Beruflich Dokumente

Kultur Dokumente

8 Codes and Standards PDF

Hochgeladen von

Mohamed BencharifOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

8 Codes and Standards PDF

Hochgeladen von

Mohamed BencharifCopyright:

Verfügbare Formate

1 General

It is not necessary for the Inspector to carry a wide range of codes and

standards in the performance of his/her duties. Normally the specification or

more precisely the contract specification is the only document required.

However the contract specification may reference supporting codes and

standards and the inspector should know where to access these normative

documents.

The following is a list of definitions relating to codes and standards which

the Inspector may come across whilst carrying out inspection duties.

2 Definitions

Normative document: A document that provides rules, guidelines or

characteristics for activities or their results. The term normative document is

a generic term, which covers documents such as standards, technical

specifications, codes of practice and regulations.*

Standard: A document that is established by consensus and approved by a

recognised body. A standard provides, for common and repeated use,

guidelines, rules, characteristics for activities or their results, aimed at the

achievement of the optimum degree of order in a given context.*

Harmonised standards: Standards on the same subject approved by

different standardising bodies, that establish interchangeability of products,

processes and services, or mutual understanding of test results or

information provided according to these standards.*

Code of practice: A document that recommends practices or procedures

for the design, manufacture, installation, maintenance, utilisation of

equipment, structures or products. A code of practice may be a standard,

part of a standard or independent of a standard.*

Regulation: A document providing binding legislative rules that is adopted

by an authority.*

Authority: A body (responsible for standards and regulations legal or

administrative entity that has specific tasks and composition) that has legal

powers and rights.*

Regulatory authority: Authority that is responsible for preparing or

adopting regulations.*

Enforcement authority: Authority that is responsible for enforcing

regulations.*

Specification: Document stating requirements. Meaningful data and its

supporting medium stating needs or expectations that are stated, generally

implied or obligatory.**

Rev 1 January 2010

Codes and Standards

Copyright TWI Ltd 2010

Procedure: Specified way to carry out an activity or a process*. Usually it is

a written description of all essential parameters and precautions to be

observed when applying a technique to a specific application following an

established standard, code or specification.

Instruction: A written description of the precise steps to be followed, based

on an established procedure, standard, code or specification.

Quality plan: A document specifying which procedures and associated

resources shall be applied by whom and when to a specific project, product,

process or contract.*

* ISO IEC Guide 2 Standardisation and related activities General vocabulary

** EN ISO 9000 2000 Quality management systems Fundamentals and

vocabulary

3 Summary

Application standards and codes of practice ensure that a structure or

component will have an acceptable level of quality and be fit for the intended

purpose.

Applying the requirements of a standard, code of practice or specification

can be a problem for the inexperienced inspector. Confidence in applying

the requirements of one or all of these documents to a specific application

only comes with use over a period of time.

If in doubt the inspector must always refer to a higher authority in order to

avoid confusion and potential problems.

Rev 1 January 2010

Codes and Standards

Copyright TWI Ltd 2010

BS number Title

BS 499: Part 1 Glossary of welding terms

BS 709 Methods of destructive testing fusion welded joints and weld metal in steel.

BS 1113 Specification for design and manufacture of water-tube steam generating

plant.

BS 1453 Specification for filler materials for gas welding.

BS 1821 Specification for Class I oxyacetylene welding of ferritic steel pipe work for

carrying fluids.

BS 2493 Low alloy steel electrodes for MMA welding.

BS 2633 Specification for Class I arc welding of ferritic steel pipe work for carrying

fluids.

BS 2640 Specification for Class II oxyacetylene welding of carbon steel pipe work

for carrying fluids.

BS 2654 Specification for manufacture of vertical steel welded non-refrigerated

storage tanks with butt-welded shells for the petroleum industry.

BS 2901: Part 3 Filler rods and wires for copper and copper alloys.

BS 2926 Specification for chromium and chromium-nickel steel electrodes for MMA

BS 3019 TIG welding.

BS 3604 Steel pipes and tubes for pressure purposes; Ferritic alloy steel with

specified elevated temperature properties for pressure purposes.

BS 3605 Specification for seamless tubes.

BS 4515 Specification for welding of steel pipelines on land and offshore.

BS 4570 Specification for fusion welding of steel castings.

BS 4677 Specification for arc welding of austenitic stainless steel pipe work for

carrying fluids.

BS 4872 Part 1: Approval testing of welders when procedure approval is not required.

Fusion welding of steel.

BS 4872 Part 2: TIG or MIG welding of aluminium and its alloys.

BS 6323 Specification for seamless and welded steel tubes for automobile,

mechanical and general engineering purposes.

BS 6693 Method for determination of diffusible hydrogen in weld metal.

BS 6990 Code of practice for welding on steel pipes containing process fluids or their

residues.

BS 7191 Specification for weldable structural steels for fixed offshore structures.

BS 7570 Code of practice for validation of arc welding equipment.

Rev 1 January 2010

Codes and Standards

Copyright TWI Ltd 2010

BS EN Number Title

BS EN 287 Part Qualification test of welders - Fusion welding - Steels.

1:

BS EN 440 Wire electrodes and deposits for gas shielded metal arc of non-

alloy and fine grain steels.

BS EN 499 Covered electrodes for manual metal arc welding of non-alloy and

fine grain steels.

BS EN 3834 - Quality requirements for fusion welding of metallic materials.

Parts 1 to 5

BS EN 756 Wire electrodes and flux wire combinations for submerged arc

welding of non-alloy and fine grain steels.

BS EN 760 Fluxes for submerged arc welding.

BS EN 910 Destructive tests on welds in metallic materials-Bend tests.

BS EN 970 Non-destructive examination of fusion welds visual

examination.

BS EN 12072 Filler rods and wires for stainless steels.

BS EN ISO Aluminium and aluminium alloys and magnesium alloys. Nickel and nick

18274 alloys.

Note: The inspector should have an awareness of the standards printed in bold.

BS EN Number Title

BS EN 1011 Welding recommendations for welding of metallic materials.

Part 1, General guidance for arc welding.

Part 2, Arc welding of ferritic steels.

Part 3, Arc welding of stainless steels.

Part 4. Arc welding of aluminium and aluminium alloys.

EN 1320 Destructive tests on welds in metallic materials.

EN 1435 Non-destructive examination of welds Radiographic examination of

welded joints.

BS EN 10002 Tensile testing of metallic materials.

BS EN 10020 Definition and classification of grades of steel.

BS EN 10027 Designation systems for steels.

BS EN 10045 Charpy impact tests on metallic materials.

BS EN 10204 Metallic products Types of inspection documents.

BS EN 22553 Welded, brazed and soldered joints Symbolic representation

on drawings.

BS EN 24063 Welding, brazing, soldering and braze welding of metal.

Nomenclature of processes and reference numbers for symbolic

representation on drawings.

BS EN 25817 Arc welded joints in steel. Guidance on quality levels for

imperfections.

BS EN 26520 Classification of imperfections in metallic fusion welds, with

explanations.

BS EN 26848 Specification for tungsten electrodes for inert gas shielded arc

welding and for plasma cutting and welding.

Rev 1 January 2010

Codes and Standards

Copyright TWI Ltd 2010

ISO Number: Title

ISO 857 - 1 Welding and allied processes Vocabulary Part 1 - Metal welding

processes.

ISO 6947 Welds Working positions Definitions of angles of slope and

rotation.

ISO 9606 - 2 Qualification test of welders Fusion welding.

Part 2 Aluminium and aluminium alloys.

ISO 15607 Specification and qualification of welding procedures for metallic

materials General rules.

ISO 15608 Welding Guidelines for a metallic material grouping system.

ISO 15609 - 1 Specification and qualification of welding procedures for metallic

materials Welding procedure specification Part 1: Arc

welding.

ISO 15610 Specification and qualification of welding procedures for metallic

materials. Qualification based on tested welding consumables.

ISO 15611 Specification and qualification of welding procedures for metallic

materials. Qualification based on previous welding experience.

ISO 15613 Specification and qualification of welding procedures for metallic

materials. Qualification based on pre-production-welding test.

ISO 15614 Specification and qualification of welding procedures for metallic

Materials Welding procedure test.

Part 1 Arc and gas welding of steels and arc welding of nickel and nickel

Part 2 alloys.

Part 3 Arc welding of aluminium and its alloys.*

Part 4 Welding procedure tests for the arc welding of cast irons.*

Part 5 Finishing welding of aluminium castings.*

Part 6 Arc welding of titanium, zirconium and their alloys.

Part 7 Copper and copper alloys.*

Part 8 Not used.

Part 9 Welding of tubes to tube-plate joints.

Part 10 Underwater hyperbaric wet welding.*

Part 11 Hyperbaric dry welding.*

Part 12 Electron and laser beam welding.

Part 13 Spot, seam and projection welding.*

Resistance butt and flash welding.*

Note: The inspector should have an awareness of the standards printed in bold.

*Proposed

Rev 1 January 2010

Codes and Standards

Copyright TWI Ltd 2010

Das könnte Ihnen auch gefallen

- ASME Understanding Codes & Stds CourseDokument4 SeitenASME Understanding Codes & Stds CourseChandrasekharNoch keine Bewertungen

- Material Selection O & GDokument26 SeitenMaterial Selection O & GJay Ganta100% (1)

- Road Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaVon EverandRoad Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaNoch keine Bewertungen

- Fujitsu Oil and Gas Asset MGMTDokument2 SeitenFujitsu Oil and Gas Asset MGMTAnshu Kumar BhartiNoch keine Bewertungen

- BWFM Presentation Template (Updated May 2018)Dokument27 SeitenBWFM Presentation Template (Updated May 2018)JanNoch keine Bewertungen

- The Complete Guide to Telephone Interview Questions and AnswersVon EverandThe Complete Guide to Telephone Interview Questions and AnswersNoch keine Bewertungen

- Piping Load DataDokument2 SeitenPiping Load DatassjunedNoch keine Bewertungen

- SES - Superheater & Reheater Outlet HeadersDokument2 SeitenSES - Superheater & Reheater Outlet HeadersSES_CincinnatiNoch keine Bewertungen

- Standard Operating Procedures For SO2 MonitoringDokument54 SeitenStandard Operating Procedures For SO2 MonitoringFredi Cari CarreraNoch keine Bewertungen

- E2glite Tutorial Part1Dokument9 SeitenE2glite Tutorial Part1linanofitaNoch keine Bewertungen

- M1703 AkashGuptaDokument43 SeitenM1703 AkashGuptaamartyadasNoch keine Bewertungen

- 5) 5.3 Heat ExchangerDokument88 Seiten5) 5.3 Heat ExchangerLarbi HammounNoch keine Bewertungen

- Well Log Interpretation Basic RelationshipsDokument41 SeitenWell Log Interpretation Basic RelationshipsJosue FishNoch keine Bewertungen

- (PDF) Assessment of Corrosion Damage Acceptance Criteria in API579-ASME - 1 CodeDokument7 Seiten(PDF) Assessment of Corrosion Damage Acceptance Criteria in API579-ASME - 1 CodeLibardo Bahamón LiscanoNoch keine Bewertungen

- Operational Practices at DIPLDokument31 SeitenOperational Practices at DIPLMisbah437Noch keine Bewertungen

- I 8 API Standards For Gas Lift Slide DeckDokument27 SeitenI 8 API Standards For Gas Lift Slide DeckalrqyshyaydhNoch keine Bewertungen

- Corrosion of WeldmentsDokument219 SeitenCorrosion of Weldments이선엽Noch keine Bewertungen

- Works & Procurement Manual 2012 PDFDokument303 SeitenWorks & Procurement Manual 2012 PDFMANNANoch keine Bewertungen

- Qualification of ERW HFIDokument17 SeitenQualification of ERW HFIovermach100% (1)

- ASME BrochureDokument2 SeitenASME BrochureumeshNoch keine Bewertungen

- Corrosion Engineer - Refinery Position DescriptionDokument2 SeitenCorrosion Engineer - Refinery Position DescriptionyagolainNoch keine Bewertungen

- Cartesian Tensors Index Notation & Summation ConventionDokument6 SeitenCartesian Tensors Index Notation & Summation ConventionHerberth Birck FröhlichNoch keine Bewertungen

- Leica Pegasus MapFactory BRO enDokument4 SeitenLeica Pegasus MapFactory BRO enpancaNoch keine Bewertungen

- Donghong Pipe Industry BrochureDokument34 SeitenDonghong Pipe Industry BrochuredonghongguanyeNoch keine Bewertungen

- Pipeline Defect Assessment Manual - Short ReviewDokument7 SeitenPipeline Defect Assessment Manual - Short Reviewbalakrishna0% (1)

- 122 Norwegian Oil and Gas Recommended Guidelines For The Mangement of Life ExtensionDokument20 Seiten122 Norwegian Oil and Gas Recommended Guidelines For The Mangement of Life ExtensionPar MadNoch keine Bewertungen

- Nen 7343Dokument7 SeitenNen 7343Soledad ViqueiraNoch keine Bewertungen

- Impact of Quality Management in The Swedish Construction ProcessDokument143 SeitenImpact of Quality Management in The Swedish Construction ProcessHabeebNoch keine Bewertungen

- In-Line Inspection of Multi-Diameter Pipelines: Standardized Development and Testing For A Highly Efficient Tool FleetDokument10 SeitenIn-Line Inspection of Multi-Diameter Pipelines: Standardized Development and Testing For A Highly Efficient Tool FleetNikhil Mohan100% (1)

- Red Hill Aoc Section 2 2 Tirm Report 2016-10-11Dokument246 SeitenRed Hill Aoc Section 2 2 Tirm Report 2016-10-11JackNoch keine Bewertungen

- (Doi 10.1115/PVP2016-63253) Lu, James Antalffy, Leslie P. Millet, Barry Smythe, Dennis - (ASME ASME 2016 Pressure Vessels and Piping Conference - Vancouver, British Columbia, Canada (Sunday 17 JDokument8 Seiten(Doi 10.1115/PVP2016-63253) Lu, James Antalffy, Leslie P. Millet, Barry Smythe, Dennis - (ASME ASME 2016 Pressure Vessels and Piping Conference - Vancouver, British Columbia, Canada (Sunday 17 JMarcus BaltesNoch keine Bewertungen

- Financial Accounting, Reporting and Business Support in The Oil and Gas IndustryDokument112 SeitenFinancial Accounting, Reporting and Business Support in The Oil and Gas IndustryTote FrotyNoch keine Bewertungen

- Project Charter Template: Purpose of The DocumentDokument4 SeitenProject Charter Template: Purpose of The DocumentBakhtawar RahmanNoch keine Bewertungen

- Black Powder in Sales Gas Pipelines: Sources and Technical RecommendationsDokument15 SeitenBlack Powder in Sales Gas Pipelines: Sources and Technical RecommendationsQueenNoch keine Bewertungen

- Desgning Sop 4 Haier IndiaDokument74 SeitenDesgning Sop 4 Haier IndiaChandra GuptaNoch keine Bewertungen

- Asset Integrity and Corrosion ManagementDokument8 SeitenAsset Integrity and Corrosion ManagementAppandai SureshNoch keine Bewertungen

- Ni 1710 KDokument19 SeitenNi 1710 KThiago MerloNoch keine Bewertungen

- Process Analysis of Refinery Crude Charge HeaterDokument21 SeitenProcess Analysis of Refinery Crude Charge HeaterNicholas RiveraNoch keine Bewertungen

- Evaluation of Smartphone Feature Preference by A Modified AHP ApproachDokument5 SeitenEvaluation of Smartphone Feature Preference by A Modified AHP ApproachSeu Ze NinguemNoch keine Bewertungen

- NLNGDokument11 SeitenNLNGAifuwa TundeNoch keine Bewertungen

- White Paper RX Large Dia PipeDokument15 SeitenWhite Paper RX Large Dia Pipetirtha sarmaNoch keine Bewertungen

- Job Analysis: A Prelude To Recruitment and PlacementDokument76 SeitenJob Analysis: A Prelude To Recruitment and PlacementJapjiv SinghNoch keine Bewertungen

- BCOGC Pipeline Operations Manual December 2015 V1.20Dokument92 SeitenBCOGC Pipeline Operations Manual December 2015 V1.20widjai10Noch keine Bewertungen

- SagdsDokument4 SeitenSagdsdattatraykolte100% (1)

- Seplat Petroleum ProspectusDokument635 SeitenSeplat Petroleum ProspectusAF Dowell MirinNoch keine Bewertungen

- Brochure - EcoSys ProductDokument8 SeitenBrochure - EcoSys ProductMichael FarinNoch keine Bewertungen

- Mechanical Integrity of Primary Reformer Hot Outlet Headers: Carl E. JaskeDokument18 SeitenMechanical Integrity of Primary Reformer Hot Outlet Headers: Carl E. Jaskevaratharajan g rNoch keine Bewertungen

- Exxon Epic Fails 1-21-17Dokument66 SeitenExxon Epic Fails 1-21-17David Lincoln100% (1)

- Henkel Loctite AdesiveDokument60 SeitenHenkel Loctite Adesive69x4Noch keine Bewertungen

- Supply Chain in The Petroleum Industry: Click To Edit Master Subtitle StyleDokument29 SeitenSupply Chain in The Petroleum Industry: Click To Edit Master Subtitle StyleAnil KumarNoch keine Bewertungen

- Material Selection For A Pressure VesselDokument9 SeitenMaterial Selection For A Pressure VesselArunkumar0% (1)

- Indira Due Diligence ReportDokument41 SeitenIndira Due Diligence ReportSetiadi MargonoNoch keine Bewertungen

- Competency Based Interviewing PDFDokument3 SeitenCompetency Based Interviewing PDFPranetNoch keine Bewertungen

- POF Specs 2009Dokument38 SeitenPOF Specs 2009eRCeckoNoch keine Bewertungen

- Oil Gas Quality Standards Presentation Tei Kabalas Dec 2014Dokument71 SeitenOil Gas Quality Standards Presentation Tei Kabalas Dec 2014George MylonakisNoch keine Bewertungen

- Metric Conversion Chart To Convert U.S. System To Metric System To Convert Metric System To U.S. SystemDokument6 SeitenMetric Conversion Chart To Convert U.S. System To Metric System To Convert Metric System To U.S. SystemneevarpsufurNoch keine Bewertungen

- US Vs EU Material Strengths PDFDokument23 SeitenUS Vs EU Material Strengths PDFAbhijeet SahuNoch keine Bewertungen

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Dokument1 SeitePipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Mohamed BencharifNoch keine Bewertungen

- 13 Mig & Mag WeldingDokument24 Seiten13 Mig & Mag WeldingMohamed BencharifNoch keine Bewertungen

- Matrice de Conformite - Norme API q1Dokument30 SeitenMatrice de Conformite - Norme API q1Mohamed BencharifNoch keine Bewertungen

- Inspection and Test Plan For Line PipeDokument4 SeitenInspection and Test Plan For Line PipeMohamed BencharifNoch keine Bewertungen

- Design of Piping Systems - MW KelloggDokument402 SeitenDesign of Piping Systems - MW KelloggSridhar Mahalingam100% (30)

- TRANE Airside EconomizerDokument8 SeitenTRANE Airside EconomizerAhmed SherifNoch keine Bewertungen

- Homework 17.Dokument2 SeitenHomework 17.Chris HeffnerNoch keine Bewertungen

- ASTM A1034 A1034M 2010a (Reapproved 2015)Dokument5 SeitenASTM A1034 A1034M 2010a (Reapproved 2015)Mukesh kumarNoch keine Bewertungen

- Vacuum Breaker Valve: DN50-DN500 PN10-16-25Dokument2 SeitenVacuum Breaker Valve: DN50-DN500 PN10-16-25Cirilo SousaNoch keine Bewertungen

- King Fahd University of Petroleum & Minerals Department of Chemical EngineeringDokument5 SeitenKing Fahd University of Petroleum & Minerals Department of Chemical Engineeringgood musicNoch keine Bewertungen

- 2 - 2011 570 Closed Book Exam (75Qs)Dokument15 Seiten2 - 2011 570 Closed Book Exam (75Qs)Sunny Thundil100% (3)

- Manual (Master 2014) Movano Ope Part 3lDokument64 SeitenManual (Master 2014) Movano Ope Part 3ledsononohara50% (2)

- 15P701Dokument4 Seiten15P701rajakrishnanNoch keine Bewertungen

- PHYA10 - Physics I (Physical Sciences) Practical Worksheet #05Dokument2 SeitenPHYA10 - Physics I (Physical Sciences) Practical Worksheet #05Sabine MohamadNoch keine Bewertungen

- Iso 2768 Tolerancias GeneralesDokument2 SeitenIso 2768 Tolerancias GeneralesjavierNoch keine Bewertungen

- LocalizationDokument45 SeitenLocalizationbobNoch keine Bewertungen

- Memo LubDokument57 SeitenMemo LubjoelNoch keine Bewertungen

- Cross Flow Part 1Dokument5 SeitenCross Flow Part 1mohmmad othmanNoch keine Bewertungen

- SRM 00067Dokument2 SeitenSRM 00067OreolNoch keine Bewertungen

- Bernoulli's Principle and Application: Ang SovannDokument45 SeitenBernoulli's Principle and Application: Ang SovannKantilal MalwaniaNoch keine Bewertungen

- Fluid Flow Operation - 130502Dokument2 SeitenFluid Flow Operation - 130502sanjayNoch keine Bewertungen

- Technický Manuál RiminiDokument30 SeitenTechnický Manuál Riminidoubleshot s.r.o.100% (1)

- Lifting Tongs: Solving Material Handling ProblemsDokument4 SeitenLifting Tongs: Solving Material Handling Problemsmohsen123100% (1)

- ENSC 3233 HW #1 Solution PDFDokument10 SeitenENSC 3233 HW #1 Solution PDFheem bashaNoch keine Bewertungen

- Ultra - Temp Installation and Maintenance Manual IOM 101.2Dokument16 SeitenUltra - Temp Installation and Maintenance Manual IOM 101.2Abdiel Kadir Martinez MendozaNoch keine Bewertungen

- HMT ManualDokument68 SeitenHMT ManualASWIN VICTOR .ENoch keine Bewertungen

- MS008 Steel Tank MSDokument9 SeitenMS008 Steel Tank MSMhando IgnasNoch keine Bewertungen

- Ito MatsuiDokument11 SeitenIto MatsuiDoinea MihailNoch keine Bewertungen

- DesignBuilderPrintableManualv4 5A4Dokument1.192 SeitenDesignBuilderPrintableManualv4 5A4ElviraMartinez100% (1)

- Liquefied Petroleum Gas Cylinder Level Indicator and Transporting DeviceDokument105 SeitenLiquefied Petroleum Gas Cylinder Level Indicator and Transporting DeviceAyorinde Oladele Tiwalade100% (1)

- Manual Wedge Action Grips - 2716-01X-02X and 2736-01XDokument3 SeitenManual Wedge Action Grips - 2716-01X-02X and 2736-01XLALO MNoch keine Bewertungen

- Big Block Chevy Info - Grumpys Performance GarageDokument104 SeitenBig Block Chevy Info - Grumpys Performance GarageAsad Khan100% (1)

- Design, Implementation and Speed Estimation of Three Phase 2 KW Out Runner Permanent Magnet BLDC MotorDokument14 SeitenDesign, Implementation and Speed Estimation of Three Phase 2 KW Out Runner Permanent Magnet BLDC MotorDavid AzadNoch keine Bewertungen

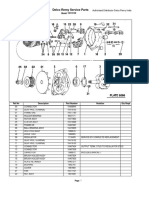

- Delco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaDokument2 SeitenDelco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaWilson AcostaNoch keine Bewertungen