Beruflich Dokumente

Kultur Dokumente

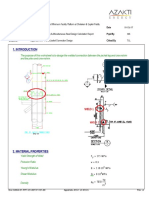

PADEYE Design Analysis

Hochgeladen von

Ramesh SelvarajOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PADEYE Design Analysis

Hochgeladen von

Ramesh SelvarajCopyright:

Verfügbare Formate

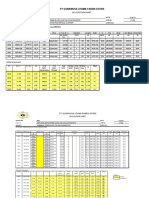

PADEYE DESIGN

1.Input- Force

Sling load Ft = 11772 KN 1200 MT

Dynamic Factor DAF = 1

Additional out of plane force = 5%

Sling angle - inplane = 22 deg

Sling angle - out of plane = 2 deg

Yield strength y = 33.50 KN/cm2

Dimensions

Component b (cm) t (cm) x (cm) y (cm)

1 70 5 35 2.5

2 290 6.3 35 150

3 31.85 2.5 15.925 124

4 31.75 3.2 54.025 124

5 56 5 35 297.5

6 31.75 2.5 15.975 247

7 31.85 2.5 54.075 247

8 0 0 31.85 0

9 0 0 38.15 0

L2 = 57.50 cm

Lengths L3 = 40.00 cm

4. Allowable stress values

Bearing br-all = 0.90 y = 30.15 KN/cm2

Shear s-all = 0.40 y = 13.40 KN/cm2

Axial a-all = 0.60 y = 20.10 KN/cm2

Tension for padeye t-all = 0.45 y = 15.08 KN/cm2

Bending b-all = 0.66 y = 22.11 KN/cm2

Max. width of c/s at left corner = 35.00 cm

Max. width of c/s at right corner = 35.00 cm

Area of cross section Acs = 2797.23 cm2

Centroid distance along-X xbar = 35.15 cm

Centroid distance along-Y ybar = 150.14 cm

M.I about centroidal X- axis IXC = 28130671.78 cm4

M.I about centroidal Y- axis IYC = 374181.98 cm4

M.I about centroidal Z- axis IZC = 30265.14 cm4

Force components

Total Force along X Fx = 742.50 KN

Force along Y Fy = 10914.81 KN

Force along Z Fz = 4407.18 KN

Eccenricity in x direction ex = 2.01 cm

Eccenricity in y direction ey = 110.14 cm

Eccenricity in z direction ez = 57.46 cm

Moment about x-x Mxx = 141820.69 KN-cm

Moment about y-y Myy = 33823.88 KN-cm

Moment about z-z Mzz = -37971.79 KN-cm

Checks

a. Axial Tension Check

Tensile stress t-cs = 1.58 KN/cm2 OK UC = 0.08

b. Bending Check

Bending stress x-x bx-cs = 0.76 KN/cm2 OK UC = 0.03

Bending stress y-y by-cs = 3.16 KN/cm 2

OK UC = 0.14

Resultant bending stress b-res = 3.25 KN/cm 2

OK UC = 0.15

c. Shear check

Shear area along x-axis As-x = 970.23 cm2

Shear area along y-axis As-y = 1827.00 cm2

Shear stress along x-axis s-cs-x = 0.765 KN/cm2 OK UC = 0.06

Shear stress along y-axis s-cs-y = 5.974 KN/cm 2

OK UC = 0.45

d.Torsion check

Minimum thickness along x-axis tmin-x = 2.50 cm

Minimum thickness along y-axis tmin-y = 6.30 cm

Torsional shear stress along x-axis Js-x = -3.14 KN/cm2

Torsional shear stress along y-axis Js-y = -7.90 KN/cm2

Total shear stress along x s-cs-t-x = -2.37 KN/cm2

Total shear stress along y s-cs-t-y = -1.93 KN/cm2

Resultant shear stress-(incl.torsion) s-cs-res = 3.06 KN/cm2 OK UC = 0.23

e. Combined stress check cs-com = 0.256 OK UC = 0.26

f. Von-mises stress vm-cs = 7.167 KN/cm2 OK UC = 0.21

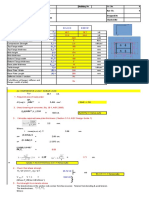

PADEYE DESIGN

1.Input- Force

Sling load Ft = 4000 KN 408 MT

Dynamic Factor DAF = 1

Additional out of plane force = 5%

Sling angle - inplane = 60 deg

Sling angle - out of plane = 5 deg

Yield strength y = 33.50 KN/cm2

Dimensions

Component b (cm) t (cm) x (cm) y (cm)

1 62.5 3.2 31.25 1.6

2 127.2 5 31.25 66.8

3 28.75 3.2 14.375 88.6

4 28.75 3.2 48.125 88.6

5 62.5 3.2 31.25 132

6 0 0 28.75 0

7 0 0 33.75 0

8 0 0 28.75 0

9 0 0 33.75 0

L2 = 45.00 cm

Lengths L3 = 45.00 cm

4. Allowable stress values

Bearing br-all = 0.90 y = 30.15 KN/cm2

Shear s-all = 0.40 y = 13.40 KN/cm2

Axial a-all = 0.60 y = 20.10 KN/cm2

Tension for padeye t-all = 0.45 y = 15.08 KN/cm2

Bending b-all = 0.66 y = 22.11 KN/cm2

Max. width of c/s at left corner = 31.25 cm

Max. width of c/s at right corner = 31.25 cm

Area of cross section Acs = 1220.00 cm2

Centroid distance along-X xbar = 31.25 cm

Centroid distance along-Y ybar = 70.09 cm

M.I about centroidal X- axis IXC = 2632701.73 cm4

M.I about centroidal Y- axis IYC = 196604.17 cm4

M.I about centroidal Z- axis IZC = 7293.39 cm4

Force components

Total Force along X Fx = 501.92 KN

Force along Y Fy = 2000.00 KN

Force along Z Fz = 3450.92 KN

Eccenricity in x direction ex = 3.92 cm

Eccenricity in y direction ey = 25.09 cm

Eccenricity in z direction ez = 44.83 cm

Moment about x-x Mxx = 3081.30 KN-cm

Moment about y-y Myy = 8965.75 KN-cm

Moment about z-z Mzz = 4747.99 KN-cm

Checks

a. Axial Tension Check

Tensile stress t-cs = 2.83 KN/cm2 OK UC = 0.14

b. Bending Check

Bending stress x-x bx-cs = 0.08 KN/cm2 OK UC = 0.00

Bending stress y-y by-cs = 1.43 KN/cm 2

OK UC = 0.06

Resultant bending stress b-res = 1.43 KN/cm 2

OK UC = 0.06

c. Shear check

Shear area along x-axis As-x = 584.00 cm2

Shear area along y-axis As-y = 636.00 cm2

Shear stress along x-axis s-cs-x = 0.859 KN/cm2 OK UC = 0.06

Shear stress along y-axis s-cs-y = 3.145 KN/cm 2

OK UC = 0.23

d.Torsion check

Minimum thickness along x-axis tmin-x = 3.20 cm

Minimum thickness along y-axis tmin-y = 5.00 cm

Torsional shear stress along x-axis Js-x = 2.08 KN/cm2

Torsional shear stress along y-axis Js-y = 3.25 KN/cm2

Total shear stress along x s-cs-t-x = 2.94 KN/cm2

Total shear stress along y s-cs-t-y = 6.40 KN/cm2

Resultant shear stress-(incl.torsion) s-cs-res = 7.04 KN/cm2 OK UC = 0.53

e. Combined stress check cs-com = 0.209 OK UC = 0.21

f. Von-mises stress vm-cs = 12.921 KN/cm2 OK UC = 0.39

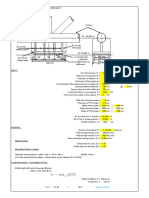

PADEYE DESIGN

1.Input- Force

Sling load Ft = 6278.4 KN 640 MT

Dynamic Factor DAF = 1

2.Shackle Data

Pin diameter D = 20.00 cm

Jaw width A = 27.50 cm

Inside distance C = 70.00 cm

Safe working load SWLsh = 700 MT

3.Sling selection

Sling diameter = 10 cm

Safe working load SWLsl = 700 MT

4.Padeye selection

Pin hole diameter P = 20.60 cm

Main plate radius Rm = 40 cm

Main plate thickness tm = 6.3 cm

Cheek plate pair-1 radius Rc1 = 33 cm

Cheek plate pair-1 thickness tc1 = 6.3 cm

Cheek plate pair-2 radius Rc2 = 28 cm

Cheek plate pair-2 thickness tc2 = 3.8 cm

Spacer plates pair thickness tsp = 0 cm

Weld b/w chk pl 1 & 2 wsc = 2.5 cm

Weld b/w chk pl 1 & main pl wsm = 4.5 cm

Additional shear length Ladd = 45.21 cm

Yield strength y = 33.50 KN/cm2

Ultimate strength in weld ult = 41.30 KN/cm2

Modulus of Elasticity E = 20000 KN/cm2

5. Allowable stress values

Bearing br-all = 0.90 y = 30.15 KN/cm2

Shear s-all = 0.40 y = 13.40 KN/cm2

Axial a-all = 0.60 y = 20.10 KN/cm2

Tension for padeye t-all = 0.45 y = 15.08 KN/cm2

Bending b-all = 0.66 y = 22.11 KN/cm2

Weld wld-all = 0.30 ult = 12.39 KN/cm2

Hertz HZ-all = 2.50 y = 83.75 KN/cm2

6: Stress Checks

a.Bearing stress at hole br = 11.85 KN/cm2 OK UC = 0.39

b. Hertz check

Parameter KD = (P x D)/ (P-D) KD = 686.67

t = 26.50

Hertz stress HZ = 49.09 KN/cm2 OK UC = 0.59

c. Shear check at hole

Area of section in shear Ashear = 1215.30 cm2

Shear stress s = 5.17 KN/cm2 OK UC = 0.39

d. Tension check at hole

Tensile/shear stress t = 5.17 KN/cm2 OK UC = 0.34

e. Tearing/Pullout check

Area of section in tearing Atear = 937.96 cm2

Tearing stress tear = 6.69 KN/cm2 OK UC = 0.50

f. Weld check

Force on cheek plate-2 Fchk-2 = 900.30 KN

Weld size required wsc-req = 1.2 cm OK UC = 0.47

Force on cheek plate-1 Fchk-1 = 1492.60 KN

Weld size required wsm-req = 2.63 cm OK UC = 0.59

Das könnte Ihnen auch gefallen

- BOX Sec-Beam-Column-AiscDokument6 SeitenBOX Sec-Beam-Column-AiscWintun73Noch keine Bewertungen

- Design Calculation Sheet: Jebel Ali Refinary ExpansionDokument4 SeitenDesign Calculation Sheet: Jebel Ali Refinary ExpansionAnish PuthusseryNoch keine Bewertungen

- PT Gunanusa Utama Fabricators: Calculation SheetDokument25 SeitenPT Gunanusa Utama Fabricators: Calculation Sheetriandi100% (1)

- Seismic Co-Efficient Calculation As Per NBCC - Equivalent Static Force Procedure For Structures Satisfying The Conditions of ArticleDokument8 SeitenSeismic Co-Efficient Calculation As Per NBCC - Equivalent Static Force Procedure For Structures Satisfying The Conditions of ArticleVEERAM AJITHNoch keine Bewertungen

- The Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimDokument5 SeitenThe Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimThomas StephenNoch keine Bewertungen

- Column Effective LengthDokument1 SeiteColumn Effective LengthjanethNoch keine Bewertungen

- Cylindrical Member DesignDokument5 SeitenCylindrical Member DesignolomuNoch keine Bewertungen

- MarineDokument9 SeitenMarineTirthGanatraNoch keine Bewertungen

- Dokumen - Tips - Perhitungan Pondasi TCDokument7 SeitenDokumen - Tips - Perhitungan Pondasi TCAlex MartiknoNoch keine Bewertungen

- Appendix A1Dokument22 SeitenAppendix A1Thomas StephenNoch keine Bewertungen

- Chapter 13 ExamplesDokument8 SeitenChapter 13 ExamplesAnonymous kBl0u3nNoch keine Bewertungen

- Load Out FixDokument47 SeitenLoad Out FixAnonymous SC5fatrFM3Noch keine Bewertungen

- Aisc Asd Gusset Plate Aisc341 16Dokument12 SeitenAisc Asd Gusset Plate Aisc341 16Zarna Modi100% (1)

- Towing Design Rev2Dokument19 SeitenTowing Design Rev2Ludovic LandemaineNoch keine Bewertungen

- Input Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingDokument6 SeitenInput Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingThomas StephenNoch keine Bewertungen

- Calculation Sheet: Tubular Brace ParametersDokument52 SeitenCalculation Sheet: Tubular Brace ParametersRamesh SelvarajNoch keine Bewertungen

- App 10 Longitudial Shear 2 UC 283Dokument3 SeitenApp 10 Longitudial Shear 2 UC 283yuNoch keine Bewertungen

- Calculation of No. of Bolts For Individual Members Bolt DiameterDokument1 SeiteCalculation of No. of Bolts For Individual Members Bolt DiametercharanNoch keine Bewertungen

- Seainp - ZULF EDP-1 OBSDokument37 SeitenSeainp - ZULF EDP-1 OBSRamesh SelvarajNoch keine Bewertungen

- Plan Elevation: D D B P M T T ADokument18 SeitenPlan Elevation: D D B P M T T ASai SushankNoch keine Bewertungen

- 3.5 POT Weld Length - 600mmDokument1 Seite3.5 POT Weld Length - 600mmSantosh ZunjarNoch keine Bewertungen

- Inplace Analysis: Check Print For Submission To Client As RequiredDokument4 SeitenInplace Analysis: Check Print For Submission To Client As RequiredRamesh SelvarajNoch keine Bewertungen

- Any Materials Permitted (602.5) 1 1 1 1 1: Windows (T-715.5) Door&Shutter (T-715.3)Dokument19 SeitenAny Materials Permitted (602.5) 1 1 1 1 1: Windows (T-715.5) Door&Shutter (T-715.3)Manju BirjeNoch keine Bewertungen

- Base Plate Design for Column Base ConnectionDokument6 SeitenBase Plate Design for Column Base ConnectionThuyTranNoch keine Bewertungen

- Multi Lift Point CalcsDokument3 SeitenMulti Lift Point CalcsPhan Trọng NghĩaNoch keine Bewertungen

- Stability CritariaDokument9 SeitenStability CritariaAbu Bakar Siddke RumiNoch keine Bewertungen

- Beam CheckDokument4 SeitenBeam CheckSai SushankNoch keine Bewertungen

- (Joint 1760) : PT - Technip IndonesiaDokument12 Seiten(Joint 1760) : PT - Technip IndonesiariandiNoch keine Bewertungen

- Star Plate Check Connection Number: Node Number: G H O P NDokument7 SeitenStar Plate Check Connection Number: Node Number: G H O P Nyogs_184Noch keine Bewertungen

- E2336 - DESIGN INPUT REQUIRED - COMBINED NAVAL and STRUCTURALDokument6 SeitenE2336 - DESIGN INPUT REQUIRED - COMBINED NAVAL and STRUCTURALRamesh SelvarajNoch keine Bewertungen

- Appendix D 2Dokument7 SeitenAppendix D 2Wistie AnnelyaNoch keine Bewertungen

- Derbyshire loss section modulus calculationsDokument2 SeitenDerbyshire loss section modulus calculationsdakidofdaboomNoch keine Bewertungen

- Environmental Forces - Aban VIIIDokument2 SeitenEnvironmental Forces - Aban VIIIPrashanth Talkad RajagopalNoch keine Bewertungen

- Jeddah South Thermal Power Plant Stage-I: OwnerDokument23 SeitenJeddah South Thermal Power Plant Stage-I: OwnerAmr AbdeinNoch keine Bewertungen

- Chapter J Design of ConnectionsDokument16 SeitenChapter J Design of Connectionsghosh73Noch keine Bewertungen

- Annex A:Lifting Lug CalculationDokument3 SeitenAnnex A:Lifting Lug CalculationVilas AndhaleNoch keine Bewertungen

- CALCULATION OF MODIFIED g AND t PARAMETERSDokument17 SeitenCALCULATION OF MODIFIED g AND t PARAMETERSSai SushankNoch keine Bewertungen

- Punching CheckDokument196 SeitenPunching CheckGURUPRASAD SHIKHARENoch keine Bewertungen

- Stiffener Local CheckingDokument1 SeiteStiffener Local CheckingSai SushankNoch keine Bewertungen

- The Equivalent Axial Tension Capacity of Soil For 42" Pile Is Calculated As Follows. T OD / Od TDokument4 SeitenThe Equivalent Axial Tension Capacity of Soil For 42" Pile Is Calculated As Follows. T OD / Od TRamesh SelvarajNoch keine Bewertungen

- Length Is Updated: Leg A2 Leg A1 202L 201LDokument3 SeitenLength Is Updated: Leg A2 Leg A1 202L 201LRamesh SelvarajNoch keine Bewertungen

- THAIOIL - VER BRACING-L SECTION - BOLTED - 003 - Rev ADokument15 SeitenTHAIOIL - VER BRACING-L SECTION - BOLTED - 003 - Rev ACivil StructureNoch keine Bewertungen

- SEA - TRANS - REACTION PAU-106-104B - Preliminary IssueDokument4 SeitenSEA - TRANS - REACTION PAU-106-104B - Preliminary IssueUMER AZIQNoch keine Bewertungen

- Design of L Shaped Cantilever Retaining Wall: 1 Preliminary DataDokument7 SeitenDesign of L Shaped Cantilever Retaining Wall: 1 Preliminary Dataraghu kiranNoch keine Bewertungen

- Tonnage CalculationDokument5 SeitenTonnage CalculationeNoch keine Bewertungen

- Bearing CapacityDokument20 SeitenBearing CapacityJhoan ParedesNoch keine Bewertungen

- Wing Plate BucklingDokument2 SeitenWing Plate BucklingSai SushankNoch keine Bewertungen

- Pile axial load analysis and FOS resultsDokument2 SeitenPile axial load analysis and FOS resultsRamesh SelvarajNoch keine Bewertungen

- List CalculationDokument7 SeitenList CalculationTavy TavyNoch keine Bewertungen

- Bridge 10 Sunshade DesignDokument4 SeitenBridge 10 Sunshade DesignSai SushankNoch keine Bewertungen

- San Jose Del Rio: Suspension Bridge DesignDokument9 SeitenSan Jose Del Rio: Suspension Bridge DesigntasingenieriaNoch keine Bewertungen

- Bridge B 1 Fixed EndDokument7 SeitenBridge B 1 Fixed EndSai SushankNoch keine Bewertungen

- API WSD Punch CodeCheckDokument7 SeitenAPI WSD Punch CodeCheckKhải TrươngNoch keine Bewertungen

- Bending Moment Diagram CalculationDokument97 SeitenBending Moment Diagram CalculationCharles HutabaratNoch keine Bewertungen

- Base Plate BiaxilDokument19 SeitenBase Plate BiaxilGunjan KolarkarNoch keine Bewertungen

- Subsee Suction Pile Installation AnalysisDokument11 SeitenSubsee Suction Pile Installation AnalysisKen KennyNoch keine Bewertungen

- Reference Drawings for Pile Foundation Design of Powerhouse Erection BayDokument12 SeitenReference Drawings for Pile Foundation Design of Powerhouse Erection Baynirez14Noch keine Bewertungen

- BucklingDokument16 SeitenBucklingMikeNoch keine Bewertungen

- Reference: AISC Anchor Chair /pressure Vessel Handbook by Moss and BasicDokument3 SeitenReference: AISC Anchor Chair /pressure Vessel Handbook by Moss and Basicswarnamalini0% (1)

- UKC 127x76x16 steel section design checkDokument3 SeitenUKC 127x76x16 steel section design checkaimkcl90Noch keine Bewertungen

- DRIVEABILITY ANALYSISDokument4 SeitenDRIVEABILITY ANALYSISRamesh SelvarajNoch keine Bewertungen

- L&T-Valdel Engineering PVT LTD Check List For Joint Numbering Contract No.: Project: Sacs Model No: Sacs Model Dated CHKD By: Appd By: LE PMDokument3 SeitenL&T-Valdel Engineering PVT LTD Check List For Joint Numbering Contract No.: Project: Sacs Model No: Sacs Model Dated CHKD By: Appd By: LE PMRamesh SelvarajNoch keine Bewertungen

- Check List For Doing Seismic AnalysisDokument3 SeitenCheck List For Doing Seismic AnalysisRamesh SelvarajNoch keine Bewertungen

- CHECK LIST FOR TOPSIDE/JACKET LOADOUT ANALYSISDokument1 SeiteCHECK LIST FOR TOPSIDE/JACKET LOADOUT ANALYSISRamesh SelvarajNoch keine Bewertungen

- Check List For Jacket/Topsides Transportation AnalysisDokument2 SeitenCheck List For Jacket/Topsides Transportation AnalysisRamesh SelvarajNoch keine Bewertungen

- Inplace Analysis: Check Print For Submission To Client As RequiredDokument4 SeitenInplace Analysis: Check Print For Submission To Client As RequiredRamesh SelvarajNoch keine Bewertungen

- Topsides lift analysis checklistDokument1 SeiteTopsides lift analysis checklistRamesh SelvarajNoch keine Bewertungen

- Check List For Jacket Seismic Analysis: Revision Originator Date Checker Date Revision Originator Date Checker DateDokument2 SeitenCheck List For Jacket Seismic Analysis: Revision Originator Date Checker Date Revision Originator Date Checker DateRamesh SelvarajNoch keine Bewertungen

- Api RP 2a WSD 1pdf - CompressDokument1 SeiteApi RP 2a WSD 1pdf - CompressRamesh SelvarajNoch keine Bewertungen

- CD CM Overrides For Report Conductor Shielding FactorDokument2 SeitenCD CM Overrides For Report Conductor Shielding FactorRamesh SelvarajNoch keine Bewertungen

- Check List For Topside Inplace Analysis: Project Client Model File NameDokument1 SeiteCheck List For Topside Inplace Analysis: Project Client Model File NameRamesh SelvarajNoch keine Bewertungen

- Check List - TransitDokument1 SeiteCheck List - TransitRamesh SelvarajNoch keine Bewertungen

- Seainp - ZULF EDP-1 OBSDokument37 SeitenSeainp - ZULF EDP-1 OBSRamesh SelvarajNoch keine Bewertungen

- Check List For Jacket Lift & Upending Analysis: Project Client Model File NameDokument2 SeitenCheck List For Jacket Lift & Upending Analysis: Project Client Model File NameogunsholadanielNoch keine Bewertungen

- E2336 - DESIGN INPUT REQUIRED - COMBINED NAVAL and STRUCTURALDokument6 SeitenE2336 - DESIGN INPUT REQUIRED - COMBINED NAVAL and STRUCTURALRamesh SelvarajNoch keine Bewertungen

- KG2 Math Practice Sheet on Numbers 1-10Dokument1 SeiteKG2 Math Practice Sheet on Numbers 1-10Ramesh SelvarajNoch keine Bewertungen

- Check List For Doing Seismic AnalysisDokument3 SeitenCheck List For Doing Seismic AnalysisRamesh SelvarajNoch keine Bewertungen

- 15-Apr - Maths Answer PDFDokument1 Seite15-Apr - Maths Answer PDFRamesh SelvarajNoch keine Bewertungen

- Plaxis Tutorial 01Dokument33 SeitenPlaxis Tutorial 01Duc Tran0% (2)

- Numbers 11-20 practice sheet answersDokument1 SeiteNumbers 11-20 practice sheet answersRamesh SelvarajNoch keine Bewertungen

- NAME: - CLASS: KG 2 - Topic: Vowels-A Competences: Communication, Independent Learning: 1. Choose The Correct Letter and Complete The WordDokument1 SeiteNAME: - CLASS: KG 2 - Topic: Vowels-A Competences: Communication, Independent Learning: 1. Choose The Correct Letter and Complete The WordRamesh SelvarajNoch keine Bewertungen

- SPMTDokument2 SeitenSPMTRamesh SelvarajNoch keine Bewertungen

- Question Q1-1 To 1-3Dokument6 SeitenQuestion Q1-1 To 1-3Ramesh SelvarajNoch keine Bewertungen

- Date: 14-04-2020: 1.identify and Match The Parts of The BodyDokument2 SeitenDate: 14-04-2020: 1.identify and Match The Parts of The BodyRamesh SelvarajNoch keine Bewertungen

- NAME: - CLASS: KG 2 - Topic: Revision of Numbers (1-10) Competences: Problem Solving, Independent LearningDokument1 SeiteNAME: - CLASS: KG 2 - Topic: Revision of Numbers (1-10) Competences: Problem Solving, Independent LearningRamesh SelvarajNoch keine Bewertungen

- 13 AprDokument1 Seite13 AprRamesh SelvarajNoch keine Bewertungen

- Plaxis Tutorial 01Dokument1 SeitePlaxis Tutorial 01Ramesh SelvarajNoch keine Bewertungen

- NRJN 1020-1025 Inplace Modified Crane Loads PresentationDokument4 SeitenNRJN 1020-1025 Inplace Modified Crane Loads PresentationRamesh SelvarajNoch keine Bewertungen

- MRJN 1020-1025 Sacs Inplace - Deck Crane Load - InitialDokument2 SeitenMRJN 1020-1025 Sacs Inplace - Deck Crane Load - InitialRamesh SelvarajNoch keine Bewertungen

- Sensitivity study of peak enhancement factor on fatigue damageDokument1 SeiteSensitivity study of peak enhancement factor on fatigue damageRamesh SelvarajNoch keine Bewertungen

- Topic 2Dokument6 SeitenTopic 2Vince Diza SaguidNoch keine Bewertungen

- Mr. Sanjeev Nanda - Devoted Son and GrandsonDokument1 SeiteMr. Sanjeev Nanda - Devoted Son and GrandsonSanjeev NandaNoch keine Bewertungen

- Odoo Video Conference User GuidesDokument12 SeitenOdoo Video Conference User GuidesZeus TitanNoch keine Bewertungen

- HB Im70 QRDokument1 SeiteHB Im70 QROsamaNoch keine Bewertungen

- Three Laws of RoboticsDokument2 SeitenThree Laws of RoboticsBav VAansoqnuaetzNoch keine Bewertungen

- Komatsu HD785-7 Shop Manual PDFDokument1.491 SeitenKomatsu HD785-7 Shop Manual PDFIB EldinNoch keine Bewertungen

- Mitsubishi Evo Vii Workshop ManualDokument1.471 SeitenMitsubishi Evo Vii Workshop ManuallimaynardNoch keine Bewertungen

- Cpar Lesson 1Dokument44 SeitenCpar Lesson 1althea villanuevaNoch keine Bewertungen

- FMS 1Dokument27 SeitenFMS 1bishal dattaNoch keine Bewertungen

- ADTHEORENT SOTI Programmatic 102722Dokument20 SeitenADTHEORENT SOTI Programmatic 102722chinmayNoch keine Bewertungen

- MA Music Education FDokument4 SeitenMA Music Education FSu YimonNoch keine Bewertungen

- CGE Quester Spec Sheet E29Dokument2 SeitenCGE Quester Spec Sheet E29Ruveen Jeetun100% (1)

- Theorizing Eco-Dystopia: Science Fiction, The Anthropocene, and The Limits of Catastrophic ImageryDokument15 SeitenTheorizing Eco-Dystopia: Science Fiction, The Anthropocene, and The Limits of Catastrophic ImageryLaura QuintanaNoch keine Bewertungen

- SAP Untangled: An Introductory Guide To SAP For New HomesDokument28 SeitenSAP Untangled: An Introductory Guide To SAP For New HomestempuserNoch keine Bewertungen

- Alchemical Psychology Uniform Edition o - HillmanDokument207 SeitenAlchemical Psychology Uniform Edition o - HillmanElsy Arana95% (22)

- Equilibrium of Supply and DemandDokument4 SeitenEquilibrium of Supply and DemandJuina Mhay Baldillo ChunacoNoch keine Bewertungen

- Gel Electrophoresis Lab ReportDokument10 SeitenGel Electrophoresis Lab Reportapi-31150900783% (6)

- Earth's StructureDokument10 SeitenEarth's StructureMaitum Gemark BalazonNoch keine Bewertungen

- Yealink Device Management Platform: Key FeaturesDokument3 SeitenYealink Device Management Platform: Key FeaturesEliezer MartinsNoch keine Bewertungen

- Calculation of Moments and Shear: Input DataDokument3 SeitenCalculation of Moments and Shear: Input DataARSENoch keine Bewertungen

- Parameter Pengelasan SMAW: No Bahan Diameter Ampere Polaritas Penetrasi Rekomendasi Posisi PengguanaanDokument2 SeitenParameter Pengelasan SMAW: No Bahan Diameter Ampere Polaritas Penetrasi Rekomendasi Posisi PengguanaanKhamdi AfandiNoch keine Bewertungen

- History of PTCLDokument4 SeitenHistory of PTCLswealumair86Noch keine Bewertungen

- Climate Change ReactionDokument2 SeitenClimate Change ReactionAngelika CotejoNoch keine Bewertungen

- Industrial Training, at DCCPPDokument26 SeitenIndustrial Training, at DCCPPGaganil SharmaNoch keine Bewertungen

- TK17 V10 ReadmeDokument72 SeitenTK17 V10 ReadmePaula PérezNoch keine Bewertungen

- AI vs ML: A Brief ExplanationDokument3 SeitenAI vs ML: A Brief Explanationkhaoula BelghitiNoch keine Bewertungen

- Dslam Commissioning Steps Punjab For 960 PortDokument8 SeitenDslam Commissioning Steps Punjab For 960 Portanl_bhn100% (1)

- The Message Development Tool - A Case For Effective Operationalization of Messaging in Social Marketing PracticeDokument17 SeitenThe Message Development Tool - A Case For Effective Operationalization of Messaging in Social Marketing PracticesanjayamalakasenevirathneNoch keine Bewertungen

- MAMALUMPONG JORDAN A. BSN-3 Literature ReviewDokument3 SeitenMAMALUMPONG JORDAN A. BSN-3 Literature ReviewJordan Abosama MamalumpongNoch keine Bewertungen

- Models of Collaboration Between Education and ServicesDokument17 SeitenModels of Collaboration Between Education and ServicesSimran Josan100% (3)