Beruflich Dokumente

Kultur Dokumente

A Comparative Study of Basalt and Polypropylene Fibers Reinforced Concrete On Compressive and Tensile Behavior

Hochgeladen von

Isha PatelOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A Comparative Study of Basalt and Polypropylene Fibers Reinforced Concrete On Compressive and Tensile Behavior

Hochgeladen von

Isha PatelCopyright:

Verfügbare Formate

International Journal of Engineering Trends and Technology (IJETT) Volume 9 Issue 6- March 2014

A comparative Study of Basalt and

Polypropylene Fibers Reinforced Concrete on

Compressive and Tensile Behavior

Mustapha Abdulhadi#1

#1

(Civil Engineering & Architecture College, Liaoning University of Technology, Jinzhou 121001China)

Abstract Concrete made with Portland cement has certain material with a random distribution of short discontinuous

characteristics: it is relatively strong in compression but weak in fiber is referred as fiber reinforced concrete (FRC).

tension and tends to be brittle. These two weaknesses have Research on fiber reinforced concrete has been conducted

limited its use. Another fundamental weakness of concrete is that since the 1960s [1]. During the 1970s the commercial use of

cracks start to form as soon as concrete is placed and before it this material began to increase, particularly in Europe, japan

has properly hardened. These cracks are major cause of and USA [2]. Common applications today are pavement,

weakness in concrete particularly in large onsite applications industrial floors, precast elements and various kinds of repairs

leading to subsequent fracture and failure and general lack of

durability. The weakness in tension can be overcome by the use

[3].

of conventional rod reinforcement and to some extent by the Fiber reinforced concrete is the composite material containing

inclusion of a sufficient volume of certain fibres. fibers in the cement matrix in an orderly manner or randomly

This paper provides result data of the compressive strength, and distributed manner. Its properties would obviously, depend

split tensile strength of basalt and polypropylene fiber reinforced upon the efficient transfer of stress between matrix and the

concrete containing fibres of 0%, 0.3%, 0.6%, 0.9%, and 1.2% fibers, which is largely dependent on the type of fiber, fiber

volume fraction by weight of cement (Vf) without admixture. For geometry, fiber content, orientation and distribution of the

compression test, fibers, mixing and compaction techniques of concrete, and

A result data obtained has been analysed and compared with a size and shape of the aggregate. Fiber reinforced concretes

control specimen (0% fiber). A relationship between

Compressive strength vs. fiber volume fraction and tensile

(FRC) exhibit property improvement caused by the fibers [4].

strength vs. fiber volume fraction of both basalt and It was reported that polypropylene fibers improves the plain

polypropylene fiber are represented graphically. Result data concrete properties including splitting tensile strength, first

clearly shows decrease in compressive strength for C30 Grade of crack strength and impact resistance [5]. Alhozaimy et al. [6]

concrete due to addition of basalt fiber and polypropylene fiber. observed that an additional amount of 0.1% polypropylene

Also, the result data shows that, the optimum dosage for the fibers in the plan concrete had 44% increases in flexural

splitting tensile strength of basalt fiber is in the vicinity of 0.6%. toughness of the concrete. Some researchers also reported

While the optimum dosage for the splitting tensile strength of evidence of small but favorable effect of fiber addition on

polypropylene fiber is in the vicinity of 0.3%. toughness [7], [8], [9], [10], [11]. Mindess et al (1988) [12]

reported that compressive strength increased by about 25% at

0.5% volume fraction of PP fibers in the concrete mixture

Keywords- Basalt fiber, Compressive strength, Control concrete, design. Hughes and Fattuhi [13] suggested that compressive

polypropylene fiber, Split tensile strength.

strength decreases but flexural properties are improved with

increasing fiber content.

The basalt fiber is a new inorganic fiber material with high

I. INTRODUCTION tensile strength, good heat resistance, high dielectric property,

Compared to other building materials such as metal and corrosion resistance, high chemical stability and low cost.

polymers, concrete is significantly more brittle and exhibit a Since it is a typical ceramic fiber with a similar density (2.63

poor tensile strength. Based on fracture toughness values, steel 2.8g/cm3) as cement concrete and mortar, it has a unique

is at least 100 times more resistance to crack growth than advantage in terms of uniform distribution, thus becoming a

concrete. Concrete in service thus cracks easily, and this new reinforcing material with a good development prospect.

cracking creates easy access routes for deleterious agents Hence this study explores the comprehensive experimental

resulting in early saturation, freeze than damage, scaling data and powerful statistical analyses regarding the effects of

discoloration and steel corrosion. adding polypropylene fibers and basalt fiber with different

As the structural use of concrete developed in the second half volume fractions; aim is to do the comparative study

of the 1800s, interest was focused on reinforcements to between the two fibers on compressive strength and tensile

enhance its low tensile capacity. The concern with the inferior strength study etc. with given grade of concrete, proportions

fracture toughness of concrete are alleviated to a large extent and percentage of fibers.

by reinforcing it with fibers of various materials. The resulting

ISSN: 2231-5381 http://www.ijettjournal.org Page 295

International Journal of Engineering Trends and Technology (IJETT) Volume 9 Issue 6- March 2014

II. MATERIAL USED AND MIX PROPORTION C. Water

In this experimental study, Cement, sand, coarse aggregate, Concrete mixing water used complies with "Chinese National

water, polypropylene fiber and basalt fibers were used. Standards (JGJ63-2006) [15]. This experiment uses Jinzhou

City tap water.

A. Cement

Cement is an important component of the concrete material D. Fiber

which directly affects its strength grade. This test used This test uses a continuous basalt and polypropylene fiber, as

32.5slag cement, and its physical and mechanical properties shown in Figure 1, and their performance as shown in Table 4

are shown in Table 1. and Table 5 respectively.

TAB. 1

PHYSICAL AND MECHANICAL PROPERTIES OF SLAG CEMENT

Ceme Fine Compressiv Flexural

Setting time

nt ness e strength strength

h:min

grade (%) MPa MPa

Initial Final 3d 28d 3d 28d

32.5A 7.0

3:11 4:26 18.9 44.3 4.4 9.3

Fig. 1 Basalt and polypropylene fiber morphology

B. Aggregate

This test is in accordance with current industries standard

aggregate "Chinese National Standards (JGJ52-2006)" [14] TAB. 4

requirements. PERFORMANCE PROPERTIES OF BASALT FIBER

Tensile Ultimate

Densiy Modulus

strength elongation Fiber Type L(m)

1) Fine Aggregate: This test uses Jinzhou NVER river (g/cm3) GPa

(MPa) (%)

sand, its grading and performance indicators shown

2.65 3000~3500 3.2 90~110 Chopped 12

in Table 2.

TAB. 2

FINE ORTHOPEDIC INDICATORS TAB. 5

PERFORMANCE PROPERTIES OF POLYPROPYLENE FIBER

Apparent Fineness Moistur Clay Ultimat

Bulk Density

Density Modulus e content Densit Tensile e

(kg/cm3) % Modulus Mp Fiber

(kg/cm3) f % y strength elongat L(m)

(GPa) () Type

(g/cm3) (MPa) ion

2670 1554 2.46 3.1 3.0

(%)

165~ Bunc

0.91 365~600 25~60 2.4~3.2 12

173 hy

2) Course Aggregate: This test uses particle size less E. Test mix design

than 20mm gravel, its findings and technical This test is based on "Chinese National Standards" (JGJ55-

indicators shown in Table 3. 2011) [16], formulated on C30 ordinary concrete, such as

shown in Table 6 below. Low elastic modulus polypropylene

TAB. 3 and high elastic modulus basalt of two kinds of fiber were

THICK ORTHOPEDIC INDICATORS used. 0.3%, 0.6%, 0.9%, and 1.2% were the percentage used

Apparent Size Clay Flakiness of a mixing fiber.

Bulk Density TAB. 6

Density grading content content C30 CONCRETE MIX

(kg/cm3) %

(kg/cm3) mm) % Cemen

Water- Water

CCemen Sand Sand t Sand Pebble

cement (kg/m3

2665 1450 10~20 0.3 14 t strength ratio species (kg/m3 (kg/m3) (kg/m3)

ratio )

)

Medium

32.5 0.3 0.5 203.7 407 535 1245

sand

ISSN: 2231-5381 http://www.ijettjournal.org Page 296

International Journal of Engineering Trends and Technology (IJETT) Volume 9 Issue 6- March 2014

III. EXPERIMENTAL METHODOLOGY B. Splitting tensile test:

The mechanical tests used for the comparative study of

polypropylene and basalt fiber were compressive strength and The specimen was placed at the splitting tensile device center,

tensile strength. the testing machine was started at the speed of 0.3 ~ 0.8MPa

This test is strictly in accordance with "Chinese National and uniformly loaded. When the destruction of the specimen

Standards" (GB / T 50081) [17]. The relevant compressive

was approached, the load reaches maximum, the breaking load

strength test specimens were produced using a non-standard

specimen size 100mm 100mm 100mm cube and Splitting was recorded. Splitting tensile strength was calculated

tensile test specimens using standard size 150mm 150mm according to equation (2)

150mm cube. The production process of concrete has a direct

impact on various performances. The test uses mixer to Fts max

properly mix the coarse aggregate sand and gravel. In order to fts 0.637 2

Ats

ensure uniformity of concrete mixture, the aggregate was dry

mix in a blender for 30 seconds, then the dry mix cement was

added, and finally the fiber. Where;

The marinated fiber concrete was poured into the test

mould, and placed on the vibration table. The specimens were f ts is the splitting tensile strength of concrete (MPa)

removed from the mould after 24 hours and moved into the

curing room; curing room temperature was 20 2 and a

relative humidity of 95% or more, the curing procedure was Fts max is the maximum load of concrete splitting failure (N)

strictly in accordance with the (GB / T 50081)". After 28d,

the test was carried out for cubic compressive strength and Ats is the splitting test specimen areamm2

splitting tensile strength.

The procedure for the test was in accordance with

"Chinese National Standards "(GB / T 50081) [17]. The

specimen was removed from the curing room to wipe clean; IV. EXPERIMENTAL RESULTS AND ANALYSIS

the size appearance of the specimen was checked immediately Results of Compressive and tensile strength for C30 grade of

after the test. concrete on cube specimen with 0%, 0.3%, 0.6%, 0.9% and

1.2% of Basalt and Polypropylene Fibers are shown in

A. Compressive strength test:

table3.1

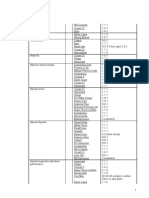

The specimen was placed at the lower platen center of the TAB. 7

testing machine. In this experiment, the speed of 0.3 ~ 0.5MPa, TESTRESULTS

continuous and uniform loading were used. The specimen

damaged when the load reaches the maximum, the breaking Test Test Dosa compressi Splitting

load was recorded. Compressive strength was calculated Packet Num ge ve strength

according to formula (1) ber (%) strength MPa

MPa

Fc max Ordina OC 0 36.09

f cu 1 2.95

Ac ry

Where; BC1 0.3 32.78 3.03

BC2 0.6 29.13 3.62

f cu is the cube compressive strength for the concrete basalt

fiber BC3 0.9 35.87 2.62

(MPa)

BC4 1.2 29.5 2.37

Fc max is the maximum load at failure of the concrete PC1 0.3 33.25 3.40

PC2 0.6 33.65 3.18

(N), polypr

opylen PC3 0.9 29.86 3.11

2

Ac is confined compression test specimen area (mm ) e PC4 1.2 27.49

2.65

fibers

ISSN: 2231-5381 http://www.ijettjournal.org Page 297

International Journal of Engineering Trends and Technology (IJETT) Volume 9 Issue 6- March 2014

A. Analysis of Compressive strength test results same series of fiber concrete, the strength decreases with the

Strength/MPa increase of fiber mixing ratio increases. Also, with the same

39 volume of fiber, the addition of different series of fiber results

37 in different compressive strength of concrete.

35

B. Analysis of splitting tensile test results

33 Table 7 records the splitting tensile test results as plotted in a

31 scatter line chart shown in Figure 4

29

27 Strength/MPa

4.0

25

0 0.3 0.6 0.9 1.2 3.5

Fiber mixing ratio/%

3.0

BC PPC

Fig. 2 Compressive strength of basalt and polypropylene fiber 2.5

2.0

1.5

40 0 0.3 0.6 0.9 1.2

35 Fiber mixing ratio/%

BC PPC

30

25

Fig. 4 Splitting tensile strength of basalt and polypropylene

20 Basalt fiber

fiber

15

10 Polypropylene

fiber Strength/MPa

5

0

Fig. 3 comparison between Compressive strength of basalt

and polypropylene fiber.

As seen in Figure 3, addition of 0.3%, 0.6%, 0.9% and 1.2%

resulted in a decrease of compressive strength relative to plain

concrete by 9%, 19%, 1%, and 18% respectively. Similarly,

addition of 0.3%, 0.6%, 0.9%, and 1.2% volume of

Fig. 5 comparison between splitting tensile strength of basalt

polypropylene resulted in a decrease of strength relative to

plain concrete by 8%, 7%, 17% and 24% respectively. and polypropylene fiber.

The incorporation of polypropylene and basalt fibers in the

As can be seen from Figure 4, the incorporation of fibers

concrete mixture has different degrees of reduction on the

in the concrete matrix greatly increases splitting tensile

compressive strength. Because many factors affect the

strength. Addition of 0.3% and 0.6% volume of basalt fiber

strength of concrete, such as cement strength, water-cement

ratio, and the size of the aggregates [14]. Incorporation of the increase the splitting tensile strength of concrete by 2.6% and

22.9% respectively; while for 9% and 1.2% volume, the

fibers within the concrete matrix changes the phase of each

splitting tensile strength of concrete decreased by 11.3% and

component. As seen from the test results analysis, with the

19.8% respectively; therefore, the optimum dosage for the

ISSN: 2231-5381 http://www.ijettjournal.org Page 298

International Journal of Engineering Trends and Technology (IJETT) Volume 9 Issue 6- March 2014

splitting tensile strength of basalt fiber is in the vicinity of

0.6%. Also, addition of 0.3%, 0.6%, and 0.9%, volume of

polypropylene fiber increase the splitting tensile strength of

concrete by 15.1%, 7.8%, and 5.6% respectively; the optimum

dosage for the splitting tensile strength of polypropylene fiber

is in the vicinity of 0.3%. a b c

V. FAILURE MODE ANALYSIS

A. Compressive strength failure mode analysis

The plain concrete specimens and basalt fiber specimens

destructed after the maximum load reached and started (d) (e) (f)

decreasing, the surface of the concrete specimen showed Fig. 7 Splitting tensile failure modes analysis of basalt

serious damage after been tapered to a shape as shown in fig. and polypropylene fiber

6 (a), (b). While for the polypropylene fiber, destruction

occurred at maximum load that is immediately after reaching

the maximum load at failure. VI. CONCLUSION

The study on the effect of Basalt and Polypropylene Fibers

with different volume can still be a promising work as there is

always a need to overcome the problem of brittleness of

concrete.

The following conclusions could be drawn from the present

investigation-

1 It is observed that the compressive strength for C30

(a) (b) c

grade of concrete from two different type of fiber at

Fig. 6 Compressive strength failure mode

analysis of basalt and polypropylene fiber. different volume fraction shows different degree of

reduction.

B. Splitting tensile test failure mode analysis 2 Addition of 0.3%, 0.6%, 0.9% and 1.2% resulted in a

As seen from the test result: Addition of low content of fiber decrease of compressive strength relative to plain

has improved the splitting tensile strength of the reinforced

concrete matrix to a varying degrees, while the splitting concrete by 9%, 19%, 1%, and 18% respectively.

tensile strength decreases with the addition of high content of Similarly, addition of 0.3%, 0.6%, 0.9%, and 1.2%

fiber to a concrete matrix. The role of each phase had volume of polypropylene resulted in a decrease of

dramatically changed, due to the high amount of fibers inside strength relative to plain concrete by 8%, 7%, 17%

the concrete matrix. Figure 7 (a), (b), and (c) represents the

failure mode of the specimen for plain and 0.3% fiber content, and 24% respectively.

due to the low content of fiber, the change in the inner part 3 It was observed that the incorporation of fibers in the

was very small, therefore, plain concrete failure modes and concrete matrix greatly increases splitting tensile

low fiber content failure mode were basically the same, where strength. Addition of 0.3% and 0.6% volume of

by all the specimens were broken in half. For high content of

fiber, the failure mode can be represented in Figure 7 (d), (e), basalt fiber increase the splitting tensile strength of

(f), in which the specimen is not completely broken in half, concrete by 2.6% and 22.9% respectively; while for

but fibers linked the two half where you can clearly see the 9% and 1.2% volume, the splitting tensile strength of

fibers in the specimens between the two cleavage planes, concrete decreased by 11.3% and 19.8%

which showed fiber effect on crack resistance of concrete, the

fundamental effect caused by high fiber content did not respectively; therefore, the optimum dosage for the

improved splitting tensile strength of concrete. splitting tensile strength of basalt fiber is in the

vicinity of 0.6%. Also, addition of 0.3%, 0.6%, and

0.9%, volume of polypropylene fiber increase the

splitting tensile strength of concrete by 15.1%, 7.8%,

and 5.6% respectively; therefore, the optimum

ISSN: 2231-5381 http://www.ijettjournal.org Page 299

International Journal of Engineering Trends and Technology (IJETT) Volume 9 Issue 6- March 2014

dosage for the splitting tensile strength of [9] Balendran R.V., Zhou F.P., Nadeem A., and Leung A.Y.T., Influence of

steel fibres on strength and ductility of normal and lightweight high strength

polypropylene fiber is in the vicinity of 0.3%. concrete, Build. Environ. 37: 1361 1367, 2002.

[10] Malisch, W. R., Polypropylene Fibers in Concrete, What do the test tell

us? Concrete Construction, 31: 363-8, 1986.

[11] Kraii, P. P., A Proposed test to determine the cracking potential due to

REFERENCES drying shrinkage of concrete. Concrete construction, 30: 775-778, 1985.

[1] Shah, S, P.; Skarendahl, A. Steel fiber concrete, preface. US-Sweden, [12] Mindess, S. & Vondran, G., Properties of concrete reinforced with

Join seminar (NSF-STU, Stockholm Sweden, 1985. fibrillated polypropylene fibers under impact loading. Cement and Concrete

[2] Clarke, J. L, Vollum, R. L., Swwannell, N. et al. Guidance for the Design Research, 18: 109-15, 1988.

of Steel-Fiber-Reinfored Concrete. Technical Report No. 63, Report of a [13] Hughes, B. P., Fattuhi, N. I., Improving the toughness of high strength

Concrete Society Working Group.UK , 2007. cement paste with fiber reinforcement, Composite, 7 (4): 185-8, 1976.

[3] Carlsward, J. Shrinkage cracking of steel fiber reinforced self compacting [14] Chinese National Standards, for technical requirements and test method

concrete overlays, test methods and theoretical modeling. Doctoral thesis, of sand and crushed stone for ordinary concrete.( JGJ52-2006).

lulea university of technology Sweden, 2006. [15] Chinese National Standards of water for concrete.(JGJ63-2006).

[4] Bentur A, Mindess S., Fibre Reinforced Cementitious Composites, [16] Chinese National Standards. Specification for mix proportion design of

Elsevier Applied Science, London, UK. 1990 Ordinary concrete. JGJ55, 2011.

[5] Song P. S., Hwang S., and Sheu B. C. Strength properties of nylon- and [17] Chinese National Standards, for test method of mechanical properties on

polypropylene-fiber reinforced concretes, Cement And Concrete Research,35: ordinary concrete.GB/T 50081)

1546-1550, 2005. [18] Shen Rong-Xi. Fiber Reinforced Concrete [M]. Beijing, China

[6] Alhozaimy A. M., Soroushian P., and Mirza F., Mechanical properties of Building Industry Press,880 ~ 920, 1995.

polypropylene fiber reinforced concrete and the effects of pozzolanic

materials, Cement and Concrete Composites, 18: 85-92, 1996.

[7] Tanyildizi H., Statistical analysis for mechanical properties of

polypropylene fiber reinforced lightweight concrete containing silica fume

exposed to high temperature, Materials and Design, 30: 32523258, 2009.

[8] Soroushian P, Nagi M, and Hsu J., Optimization of the use of lightweight

aggregate in carbon fiber reinforced cement. ACI Mater J, 89(3):26776,

1992

ISSN: 2231-5381 http://www.ijettjournal.org Page 300

Das könnte Ihnen auch gefallen

- Total04 Digital Version PDFDokument52 SeitenTotal04 Digital Version PDFbeatriz matos67% (3)

- FORD Falcon XA Repair ManualDokument770 SeitenFORD Falcon XA Repair ManualMark Kenzie100% (10)

- Working at Heights GuidelineDokument15 SeitenWorking at Heights Guidelinechanks498Noch keine Bewertungen

- Piles DesignDokument15 SeitenPiles Designvenkatesh19701Noch keine Bewertungen

- Scientific Exploration and Expeditions PDFDokument406 SeitenScientific Exploration and Expeditions PDFana_petrescu100% (2)

- Over Current & Earth Fault RelayDokument2 SeitenOver Current & Earth Fault RelayDave Chaudhury67% (6)

- 100 Years of Hydrodynamic PDFDokument28 Seiten100 Years of Hydrodynamic PDFnikodjoleNoch keine Bewertungen

- QTM - Soap Battle CaseDokument7 SeitenQTM - Soap Battle CaseAshish Babaria100% (1)

- Transfer Case Electrical RMDokument51 SeitenTransfer Case Electrical RMDaniel Canales75% (4)

- Article Unleashing The Power of Your StoryDokument17 SeitenArticle Unleashing The Power of Your StoryAnkit ChhabraNoch keine Bewertungen

- Fibre Reinforced ConcreteDokument12 SeitenFibre Reinforced ConcretePradeepLokhande100% (2)

- Estimation of Safe Vertical Load Capacity of Pile For Normal ConditionDokument4 SeitenEstimation of Safe Vertical Load Capacity of Pile For Normal ConditionVasanthakumarNoch keine Bewertungen

- Fibre Reinforced ConcreteDokument50 SeitenFibre Reinforced ConcreteRaheelAfzaal100% (1)

- Experimental Strength On Polypropylen Fiber Reinforced ConcreteDokument7 SeitenExperimental Strength On Polypropylen Fiber Reinforced ConcreteIJRASETPublicationsNoch keine Bewertungen

- Fibre Reinforced ConcreteDokument50 SeitenFibre Reinforced ConcreteAishwarya Madhivanan100% (3)

- Structural Behaviour of Fibrous Concrete Using Polypropylene FibresDokument4 SeitenStructural Behaviour of Fibrous Concrete Using Polypropylene FibresPatricia ClarkNoch keine Bewertungen

- AFBAD2A10971Dokument10 SeitenAFBAD2A10971Samuel NkereuwemNoch keine Bewertungen

- Comparison Between Reinforced Cement Concrete and Fibre Reinforced Beam Using Finite Element MethodDokument2 SeitenComparison Between Reinforced Cement Concrete and Fibre Reinforced Beam Using Finite Element MethodEditor IJTSRDNoch keine Bewertungen

- FibersDokument15 SeitenFibersSACHINNoch keine Bewertungen

- Shear Performance of Reinforced Concrete Deep Beams Using Hybrid Fiber Reinforcement (7-11-22) - 2pmDokument8 SeitenShear Performance of Reinforced Concrete Deep Beams Using Hybrid Fiber Reinforcement (7-11-22) - 2pmluckyNoch keine Bewertungen

- 2015 A Study On Strength Properties of Hybrid Fiber Reinforced PDFDokument5 Seiten2015 A Study On Strength Properties of Hybrid Fiber Reinforced PDFSrikanth KonikiNoch keine Bewertungen

- (12302945 - Archives of Civil Engineering) Load-Deflection Characteristics of Steel, Polypropylene and Hybrid Fiber Reinforced Concrete BeamsDokument14 Seiten(12302945 - Archives of Civil Engineering) Load-Deflection Characteristics of Steel, Polypropylene and Hybrid Fiber Reinforced Concrete Beamselmitodeherta3Noch keine Bewertungen

- Strain Hardening HPFRCDokument10 SeitenStrain Hardening HPFRCsaiNoch keine Bewertungen

- Am NQ77306Dokument7 SeitenAm NQ77306luckyNoch keine Bewertungen

- Influence of Mineral Nano-Fibers On The Physical Properties of Road Cement Concrete MaterialDokument8 SeitenInfluence of Mineral Nano-Fibers On The Physical Properties of Road Cement Concrete MaterialDania Marlen ValenzuelaNoch keine Bewertungen

- Fiber Reinforced ConcreteDokument5 SeitenFiber Reinforced ConcreteJournalNX - a Multidisciplinary Peer Reviewed JournalNoch keine Bewertungen

- Experimental Investigation of Steel Fiber Reinforced ConcetreDokument6 SeitenExperimental Investigation of Steel Fiber Reinforced ConcetreJETLYNoch keine Bewertungen

- Investigation of Properties of Fiber Reinforced Concrete Using RubberDokument5 SeitenInvestigation of Properties of Fiber Reinforced Concrete Using RubberSumit Geete100% (1)

- Glass Fiber Reinforced Concrete (GFRC) - Strength and Stress Strain Behavior For Different Grades of ConcreteDokument6 SeitenGlass Fiber Reinforced Concrete (GFRC) - Strength and Stress Strain Behavior For Different Grades of ConcretePiyush SaxenaNoch keine Bewertungen

- Mechanical Properties of Concrete Using Flyash With Addition of Polypropylene FibresDokument39 SeitenMechanical Properties of Concrete Using Flyash With Addition of Polypropylene FibresMohammed AzharuddinNoch keine Bewertungen

- Experimental Study On Behavior of SteelDokument6 SeitenExperimental Study On Behavior of Steelharshithak.cee21Noch keine Bewertungen

- Irjet V7i2252Dokument4 SeitenIrjet V7i2252vinay solankarNoch keine Bewertungen

- Comparative Study On Tensile Strength and Impact Load Carrying Capacity of Concrete With Rubber and Steel FiberDokument10 SeitenComparative Study On Tensile Strength and Impact Load Carrying Capacity of Concrete With Rubber and Steel Fiberjai2009Noch keine Bewertungen

- Glass Fiber Reinforced Concrete & Its Properties: Shrikant Harle, Prof. Ram MegheDokument4 SeitenGlass Fiber Reinforced Concrete & Its Properties: Shrikant Harle, Prof. Ram MegheRakeshNoch keine Bewertungen

- Mechanical Behaviour of Basalt Fibre Reinforced ConcreteDokument9 SeitenMechanical Behaviour of Basalt Fibre Reinforced ConcretesaiyajinoatNoch keine Bewertungen

- Strength Behavior of Bamboo Reinforced CDokument9 SeitenStrength Behavior of Bamboo Reinforced CBRYLLE KYLLE OIDEMNoch keine Bewertungen

- Construction and Building MaterialsDokument12 SeitenConstruction and Building MaterialsSURIYA A (RA2012001010008)Noch keine Bewertungen

- Experimental Study and Analysis On Compressive and Tensile Behavior of Basalt Fibre Reinforced ConcreteDokument15 SeitenExperimental Study and Analysis On Compressive and Tensile Behavior of Basalt Fibre Reinforced ConcreteJuan Manuel Fiestas FiestasNoch keine Bewertungen

- Study The Effect of Polypropylene FiberDokument4 SeitenStudy The Effect of Polypropylene FiberHrishikesh GosaviNoch keine Bewertungen

- Yoon Et Al. - 2007 - Effects of Adhesive Joint On The Failure StrengthDokument6 SeitenYoon Et Al. - 2007 - Effects of Adhesive Joint On The Failure StrengthHenrique QueirozNoch keine Bewertungen

- Construction and Building Materials: Tahereh Ansari Rad, Javad Tanzadeh, Azin PourdadaDokument11 SeitenConstruction and Building Materials: Tahereh Ansari Rad, Javad Tanzadeh, Azin PourdadaKashif NazirNoch keine Bewertungen

- Flexural Behavior of Self-Compacting Concrete Reinforced With Polypropylene FibersDokument6 SeitenFlexural Behavior of Self-Compacting Concrete Reinforced With Polypropylene Fibersshubhamyadav7462Noch keine Bewertungen

- Delta ConcreteDokument7 SeitenDelta ConcreteHari AppathuraiNoch keine Bewertungen

- 04 15 Lantif Hakam Muhtarom r2Dokument8 Seiten04 15 Lantif Hakam Muhtarom r2ayu annisaNoch keine Bewertungen

- Effect of Fibres On The Compressive Stre PDFDokument10 SeitenEffect of Fibres On The Compressive Stre PDFjenecil budionganNoch keine Bewertungen

- Effect of Hybrid Fiber Reinforcement On The Structural Behaviour of Beam and Beam - Column JointDokument3 SeitenEffect of Hybrid Fiber Reinforcement On The Structural Behaviour of Beam and Beam - Column JointEditor IJTSRDNoch keine Bewertungen

- Production of Durable High Strength Flowable Mortar Reinforced With Hybrid FibersDokument12 SeitenProduction of Durable High Strength Flowable Mortar Reinforced With Hybrid FibersjasimabdNoch keine Bewertungen

- Jeas 1216 5411 PDFDokument6 SeitenJeas 1216 5411 PDFHAJARA SULTHANANoch keine Bewertungen

- Comparative Study On Durability Properties of Engineered Cementitious Composites With Polypropylene Fiber and Glass FiberDokument19 SeitenComparative Study On Durability Properties of Engineered Cementitious Composites With Polypropylene Fiber and Glass Fiberci_balaNoch keine Bewertungen

- Increase in Strength of Concrete by Using Bottle CapsDokument6 SeitenIncrease in Strength of Concrete by Using Bottle Capsaffan aliNoch keine Bewertungen

- STRENGTHENING OF RCC BEAM WITH ADVANCED COMPOSITE MATERIALS IeeeDokument3 SeitenSTRENGTHENING OF RCC BEAM WITH ADVANCED COMPOSITE MATERIALS Ieeettk qsNoch keine Bewertungen

- Snthetic FibersDokument4 SeitenSnthetic FibersA SierraNoch keine Bewertungen

- 1 s2.0 S2214509522003795 MainDokument11 Seiten1 s2.0 S2214509522003795 MainahmadNoch keine Bewertungen

- Behaviour of Concrete Utilizing AR Glass Fibre As A Partial Replacement of CementDokument5 SeitenBehaviour of Concrete Utilizing AR Glass Fibre As A Partial Replacement of CementdarshanNoch keine Bewertungen

- The Detection of Suspicious Email Based On Decision TreeDokument4 SeitenThe Detection of Suspicious Email Based On Decision TreeAnonymous kw8Yrp0R5rNoch keine Bewertungen

- Experimental Investigation On Hybrid Fiber Reinforced ConcreteDokument5 SeitenExperimental Investigation On Hybrid Fiber Reinforced ConcreteRakeshNoch keine Bewertungen

- Siva Kumar 2007Dokument6 SeitenSiva Kumar 2007akaiNoch keine Bewertungen

- Hybrid Short Glass Fibre Composites Reinforced WitDokument11 SeitenHybrid Short Glass Fibre Composites Reinforced WitBruno DornelesNoch keine Bewertungen

- Flexural and Shear Performance of HFRC BeamsDokument5 SeitenFlexural and Shear Performance of HFRC BeamsStephenNoch keine Bewertungen

- Effect of Recycled Coarse Aggregate On Workability and Shear Strength of Fibre Reinforced High Strength ConcreteDokument7 SeitenEffect of Recycled Coarse Aggregate On Workability and Shear Strength of Fibre Reinforced High Strength ConcreteTyler WhiteNoch keine Bewertungen

- Cement: Concrete CompositesDokument9 SeitenCement: Concrete CompositesAdi PrasetyoNoch keine Bewertungen

- Concrete StrengthDokument4 SeitenConcrete StrengthJournalNX - a Multidisciplinary Peer Reviewed JournalNoch keine Bewertungen

- Effect of Steel Fibers and GFRP Sheet On PDFDokument8 SeitenEffect of Steel Fibers and GFRP Sheet On PDFNiyitegeka SimonNoch keine Bewertungen

- Khan2020 SinergiaDokument5 SeitenKhan2020 SinergiaJulio Cesar Gonzalez FelixNoch keine Bewertungen

- IRJET V8I3425 With Cover Page v2Dokument8 SeitenIRJET V8I3425 With Cover Page v2Avula Siva Rami reddyNoch keine Bewertungen

- Behaviour of Hybrid Fibre Reinforced Concrete-FillDokument12 SeitenBehaviour of Hybrid Fibre Reinforced Concrete-Fillsbaia amineNoch keine Bewertungen

- Xu 2020Dokument19 SeitenXu 2020Liya WilsonNoch keine Bewertungen

- CivilDokument2 SeitenCivilShiyaNoch keine Bewertungen

- Effects of Fibre Geometry and Volume Fraction On The Flexural Behaviour of Steel-Fibre Reinforced ConcreteDokument7 SeitenEffects of Fibre Geometry and Volume Fraction On The Flexural Behaviour of Steel-Fibre Reinforced ConcreteHrishav SinghNoch keine Bewertungen

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessVon EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNoch keine Bewertungen

- Manganese Metal Composites Properties ExplorationVon EverandManganese Metal Composites Properties ExplorationNoch keine Bewertungen

- Pandey 2003 PDFDokument4 SeitenPandey 2003 PDFIsha PatelNoch keine Bewertungen

- 173 - Balachandar Pmu PDFDokument7 Seiten173 - Balachandar Pmu PDFHhNoch keine Bewertungen

- CRZ Reference Manual PDFDokument37 SeitenCRZ Reference Manual PDFmurshida parveen100% (1)

- Pile CapDokument2 SeitenPile CapIsha PatelNoch keine Bewertungen

- A Comparative Study of Self-Consolidating Concretes Incorporating High-Volume Natural Pozzolan or High-Volume Fly AshDokument12 SeitenA Comparative Study of Self-Consolidating Concretes Incorporating High-Volume Natural Pozzolan or High-Volume Fly AshIsha PatelNoch keine Bewertungen

- Dale Bentz Fa Ls PDFDokument17 SeitenDale Bentz Fa Ls PDFIsha PatelNoch keine Bewertungen

- Canpolat 2004 PDFDokument5 SeitenCanpolat 2004 PDFIsha PatelNoch keine Bewertungen

- Barbhuiya 2009 PDFDokument7 SeitenBarbhuiya 2009 PDFIsha PatelNoch keine Bewertungen

- Mechanical and Transport Properties in Ternary Blended Self Compacting Concrete With Metakaolin and Fly AshDokument10 SeitenMechanical and Transport Properties in Ternary Blended Self Compacting Concrete With Metakaolin and Fly AshIsha PatelNoch keine Bewertungen

- Soil Structure Interaction Effect On 200m Tall Industrial Chimney Under Seismic Load-533Dokument8 SeitenSoil Structure Interaction Effect On 200m Tall Industrial Chimney Under Seismic Load-533aleNoch keine Bewertungen

- Studies On Cement and Mortar Containing Low-Calcium y Ash, Limestone, and Dolomitic LimestoneDokument8 SeitenStudies On Cement and Mortar Containing Low-Calcium y Ash, Limestone, and Dolomitic LimestoneIsha PatelNoch keine Bewertungen

- Art 04 N58 de WerdtDokument20 SeitenArt 04 N58 de WerdtIsha PatelNoch keine Bewertungen

- Seismic Analysis and Design of RCC Chimney: International Journal of Advance Engineering and Research DevelopmentDokument11 SeitenSeismic Analysis and Design of RCC Chimney: International Journal of Advance Engineering and Research DevelopmentIsha PatelNoch keine Bewertungen

- Dale Bentz Fa Ls PDFDokument17 SeitenDale Bentz Fa Ls PDFIsha PatelNoch keine Bewertungen

- Studies On Cement and Mortar Containing Low-Calcium y Ash, Limestone, and Dolomitic LimestoneDokument8 SeitenStudies On Cement and Mortar Containing Low-Calcium y Ash, Limestone, and Dolomitic LimestoneIsha PatelNoch keine Bewertungen

- Sarkaretal IITD SEC2014Dokument13 SeitenSarkaretal IITD SEC2014Isha PatelNoch keine Bewertungen

- Journc, L o F Industrial AerodynamicsDokument10 SeitenJournc, L o F Industrial AerodynamicsIsha PatelNoch keine Bewertungen

- 97Dokument16 Seiten97Isha PatelNoch keine Bewertungen

- 4modal Analysis of RCC Chimney Gm23sept13vitDokument4 Seiten4modal Analysis of RCC Chimney Gm23sept13vitKiran DudaNoch keine Bewertungen

- Sarkaretal IITD SEC2014Dokument13 SeitenSarkaretal IITD SEC2014Isha PatelNoch keine Bewertungen

- Seismic Analysis and Design of Industrial Chimneys by Using Staad ProDokument8 SeitenSeismic Analysis and Design of Industrial Chimneys by Using Staad ProAJBAJBNoch keine Bewertungen

- 2 IjmeitDokument6 Seiten2 IjmeitIsha PatelNoch keine Bewertungen

- 97Dokument16 Seiten97Isha PatelNoch keine Bewertungen

- 1290 PDFDokument10 Seiten1290 PDFIsha PatelNoch keine Bewertungen

- 13Dokument15 Seiten13Isha PatelNoch keine Bewertungen

- Seismic Analysis and Design of RCC Chimney: International Journal of Advance Engineering and Research DevelopmentDokument11 SeitenSeismic Analysis and Design of RCC Chimney: International Journal of Advance Engineering and Research DevelopmentIsha PatelNoch keine Bewertungen

- Seismic Analysis and Design of RCC Chimney: International Journal of Advance Engineering and Research DevelopmentDokument11 SeitenSeismic Analysis and Design of RCC Chimney: International Journal of Advance Engineering and Research DevelopmentIsha PatelNoch keine Bewertungen

- ChimneyDokument14 SeitenChimneym_aswantoNoch keine Bewertungen

- Mid-Year Examination, 2023 Science Year 7 1 HourDokument23 SeitenMid-Year Examination, 2023 Science Year 7 1 HourAl-Hafiz Bin SajahanNoch keine Bewertungen

- NURS1108 Lecture 10 - Nervous System ENHANCEDDokument40 SeitenNURS1108 Lecture 10 - Nervous System ENHANCEDJacia’s SpaceshipNoch keine Bewertungen

- RE2S PE LPG CNG SPC Part 1Dokument32 SeitenRE2S PE LPG CNG SPC Part 1Inversiones RinocellNoch keine Bewertungen

- Assignment On Cholera: Submitted ToDokument17 SeitenAssignment On Cholera: Submitted ToEhesanulHaqueSaifNoch keine Bewertungen

- Afectiuni Si SimptomeDokument22 SeitenAfectiuni Si SimptomeIOANA_ROX_DRNoch keine Bewertungen

- Data Sheet: W-Series WSI 6/LD 10-36V DC/ACDokument12 SeitenData Sheet: W-Series WSI 6/LD 10-36V DC/ACLUIS FELIPE LIZCANO MARINNoch keine Bewertungen

- Nicotine From CigarettesDokument2 SeitenNicotine From CigarettesAditya Agarwal100% (1)

- AC350 Specs UsDokument18 SeitenAC350 Specs Uskloic1980100% (1)

- Volvo PDFDokument218 SeitenVolvo PDFNelio Lara Ricaldi0% (1)

- Daphne Alpha Cleaner Series: Lubricant Product InformationDokument2 SeitenDaphne Alpha Cleaner Series: Lubricant Product InformationChart ChNoch keine Bewertungen

- Non-Pen MountDokument17 SeitenNon-Pen MountT BagNoch keine Bewertungen

- Theology of Work and Practical ImplicationsDokument28 SeitenTheology of Work and Practical ImplicationsVinicius CardosoNoch keine Bewertungen

- EASA - Design OrganisationsDokument30 SeitenEASA - Design Organisationsyingqi.yangNoch keine Bewertungen

- Progress Report Week#9 UlubeluDokument6 SeitenProgress Report Week#9 UlubelutiantaufikNoch keine Bewertungen

- Calculate Cable Size and Voltage Drop Electrical Notes Articles PDFDokument10 SeitenCalculate Cable Size and Voltage Drop Electrical Notes Articles PDFRavi SharmaNoch keine Bewertungen

- Company Profile: Only Milling Since 1967Dokument16 SeitenCompany Profile: Only Milling Since 1967PavelNoch keine Bewertungen

- Deld12070 CC18 GT 371 C CDokument1 SeiteDeld12070 CC18 GT 371 C CDEBASIS BARMANNoch keine Bewertungen

- Wic ReflectionDokument3 SeitenWic Reflectionapi-307029735Noch keine Bewertungen

- Digital Trail Camera: Instruction ManualDokument20 SeitenDigital Trail Camera: Instruction Manualdavid churaNoch keine Bewertungen

- 5 Years High and Low PointsDokument7 Seiten5 Years High and Low PointsNaresh Kumar VishwakarmaNoch keine Bewertungen

- With EU Stage V Engine Installed: 200 HP (149 KW) / 2,200 RPMDokument4 SeitenWith EU Stage V Engine Installed: 200 HP (149 KW) / 2,200 RPMSara Sarmiento EcheverryNoch keine Bewertungen