Beruflich Dokumente

Kultur Dokumente

IrrigSmart 3241 J Pump Efficiency

Hochgeladen von

Einstein JeboneOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

IrrigSmart 3241 J Pump Efficiency

Hochgeladen von

Einstein JeboneCopyright:

Verfügbare Formate

Pump Efficiency

Blair Stringam, Extension Plant Sciences, New Mexico State University

This publication includes a definition of Total Head

pump horsepower, an explanation of pump

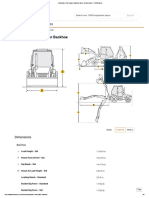

efficiency and information about how to Total head is determined by measuring

calculate those values. the distance from the source water surface

to the output of the pump, as well as the

Efficiency Significance pressure the pump is producing at the

pump outlet. If this value is measured for

Selecting a proper pumping system will a centrifugal pump, the distance from the

conserve fuel or electricity and decrease water surface to the pump outlet needs to

the annual pumping costs. Inefficient be measured as indicated in the following

and poorly chosen pumping systems can diagram.

increase annual costs dramatically. There Centrifugal pump

also is a possibility excessive wear will occur

on the pumping plant, and water may be

wasted.

Pump Efficiency

Pump efficiency is defined as the ratio of

water horsepower output from the pump to

the shaft horsepower input for the pump.

Water horsepower is determined by the flow

rate and pressure delivered from the pump.

The shaft horsepower is delivered to the

pump from the power unit, which usually

is an electric motor or internal combustion

In addition, the pressure at the pump

engine.

outlet also needs to be measured. The total

If a pump was 100 percent efficient, head can then be determined by knowing

the mechanical horsepower input would be that 2.306 feet of water is equal to 1

equal to the water horsepower output by pound per square inch of pressure (psi).

the pump. No pump is 100 percent efficient, For example, if the distance from the water

so the mechanical horsepower input will be surface to the pump outlet was 8 feet and

greater than the water horsepower output. the pressure measured at the pump outlet

Lower efficiencies are due to energy losses was 60 psi, the total pressure head would

caused by friction, leakages originating from be:

pressure differentials within the pump case H = 8 + 60 2.306 = 146.4 feet

and losses due to a more complex nature.

Total head can be determined for a deep

The efficiency of a particular pump is well turbine pump, as well. Again, the

estimated by determining two values. These distance from the pumped water surface to

values are pump flow rate and total head. the pump outlet must be measured (See

the following diagram.). There will always

1 LSU AgCenter Pub. 3241-J: Pump Efficiency

be a drop from the static water surface to Determining Pump Efficiency

the pumped water surface. The pressure

that is delivered at the pump outlet also is Water horsepower can be calculated by

measured. using this formula:

HQ

WHP =

Deepwell turbine pump 3960

Where H is the total head of the water in

feet and Q is the flow rate in gallons per

minute. For example, if the flow rate for the

previous centrifugal pump was 654 gpm,

the water horsepower for the pump would

be:

146.4 x 654

WHP = = 24.2 WHP

3960

If the same flow rate was used for the

previous turbine pump example, the water

horsepower would be 44.98 WHP.

Pump input horsepower is determined

by measuring the speed and torque of the

motor shaft input to the pump.

Once these two values have been

For example, if the distance from the determined, pump efficiency is a simple

pumped water surface to the pump outlet calculation that can be determined by this

was 134 feet and the pressure measured formula:

hp

at the pump outlet was 60 psi, the total h = hpwater

pressure head would be: of pump

H = 134 + 60 2.306 = 272.4 feet If the horsepower input to the previous

centrifugal pump example was 33

Flow Rate horsepower, the pump efficiency would be:

Flow rate is the total water volume that 24.2

passes through a fixed point over time. Flow h= 33

= 0.73 or 73%

rate can be measured using a flow meter. It should be noted that this document

Numerous flow meters are available, but outlines the procedures for determining

an ultrasonic flow meter usually is the most pump efficiency only. Operators may

convenient flow meter to use. want their pumping unit efficiency to be

This flow meter can be programmed evaluated for the complete unit. If so, the

to read flow rate in whatever units are efficiency of the motor or engine will be

required, but gallons per minute usually is included, and the overall efficiency will be

the measurement used. lower than pump efficiency.

Ultrasonic flow meter

www.LSUAgCenter.com

Louisiana State University Agricultural Center

Louisiana Agricultural Experiment Station

Louisiana Cooperative Extension Service

William B. Richardson, Chancellor and Director

Pub. 3241-J (200) 8/13

The LSU AgCenter is a statewide campus of the LSU System and

provides equal opportunities in programs and employment.

2 LSU AgCenter Pub. 3241-J: Pump Efficiency

Das könnte Ihnen auch gefallen

- Performance of PumpDokument6 SeitenPerformance of PumpAidilNoch keine Bewertungen

- Selection of Centrifugal Pumping Equipment PDFDokument11 SeitenSelection of Centrifugal Pumping Equipment PDFjdgh1986Noch keine Bewertungen

- Pump Course Material Chapter 3Dokument28 SeitenPump Course Material Chapter 3engr victorNoch keine Bewertungen

- Exp 8 Turbo Centrifugal PumpDokument8 SeitenExp 8 Turbo Centrifugal PumpChirag JainNoch keine Bewertungen

- Full Report PumpDokument21 SeitenFull Report Pumpfaiman asyraf baharinNoch keine Bewertungen

- Selection of Centrifugal Pumping EquipmentDokument11 SeitenSelection of Centrifugal Pumping Equipmentshahzad32552372Noch keine Bewertungen

- Libro de BombasDokument260 SeitenLibro de BombasBoris SalazarNoch keine Bewertungen

- Application of Computer Programs: Fundamentals of Flow in Closed ConduitsDokument49 SeitenApplication of Computer Programs: Fundamentals of Flow in Closed ConduitsLovely AnneNoch keine Bewertungen

- Performance PumpDokument13 SeitenPerformance PumpPutera AshrafNoch keine Bewertungen

- Week 2 Water PumpingDokument76 SeitenWeek 2 Water PumpingAbdullahi Dirie AbdiNoch keine Bewertungen

- A-1 Head: Section A - Centrifugal Pump FundamentalsDokument18 SeitenA-1 Head: Section A - Centrifugal Pump FundamentalsReNyy ChowNoch keine Bewertungen

- How To Design A Centrifugal Pump - SciencingDokument3 SeitenHow To Design A Centrifugal Pump - SciencingKaran MalikNoch keine Bewertungen

- PumpsDokument75 SeitenPumpsSurendra ReddyNoch keine Bewertungen

- Title: Figure 1: Categories of Centrifugal PumpDokument7 SeitenTitle: Figure 1: Categories of Centrifugal PumpHaziq Pazli100% (1)

- Selection of PumpsDokument8 SeitenSelection of Pumpssmohsinshah9492100% (9)

- GPM RevDokument138 SeitenGPM RevJuan Cortes TorizNoch keine Bewertungen

- Apuntes Bombas (Inglés)Dokument19 SeitenApuntes Bombas (Inglés)Amanita Roja BlancaNoch keine Bewertungen

- BFC21103 Chapter 6 Hydraulic MachineryDokument43 SeitenBFC21103 Chapter 6 Hydraulic MachineryMuhammad Hazim Bin Ahmad FauziNoch keine Bewertungen

- Centrifugal Pump Performance CharacteristicDokument7 SeitenCentrifugal Pump Performance CharacteristicOrcraNoch keine Bewertungen

- Useful Pump & Hydraulic Engineering Data Definitions, Equations, Testing, Tables, Charts DeterminationsDokument12 SeitenUseful Pump & Hydraulic Engineering Data Definitions, Equations, Testing, Tables, Charts DeterminationsDiana Catalina Molano BayonaNoch keine Bewertungen

- Centrifugal PumpDokument23 SeitenCentrifugal Pumpheri monawir zebuaNoch keine Bewertungen

- Test On A Centrifugal Pump (Complete Report)Dokument12 SeitenTest On A Centrifugal Pump (Complete Report)Bshfirnaudz50% (4)

- Pumps & Pumping SystemDokument4 SeitenPumps & Pumping SystemAjay kunwar singhNoch keine Bewertungen

- Efficiency and Input Power of The PumpDokument14 SeitenEfficiency and Input Power of The PumpMohammed BrashdiNoch keine Bewertungen

- PumpsDokument75 SeitenPumpsmd junuNoch keine Bewertungen

- لقطة شاشة ٢٠٢٤-٠٢-١١ في ٨.٣٨.٤٩ صDokument28 Seitenلقطة شاشة ٢٠٢٤-٠٢-١١ في ٨.٣٨.٤٩ صabdollahali2004Noch keine Bewertungen

- Chapter 6 - Hydraulic MachineryDokument43 SeitenChapter 6 - Hydraulic MachineryHalimi Honan100% (1)

- Pump Characteristic CurvesDokument7 SeitenPump Characteristic CurvesRio CañalNoch keine Bewertungen

- Theory Practical 1Dokument10 SeitenTheory Practical 1Dilhara PinnaduwageNoch keine Bewertungen

- Process Equipment Design and DrawingDokument35 SeitenProcess Equipment Design and DrawingKutty Krishnan MankaraNoch keine Bewertungen

- PumpsDokument17 SeitenPumpsMara Erna TagupaNoch keine Bewertungen

- Pump Tech 4 CurvesDokument45 SeitenPump Tech 4 CurvesGAMUCHIRAI MUGADZANoch keine Bewertungen

- Water PumpDokument30 SeitenWater PumpAurnab KhisaNoch keine Bewertungen

- Transportation of Fluids: Prepared By: Engr. Joseph R. OrteneroDokument48 SeitenTransportation of Fluids: Prepared By: Engr. Joseph R. OrteneroChristianNoch keine Bewertungen

- Goulds-Pumps Fundamentals PDFDokument140 SeitenGoulds-Pumps Fundamentals PDFAgustinus Made Theo Dwijaya100% (2)

- 1.0 Abstracts: Fluid Pressure Pumps TurbinesDokument11 Seiten1.0 Abstracts: Fluid Pressure Pumps TurbinesZahid ZakariaNoch keine Bewertungen

- Chapter 7Dokument28 SeitenChapter 7lockas222Noch keine Bewertungen

- Chapter 5 Pump and Control Devices PDFDokument68 SeitenChapter 5 Pump and Control Devices PDFRana G100% (2)

- 4 Applied HydraulicsDokument30 Seiten4 Applied Hydraulicsمهندس ابينNoch keine Bewertungen

- GPM8-E Complete CDDokument147 SeitenGPM8-E Complete CDGuztavo Nm G0% (1)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesVon EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesBewertung: 5 von 5 Sternen5/5 (1)

- Chapter 10 - Hydraulic MachineryDokument20 SeitenChapter 10 - Hydraulic Machineryintern kncesbNoch keine Bewertungen

- Centifugal PumpDokument8 SeitenCentifugal PumpTinaaTinyNoch keine Bewertungen

- Chapter 7 Centrifugal PumpDokument37 SeitenChapter 7 Centrifugal Pump01fe20bme014Noch keine Bewertungen

- Reading Cent Pump CurvesDokument5 SeitenReading Cent Pump CurvesMohammad Asif KabirNoch keine Bewertungen

- Irrigation Water Pumps: AE1057 (Revised)Dokument12 SeitenIrrigation Water Pumps: AE1057 (Revised)Kashif AdeemNoch keine Bewertungen

- Experiment No-5: Pumps Are The Fluid Moving Machineries Which Increase The Mechanical Energy ofDokument9 SeitenExperiment No-5: Pumps Are The Fluid Moving Machineries Which Increase The Mechanical Energy ofAbhishek MishraNoch keine Bewertungen

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsVon EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsBewertung: 5 von 5 Sternen5/5 (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- Scientific American Supplement, No. 633, February 18, 1888Von EverandScientific American Supplement, No. 633, February 18, 1888Noch keine Bewertungen

- Liquid Pipeline Hydraulics: Second EditionVon EverandLiquid Pipeline Hydraulics: Second EditionNoch keine Bewertungen

- Groundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterVon EverandGroundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterBewertung: 5 von 5 Sternen5/5 (1)

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideVon EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideBewertung: 5 von 5 Sternen5/5 (1)

- RP1Dokument1 SeiteRP1Einstein JeboneNoch keine Bewertungen

- Appropriate Technology For Disaster Resistant and Post-DisasterDokument3 SeitenAppropriate Technology For Disaster Resistant and Post-DisasterEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- Automated Highway SystemsDokument6 SeitenAutomated Highway SystemsEinstein JeboneNoch keine Bewertungen

- A Pavement Management PrimerDokument54 SeitenA Pavement Management PrimerEinstein JeboneNoch keine Bewertungen

- Application of Zycosil Soil On PavementsDokument3 SeitenApplication of Zycosil Soil On PavementsEinstein JeboneNoch keine Bewertungen

- Photos of SetupDokument6 SeitenPhotos of SetupEinstein JeboneNoch keine Bewertungen

- Advantages of Piers Constructed Monolithically, I.E. Integral Bridges With The Bridge Deck Over Usage of BearingsDokument2 SeitenAdvantages of Piers Constructed Monolithically, I.E. Integral Bridges With The Bridge Deck Over Usage of BearingsEinstein JeboneNoch keine Bewertungen

- Love Story: Name: Jebone, Einstein Webster J. Subject: Phil. Literature Course: BSCE Subj. Schedule: TH 7-10 AMDokument1 SeiteLove Story: Name: Jebone, Einstein Webster J. Subject: Phil. Literature Course: BSCE Subj. Schedule: TH 7-10 AMEinstein JeboneNoch keine Bewertungen

- Photos of SetupDokument7 SeitenPhotos of SetupEinstein JeboneNoch keine Bewertungen

- Sieve Analysis of Fine and Coarse Aggregates Dsdasd: Name: Date Performed: Course/Year: InstructorDokument3 SeitenSieve Analysis of Fine and Coarse Aggregates Dsdasd: Name: Date Performed: Course/Year: InstructorEinstein JeboneNoch keine Bewertungen

- Municipality Historical Population BulanDokument16 SeitenMunicipality Historical Population BulanEinstein JeboneNoch keine Bewertungen

- Photos of SetupDokument6 SeitenPhotos of SetupEinstein JeboneNoch keine Bewertungen

- Photos of SetupDokument6 SeitenPhotos of SetupEinstein JeboneNoch keine Bewertungen

- Photos of SetupDokument6 SeitenPhotos of SetupEinstein JeboneNoch keine Bewertungen

- Photos of SetupDokument6 SeitenPhotos of SetupEinstein JeboneNoch keine Bewertungen

- SML Lab13Dokument7 SeitenSML Lab13Einstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specifdic Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specifdic Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- Photos of SetupDokument6 SeitenPhotos of SetupEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specifdic Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specifdic Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specifdic Gravity of Soil Using Volumetric Flask SFSFSDFSDFSDF Preliminary Data SheetDokument1 SeiteLaboratory Exercise No. 6 Determination of Specifdic Gravity of Soil Using Volumetric Flask SFSFSDFSDFSDF Preliminary Data SheetEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specifdic Gravity of Soil Using Volumetric Flask SFSFSD Preliminary Data SheetDokument1 SeiteLaboratory Exercise No. 6 Determination of Specifdic Gravity of Soil Using Volumetric Flask SFSFSD Preliminary Data SheetEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specifdic Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specifdic Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- Laboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskDokument1 SeiteLaboratory Exercise No. 6 Determination of Specific Gravity of Soil Using Volumetric FlaskEinstein JeboneNoch keine Bewertungen

- The All New Actros 4x2 Tractor Head Range - Euro IV VDokument5 SeitenThe All New Actros 4x2 Tractor Head Range - Euro IV VAlin NitaNoch keine Bewertungen

- Basic Hydraulics - Pressure ControlDokument10 SeitenBasic Hydraulics - Pressure ControlmkNoch keine Bewertungen

- Eng 2Dokument24 SeitenEng 2LcNoch keine Bewertungen

- HB Komatsu HD 255-5Dokument5 SeitenHB Komatsu HD 255-5DarfiinnNoch keine Bewertungen

- Ficha Retroexcavadora Caterpillar 416DDokument8 SeitenFicha Retroexcavadora Caterpillar 416DOBRAS CIVILES Y MARITIMAS S,A DE C,V.Noch keine Bewertungen

- 345C Specalog APD (AEHQ5622) PDFDokument32 Seiten345C Specalog APD (AEHQ5622) PDFsuwarjitechnic100% (1)

- Masina Multifunctionala de Doborat ArboriDokument16 SeitenMasina Multifunctionala de Doborat ArboritwacacaNoch keine Bewertungen

- Bomba Dezp PositivoDokument108 SeitenBomba Dezp PositivofornelasNoch keine Bewertungen

- 19 Essential Information You Can Find On Motor Nameplate - EEPDokument12 Seiten19 Essential Information You Can Find On Motor Nameplate - EEPmatthewivanNoch keine Bewertungen

- Cat 992B Wheel Loader SpecsDokument6 SeitenCat 992B Wheel Loader SpecsLuã Rezende NogueiraNoch keine Bewertungen

- Klixon SensataDokument32 SeitenKlixon SensataSergio Muñoz BarriosNoch keine Bewertungen

- VW Engine CodesDokument2 SeitenVW Engine CodesGenoNoch keine Bewertungen

- Hydraulic Motor ParkerDokument56 SeitenHydraulic Motor ParkerDian PramadiNoch keine Bewertungen

- MTU Marine Spec 8V2000M84 L 1DDokument3 SeitenMTU Marine Spec 8V2000M84 L 1Dkhmiri islemNoch keine Bewertungen

- Product Brochure BL61B-BL71B en A 1006563Dokument24 SeitenProduct Brochure BL61B-BL71B en A 1006563mcsputnik100% (1)

- T7 BSI3 V 30Dokument24 SeitenT7 BSI3 V 30ArabyAbdel Hamed SadekNoch keine Bewertungen

- Track Drive MotorDokument16 SeitenTrack Drive Motoreaglego00100% (1)

- Direct Indirect: J. R. Watt, Evaporative Air Conditioning Handbook © Chapman and Hall 1986Dokument4 SeitenDirect Indirect: J. R. Watt, Evaporative Air Conditioning Handbook © Chapman and Hall 1986mrccahmedNoch keine Bewertungen

- Spare Parts Series V14: Effective: October, 2010 Supersedes: March, 2010Dokument12 SeitenSpare Parts Series V14: Effective: October, 2010 Supersedes: March, 2010Екатерина КалашниковаNoch keine Bewertungen

- Kawasaki Versys Service ManualDokument20 SeitenKawasaki Versys Service Manualrobyn100% (58)

- FULL CycloCatalog Web 2 PDFDokument248 SeitenFULL CycloCatalog Web 2 PDFprayogo1010Noch keine Bewertungen

- Ds0h Ufaa68 ProposalDokument11 SeitenDs0h Ufaa68 Proposaledward baskaraNoch keine Bewertungen

- MJAE Volume 28 Issue 1 Pages 19-31Dokument13 SeitenMJAE Volume 28 Issue 1 Pages 19-31Radient MushfikNoch keine Bewertungen

- OFE1Dokument54 SeitenOFE1سالم العيساويNoch keine Bewertungen

- Triplex Mud PumpsDokument5 SeitenTriplex Mud PumpsDharmendra khatri100% (1)

- CM20150826 46958 08410Dokument170 SeitenCM20150826 46958 08410Jordy Bernabe SalasNoch keine Bewertungen

- Placement Question With AnswersDokument45 SeitenPlacement Question With AnswersUmar SabaNoch keine Bewertungen

- Industrial Divisional Brochure 3230Dokument136 SeitenIndustrial Divisional Brochure 3230purnimaNoch keine Bewertungen

- 2024 Honda CR-V Specifications - enDokument3 Seiten2024 Honda CR-V Specifications - enAhmed GaballaNoch keine Bewertungen