Beruflich Dokumente

Kultur Dokumente

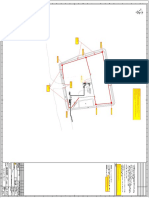

Gambar Concrete Pole

Hochgeladen von

rifkynetCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gambar Concrete Pole

Hochgeladen von

rifkynetCopyright:

Verfügbare Formate

NOTES:

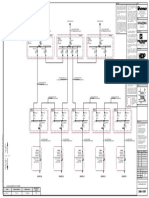

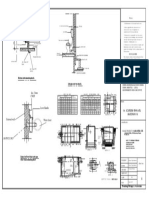

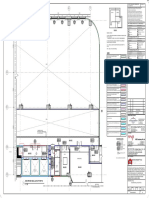

Design Poles (Concrete and Strain Poles) in accordance with the 1994 Attach span wire assemblies (consisting of the catenary wire, the messenger

edition of the AASHTO "Standard Specifications for Structural Supports wire, and the tether wire) to the concrete poles in accordance with Section 634. To Roadway

for Highway Signs, Luminaires and Traffic Signals" and Supplement

thereto. For allowable unit stresses, meet the requirements of Section 6.

1-0" \ Hole for

If a two point attachment is required by the plans, provide an eye bolt hole for

the messenger wire, or field drill one at the location indicated in the plans.

Manufacturers seeking approval of a prestressed concrete pole for inclusion

3/4 " Bolt

Field drill the eyebolt hole for the tether wire, when required, prior to

on the Qualified Products List must submit a QPL Products Evaluation T

installation.

Application along with design documentation and drawings showing the

Plug Top of Pole with

product meets all specified requirements of this Index.

Use cover plates made of non-corrosive materials and attached to the pole using a minimum of 3"

of concrete

*

lead anchors or threaded inserts embedded in the pole and round head chrome

Place the prestressing symmetrically. Supply a sufficient amount of

**

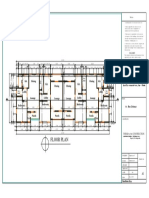

plated screws. MINIMUM REQUIRED MOMENT CAPACITY

9" Below Messenger For Two Point Connection

prestressing to provide a calculated compressive stress of 2.2 ksi

No. 6 Stranded

2-0" Max.

Bare Copper

Ground Wire)

forType N-?? and 3 ksi forType N-??? at the top of pole after

Attach ground wires to the reinforcing steel in the pole as necessary to TYPE OF POLE

all losses.

prevent the ground wire from being displaced during concreting operations. D (feet)

N-?! (k-ft) N-! (k-ft) N-!? (k-ft) N-!?? (k-ft) N-!??? (k-ft)

Concrete Strength shall be 6 ksi minimum at 28 days and 4 ksi

3-0" For Single Point Connection

20 33 106 152 210 266

*

minimum at transfer of the Prestressing force. Identify concrete poles as to pole manufacturer, Departments pole type, length

and Qualified Product List qualification number by inset numerals 1" in

22 37 111 159 218 275

Reinforcing steel shall be A615 Grade 60. Provide a minimum area height inscribed on the same face of the pole as the handhole and ground wire.

of non-prestressed reinforcement equal to 0.33% of the concrete area. 24 41 116 163 226 284

Provide a Class 3 Surface Finish as Specified in 400-15.2.4.

26 44 121 172 234 293

Prestressed Strands shall be A416 Grade 270 stress relieved

45^

or low relaxation. Provide a minimum cover of 1". 28 48 127 179 242 302

Provide all poles with total taper of 0.152 IN/FT. 30 52 132 185 250 311

One turn required for spiral splices and two turns required at the

top and bottom of poles. Spiral shall be manufactured from cold-drawn 32 56 137 192 258 320

*

steel wire meeting the requirements of ASTM A82. 2" Galv. Nipple

34 60 142 199 266 329

36 63 148 205 274 338

Plug Top of Pole with 38 67 153 212 282 346

a minimum of 3" 1 1/2 " \ Galvanized

6" 40 71 158 219 290 355

Total Length Variable (2-0" Increments)

D

of concrete Threaded Nipple Plug Top of Pole with Plug Top of Pole with

6" 6"

a minimum of 3" a minimum of 3" 42 75 163 225 298 364

1-0" No. 6 Ground Wire of concrete of concrete

2"

44 79 168 232 306 373

7"

46 82 173 239 314 382

Handhold with cover

Identification

Galvanized Conduit

1-0"

Markings 48

Shear Reinforcing

86 177 245 322 391

3-6" to 2" \

1-6"

with cover

3-6"

4"x 6"

50 90 180 252 330 400

**

Service Conditions: Design poles to carry the "Minimum Required Moment

2-0" No. 6 Capacity." These moments are based on a dead load plus wind load

Ground Wire combinations, therefore obtain the allowable stresses by multiplying those

2-0" No. 6 for normal exposure conditions given in Section 6 by the appilcable factor

Final from Section 2 of the AASHTO Standard Specifications for Structural

Ground Wire

Grade

Conduit entry hole)

Supports for Highway Signs, Luminaires and Traffic Signals.

The ultimate moment capacity of each pole shall be a minimum of 1.3 times

(3" x 5"

2-6"

the "Minimum Required Moment Capacity."

Identification Identification

Markings Markings CONCRETE POLE

9 Gauge Spiral @ 6"

9 Gauge Spiral @ 6"

TYPE OF

9 Gauge Spiral @ 6"

POLE SIZE AT TOP (T) SHEAR REINFORCING

36-0"

Identification

12-0"

12-0"

Markings Top of Type ?? 6" x 6" 9 Gauge Spiral @ 6"

Footing

Type ??? 6" x 6" 6 Gauge Spiral @ 6"

3" x 5" Load Face

4-0" No. 6

Handhole Type ?! 8" x 8" 5 Gauge Spiral @ 6"

Ground Wire

with Cover

Type ! 10" x 10" 5 Gauge Spiral @ 6"

Type !? 12" x 12" 5 Gauge Spiral @ 6"

(4-0" No. 6 Ground Wire)

Type !?? 14" x 14" 5 Gauge Spiral @ 6"

4-0"

12-0"

8-0"

4-0" No. 6

of No. 6 Type !??? 16" x 16" 5 Gauge Spiral @ 6"

6-0" Max.

7-0"

Ground Wire

Ground

Wire

4-0" Max.

5-6"

*

1-6" Max.

1-6" Max.

1-0"

45^

2" Galv. Nipple

TYPE N-?? POLE ON SERVICE POLES - TYPE N-?? POLE TYPES N-??? THROUGH N-V???

(For Installation, refer to Roadway and Traffic *

Do not apply these items to Type N-??? Establish bolt hole locations, ground

CONCRETE PEDESTAL

Design Standard. Index No. 17504) wire location and conduit location as shown in the plans.

Ref. Index 17900 and Sec. 744 for modifications to Type N-~~~ poles used

at traffic monitoring sites.

Last

2006 FDOT Design Standards Sheet No.

Revision

07/01/05 1 of 1

Index No.

CONCRETE POLES

17725

Das könnte Ihnen auch gefallen

- Gambar Concrete Pole PDFDokument1 SeiteGambar Concrete Pole PDFrifkynetNoch keine Bewertungen

- SVC Specifications For Civil WorksDokument33 SeitenSVC Specifications For Civil WorksFarooq BhuttaNoch keine Bewertungen

- A.Typical Roadway Section: Pavement Design ParametersDokument1 SeiteA.Typical Roadway Section: Pavement Design ParametersrickNoch keine Bewertungen

- Mc616ste 20Dokument2 SeitenMc616ste 20ahmed ktebahNoch keine Bewertungen

- Architectural Drawings 1Dokument13 SeitenArchitectural Drawings 1Manish PandeyNoch keine Bewertungen

- 137778-P5545 Instr. Footprint 3K Elec Rem Spec 300 Rev A 05 29 18Dokument1 Seite137778-P5545 Instr. Footprint 3K Elec Rem Spec 300 Rev A 05 29 18Pepe Queño MtzNoch keine Bewertungen

- Rogers Wright-22.06.2020Dokument11 SeitenRogers Wright-22.06.2020best essaysNoch keine Bewertungen

- Drawing 3.Dokument1 SeiteDrawing 3.tiyaniNoch keine Bewertungen

- 66 RoofScreen Square Base RotoLock PDSDokument3 Seiten66 RoofScreen Square Base RotoLock PDSmtNoch keine Bewertungen

- 2.4GHz - Inverted F AntennaDokument15 Seiten2.4GHz - Inverted F AntennasinnmleeNoch keine Bewertungen

- General Notes:: DIVISION 4: Masonry DIVISION 7: Thermal & Moisture DIVISION 9: FinishesDokument5 SeitenGeneral Notes:: DIVISION 4: Masonry DIVISION 7: Thermal & Moisture DIVISION 9: FinishesKarim TarekNoch keine Bewertungen

- Pipe Specification: A B C D A B C DDokument1 SeitePipe Specification: A B C D A B C Dblah blehNoch keine Bewertungen

- QC02002 CNP DRW PLN Id 04 Ce1 00004 00 (PDF)Dokument1 SeiteQC02002 CNP DRW PLN Id 04 Ce1 00004 00 (PDF)Moosa RizwanNoch keine Bewertungen

- 17 1197 Column LayoutDokument1 Seite17 1197 Column LayoutKeise AliNoch keine Bewertungen

- Ifc - Issued For Construction: AngloamericanDokument1 SeiteIfc - Issued For Construction: AngloamericanRicardo Alberto Zapata BalcazarNoch keine Bewertungen

- 030 RFI ELLIPSE Beam Admin Auditorium ACT Response 20231113Dokument4 Seiten030 RFI ELLIPSE Beam Admin Auditorium ACT Response 20231113Muriyanto MuriNoch keine Bewertungen

- Cast SteelDokument20 SeitenCast SteelRafique SoomroNoch keine Bewertungen

- Kingspan - Kingzip - Roof - KS500 1000 ZIP IP Installation Guide - 032017 - UKDokument1 SeiteKingspan - Kingzip - Roof - KS500 1000 ZIP IP Installation Guide - 032017 - UKGeorgios PNoch keine Bewertungen

- 564shj22-01-Gym-Tc-100 R1Dokument1 Seite564shj22-01-Gym-Tc-100 R1IbrahimUnesNoch keine Bewertungen

- 800 Col Line: Bill of Material Sketch ListDokument1 Seite800 Col Line: Bill of Material Sketch ListAcfMacNoch keine Bewertungen

- Otter Tail County, Henning Transfer Station Designs, FOTH Engineering, Feb. 2023Dokument4 SeitenOtter Tail County, Henning Transfer Station Designs, FOTH Engineering, Feb. 2023Michael AchterlingNoch keine Bewertungen

- King Khalid International Airport Kkia: SubmittalsDokument49 SeitenKing Khalid International Airport Kkia: SubmittalsDILSHAD AHEMADNoch keine Bewertungen

- Kop-Flex - KS (Membranas HP)Dokument3 SeitenKop-Flex - KS (Membranas HP)marcelo castilloNoch keine Bewertungen

- 3RD Storey Wall Layout Part CDokument1 Seite3RD Storey Wall Layout Part CDhrubajyoti BordoloiNoch keine Bewertungen

- dn15 To dn50 PRVDokument2 Seitendn15 To dn50 PRVPriyanka rajpurohitNoch keine Bewertungen

- 3RD Storey Wall Layout Part ADokument1 Seite3RD Storey Wall Layout Part ADhrubajyoti BordoloiNoch keine Bewertungen

- Concrete Paving Airfield PosterDokument1 SeiteConcrete Paving Airfield PosterdavidhmoloneyNoch keine Bewertungen

- East Elevation South Elevation: Church HallDokument1 SeiteEast Elevation South Elevation: Church HallanzaniNoch keine Bewertungen

- Acuv Stage 5-PlansDokument1 SeiteAcuv Stage 5-PlansMonde Tidimalo Lunathi MbaluNoch keine Bewertungen

- DMM 1 e 007Dokument1 SeiteDMM 1 e 007mahesh reddy mNoch keine Bewertungen

- Dia. 13mm CWSP: R.C Wall/Block Wall Dia. 50mm Vent PipeDokument1 SeiteDia. 13mm CWSP: R.C Wall/Block Wall Dia. 50mm Vent PipeAmadi HenryNoch keine Bewertungen

- 250603DEDLD0130 EXDE00 01-With CommentsDokument1 Seite250603DEDLD0130 EXDE00 01-With CommentsMohammed HijaziNoch keine Bewertungen

- Cicpa - C&mcig1w922Dokument782 SeitenCicpa - C&mcig1w922mahmoudNoch keine Bewertungen

- Warehouse DrawingsDokument6 SeitenWarehouse DrawingsnokoNoch keine Bewertungen

- 05 First FloorDokument1 Seite05 First FloorAbu Baker DajahNoch keine Bewertungen

- ( (34.0L×16.0W) + (26.0L×12.0W) ) ×5.0H: Y. J Lee Y. J Lee Y. J LeeDokument1 Seite( (34.0L×16.0W) + (26.0L×12.0W) ) ×5.0H: Y. J Lee Y. J Lee Y. J LeeHamzeh TarteerNoch keine Bewertungen

- Specs 1Dokument1 SeiteSpecs 1mohammedpetiwalaNoch keine Bewertungen

- ABAC GenesisDokument7 SeitenABAC GenesisAndy KershawNoch keine Bewertungen

- Bdstde01 16 PDFDokument1 SeiteBdstde01 16 PDFAhmed HadeeNoch keine Bewertungen

- 8948 Rev1 Milton Wsg001 Eng Sh5 1Dokument1 Seite8948 Rev1 Milton Wsg001 Eng Sh5 1tshepo hlakudiNoch keine Bewertungen

- Mining: Key Industry ProgramDokument8 SeitenMining: Key Industry ProgramAyşe BaturNoch keine Bewertungen

- Plakat FESTO CPX MPA VTSADokument2 SeitenPlakat FESTO CPX MPA VTSAtadNoch keine Bewertungen

- Col Line HDokument1 SeiteCol Line HAcfMacNoch keine Bewertungen

- 3RD Storey Wall Layout Part BDokument1 Seite3RD Storey Wall Layout Part BDhrubajyoti BordoloiNoch keine Bewertungen

- Muriithi 19 - 04 Sheet1Dokument1 SeiteMuriithi 19 - 04 Sheet1alexNoch keine Bewertungen

- 2022-09-01 5F MAIN OFFICE - STEPS FOR MEZZANINE - CommentsDokument2 Seiten2022-09-01 5F MAIN OFFICE - STEPS FOR MEZZANINE - CommentsParamanathan SubramaniamNoch keine Bewertungen

- Openfoam Simulation of The Flow in The Hoelleforsen Draft Tube ModelDokument15 SeitenOpenfoam Simulation of The Flow in The Hoelleforsen Draft Tube ModelAghajaniNoch keine Bewertungen

- Transmission Towers: More With MetalsDokument2 SeitenTransmission Towers: More With MetalsRajesh KrishnanNoch keine Bewertungen

- S781-CV-DWG-00004-01-213036-B - OQ Approved - 14.03.2023Dokument2 SeitenS781-CV-DWG-00004-01-213036-B - OQ Approved - 14.03.2023MDhana SekarNoch keine Bewertungen

- Form Tagihan Trisula.Dokument41 SeitenForm Tagihan Trisula.tomy ramaNoch keine Bewertungen

- Timboon Housing Estate PlansDokument17 SeitenTimboon Housing Estate PlansKyra GillespieNoch keine Bewertungen

- Structural GilbaneDokument11 SeitenStructural Gilbanejh50000Noch keine Bewertungen

- 8 631 CA 740302 Mfy NDT Rev00a - Elevation at Row 1Dokument3 Seiten8 631 CA 740302 Mfy NDT Rev00a - Elevation at Row 1Vinu MadhavanNoch keine Bewertungen

- Collinear Ant BuildingDokument7 SeitenCollinear Ant BuildingAhmed JafarNoch keine Bewertungen

- Floor Plan: Kit. Kit. Dining Dining Lobby Lounge Lounge Bedroom Bedroom Kit. Kit. Dining Dining LobbyDokument1 SeiteFloor Plan: Kit. Kit. Dining Dining Lobby Lounge Lounge Bedroom Bedroom Kit. Kit. Dining Dining Lobbyamadi4bizNoch keine Bewertungen

- RTC 2017Dokument1 SeiteRTC 2017Marco Antonio Rubiano GómezNoch keine Bewertungen

- MPPTDokument5 SeitenMPPTMahir Asif ShadmanNoch keine Bewertungen

- Instant Assessments for Data Tracking, Grade 5: MathVon EverandInstant Assessments for Data Tracking, Grade 5: MathNoch keine Bewertungen

- Instant Assessments for Data Tracking, Grade 3: MathVon EverandInstant Assessments for Data Tracking, Grade 3: MathBewertung: 5 von 5 Sternen5/5 (2)

- Soil Bearing CalculationDokument5 SeitenSoil Bearing CalculationrifkynetNoch keine Bewertungen

- Load CalculationDokument5 SeitenLoad CalculationrifkynetNoch keine Bewertungen

- Load CombinationDokument2 SeitenLoad CombinationrifkynetNoch keine Bewertungen

- Design ParameterDokument1 SeiteDesign ParameterrifkynetNoch keine Bewertungen

- Design LoadDokument2 SeitenDesign LoadrifkynetNoch keine Bewertungen

- Meyerhof Method Pile CapacityDokument1 SeiteMeyerhof Method Pile CapacityrifkynetNoch keine Bewertungen

- MDS Diesel TankDokument2 SeitenMDS Diesel TankrifkynetNoch keine Bewertungen

- Perbandingan Precast Dan Convensional Pada TribunDokument7 SeitenPerbandingan Precast Dan Convensional Pada TribunrifkynetNoch keine Bewertungen

- Structure Analysis Report ST 30M MAJALENGKA 08-September-16 Rev.0Dokument34 SeitenStructure Analysis Report ST 30M MAJALENGKA 08-September-16 Rev.0rifkynetNoch keine Bewertungen

- Screw Pile 2 PDFDokument334 SeitenScrew Pile 2 PDFrifkynetNoch keine Bewertungen

- Design of Spiral Reinforcement PDFDokument53 SeitenDesign of Spiral Reinforcement PDFrifkynetNoch keine Bewertungen

- Calculation Jembatan CastelatedDokument18 SeitenCalculation Jembatan CastelatedrifkynetNoch keine Bewertungen

- Compaction Factor ExperimentDokument23 SeitenCompaction Factor ExperimentYI HEN ONGNoch keine Bewertungen

- 2014 - Veli-Mati - Uottinen - Development of RD-pile WallDokument10 Seiten2014 - Veli-Mati - Uottinen - Development of RD-pile WallAnonymous PibYPghNoch keine Bewertungen

- Production Rates Guidelines For Arizona Highway ConstructionDokument14 SeitenProduction Rates Guidelines For Arizona Highway Constructionlecter34Noch keine Bewertungen

- Design Calculations For The Dome Structure-Type 1Dokument6 SeitenDesign Calculations For The Dome Structure-Type 1msiddiq1100% (2)

- Micropile Presentation PDFDokument76 SeitenMicropile Presentation PDFgizmopowa100% (1)

- Support 3Dokument15 SeitenSupport 3Shreyas AlagundiNoch keine Bewertungen

- Structural Investigation of Historic Buildings - David C FischettiDokument10 SeitenStructural Investigation of Historic Buildings - David C FischettiMohammad Javad AarabiNoch keine Bewertungen

- Concrete Beam DesignDokument3 SeitenConcrete Beam Designheherson juanNoch keine Bewertungen

- Concrete Structures For Retaining Aqueous Liquids - Code of PracticeDokument28 SeitenConcrete Structures For Retaining Aqueous Liquids - Code of PracticeManvendra Nigam100% (3)

- Chartered Membership (Part 3) Examination: (Old Examination Format For Reference Only)Dokument16 SeitenChartered Membership (Part 3) Examination: (Old Examination Format For Reference Only)Ng Chee PengNoch keine Bewertungen

- Construction CETINA Arch BridgeDokument6 SeitenConstruction CETINA Arch BridgeVIDAL MAMANINoch keine Bewertungen

- Week 13 - PilesDokument15 SeitenWeek 13 - PilesCristina SarmientoNoch keine Bewertungen

- Failures and Repair of Silo and BunkersDokument51 SeitenFailures and Repair of Silo and BunkersBalan-Nogi Dan100% (1)

- IS800 2007 (Reaffirmed2017) Smx1mhtgqfgnyculmeemie1srmsd20230207100541Dokument155 SeitenIS800 2007 (Reaffirmed2017) Smx1mhtgqfgnyculmeemie1srmsd20230207100541baubleNoch keine Bewertungen

- Structural Response and Damage Evaluation of A Typical Highrise RC Building in Dubai Under An Earthquake With Single and Multiple PeaksDokument14 SeitenStructural Response and Damage Evaluation of A Typical Highrise RC Building in Dubai Under An Earthquake With Single and Multiple PeaksKaren EstradaNoch keine Bewertungen

- Roofs 1Dokument113 SeitenRoofs 1Bini FrancisNoch keine Bewertungen

- Assignment #1.1Dokument23 SeitenAssignment #1.1teweldeNoch keine Bewertungen

- Neville CH 1-2 PDFDokument585 SeitenNeville CH 1-2 PDFShaik BademiyaNoch keine Bewertungen

- Cheng Publications ListingDokument2 SeitenCheng Publications ListingponjoveNoch keine Bewertungen

- Keystone Lintel Manual 08Dokument25 SeitenKeystone Lintel Manual 08shiraz2012Noch keine Bewertungen

- Pile Cap Design 6pileDokument18 SeitenPile Cap Design 6pileAnkit GhildiyalNoch keine Bewertungen

- Desain Box GirderDokument187 SeitenDesain Box GirderZaendals JepitNoch keine Bewertungen

- Aashhto LRFD 2007 - Concrete Deck Design: HC 17,5 CM OKDokument7 SeitenAashhto LRFD 2007 - Concrete Deck Design: HC 17,5 CM OKprasadnn2001Noch keine Bewertungen

- R2 - Design Formulae For Bending (2014!08!01)Dokument44 SeitenR2 - Design Formulae For Bending (2014!08!01)Abhishek KumarNoch keine Bewertungen

- Composite ColumnsDokument49 SeitenComposite ColumnsPrasad GN100% (2)

- EQ06Dokument133 SeitenEQ06hansa588Noch keine Bewertungen

- Codes and Standards - SenegalDokument8 SeitenCodes and Standards - SenegalRamachandran SundararamanNoch keine Bewertungen

- Analysis of Cracked Prestressed Concrete Sections - A Practical ApproachDokument12 SeitenAnalysis of Cracked Prestressed Concrete Sections - A Practical ApproachRushabh JainNoch keine Bewertungen

- ProtaStructure Suite 2016 Whats NewDokument42 SeitenProtaStructure Suite 2016 Whats NewChin Chloe100% (1)

- Pile Cap Balanced LoadsDokument1 SeitePile Cap Balanced LoadsKausik DewanNoch keine Bewertungen