Beruflich Dokumente

Kultur Dokumente

We Make A Point of Grinding Tungsten Electrodes

Hochgeladen von

meet_sachin-1Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

We Make A Point of Grinding Tungsten Electrodes

Hochgeladen von

meet_sachin-1Copyright:

Verfügbare Formate

Grinding Tungsten electrodes

In order to obtain perfect TIG and

plasma weldings, it is necessary to

have perfectly grinded Tungsten elec-

trodes. Inelco Grinders offers the per-

fect solution and our grinders are

environmentally secure and safe for

We make a point

the employees and company.

of grinding tungsten

Honed technology electrodes

We have honed the technology, and

the ef cient and environmentally safe

grinding process consolidates our po-

sition among the leading

producers of Tungsten

grinders in the world. Our

products are recognized

for their simple operation,

high exibility and unique

grinding precision.

Precise and safe

The use of a special elec-

trode holder ensures per-

fectly centred electrode tips each time

and minimises the waste of electro-

des. Our products are environmentally

friendly and safe for the employees,

due to the fact that the grinding takes

place in a closed chamber, and the

toxic grinding dust is collected safely.

All our grinders:

have stepless angle adjustment

automatically centre the electrode

tip

have 100% dust collection

minimise the waste of electrodes

Neutrix Ultima-Tig-Cut

- the portable grinder, easy to bring along electrode grinder and cutter in one device

and perfect for the welder

ULTIMA-TIG-CUT grinds electrodes just like the

NEUTRIX grinds electrodes up to 4 mm and ULTIMA-TIG but in addition, it cuts them in the

down to 15 mm in length and in addition, down precise length for e.g. orbital and robotic wel-

to 8 mm with special electrode clamps. The elec- ding and welding in difcult accessible areas.

trode clamp facilitates grinding of all electrode

Using liquid cooling for the cutting device pre-

diameters and centres the electrodes perfectly.

vents overheating of the electrode. The grin-

Low weight and portable suitcase make NEUTRIX ding dust is collected in a closed container.

perfect for service engineers and any other pur-

Integrated trimming removes any impurity

poses, which require a portable grinder.

from the electrode

Stepless angle adjustment facilitates grinding

Grinding and cutting of the electrode with the

in all angles

same electrode holder

Ultima-Tig

Integrated lter collects the toxic cutting dust

Cutting off a damaged electrode tip, if neces-

Automatic grinding stop minimises the use of sary

electrodes

ULTIMA-TIG-CUT grinds and cuts electrodes

Grinding in 3 tracks ensures optimum use of - stationary liquid cooled grinder for work- from 0.8 mm to 4.0 mm and in addition,

grinding disc shops and industry from 7 to 175 mm in length.

Adjustment of grinding speed according to elec- Liquid cooled grinding of electrodes results in a

trode diameter smooth and even surface and at the same time,

cooling of the electrodes prevents overheating.

Sight glass allow view of the grinding process

ULTIMA-TIG grinds electrodes up to 4 mm and

In order to facilitate work with NEUTRIX on a

down to 15 mm in length and in addition, down

table, a useful stand is available.

to 8 mm with special electrode clamps. The elec-

trode clamp facilitates grinding of all electrode

diameters and centres the electrodes perfectly.

Perfectly centred electrodes

Stepless angle adjustment facilitates grinding in

all angles

Liquid cooling ensures collection and deposit of

toxic grinding dust

Automatic grinding stop minimises the use of

electrodes

The large grinding disc allows high grinding

speed

A special version of ULTIMA-TIG permits grinding

of electrodes up to 8 mm.

Das könnte Ihnen auch gefallen

- Dent PullerDokument1 SeiteDent PullerblazeramakrishnanNoch keine Bewertungen

- TPS 4000 5000Dokument16 SeitenTPS 4000 5000MohamedAbdelkaderNoch keine Bewertungen

- Electric Discharge Machining: Presented By: Srinivas Shenoy HDokument21 SeitenElectric Discharge Machining: Presented By: Srinivas Shenoy HsharathwaramballiNoch keine Bewertungen

- Project PPT Spot WeldingDokument19 SeitenProject PPT Spot WeldingMehul BariyaNoch keine Bewertungen

- Advantages and Limitations of Electrical-Discharge Machining (EDM)Dokument20 SeitenAdvantages and Limitations of Electrical-Discharge Machining (EDM)WongXinXinNoch keine Bewertungen

- Cutters: C15.25 Material Max Cutting Diameter MM C15.40.1 Material Max Cutting Diameter MMDokument1 SeiteCutters: C15.25 Material Max Cutting Diameter MM C15.40.1 Material Max Cutting Diameter MMابو محمد البصري العراقيNoch keine Bewertungen

- Cutters: C15.25 Material Max Cutting Diameter MM C15.40.1 Material Max Cutting Diameter MMDokument1 SeiteCutters: C15.25 Material Max Cutting Diameter MM C15.40.1 Material Max Cutting Diameter MMLuthfi AnandhikaNoch keine Bewertungen

- Wire Edm, Edg, EddgDokument23 SeitenWire Edm, Edg, EddgKrishna GopalNoch keine Bewertungen

- Electronic Discharge MachineDokument28 SeitenElectronic Discharge MachineShivanshu SinghNoch keine Bewertungen

- Fronius TPS-3200-9000 BrochureDokument16 SeitenFronius TPS-3200-9000 BrochuremaciejNoch keine Bewertungen

- Fusion Welding Processes2011Dokument33 SeitenFusion Welding Processes2011Anish Chakrabarti100% (1)

- Cartridge Heaters Metric FIRERODDokument10 SeitenCartridge Heaters Metric FIRERODEliasNoch keine Bewertungen

- 2022 23 M ToolsDokument16 Seiten2022 23 M ToolsPhafudi MalatjiNoch keine Bewertungen

- Elga Electrodes LRDokument6 SeitenElga Electrodes LRgori5Noch keine Bewertungen

- Welding AutomationDokument14 SeitenWelding AutomationPrakash RajNoch keine Bewertungen

- All Position Oxy-Fuel Cutting Machine: Features and BenefitsDokument5 SeitenAll Position Oxy-Fuel Cutting Machine: Features and BenefitsDuctoanNoch keine Bewertungen

- Lincoln Welder SpecsDokument4 SeitenLincoln Welder SpecsJJ GreggNoch keine Bewertungen

- CNC Wire CutDokument36 SeitenCNC Wire CutAviNoch keine Bewertungen

- Lincoln ServiceDokument8 SeitenLincoln ServicevargheseNoch keine Bewertungen

- CirculationDokument56 SeitenCirculationLuis Nahuelhuaique LemusNoch keine Bewertungen

- DGP - Line Card 2022Dokument1 SeiteDGP - Line Card 2022spindo.unit1Noch keine Bewertungen

- Endorace SystemDokument2 SeitenEndorace SystemBernardo Pinheiro de AndradeNoch keine Bewertungen

- SB 860420 R3 125CCC CeDokument4 SeitenSB 860420 R3 125CCC CeMohammed AhmedNoch keine Bewertungen

- Plasma Arc Machining - Lect 2Dokument17 SeitenPlasma Arc Machining - Lect 2sachhpNoch keine Bewertungen

- Cigweld WeldingDokument239 SeitenCigweld Weldingtanase_vNoch keine Bewertungen

- Vantage® 500-I (Disel Engine+ElectricDokument3 SeitenVantage® 500-I (Disel Engine+ElectricKumar RNoch keine Bewertungen

- Cutting and hardness testing machineDokument4 SeitenCutting and hardness testing machineJacques LopezNoch keine Bewertungen

- Stick Welding EngDokument6 SeitenStick Welding EngWilmer Ramírez MerejildoNoch keine Bewertungen

- TrueZONE User GuideDokument8 SeitenTrueZONE User GuideoscargerardoaNoch keine Bewertungen

- Electric Discharge Machining (Edm) BY: Dr. Manas Das Assistant ProfessorDokument40 SeitenElectric Discharge Machining (Edm) BY: Dr. Manas Das Assistant ProfessorSrinivasanNoch keine Bewertungen

- Watlow Mineral Insulated ThermocoupleDokument3 SeitenWatlow Mineral Insulated ThermocoupleTadau EnergyNoch keine Bewertungen

- Advanced Manufacturing Choices: MAE 165-265 Spring 2012, Class 5Dokument46 SeitenAdvanced Manufacturing Choices: MAE 165-265 Spring 2012, Class 5snvijayanNoch keine Bewertungen

- Catalogue: Accessory ProductsDokument58 SeitenCatalogue: Accessory ProductsStefanNoch keine Bewertungen

- Matrix 4000 AcdcDokument42 SeitenMatrix 4000 Acdcsonnguyen2041996Noch keine Bewertungen

- Soldering DescribedDokument6 SeitenSoldering Describedyashj91Noch keine Bewertungen

- Creepresistant Hightemperature FCAW ENGDokument12 SeitenCreepresistant Hightemperature FCAW ENGRuben Dario Mamani ArellanoNoch keine Bewertungen

- 1.0 TitleDokument10 Seiten1.0 TitlezackziffiNoch keine Bewertungen

- TS200 Manual SML 1 PDFDokument32 SeitenTS200 Manual SML 1 PDFTimNoch keine Bewertungen

- Advanced Manufacturing Choices: Thermal Energy Based Removing TechniquesDokument46 SeitenAdvanced Manufacturing Choices: Thermal Energy Based Removing Techniquessiva boyNoch keine Bewertungen

- CNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WDokument16 SeitenCNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WSot DesignNoch keine Bewertungen

- MAE250 Electrical Discharge Machining EDMDokument23 SeitenMAE250 Electrical Discharge Machining EDMForhad HossainNoch keine Bewertungen

- The Performance ST: Andard For Air Plasma Cutting and GougingDokument4 SeitenThe Performance ST: Andard For Air Plasma Cutting and GougingThe Normal HeartNoch keine Bewertungen

- Power CAGE CLAMP 60369122Dokument12 SeitenPower CAGE CLAMP 60369122Rafael GermanoNoch keine Bewertungen

- Seminar On Tig WeldingDokument17 SeitenSeminar On Tig WeldingAshishYadavNoch keine Bewertungen

- New Microsoft Office Power Point PresentationDokument17 SeitenNew Microsoft Office Power Point Presentationrahulm135100% (1)

- ae8d18e5e2f4953f454e9adc88b79010b71395b4Dokument20 Seitenae8d18e5e2f4953f454e9adc88b79010b71395b4Стоян МитевNoch keine Bewertungen

- Electrical Discharge MachiningDokument7 SeitenElectrical Discharge Machiningwunan07100% (3)

- UD SeriesDokument3 SeitenUD Seriesyuvaraj kamleNoch keine Bewertungen

- Self-Adjusting Crimping Pliers For Cable Ferrules PDFDokument3 SeitenSelf-Adjusting Crimping Pliers For Cable Ferrules PDFbaolifengNoch keine Bewertungen

- Advanced Manufacturing Choices: MAE 165-265 Spring 2012, Class 5Dokument46 SeitenAdvanced Manufacturing Choices: MAE 165-265 Spring 2012, Class 5Subramaniyan MahendiranNoch keine Bewertungen

- Tolomatic ERD 2011 CatalogDokument26 SeitenTolomatic ERD 2011 CatalogElectromateNoch keine Bewertungen

- Arc Stud Welding Solutions GuideDokument42 SeitenArc Stud Welding Solutions GuideRajan SteeveNoch keine Bewertungen

- Matrix Ac/Dc: Tig Inverter Welding EquipmentDokument4 SeitenMatrix Ac/Dc: Tig Inverter Welding EquipmentRoussos GeorgiadisNoch keine Bewertungen

- Basics in WeldingDokument63 SeitenBasics in WeldingK JeevanNoch keine Bewertungen

- Eutectic Eutronic Arc Spray 4 HFDokument4 SeitenEutectic Eutronic Arc Spray 4 HFjhonatan VBNoch keine Bewertungen

- Riland Arc 251cDokument1 SeiteRiland Arc 251ctmdhorphanNoch keine Bewertungen

- TIG Welding GuideDokument20 SeitenTIG Welding GuideAyat KursiNoch keine Bewertungen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesVon EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesBewertung: 1 von 5 Sternen1/5 (1)

- Nautic Steels Catalogue 2014b PDFDokument79 SeitenNautic Steels Catalogue 2014b PDFmeet_sachin-1Noch keine Bewertungen

- Technical 133 PDFDokument1 SeiteTechnical 133 PDFSatheshkumar EagambaramNoch keine Bewertungen

- F664 Bend DetailsDokument1 SeiteF664 Bend Detailsmeet_sachin-1Noch keine Bewertungen

- Piping Design AidsDokument248 SeitenPiping Design AidsSunday PaulNoch keine Bewertungen

- Ajax Fastener HandbookDokument132 SeitenAjax Fastener Handbookandrew_ferrier9390Noch keine Bewertungen

- Access Stair TreadsDokument2 SeitenAccess Stair TreadsAndrea GibsonNoch keine Bewertungen

- Gunnebo Load Ring RPLDokument12 SeitenGunnebo Load Ring RPLmeet_sachin-1Noch keine Bewertungen

- Material FlowDokument1 SeiteMaterial Flowmeet_sachin-1Noch keine Bewertungen

- Weld CalculationsDokument12 SeitenWeld Calculationshakr5100% (1)

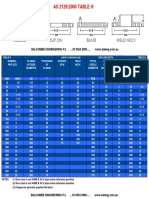

- Weld Neck Bossed Blind Slip On: AS 2129:2000 TABLE HDokument1 SeiteWeld Neck Bossed Blind Slip On: AS 2129:2000 TABLE Hmeet_sachin-1Noch keine Bewertungen

- Dimensions Elbows Long Radius 45° and 90° and Elbows 3D According To ASME B16.9Dokument2 SeitenDimensions Elbows Long Radius 45° and 90° and Elbows 3D According To ASME B16.9meet_sachin-1Noch keine Bewertungen

- OneSteel Piping Systems Data ChartDokument18 SeitenOneSteel Piping Systems Data Chartpete0980100% (1)

- Slip On Weld Neck Blind: AS 2129:2000 TABLE SDokument1 SeiteSlip On Weld Neck Blind: AS 2129:2000 TABLE Smeet_sachin-1Noch keine Bewertungen

- Dimensions Elbows Long Radius 45° and 90° and Elbows 3D According To ASME B16.9Dokument2 SeitenDimensions Elbows Long Radius 45° and 90° and Elbows 3D According To ASME B16.9meet_sachin-1Noch keine Bewertungen

- Weld Neck Bossed Blind Slip On: AS 2129:2000 TABLE FDokument1 SeiteWeld Neck Bossed Blind Slip On: AS 2129:2000 TABLE Fmeet_sachin-1Noch keine Bewertungen

- Grinding TungstenDokument2 SeitenGrinding TungstenThomas SjölingNoch keine Bewertungen

- Cu Ni FabricationDokument28 SeitenCu Ni FabricationAli Varmazyar100% (1)

- Hot Rolled Steel Catalogue - Nov01Dokument30 SeitenHot Rolled Steel Catalogue - Nov01meet_sachin-1Noch keine Bewertungen

- Cu Ni FabricationDokument28 SeitenCu Ni FabricationAli Varmazyar100% (1)

- ANSI B16.5 Flange Specs and DimensionsDokument23 SeitenANSI B16.5 Flange Specs and Dimensionsmeet_sachin-1Noch keine Bewertungen

- ANSI B16.5 Flange Specs and DimensionsDokument23 SeitenANSI B16.5 Flange Specs and Dimensionsmeet_sachin-1Noch keine Bewertungen

- Weld Neck Bossed Blind Slip On: AS 2129:2000 TABLE HDokument1 SeiteWeld Neck Bossed Blind Slip On: AS 2129:2000 TABLE Hmeet_sachin-1Noch keine Bewertungen

- Nautic Steels Catalogue 2014b PDFDokument79 SeitenNautic Steels Catalogue 2014b PDFmeet_sachin-1Noch keine Bewertungen

- Projects Oil & Gas Structural Steel Stock Program Tolerance TitleDokument11 SeitenProjects Oil & Gas Structural Steel Stock Program Tolerance Titlemeet_sachin-1Noch keine Bewertungen

- Bolted Moment ConnectionDokument18 SeitenBolted Moment ConnectionHugo EzequielNoch keine Bewertungen

- Nautic Steels Catalogue 2014b PDFDokument79 SeitenNautic Steels Catalogue 2014b PDFmeet_sachin-1Noch keine Bewertungen

- The 4Ms of Operations: Prepared By: Karla Jane F. BangaysisoDokument18 SeitenThe 4Ms of Operations: Prepared By: Karla Jane F. BangaysisoKarla BangFerNoch keine Bewertungen

- Environment Health: European Research OnDokument73 SeitenEnvironment Health: European Research OnDaiuk.DakNoch keine Bewertungen

- rfg040208 PDFDokument2.372 Seitenrfg040208 PDFMr DungNoch keine Bewertungen

- Transforming City Governments For Successful Smart CitiesDokument194 SeitenTransforming City Governments For Successful Smart CitiesTri Ramdani100% (2)

- Chapter 4-Market EquilibriumDokument24 SeitenChapter 4-Market EquilibriumAiman Daniel100% (2)

- Speed Limits in The PhilippinesDokument4 SeitenSpeed Limits in The Philippinesmark carloNoch keine Bewertungen

- Piping and Equipment IsolationDokument8 SeitenPiping and Equipment IsolationBilal Mustafa Siddiqui100% (1)

- Human Resource Planning and Corroporate Strategies: Meaning and Definition of StrategyDokument19 SeitenHuman Resource Planning and Corroporate Strategies: Meaning and Definition of StrategyRashmi KhublaniNoch keine Bewertungen

- The Barber of SevilleDokument1 SeiteThe Barber of SevilleAine MulveyNoch keine Bewertungen

- Game Informer September 2013Dokument104 SeitenGame Informer September 2013Igor IvkovićNoch keine Bewertungen

- Cambridge Ext2 Ch1 Complex Numbers IWEBDokument62 SeitenCambridge Ext2 Ch1 Complex Numbers IWEBchenNoch keine Bewertungen

- Chobani: The Falling First Mover: Jianan LiaoDokument5 SeitenChobani: The Falling First Mover: Jianan Liaowofop34547Noch keine Bewertungen

- Underpinning Methods, Procedure and ApplicationsDokument10 SeitenUnderpinning Methods, Procedure and ApplicationsShivaun Seecharan0% (1)

- Lembar Kerja Lap Keu - Tahap 1Dokument4 SeitenLembar Kerja Lap Keu - Tahap 1Safana AuraNoch keine Bewertungen

- Chapter 2 ResearchDokument14 SeitenChapter 2 ResearchabibualNoch keine Bewertungen

- Computer Assisted Language LearningDokument9 SeitenComputer Assisted Language Learningapi-342801766Noch keine Bewertungen

- Gas Turbine MaintenanceDokument146 SeitenGas Turbine MaintenanceMamoun1969100% (8)

- Role of MicrofinanceDokument1 SeiteRole of MicrofinanceuttamsudhirNoch keine Bewertungen

- Non-Traditional Machining: Unit - 1Dokument48 SeitenNon-Traditional Machining: Unit - 1bunty231Noch keine Bewertungen

- Bid Document Vol. II Attachment BOQDokument6 SeitenBid Document Vol. II Attachment BOQHrityush ShivamNoch keine Bewertungen

- Bank 12Dokument19 SeitenBank 12Shivangi GuptaNoch keine Bewertungen

- 28/08/2016 1 Advanced Research Methodology... RU, Bangalore-64Dokument38 Seiten28/08/2016 1 Advanced Research Methodology... RU, Bangalore-64Ananthesh RaoNoch keine Bewertungen

- Attaei PDFDokument83 SeitenAttaei PDFHandsomē KumarNoch keine Bewertungen

- MIT6 003S10 FrontDokument11 SeitenMIT6 003S10 Frontclique_devNoch keine Bewertungen

- Ahmed (2018)Dokument9 SeitenAhmed (2018)zrancourttremblayNoch keine Bewertungen

- Summary of Relief Scenarios: Contingency DataDokument3 SeitenSummary of Relief Scenarios: Contingency Dataimtinan mohsinNoch keine Bewertungen

- L10: Factors that Affect a Pendulum's PeriodDokument9 SeitenL10: Factors that Affect a Pendulum's PeriodHeide CarrionNoch keine Bewertungen

- Physics Chapter on Motion and Force EquationsDokument2 SeitenPhysics Chapter on Motion and Force EquationsMalikXufyanNoch keine Bewertungen

- Using Social Stories With Students With Social Emotional and Behavioral Disabilities The Promise and The Perils (2019)Dokument17 SeitenUsing Social Stories With Students With Social Emotional and Behavioral Disabilities The Promise and The Perils (2019)SarahNoch keine Bewertungen