Beruflich Dokumente

Kultur Dokumente

Bearing Stress Glass

Hochgeladen von

lingchenhOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bearing Stress Glass

Hochgeladen von

lingchenhCopyright:

Verfügbare Formate

Structural Bearings In Holes In Glass

Brian Eckersley, James O’Callaghan

Eckersley O’Callaghan Structural Design, 5 Laycock St, London N1 1SN, UK

Jon Corpe and Sheila Bull

PPR&D, London, UK

Keywords

1=structural 2=bearings 3=holes

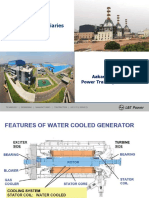

Abstract Figure 1

Ideogram of nuclei / bond

One of the most fundamental array in ductile & brittle

engineering problems is that of the materials

connection of parts.

The simple problem of loading

a bolt in a hole in glass becomes a

complex analytical issue owing to the

brittle-elastic nature of the material.

Manufacturing and processing methods

in glass limit the size of glass structural

components and so increase the

importance of connecting methods.

The development of structural bolted

connecting methods using bearings in

holes is explored through built projects

around the world by both testing and

analysis. The aim is to present simple

rules for the calculation of bearing loads

in these holes.

Introduction: the development of

structural bearings:

Though glass is such a good model

structural medium that Galileo in the

Safety Glass in Buildings

16th century and Griffith in the 20th

Figure 2 Figure 3

century used it to test hypotheses,

only recently have techniques been RFR, Tokyo & Seoul joints Parc La Villette

developed to attach 2 pieces of glass

together using connections developed

over the centuries for timber and steel. dropped into oversized holes providing During the development of the Tokyo

Pieces of wood were joined together a degree of tolerance. Friction bolting bearing, the Academic on the team Dr

with wood pins hammered into holes was the first to cross over into glass Jim Morris of City University, pointed

distorting both the pin and the hole C1960 primarily to bolt glass mullions to out that the chamfered shoulders were

to get a perfect fit. The fit between the sub-structure. Bolt groups, applying not necessary to the load-bearing

pin and hole needs to be 0.5% of the loads to the face of the glass could capacity of the hole. The last tests using

diameter making tolerance difficult carry quite high loads whilst supplying reject flat holes proved his point and

without distortion. This method was tolerance, but they are accompanied by whilst it was too late to incorporate

adapted to steel by hammering red- unsightly flitch plates. this finding for Tokyo with it’s 90

hot rivets into holes in plates, again to This was no real solution for glass bearings, they were just right for the

ensure a perfect fit. walls. At Parc La Villette C1982, Peter next project a horizontally cross-beamed

Such hammering destroys glass. This Rice extended the notion of the friction façade in Seoul with 2,000 bearings

is due to the different array of nuclei joint by chamfering the hole and on which James O’Callaghan was the

and bond in wood & metal and glass. clamping the sheet to the background development Engineer for Tim.

The bond strength is much weaker than with a bush bearing to produce a flush These joints would not exist without

the nuclei. Wood & steel have an array surface (the RFR joint). The RFR joint is the developments in the use of stainless

such that the breaking of the bond a satisfactory solution for bolting glass steel and tempered glass. Rusting mild

allows the nuclei behind to reinforce the back onto steel frames and armatures, steel like ice, requires more volume

bond. This spreads out until the pressure but its essential asymmetry makes it than the iron it transforms, creating

is accommodated, making the material difficult to use for bolting glass beams uneven pressure points which destroy

ductile. In glass, the nuclei line up together. For the structural glass the bonds in glass. Replacing it with the

allowing the bonds to continually break canopy in Tokyo 1995 Tim Macfarlane right grade of stainless steel removes

concentrating the pressure on the break reinstated the symmetry by putting two this eventuality. Poor understanding of

until it collapses, making the material RFR joints back to back in one sheet. the nature of glass which concentrates,

brittle. The initial tests we conducted on Tim’s rather than disperses load meant that

Friction bolts apply large loads to behalf showed that the idea worked the early rather roughly drilled holes left

the face of the plates to stop them and subsequent testing showed this potential bond failure pressure points.

sliding against each other, developed joint carried considerable load, it even These were strengthened as a by-

in steelwork, so that bolts could be sheared a bolt in an early test. product of tempering sheets of glass.

GLASS PROCESSING DAYS 2005 - www.gpd.fi 469

Figure 6

RFR, Tokyo & double

drilled hole drillings

Figure 4

Tokyo Forum Canopy

any additional loads into the glass

via the laminate. This was done by

milling shoulders onto the bearings

to accommodate the laminate so that

all the bushes locked solidly together.

Square holes produce no side thrust,

and can load directly onto the bearings

with the ends of the pins having plates

solely to maintain position, not take

load.

Figure 7

However, as well as edge bearing

on the glass, the face can also be used

Glass cabinets

to take load but care must be taken

to ensure the interlayer is stiff enough

those used on the cantilevering glass not to deform under the load. Since it

cabinets for the Clerkenwell Green has nowhere to go, and there is such

Association. a relatively large area, the interlayer

However, to date, the level of finish (unless it is resin) is unlikely to deflect

recommended by research bodies for enough to increase the glass stresses,

the edges of glass sheets has never been but it has not been tested, only

achieved inside the holes. The milling developed through use.

Figure 5 and drills only go down to fine grit, and

Samsung Building, Seoul it has proved impossible to economically Tolerance:

get polishing heads into the holes. Unlike the engineering industry which

Therefore care is required to make sure quite happily turns out components at

The parameters of a structural that the interface can accommodate the +0 / -0.1mm tolerances, the GGF will

bearing in glass: finished surface of the hole. not reduce their tolerances lower than

Safety Glass in Buildings

The basic resolution of a high load- ±2 even using CNC machines (3 in

bearing joint in glass immediately raised Safety: Europe). On the RFR joint this is taken

5 areas of concern: Workmanship, Regardless of redundancy calculations, out by a loose fit hole on the backing

Safety, Tolerance, Interface and Analysis building regulations worldwide generally plate to which it is anchored. Whilst

require that all structural glass is this was satisfactory for a single sheet

laminated, even though it might be of glass on the outside, it was not

Workmanship: satisfactory for the high loads of the

tempered, and this rather complicates

Concurrent with the development in issues. The laminates range from resin Tokyo bearing, and to guarantee perfect

profiles has been the improvement in via PVB to SGP. They can transfer loads fit at all times (up and down loads),

technology for drilling holes in glass. in a stable temperature environment double cams were introduced between

The RFR joint can be made by using of between 10°C & 20°C. Recently we the bearing and the pin to ensure no

a single drill head, drilling the hole have had some interesting results from additional pressure was put on the glass

from one side with the inevitable SGP shear bearings, but outside this due to the misalignment of the holes.

shelling removed by a chamfer bit temperature range they fail, making However, each sheet of glass requires

from the other face. This is a prey to them irrelevant in external glass terms. its own cam, as holes cannot be post-

workmanship with the holes being In the Tokyo bearing there was drilled in tempered glass.

off-centre or out-of-square, but it is residual side-thrust due to the chamfers This complication led to the joint

satisfactory for cladding loads. and therefore all the bearings had to used on the Apple stores in which a

The increased loads of Tokyo required be bolted together without inducing transfer medium takes out tolerance

larger, more accurately placed holes.

A CNC machine drilled a lead hole

Figure 8

from one side which allowed a set of

specially modified milling heads to dress RFR, Tokyo & Apple

bearings

the chamfers from both sides at once

ensuring alignment, squareness, fit

and the removal of the shellings. This

technique also applies to large square-

faced holes such as those used on

Seoul.

Latterly, double drills have become

available which (when properly set up)

drill in from both faces at once and so

avoid the problem of shelling, allowing

small holes to be produced such as

470 GLASS PROCESSING DAYS 2005 - www.gpd.fi

allowable stresses are inconsistent but

the rule of thumb sits at the lower end

of the range with regard to toughened

bearings but annealed bearings may

require an additional factor of safety for

long term loads.

Removal of the Safety Factor gives

the average bearing stress at which the

joint would be expected to fail. This

is the figure used in testing. Very high

strength steels & titaniums are often

Figure 10 required in test pins to ensure that they

do not fail before the glass.

The load ideogram

This rule of thumb is for sizing

bearings in a simple elastic analysis

where the actual stress distributions

gives the area on which the load acts. are not known. These can be refined

The load divided by the area gives the by FE analysis and complex designs

average bearing stress in the hole. should be checked by FE. Care must

Conversely the load of a hole can be be taken to ensure that the modelled

Figure 9 predicted by the load ideogram. Whilst fittings are correctly released, as failure

Apple staircase, Nagoya D and T are clear, the stress is more to do so will induce large stresses in

complicated. Glass fails in tension the model. Of course, even when the

as well using a technique recently so the allowable bearing stress is an most sophisticated FE is carried out,

developed by Apple, James O’Callaghan approximation of the maximum tensile the ACTUAL stress distributions are still

and Seele GmbH for injecting Epoxy stress relative to the applied load. not known since one is dealing with a

cement between the pin and the hole. Holes should be a diameter of the theoretical representation of reality.

This marks a return to the timber pegs hole or 1½ thicknesses of the glass Whilst there is some reticence

and hot rivets of the past, but without from the edge, 4 times the thickness to using bearing holes in annealed

using stress to provide the fit, just the at the corner whichever is the greater. glass, modern and improving drilling

chemical reaction in the Epoxy as it In general holes should be placed with techniques which produce good quality

changes from liquid to solid. regard to the observations set out in holes should theoretically make bearing

Peterson’s Stress Concentration Factors. possible and allow standard laminate

Interface: Although Griffith had worked out in sheets to be post-drilled, reducing the

the 1930’s that the theoretical tensile need for tolerance between sheets. A

Friction bolting always had a high strength of glass is c14,000 N/mm2,

friction medium between the loading project for a staircase using annealed

this figure is considerably reduced by balustrades as well as treads was

face and the glass to reduce the the action of the molecules in the air,

slipperiness of the glass and protect it designed, but did not come to fruition,

breaking the bonds as it cools and and so the joint has not been tested.

from the steel. In the RFR joint, this was reducing it’s strength in annealed

changed to pure aluminium which could The above design bearing stresses

flat building glass to C 50 N/mm2. are only true of a symmetrically loaded

be milled into a cup to isolate the bolt Tempering improves the strength to

head from the glass and take load. In

Safety Glass in Buildings

C160 N/mm2. Fire glass, borosilicate

the intervening years, the aluminium has to be tempered for use and has

was replaced by Nylon 66, but for Tokyo the same characteristics as tempered

it proved to be too rigid to flow into the building glass.

lines in the holes produced by the mill

head. Very poor results were achieved

until it was changed to Delrin, and this

flow is achieved equally well with the

correct specification of the injected

Epoxy cement in the Apple joint.

Analysis:

Testing showed that small non-

alignments of bolts either due to

lack of squareness or correct position

could induce large stresses in the glass

reducing the carrying capacity of the

joint. To reduce the number of holes Figure 11 Figure 12

and therefore the risk of inducing stress, Rule of thumb for glass bearing stress (N/mm2) Annealed staircase

it was agreed that the design had to be

analysed into pure couples with one pin A Factor of Safety (FOS) of 3 pin. If the pin is asymmetrically loaded

at the centre of each end of the couple, is applied to these figures for the such as the RFR joint or the Apple tread

not the bolt groups common to friction allowable stress. The presence of holes connector, the bearing capacity is a

bolting. This has the added advantage increases the stresses in their vicinity quarter of the symmetrical pin, ie 4.5 N/

that the pins, being larger, are stiffer and so the allowable stresses is modified mm2 in tempered glass and the stability

and therefore less likely to bend in the using a Stress Concentration Factor of the bonds on the edge of the hole

hole. (SCF) from Peterson of 3 to account becomes a great problem.

The load transfer around the bearing for the hole and its surface . These For face bearing of a panel such as

can be idealised in the following way: factors, when applied to the glass failure the couple used to support the Apple

The load is transferred into the pins strengths, produce the table of the balustrade (assuming satisfactory

over 120º, ie 1/3rd of the hole, making rule of thumb of 3’s for the allowable stiffness of the interlayer) the bearing

the loaded part of the circumference bearing stress in the hole for the capacity is equal to the Area of outer

effectively the diameter, which when grossed-up short medium and long term diameter of the washer, minus the Area

multiplied by the thickness of the sheet loads. Worldwide codes of practice for

GLASS PROCESSING DAYS 2005 - www.gpd.fi 471

Figure 13 Figure 14

Apple balustrade Galileo’s cantilever drawing

of the hole, times the allowable stress of bearings based on empirical information References

the interlayer. garnered in design, testing and building [1] J. E. Gordon: The New Science of Strong

glass structures over the last 10 years. Materials

Summary: We are at the dawn of the use of glass [2] Stephen P.Timoshenko: History of the Strength

for self-supporting structures, the first, of Materials

1 Bolted bearings in holes in glass can [3] Institute of Structural Engineers: The Structural

the canopy in Tokyo is only 10 years

be sized on the basis of simple allowable Use of Glass in Buildings

old. There is a lot of research out there [4] Peterson: Stress Concentration Factors

bearing stresses.

into carbon fibre brittle structures

2 It is essential that tolerances are dealt

for the aero-space and car industries

with using fit rather than force.

but it is commercially secret, so the

3 Bolting rather than gluing will

information on glass is not much better

continue to be the preferred method of

than Galileo’s drawing of a cantilever. So

connecting elements together as high

this is a plea to industry and academia

loads can be carried without fear of

to measure, improve techniques,

“creep” failure.

and maybe invent, but above all

This is not a scientific paper but a

Safety Glass in Buildings

make observations clear, concise and

pragmatic record of the use of glass

comprehensible.

472 GLASS PROCESSING DAYS 2005 - www.gpd.fi

Das könnte Ihnen auch gefallen

- SJ MEPLA Calculation Protocol:: Spacers in Insulating Glass UnitsDokument5 SeitenSJ MEPLA Calculation Protocol:: Spacers in Insulating Glass UnitsSudhakar KrishnamurthyNoch keine Bewertungen

- All About GlassDokument58 SeitenAll About Glassdwivedi.p.kNoch keine Bewertungen

- CVDokument21 SeitenCVAngelica chea NatividadNoch keine Bewertungen

- Facade SelectionDokument34 SeitenFacade SelectionSarvesh TaleleNoch keine Bewertungen

- Structural Design Report For Glass BalustradeDokument14 SeitenStructural Design Report For Glass Balustradeantonv0421Noch keine Bewertungen

- 17-10-23 Inhabit - Presentation Glass MakassarDokument41 Seiten17-10-23 Inhabit - Presentation Glass MakassarBINAZIRNoch keine Bewertungen

- A1-10 Curtain WallsDokument58 SeitenA1-10 Curtain WallsZYWNoch keine Bewertungen

- Designcal Sky 2 AluminiumDokument17 SeitenDesigncal Sky 2 AluminiumMuraleedharanNoch keine Bewertungen

- A1-10 Curtain WallsDokument62 SeitenA1-10 Curtain WallsJacky TiongNoch keine Bewertungen

- SJ MEPLA Calculation Protocol:: Basic Form: QuadrangleDokument5 SeitenSJ MEPLA Calculation Protocol:: Basic Form: Quadranglewaweng22Noch keine Bewertungen

- Spontaneous Glass BreakageDokument4 SeitenSpontaneous Glass Breakagey2kareinNoch keine Bewertungen

- Glass Floor - Structural CalcsDokument3 SeitenGlass Floor - Structural CalcsIlirQosjaNoch keine Bewertungen

- Curtain WallDokument16 SeitenCurtain WallNp PwNoch keine Bewertungen

- Glass Balustrade Hand CalculationDokument2 SeitenGlass Balustrade Hand CalculationCiprian POPANoch keine Bewertungen

- Silicone Structural Glazing Manual - Dow CorningDokument52 SeitenSilicone Structural Glazing Manual - Dow Corningnithya174100% (2)

- SPIGOT GLASS RAILING @1.5KPaDokument18 SeitenSPIGOT GLASS RAILING @1.5KPaAniket InarkarNoch keine Bewertungen

- Cantilever Curtain WallDokument18 SeitenCantilever Curtain WallkingdbmNoch keine Bewertungen

- TECHNICAL MANUAL - MC600 v012021 PDFDokument108 SeitenTECHNICAL MANUAL - MC600 v012021 PDFmcbluedNoch keine Bewertungen

- Drilled Glass BearingDokument11 SeitenDrilled Glass BearingRichard GreenNoch keine Bewertungen

- 1e5 Glass Structures l5 Me Glued ConnectionDokument60 Seiten1e5 Glass Structures l5 Me Glued ConnectionPaulNoch keine Bewertungen

- Buckling Behavior of Split MullionDokument41 SeitenBuckling Behavior of Split MullionNguyễn SơnNoch keine Bewertungen

- Viracon Architectural Glass: Tech TalkDokument4 SeitenViracon Architectural Glass: Tech TalkJohn LeungNoch keine Bewertungen

- Standard Practice For Determining Load Resistance of Glass in BuildingsDokument62 SeitenStandard Practice For Determining Load Resistance of Glass in BuildingsBegging CoinsNoch keine Bewertungen

- CWCTDokument5 SeitenCWCTtroyel99Noch keine Bewertungen

- Spontanous Breakage - Nis PDFDokument22 SeitenSpontanous Breakage - Nis PDFNaveen KarkiNoch keine Bewertungen

- Code of Practice For Use of Glass in BuildingsDokument110 SeitenCode of Practice For Use of Glass in BuildingsNaveen KarkiNoch keine Bewertungen

- MULTIVER-Spontaneous Glass Breakage-Causes Solution enDokument7 SeitenMULTIVER-Spontaneous Glass Breakage-Causes Solution enBoby PrimatamaNoch keine Bewertungen

- Strength Calculator ExampleDokument4 SeitenStrength Calculator Examplerandy_pabilonaNoch keine Bewertungen

- SSGPGDokument56 SeitenSSGPGtroyel99Noch keine Bewertungen

- Sg12 Frameless Balustrades Structural CalculationsDokument12 SeitenSg12 Frameless Balustrades Structural CalculationsAhmed Mohamed LabibNoch keine Bewertungen

- Fin Glass 6Dokument4 SeitenFin Glass 6EIWAANoch keine Bewertungen

- Condensation On GlassDokument3 SeitenCondensation On GlassMancasi RazvanNoch keine Bewertungen

- A1-30 Sun-Screens and LouvresDokument17 SeitenA1-30 Sun-Screens and LouvresJacky TiongNoch keine Bewertungen

- Case 1Dokument19 SeitenCase 1JonathanNoch keine Bewertungen

- SJ Mepla Version 40 f88f9Dokument4 SeitenSJ Mepla Version 40 f88f9wal1547Noch keine Bewertungen

- Technical CalculationDokument33 SeitenTechnical CalculationmcbluedNoch keine Bewertungen

- 10th Aug. 2011 Structural Calculation (For Sub.) - 05Dokument26 Seiten10th Aug. 2011 Structural Calculation (For Sub.) - 05Nguyễn Tiến ViệtNoch keine Bewertungen

- The Dubai Chamber of Commerce and Industry Building ExtensionDokument22 SeitenThe Dubai Chamber of Commerce and Industry Building ExtensionAhammad KabeerNoch keine Bewertungen

- MEPLADokument4 SeitenMEPLAinitbashNoch keine Bewertungen

- GlassDokument221 SeitenGlassManuel CassarNoch keine Bewertungen

- Facade Toggle CalculationDokument11 SeitenFacade Toggle CalculationSudhakar KrishnamurthyNoch keine Bewertungen

- Window Full CalDokument65 SeitenWindow Full CalOn YouNoch keine Bewertungen

- Toaz - Info Design Calculation Skylight Structure PRDokument7 SeitenToaz - Info Design Calculation Skylight Structure PRAbdul khaliquNoch keine Bewertungen

- Design of Mullion-BS enDokument16 SeitenDesign of Mullion-BS enPrasad kapure100% (1)

- Curtain Wall Glazing Stick System CALCUL PDFDokument11 SeitenCurtain Wall Glazing Stick System CALCUL PDFAli SaifNoch keine Bewertungen

- Glass Design ASTM E1300Dokument2 SeitenGlass Design ASTM E1300irshad khanNoch keine Bewertungen

- 04 4012 00 PDFDokument38 Seiten04 4012 00 PDFrmdarisaNoch keine Bewertungen

- Design Components For Structural GlazingDokument8 SeitenDesign Components For Structural GlazingnonspodNoch keine Bewertungen

- Hilti HIT HY70 For Structural Glass Brochure ASSET DOC LOC 2521814Dokument8 SeitenHilti HIT HY70 For Structural Glass Brochure ASSET DOC LOC 2521814Efraim Fernandes FernandesNoch keine Bewertungen

- WK4-Salhia Shading CoeffficientDokument17 SeitenWK4-Salhia Shading CoeffficienttriplbingaziNoch keine Bewertungen

- Glass SpecificationDokument36 SeitenGlass SpecificationSayed Abdul Hafiz100% (1)

- 3M - VHB - Structural Glazing Tapes Structural Performance Tests Technical BulletinDokument9 Seiten3M - VHB - Structural Glazing Tapes Structural Performance Tests Technical BulletinkalidindivenkatarajuNoch keine Bewertungen

- Short 27Dokument1 SeiteShort 27Kavish SobronNoch keine Bewertungen

- Calculation Sheet 0Dokument10 SeitenCalculation Sheet 0Bahiya Al-rifaiiNoch keine Bewertungen

- Datasheet Adani Solar India 550w 555w 560w 565w 570w TOPCon Bifacial Elan ShineDokument2 SeitenDatasheet Adani Solar India 550w 555w 560w 565w 570w TOPCon Bifacial Elan ShineDept EnglishNoch keine Bewertungen

- Hook CheckDokument2 SeitenHook Checkwaweng22Noch keine Bewertungen

- Fin Glass 6 PDFDokument6 SeitenFin Glass 6 PDFEIWAA100% (1)

- GlassColumn DelftTUDokument4 SeitenGlassColumn DelftTUInga PerlovskaNoch keine Bewertungen

- 2005 GPD2005 PlateBuckling 18-07LuibleAndreascorrectedDokument5 Seiten2005 GPD2005 PlateBuckling 18-07LuibleAndreascorrectedLo WongNoch keine Bewertungen

- SN003b Secure PDFDokument14 SeitenSN003b Secure PDFlingchenhNoch keine Bewertungen

- GB700 2006Dokument11 SeitenGB700 2006lingchenhNoch keine Bewertungen

- NCCI: Determination of Non-Dimensional Slenderness of I and H SectionsDokument11 SeitenNCCI: Determination of Non-Dimensional Slenderness of I and H SectionslingchenhNoch keine Bewertungen

- BreDokument1 SeiteBrelingchenhNoch keine Bewertungen

- Bc1-Alternative Steel MaterialDokument4 SeitenBc1-Alternative Steel MateriallingchenhNoch keine Bewertungen

- Solution Manual For Physics For ScientisDokument17 SeitenSolution Manual For Physics For ScientisgoncaloNoch keine Bewertungen

- Sewer JointsDokument12 SeitenSewer JointsSalahuddin D. EdolNoch keine Bewertungen

- Tema HexDokument7 SeitenTema HexPrashanthMNairNoch keine Bewertungen

- Additional Objective Type QuestionDokument32 SeitenAdditional Objective Type QuestionThinnai TheniNoch keine Bewertungen

- Geothermal Well Operation and Maintenance: Sverrir ThorhallssonDokument23 SeitenGeothermal Well Operation and Maintenance: Sverrir ThorhallssonLaras PutiNoch keine Bewertungen

- Chapter 1 RC Column Design SlidesDokument28 SeitenChapter 1 RC Column Design SlidesMesfin Derbew100% (9)

- User Manual: Electronic ControlDokument72 SeitenUser Manual: Electronic ControlChí Khang NguyễnNoch keine Bewertungen

- Car Dynamics Using Quarter Model and Passive Suspension, PDFDokument9 SeitenCar Dynamics Using Quarter Model and Passive Suspension, PDFwelsya100% (1)

- Lesson plan-2015-XI PDFDokument3 SeitenLesson plan-2015-XI PDFprashant vaishnavNoch keine Bewertungen

- R171 Vario Roof Troubleshooting TreeDokument30 SeitenR171 Vario Roof Troubleshooting TreeBadi TrsatNoch keine Bewertungen

- Suzuki Jimny 4WD SystemDokument29 SeitenSuzuki Jimny 4WD SystemRuben Michel67% (9)

- Sankalp Phase IV SHM 4Dokument3 SeitenSankalp Phase IV SHM 4manjugupta05121975Noch keine Bewertungen

- Injection Mold Parting PlaneDokument19 SeitenInjection Mold Parting PlaneKodhansNoch keine Bewertungen

- Chapter 3 - Compressed Air Treatment (Dryers and Filters)Dokument34 SeitenChapter 3 - Compressed Air Treatment (Dryers and Filters)ppluis90Noch keine Bewertungen

- An IDEX Water & Wastewater Business: Hydraulic & Mechanical Metering Pumps API 675Dokument8 SeitenAn IDEX Water & Wastewater Business: Hydraulic & Mechanical Metering Pumps API 675SabbirHasanNoch keine Bewertungen

- Drop Impact Dynamics: Splashing, Spreading, Receding, BouncingDokument36 SeitenDrop Impact Dynamics: Splashing, Spreading, Receding, BouncingHarshini AichNoch keine Bewertungen

- Mech Engg Curriculum According To HecDokument92 SeitenMech Engg Curriculum According To HecRameez AnwarNoch keine Bewertungen

- Manual de Partes Dumper 730 Caterpillar Vol IIDokument591 SeitenManual de Partes Dumper 730 Caterpillar Vol IIRobinson Guaneme85% (13)

- E46 All-Wheel Drive System Model: E46/16 (330xi/a, 325xi/a, 325xi/a Sport Wagon) - Production Date: 330xi 8/00, 325xi 9/00Dokument11 SeitenE46 All-Wheel Drive System Model: E46/16 (330xi/a, 325xi/a, 325xi/a Sport Wagon) - Production Date: 330xi 8/00, 325xi 9/00Florin MaguranNoch keine Bewertungen

- Tech HIT HY 200 R V3 2021 en Technical Information ASSET DOC 11768542Dokument37 SeitenTech HIT HY 200 R V3 2021 en Technical Information ASSET DOC 11768542Jaouhar JerbiNoch keine Bewertungen

- Mechanical QuestionsDokument6 SeitenMechanical QuestionsarupNoch keine Bewertungen

- Generator AuxiliariesDokument39 SeitenGenerator Auxiliariesharry2586Noch keine Bewertungen

- SCALARS and VECTORS NotesDokument3 SeitenSCALARS and VECTORS NotesJoana MendoNoch keine Bewertungen

- 3b. Column Base Plate Ce134p Escruz LRFDDokument17 Seiten3b. Column Base Plate Ce134p Escruz LRFDjohn devonNoch keine Bewertungen

- Relief Valve CrossoverDokument5 SeitenRelief Valve CrossoverSherlock HolmesNoch keine Bewertungen

- Classification of Steam TurbinesDokument10 SeitenClassification of Steam TurbinesShon Rick AnisNoch keine Bewertungen

- 2-Hydrodynamic Methods (Sedimentation, Centrifugation and UltracentrifugationDokument24 Seiten2-Hydrodynamic Methods (Sedimentation, Centrifugation and UltracentrifugationEKANoch keine Bewertungen

- 1174-Powder Flow PDFDokument6 Seiten1174-Powder Flow PDFDymas AlfyanNoch keine Bewertungen

- F DampersDokument17 SeitenF Dampersbaba onuNoch keine Bewertungen

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansBewertung: 4.5 von 5 Sternen4.5/5 (21)

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (138)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetVon EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetBewertung: 4.5 von 5 Sternen4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Von EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Noch keine Bewertungen

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeVon EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeBewertung: 4.5 von 5 Sternen4.5/5 (59)

- Environmental Impact Assessment: Theory and PracticeVon EverandEnvironmental Impact Assessment: Theory and PracticeBewertung: 5 von 5 Sternen5/5 (5)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsVon EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsBewertung: 4 von 5 Sternen4/5 (16)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyVon EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Principles of Forensic Engineering Applied to Industrial AccidentsVon EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNoch keine Bewertungen

- Troubleshooting and Repair of Diesel EnginesVon EverandTroubleshooting and Repair of Diesel EnginesBewertung: 1.5 von 5 Sternen1.5/5 (2)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownVon EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsVon EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNoch keine Bewertungen

- The History of the Theory of Structures: From Arch Analysis to Computational MechanicsVon EverandThe History of the Theory of Structures: From Arch Analysis to Computational MechanicsNoch keine Bewertungen

- Introduction To Civil EngineeringVon EverandIntroduction To Civil EngineeringBewertung: 3.5 von 5 Sternen3.5/5 (5)

- Rock Fracture and Blasting: Theory and ApplicationsVon EverandRock Fracture and Blasting: Theory and ApplicationsBewertung: 5 von 5 Sternen5/5 (2)

- Structural Cross Sections: Analysis and DesignVon EverandStructural Cross Sections: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (19)