.22) 31.14(8.62)

Ethanol Aa Bbc water Aa Bb

Absolute *43.23(7.91) *25.08(2.12) 75% 27.82(5.81) 27.23(8.23)

ethanol Aa Bc Ethanol Aa Bbc

100 Absolute 34.13(6.80) 23.23(8.49)

Air *37.18(6.57) *40.02(7.68) ethanol Aa Bc

Aa Aa 100

B Distilled 30.91(8.64) 27.84(9.53) Air 31.07(10.11) 32.80(8.30)

water Aa Bb Aa Aa

75% 40.86(8.10) 32.11(1.52)

Ethanol Aa Bbc Mean values followed by different case letters(uppercase in row, lowercase

in column) were statistically different(P<0.05). *Differs from bottom surface

Contd... inside the same lightactivation protocol, storage media, and microhardness

European Journal of Dentistry, Vol 8 / Issue 1 / Jan-Mar 2014 11

[Downloaded free from http://www.eurjdent.com on Thursday, February 11, 2016, IP: 36.83.94.120]

Giorgi, etal.: Resincomposite polymer structure

water and 75% ethanol. Samples stored in distilled water samples were 2 mm in height, which is an acceptable

presented KHNa values that were different from the thickness for lightcuring resin composites based on

values obtained for samples stored in absolute ethanol. methacrylate.[15,16]

DISCUSSION In all of the conditions evaluated, the T surfaces

presented higher hardness values than the B

The aim of this investigation was to evaluate the surfaces[Table2]. During the lightactivation process,

influence of different lightactivation protocols and the light that passes through the resin composite is

storage media on the DC and microhardness values absorbed and scattered. Thus, the light intensity is

of a microhybrid resin composite. attenuated, and its effectiveness is reduced as the

depth increases.[17,18] For this test, the effect of light

In the history of adhesive dentistry, two main scattering was noted, which promoted a decrease

technologies of LCUs and several lightcuring in light transmittance along the bulk of material.

protocols have been proposed to promote effective Consequently, less energy reached the bottom

polymerization. Effective polymerization of the surface,[9,19] resulting in a less crosslinked polymer

adhesive bond system and resin composite is required on that surface. Clinically, this result means that the

to obtain longterm clinical success.[9] The quality light activation of a 2mm increment resulted in a

of the network formed during polymerization will heterogenic material, with decreased crosslinking

dictate the extent to which molecular uptake and along the bulk of the material. As a result, the B

swelling occur when a polymer is submerged in an surface polymer will be more susceptible to organic

organic solvent,[10] which is the condition present in solvents.

the oral cavity.

After 24 h of immersion in storage media, differences

The LED LCU used in this study delivered light at were detected in KHN a. The effects of chemical

three irradiances, all in continuous mode: Standard solvents vary, but typically involve an elution of

(1000 mW/cm2), high power (1400 mW/cm2), and unreacted components and some degradative effect

plasma emulation (3200 mW/cm2). The continuous on the polymer network.[10] In the present study,

mode delivers the same power density without except for samples stored in air, all experimental

interruption throughout the entire exposure period.[11] conditions showed significant differences from the

Although an extremely high irradiance is generated initial measurement(KHN b). Samples stored in

in plasma emulation mode, this high irradiance is not absolute or 75% ethanol showed higher decreases in

obtained by the generation of a plasma field, as it is hardness, thus presenting similar behaviors. When

for PAC LCUs(plasma arc lightcuring units). Instead, ethanol penetrates the polymer network, it causes an

according to the manufacturer, the high irradiance is expansion of the structure, allowing a softening of

generated by highpowered LED chips, which boost the resin composite surface by removing the polymer

the light output to levels that, in some cases, surpass structure as unreacted monomer, oligomers, and linear

that of PAC lights. The PAC LCUs were developed polymers.[4,14] This expansion is facilitated when the

in an attempt to decrease the polymerization time, CLD is low because the solvent can disrupt secondary

reducing the time needed to cure resin composites interchain bonds, but not primary crosslink bonds.[5]

from 30-40 s to 3 s.[12] However, some reports have The reduction in hardness is a consequence of polymer

demonstrated that this approach is more costly, shows plasticization.[10]

more shrinkage and stress, and generates more heat,

which could injure the pulp.[13] In the present work, there was no difference between

absolute ethanol and 75% ethanol. This finding is

The lightactivation protocols used in this study did not not consistent with the results of a previous study[8]

affect the DC of the tested resin composite[Table1]. which showed that the ethanol concentration affected

This finding is in agreement with the results from polymer softening. The discrepancy between these

other studies that used different curing protocols with studies may be explained by the immersion time. In

similar energy densities and did not find differences the present study, the samples were light activated

in DC.[3,4,7,14] The energy density used was sufficient to and immediately immersed in storage media. In

attain a DC between 55% and 57%, without achieving other studies, [79] the immersion in the softening

statistically significant differences between the T and B test occurred after 24 h of dry storage. Immediate

surfaces. This result may be explained by the fact that immersion favored the solvent action, and both

12 European Journal of Dentistry, Vol 8 / Issue 1 / Jan-Mar 2014

[Downloaded free from http://www.eurjdent.com on Thursday, February 11, 2016, IP: 36.83.94.120]

Giorgi, etal.: Resincomposite polymer structure

absolute ethanol and 75% ethanol showed similar highpower and shorttime protocol on the shrinkage

behaviors. Absolute ethanol had a higher potential stress and temperature increases.

to dissolve the polymer network than water. Samples

stored in distilled water showed a lower potential In summary, the present findings showed that

to decrease the hardness than absolute ethanol and different lightactivation protocols delivering the

presented no significant difference compared to 75% same energy density did not influence the DC on

ethanol. Dental polymer networks absorb aqueous either the T or B surfaces of 2mm samples. However,

solvents to the extent of several percentage points they did affect the KHN values according to the

of their total weight. There is a general trend for the surface. Top surfaces showed higher KHN values

sorption of ethanol/water solutions to be greater than in all experimental conditions, supporting the idea

that of water alone.[10] Thus, different storage media that the bottom surfaces are usually more critical

present different abilities to evaluate CLD. areas. Although the energy density was delivered by

different protocols, these different protocols did not

The lightactivation protocol showed no differences result in polymers with distinct solvent susceptibilities.

in the microhardness test(P=0.3706). All of the Absolute ethanol and 75% ethanol showed higher

curing protocols delivered energy continuously at potentials for analyzing the polymer structure than

a minimum of 500 mW/cm2/s, and no significant other softening solutions.

differences were noticed. This quantity of irradiance

probably sensitizes several photoinitiator molecules, REFERENCES

initiating a multitude of growth centers and resulting

in a polymer with a higher CLD. [7] Within the 1. JimnezPlanasA, Martn J, AbalosC, LlamasR. Developments in

polymerization lamps. Quintessence Int 2008;39:e7484.

conditions of this study, the absence of differences 2. PeutzfeldtA. Resin composite in dentistry: The monomer systems.

among lightactivation protocols indicates that Eur J Oral Sci 1997;105:97116.

3. Gonalves F, CalheirosFC, WitzelMF, KawanoY, BragaRR. Effect

above 500 mW/cm2, the initiation process might of photoactivation protocol and radiant exposure on monomer

reach a plateau. This result is not in agreement conversion and flexural strength of a resin composite after

with that of a study [20] that evaluated the effect water and ethanol storage. JBiomed Mater Res B Appl Biomater

2007;82:8992.

of four different lightcuring protocols(standard, 4. AsmussenE, PeutzfeldtA. Influence of selected components

high irradiance, pulse delay, and softstart) on the on crosslink density in polymer structures. Eur J Oral Sci

2001;109:2825.

microtensile bond strength, ultimate bond strength, 5. SohMS, YapAU. Influence of curing modes on crosslink density in

KHN, and CLD of nanohybrid resin composite polymer structures. JDent 2004;32:3216.

samples. This previous study concluded that a 6. DewaeleM, AsmussenE, PeutzfeldtA, MunksgaardEC, BenettiAR,

Finn G, etal. Influence of curing protocol on selected properties of

softstart protocol might improve the ultimate lightcuring polymers: Degree of conversion, volume contraction,

tensile strength and KHN without compromising elastic modulus, and glass transition temperature. Dent Mater

2009;25:157684.

the resindentine microtensile bond strength. 7. AsmussenE, PeutzfeldtA. Influence of pulsedelay curing on softening

However, softstart and pulse delay protocols may of polymer structures. JDent Res 2001;80:15703.

reduce the CLD of the resin composite polymeric 8. SchneiderLF, MoraesRR, CavalcanteLM, SinhoretiMA,

CorrerSobrinhoL, ConsaniS. Crosslink density evaluation

network.[20] through softening tests: Effect of ethanol concentration. Dent Mater

2008;24:199203.

The plasma emulation mode, which delivered a very 9. AguiarFH, BraceiroAT, AmbrosanoGM, LovadinoJR. Hardness and

diametrical tensile strength of a hybrid composite resin polymerized

high irradiance in a short time, was expected to result with different modes and immersed in ethanol or distilled water

in a polymer with poor structure. The rapid initiation media. Dent Mater 2005;21:1098103.

10. FerracaneJL. Hygroscopic and hydrolytic effects in dental polymer

of polymerization could induce shorter chain lengths, networks. Dent Mater 2006;22:21122.

thereby leading to a lower molecular weight and 11. BenettiAR, AsmussenE, MunksgaardEC, DewaleM, PeutzfeldtA,

compromising the physical and mechanical properties LeloupG, etal. Softening and elution of monomers in ethanol. Dent

Mater 2009;25:100713.

of resin composite materials.[21] The results of the 12. BagisB, BagisY, ErtasE, UstaomerS. Comparison of the heat

present study do not corroborate this idea. This generation of light curing units. JContemp Dent Pract 2008;9:6572.

13. MoonHJ, LeeYK, LimBS, KimCW. Effects of various light curing

discrepancy might be explained by the 6s exposure methods on the leachability of uncured substances and hardness of

time used, which differed from the 3s exposure time a composite resin. JOral Rehabil 2004;31:25864.

commonly used in PAC LCUs. Thus, the extended 14. WitzelMF, CalheirosFC, Gonalves F, KawanoY, BragaRR. Influence

of photoactivation method on conversion, mechanical properties,

exposure time probably allowed the activation of more degradation in ethanol and contraction stress of resinbased materials.

growth centers, resulting in a network with longer JDent 2005;33:7739.

15. YapAU. Effectiveness of polymerization in composite restoratives

chain lengths and higher CLDs. However, further claiming bulk placement: Impact of cavity depth and exposure time.

studies should evaluate the consequences of this very Oper Dent 2000;25:11320.

European Journal of Dentistry, Vol 8 / Issue 1 / Jan-Mar 2014 13

[Downloaded free from http://www.eurjdent.com on Thursday, February 11, 2016, IP: 36.83.94.120]

Giorgi, etal.: Resincomposite polymer structure

16. PriceRB, Drand T, LoneyRW, AndreouP. Effect of light source and Microhardness evaluation of resin composites polymerized by three

specimen thickness on the surface hardness of resin composite. Am different light sources. Dent Mater J 2007;26:84553.

J Dent 2002;15:4753.

17. Watts DC. Reaction kinetics and mechanics in photopolymerised

networks. Dent Mater 2005;21:2735. Access this article online

18. dos SantosGB, AltoRV, FilhoHR, da SilvaEM, FellowsCE. Light Quick Response Code:

transmission on dental resin composites. Dent Mater 2008;24:5716. Website:

19. ArikawaH, FujiiK, KanieT, InoueK. Light transmittance www.eurjdent.com

characteristics of lightcured composite resins. Dent Mater

1998;14:40111.

Source of Support: This study

20. FeitosaVP, FugolinAP, CorrerAB, CorrerSobrinhoL, ConsaniS,

was supported by Coordenao de

WatsonTF, etal. Effects of different photopolymerization protocols

Aperfeioamento de Pessoal de Nvel

on resindentine TBS, mechanical properties and crosslink density Superior CAPES - Brasil

of a nanofilled resin composite. JDent 2012;40:8029. Conflict of Interest: None declared

21. Hubbezolu I, Bolayir G, Doan OM, Doan A, Ozer A, Bek B.

14 European Journal of Dentistry, Vol 8 / Issue 1 / Jan-Mar 2014

Das könnte Ihnen auch gefallen

- 1 s2.0 S0300571220301949 MainDokument10 Seiten1 s2.0 S0300571220301949 MainpyrockerNoch keine Bewertungen

- Randolph 2014Dokument11 SeitenRandolph 2014pyrockerNoch keine Bewertungen

- Surface ResistenceDokument3 SeitenSurface Resistencejarjar bin binxNoch keine Bewertungen

- Saade 2010Dokument6 SeitenSaade 2010johnNoch keine Bewertungen

- Effectiveness of Light Emitting Diode and Halogen Light Curing Units For Curing Microhybrid and NanocompositesDokument5 SeitenEffectiveness of Light Emitting Diode and Halogen Light Curing Units For Curing Microhybrid and NanocompositespriyadharshiniNoch keine Bewertungen

- Dewaele M. 2009 Dent. Mater. Influence of Curing Protocol On Selected Properties of Light Curing Polymers Degree of Conversion, Volume Contraction, Elastic Modulus, and Glass Transition TemperatureDokument9 SeitenDewaele M. 2009 Dent. Mater. Influence of Curing Protocol On Selected Properties of Light Curing Polymers Degree of Conversion, Volume Contraction, Elastic Modulus, and Glass Transition TemperatureLilyan YamasakiNoch keine Bewertungen

- Curing Efficiency of High-Intensity Light-Emitting Diode (LED) DevicesDokument9 SeitenCuring Efficiency of High-Intensity Light-Emitting Diode (LED) DevicesJUNIORCHACONNoch keine Bewertungen

- TMP BBEADokument7 SeitenTMP BBEAFrontiersNoch keine Bewertungen

- Simple and Low Coast ThermalDokument6 SeitenSimple and Low Coast ThermalEDWIN MILER REISHTATTER REISHTATTERNoch keine Bewertungen

- Evaluation of Different Light-Curing Lamps HalogenDokument7 SeitenEvaluation of Different Light-Curing Lamps HalogenKenny Rafael Iglesias AlvarezNoch keine Bewertungen

- The Effect of The Light Intensity and Light DistanDokument13 SeitenThe Effect of The Light Intensity and Light Distangame.you.k.6119Noch keine Bewertungen

- 2019 Polimerizacion Adecuada de Las BulkDokument7 Seiten2019 Polimerizacion Adecuada de Las BulkOskar OrtizNoch keine Bewertungen

- Degree of ConversionDokument8 SeitenDegree of ConversionAna-Maria DucuNoch keine Bewertungen

- Polymer: Keroles B. Riad, Rolf Schmidt, Alexandre A. Arnold, Rolf Wuthrich, Paula M. Wood-AdamsDokument8 SeitenPolymer: Keroles B. Riad, Rolf Schmidt, Alexandre A. Arnold, Rolf Wuthrich, Paula M. Wood-AdamsMia PhanNoch keine Bewertungen

- 15 CoDokument9 Seiten15 CoSaad LiaqatNoch keine Bewertungen

- Radiation-Induced Crosslinking of UHMWPE in The Presence of Co-Agents: Chemical and Mechanical CharacterisationDokument10 SeitenRadiation-Induced Crosslinking of UHMWPE in The Presence of Co-Agents: Chemical and Mechanical CharacterisationJobin VargheseNoch keine Bewertungen

- Biocompatibility and Bioactivity of A Dual Cured RDokument8 SeitenBiocompatibility and Bioactivity of A Dual Cured RchannadrasmaNoch keine Bewertungen

- Sae Technical Paper Series: M.-T. Ton-That, J. Denault and K. C. ColeDokument6 SeitenSae Technical Paper Series: M.-T. Ton-That, J. Denault and K. C. ColeSagar MehtaNoch keine Bewertungen

- Komposisi z350Dokument9 SeitenKomposisi z350muchlis fauziNoch keine Bewertungen

- The Effect of Different Light-Curing Units On Tensile Strength and Microhardness of A Composite ResinDokument5 SeitenThe Effect of Different Light-Curing Units On Tensile Strength and Microhardness of A Composite ResinmartariwansyahNoch keine Bewertungen

- Effect of Rapid High-Intensity Light-Curing On Polymerization Shrinkage Properties of Conventional and Bulk-Fill CompositesDokument12 SeitenEffect of Rapid High-Intensity Light-Curing On Polymerization Shrinkage Properties of Conventional and Bulk-Fill Compositesmuchlis fauziNoch keine Bewertungen

- Vvimportent Paper On Polymer BlendDokument15 SeitenVvimportent Paper On Polymer Blendswapnil kaleNoch keine Bewertungen

- Degree of Conversion of Three Composite PDFDokument6 SeitenDegree of Conversion of Three Composite PDFFreddy GarciaNoch keine Bewertungen

- Evaluation of The Degree Conversion of Dental Composite Nanoparticles As An Effect On The Variation of Initial Temperature TreatmentDokument4 SeitenEvaluation of The Degree Conversion of Dental Composite Nanoparticles As An Effect On The Variation of Initial Temperature TreatmentInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Bulk Fill PDFDokument10 SeitenBulk Fill PDFJoselyn RodríguezNoch keine Bewertungen

- 3Dokument8 Seiten3DeepikaNoch keine Bewertungen

- New Gneration of Bulk Fill CompositeDokument9 SeitenNew Gneration of Bulk Fill CompositeHamilton AndradeNoch keine Bewertungen

- Investigation of Mechanical Performances and Polymerization Shrinkage of Dual-Cured Resin Composites As Core Build-Up MaterialDokument9 SeitenInvestigation of Mechanical Performances and Polymerization Shrinkage of Dual-Cured Resin Composites As Core Build-Up MaterialrojNoch keine Bewertungen

- Kumar 2020Dokument8 SeitenKumar 2020bumbumNoch keine Bewertungen

- Efficient Light Harvesting by Using Green Zn-Porphyrin-Sensitized Nanocrystalline Tio FilmsDokument13 SeitenEfficient Light Harvesting by Using Green Zn-Porphyrin-Sensitized Nanocrystalline Tio FilmsRoy StrawhunNoch keine Bewertungen

- J Mat Sci 2011, 46, 6508 Efecto de La Organoarcilla Con Diferentes Modificadores Organicos en Las Propiedades TermoplasticasDokument10 SeitenJ Mat Sci 2011, 46, 6508 Efecto de La Organoarcilla Con Diferentes Modificadores Organicos en Las Propiedades TermoplasticasDavid ContrerasNoch keine Bewertungen

- 1 s2.0 S0109564118302161 MainDokument10 Seiten1 s2.0 S0109564118302161 Mainadrianafrcv26Noch keine Bewertungen

- Ilie 2013Dokument8 SeitenIlie 2013martina.cirronis96Noch keine Bewertungen

- Barszczewska Rybarek Barszczewska Rybarek 2012Dokument8 SeitenBarszczewska Rybarek Barszczewska Rybarek 2012yussefmontplaisirNoch keine Bewertungen

- 1 s2.0 S0109564106001710 MainDokument7 Seiten1 s2.0 S0109564106001710 MainPABLO LENIN BENITEZ SELLANNoch keine Bewertungen

- COBEM-2017-2774 Evaluation of The Properties of The Epoxy Resin by Adding Layered Double HidroxidesDokument7 SeitenCOBEM-2017-2774 Evaluation of The Properties of The Epoxy Resin by Adding Layered Double HidroxidesAdilsonNoch keine Bewertungen

- Resin CompoitesDokument7 SeitenResin CompoitesShabia AzharNoch keine Bewertungen

- Polymer 178 32-A Novel Route To Synthesis Polythiophene With Great Yield and High Electrical Conductivity Without Post Doping ProcessDokument9 SeitenPolymer 178 32-A Novel Route To Synthesis Polythiophene With Great Yield and High Electrical Conductivity Without Post Doping Processsilambarasan kNoch keine Bewertungen

- 3 Hasslen 2019 Depth of Cure of High-Viscosity Bulk-Fill and Conventional Resin Composites Using Varying Irradiance Exposures With A Light-Emitting Diode Curing UnitDokument6 Seiten3 Hasslen 2019 Depth of Cure of High-Viscosity Bulk-Fill and Conventional Resin Composites Using Varying Irradiance Exposures With A Light-Emitting Diode Curing UnitAlejandra Herrera BarreraNoch keine Bewertungen

- Synthesis and Characterization of Some Novel Dendritic Architectures Bearing Chalcone at The PeDokument12 SeitenSynthesis and Characterization of Some Novel Dendritic Architectures Bearing Chalcone at The Peevsgoud_goudNoch keine Bewertungen

- Evaluate Polymer Degree of Conversion of Bulk-Fill Composite RestorationDokument5 SeitenEvaluate Polymer Degree of Conversion of Bulk-Fill Composite RestorationIOSRjournalNoch keine Bewertungen

- Short All 2013Dokument9 SeitenShort All 2013JumanjiNoch keine Bewertungen

- Initial Fracture Resistance and Curing Temperature Rise of Ten Contemporary Resin-Based Composites With Increasing Radiant ExposureDokument9 SeitenInitial Fracture Resistance and Curing Temperature Rise of Ten Contemporary Resin-Based Composites With Increasing Radiant ExposureheycoolalexNoch keine Bewertungen

- Thin Solid FilmsDokument8 SeitenThin Solid FilmsLarissa Nunes da CostaNoch keine Bewertungen

- International Journal of Adhesion and AdhesivesDokument7 SeitenInternational Journal of Adhesion and AdhesivesDeisy Angarita FlorezNoch keine Bewertungen

- Polymerization Reaction Dynamics of Ethylene Glycol Methacrylates and Dimethacrylates by CalorimetryDokument7 SeitenPolymerization Reaction Dynamics of Ethylene Glycol Methacrylates and Dimethacrylates by CalorimetryValentin ParaschivNoch keine Bewertungen

- Polymerization Lamps and Photocuring in OrthodonticsDokument8 SeitenPolymerization Lamps and Photocuring in Orthodonticsgriffone1Noch keine Bewertungen

- International Journal of Smart and Nano MaterialsDokument16 SeitenInternational Journal of Smart and Nano Materialsadi_agNoch keine Bewertungen

- Polymers 12 01346Dokument14 SeitenPolymers 12 01346zaryab khanNoch keine Bewertungen

- Poly (Dimethylsiloxane) Coatings For Controlled Drug Release. II. Mechanism of The Crosslinking Reaction in EmulsionDokument9 SeitenPoly (Dimethylsiloxane) Coatings For Controlled Drug Release. II. Mechanism of The Crosslinking Reaction in EmulsionMateoNoch keine Bewertungen

- Polymers 11 01272 PDFDokument19 SeitenPolymers 11 01272 PDFkajol agarwalNoch keine Bewertungen

- App AnalysisofuvcurableresinsbyftirDokument3 SeitenApp AnalysisofuvcurableresinsbyftirjaninaNoch keine Bewertungen

- J Tet 2018 10 026Dokument11 SeitenJ Tet 2018 10 026Phương NguyễnNoch keine Bewertungen

- 2018 - Zakaria Mohyi Eddine - Ground State Geometries, UV-vis Absorption Spectra and Charge TransferDokument10 Seiten2018 - Zakaria Mohyi Eddine - Ground State Geometries, UV-vis Absorption Spectra and Charge TransferTomas Delgado MontielNoch keine Bewertungen

- 1678 7757 Jaos 17 04 0289Dokument5 Seiten1678 7757 Jaos 17 04 0289Percy Andree Bayona GuillermoNoch keine Bewertungen

- Alizarin 3 2016Dokument13 SeitenAlizarin 3 2016Tatiana Gomez CanoNoch keine Bewertungen

- Curing Capability of Halogen and LED Light Curing Units in Deep Class II Cavities in Extracted Human MolarsDokument10 SeitenCuring Capability of Halogen and LED Light Curing Units in Deep Class II Cavities in Extracted Human MolarsNADIA VICUÑA CRIADONoch keine Bewertungen

- Naddeo 2004Dokument5 SeitenNaddeo 2004Roshni PattanayakNoch keine Bewertungen

- Blend UvDokument6 SeitenBlend UvArun APNoch keine Bewertungen

- Modified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975Von EverandModified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975A. RomanovBewertung: 5 von 5 Sternen5/5 (1)

- Hape Hape AjhsjdjDokument1 SeiteHape Hape AjhsjdjAini Dwi HandiniNoch keine Bewertungen

- Biological and Mechanical Properties of An Partial Replacement of Cao With Mgo or ZnoDokument7 SeitenBiological and Mechanical Properties of An Partial Replacement of Cao With Mgo or ZnoAini Dwi HandiniNoch keine Bewertungen

- AlamaaaasssDokument1 SeiteAlamaaaasssAini Dwi HandiniNoch keine Bewertungen

- Life Never Felt So GoodDokument1 SeiteLife Never Felt So GoodAini Dwi HandiniNoch keine Bewertungen

- Evaluation of Microleakage of Dental Composites Using Bonding Agents With Different Placement Techniques: An Invitro StudyDokument4 SeitenEvaluation of Microleakage of Dental Composites Using Bonding Agents With Different Placement Techniques: An Invitro StudyAini Dwi HandiniNoch keine Bewertungen

- Evaluation of Microleakage of Dental Composites Using Bonding Agents With Different Placement Techniques: An Invitro StudyDokument4 SeitenEvaluation of Microleakage of Dental Composites Using Bonding Agents With Different Placement Techniques: An Invitro StudyAini Dwi HandiniNoch keine Bewertungen

- Bonding of Contemporary Glass Ionomer Cements To Different Tooth Substrates Microshear Bond Strength and Scanning Electron Microscope StudyDokument7 SeitenBonding of Contemporary Glass Ionomer Cements To Different Tooth Substrates Microshear Bond Strength and Scanning Electron Microscope StudyAini Dwi HandiniNoch keine Bewertungen

- Improving Composite Resin Performance Through Decreasing Its Viscosity by Different MethodsDokument8 SeitenImproving Composite Resin Performance Through Decreasing Its Viscosity by Different MethodsAini Dwi HandiniNoch keine Bewertungen

- Effect of Resin-Modified Glass-Ionomer Cement Lining and Composite Layering Technique On The Adhesive Interface of Lateral WallDokument6 SeitenEffect of Resin-Modified Glass-Ionomer Cement Lining and Composite Layering Technique On The Adhesive Interface of Lateral WallAini Dwi HandiniNoch keine Bewertungen

- Effect of Resin-Modified Glass-Ionomer Cement Lining and Composite Layering Technique On The Adhesive Interface of Lateral WallDokument6 SeitenEffect of Resin-Modified Glass-Ionomer Cement Lining and Composite Layering Technique On The Adhesive Interface of Lateral WallAini Dwi HandiniNoch keine Bewertungen

- Microtensile Bond Strength of Silorane-Based Composite Specific Adhesive System Using Different Bonding StrategiesDokument7 SeitenMicrotensile Bond Strength of Silorane-Based Composite Specific Adhesive System Using Different Bonding StrategiesAini Dwi HandiniNoch keine Bewertungen

- 784 2010 Article 426Dokument9 Seiten784 2010 Article 426Aini Dwi HandiniNoch keine Bewertungen

- Recent Advances and Developments in Composite Dental Restorative MaterialsDokument15 SeitenRecent Advances and Developments in Composite Dental Restorative MaterialsAini Dwi HandiniNoch keine Bewertungen

- Failure of A Glass Ionomer To Remineralize Apatite-Depleted DentinDokument6 SeitenFailure of A Glass Ionomer To Remineralize Apatite-Depleted DentinAini Dwi HandiniNoch keine Bewertungen

- Color Stability of Nanocomposites Polished With One-Step SystemsDokument8 SeitenColor Stability of Nanocomposites Polished With One-Step SystemsAini Dwi HandiniNoch keine Bewertungen

- Analisis S MutansDokument12 SeitenAnalisis S MutansAini Dwi HandiniNoch keine Bewertungen

- Current Fluoirdes For Reduction Dental CariesDokument8 SeitenCurrent Fluoirdes For Reduction Dental CariesAini Dwi HandiniNoch keine Bewertungen

- BJBMS 12 273Dokument6 SeitenBJBMS 12 273Aini Dwi HandiniNoch keine Bewertungen

- Jumlah Koloni S. Mutans (CFU) No Nama Usia Jenis Kelamin Ohi-S Pre TestDokument2 SeitenJumlah Koloni S. Mutans (CFU) No Nama Usia Jenis Kelamin Ohi-S Pre TestAini Dwi HandiniNoch keine Bewertungen

- Larutan Teh Hijau Pre Jumlah Koloni S. Mutans No Nama Usia Jenis Kelamin Ohi-SDokument5 SeitenLarutan Teh Hijau Pre Jumlah Koloni S. Mutans No Nama Usia Jenis Kelamin Ohi-SAini Dwi HandiniNoch keine Bewertungen

- Prevalence of Periodontitis in Adults in The United States 2009 and 2010. Full Text AvailableDokument8 SeitenPrevalence of Periodontitis in Adults in The United States 2009 and 2010. Full Text AvailableAini Dwi HandiniNoch keine Bewertungen

- Periodontal Disease in Norwegian Old-Age PensionersDokument6 SeitenPeriodontal Disease in Norwegian Old-Age PensionersAini Dwi HandiniNoch keine Bewertungen

- Ammonia Vs FreonDokument6 SeitenAmmonia Vs FreonMedo TitoNoch keine Bewertungen

- MAE 207 - Microfluidics - Winter 2012 Lecture 17 - Notes Prepared by Sandeep KannanDokument8 SeitenMAE 207 - Microfluidics - Winter 2012 Lecture 17 - Notes Prepared by Sandeep KannanSandeep KannanNoch keine Bewertungen

- International Journal of Heat and Mass Transfer: Bachir El Fil, Girish Kini, Srinivas GarimellaDokument21 SeitenInternational Journal of Heat and Mass Transfer: Bachir El Fil, Girish Kini, Srinivas Garimellaشهيد مهدي ابو العيسNoch keine Bewertungen

- Lecture 9 The Second Law of ThermodynamicsDokument28 SeitenLecture 9 The Second Law of ThermodynamicsGean GenizaNoch keine Bewertungen

- Chemistry Ch-1 (Chemical Reactions and Equations) NotesDokument9 SeitenChemistry Ch-1 (Chemical Reactions and Equations) NotesKumaravel BNoch keine Bewertungen

- HysysDokument36 SeitenHysysRamiro ArcentalesNoch keine Bewertungen

- Approvals - Listofproducts - Siemens 2019 PDFDokument3 SeitenApprovals - Listofproducts - Siemens 2019 PDFHussain SyedNoch keine Bewertungen

- 6.1 Types of Chemical Reactions LabDokument7 Seiten6.1 Types of Chemical Reactions LabAndrew NapierNoch keine Bewertungen

- Chem Lab Report 2 - UwcDokument10 SeitenChem Lab Report 2 - UwcVy TruongNoch keine Bewertungen

- Experiment 1 Chem 200 L Formal ReportDokument6 SeitenExperiment 1 Chem 200 L Formal ReportGrace AquinoNoch keine Bewertungen

- 0620 w17 Ms 43 PDFDokument7 Seiten0620 w17 Ms 43 PDFyuke kristinaNoch keine Bewertungen

- Sergey Vulfson PHD (Author) - Molecular Magnetochemistry (1998)Dokument492 SeitenSergey Vulfson PHD (Author) - Molecular Magnetochemistry (1998)EUGENNoch keine Bewertungen

- Chemistry Lab ManualDokument8 SeitenChemistry Lab ManualKritin ReddyNoch keine Bewertungen

- AHRI Low-GWP AREP-Literature Review PDFDokument30 SeitenAHRI Low-GWP AREP-Literature Review PDFAnonymous ffje1rpa100% (2)

- Sci8 Ch1 L1 Forces and FrictionDokument23 SeitenSci8 Ch1 L1 Forces and Frictiontchr keiNoch keine Bewertungen

- Ch16 StudentsDokument29 SeitenCh16 Studentsqvk8yy9pxcNoch keine Bewertungen

- Fundamental Approach To The Design of Single Vertical Shaft Lime KilnDokument9 SeitenFundamental Approach To The Design of Single Vertical Shaft Lime KilnMohammad Ali TaghdiriNoch keine Bewertungen

- Paper Specific Instructions:: GATE Chemical Engineering MSQ Paper - 1Dokument11 SeitenPaper Specific Instructions:: GATE Chemical Engineering MSQ Paper - 1Mayank ShelarNoch keine Bewertungen

- Drafting Mechanical Layout and DetailsDokument60 SeitenDrafting Mechanical Layout and Detailsrannie joy glor100% (1)

- Notes - Acids Bases and SaltsDokument2 SeitenNotes - Acids Bases and SaltsantonyNoch keine Bewertungen

- Paquet Evaluation of Shelf Lifes of NCDokument18 SeitenPaquet Evaluation of Shelf Lifes of NCAkhilNoch keine Bewertungen

- Phisical Propertis Palm and Cooking OilDokument10 SeitenPhisical Propertis Palm and Cooking OilArifin HidayatNoch keine Bewertungen

- Production of Nitric Acid PDFDokument20 SeitenProduction of Nitric Acid PDFPanji Aji Wibowo100% (5)

- Chapter 4 PDFDokument30 SeitenChapter 4 PDFAram Nasih MuhammadNoch keine Bewertungen

- Boyles Law and Charles LawDokument7 SeitenBoyles Law and Charles Lawᜃᜒᜋ᜔ ᜊᜒᜎ᜔ᜌᜈ᜔ᜆᜒNoch keine Bewertungen

- ch18 PDFDokument45 Seitench18 PDFHafidz RafiqiNoch keine Bewertungen

- Section 07 - Fired Heaters PDFDokument112 SeitenSection 07 - Fired Heaters PDFaldoacss_148400122Noch keine Bewertungen

- (SSC) Consumer Chemistry9 Q1 M6 W6Dokument24 Seiten(SSC) Consumer Chemistry9 Q1 M6 W6.Noch keine Bewertungen

- AnskjhbljsDokument7 SeitenAnskjhbljsmillinagi95Noch keine Bewertungen

- 3 - Extended Surface FinsDokument5 Seiten3 - Extended Surface Finssayedelboss0% (1)