Beruflich Dokumente

Kultur Dokumente

Control and Modelling of Wireless Robot

Hochgeladen von

Phaniendra KundetiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Control and Modelling of Wireless Robot

Hochgeladen von

Phaniendra KundetiCopyright:

Verfügbare Formate

Control and Monitoring System for Modular Wireless Robot

I. Firmansyah, B. Hermanto and L.T. Handoko

Group for Theoretical and Computational Physic, Research Center for Physics, Indonesian Institute of Sciences, Kompleks

Puspiptek Serpong, Tangerang 15310, Indonesia

firmansyah@teori.fisika.lipi.go.id

Abstract system. Finally we summarize the result and discuss future

We introduce our concept on the modular wireless robot plans.

consisting of three main modules : main unit, data acquisition

and data processing modules. We have developed a generic 2. The concept

prototype with an integrated control and monitoring system to First of all, we have developed LWR to be as modular as

enhance its flexibility, and to enable simple operation through a possible to make it flexible to users' needs. This concept is

web-based interface accessible wirelessly. In present paper, we depicted in Fig. 1, consisting of three modules : 1) main unit, 2)

focus on the microcontroller based hardware to enable data data-acquisition and 3) data processing modules. So, the system

acquisition and remote mechanical control. is divided into two independent units : the main unit and the unit

of data acquisition and its processing software. Let us call the

1. Introduction second unit briefly as DAPS throughout the paper. In principle,

Automation systems have been becoming the main issue since one might have single main unit with different packages of

many decades ago to improve the efficiency and to avoid DAPS, or vice versa according to the needs. This characteristic

unnecessary defects, especially in modern manufactures. It also would enable users to easily replace, for instance the censors and

plays an important role in some manufacturing processes which relevant data processing modules with any available packages

require high precision. On the other hand, automation systems later on with the same main unit.

with embedded remote robots are getting common in non- Since we are going to open our main unit and its architecture

manufacturing industries where safety is the main issue, as mine freely, further this approach could encourage third parties to

explorations, etc. develop independently any relevant packages designed for some

Nowadays, following the advances on internet technology particular needs. Inversely, ones interested more in hardware

some groups have developed new kind of robots which can be developments, might build alternative main unit with different

teleoperated over web as MAX project [1] and also its successor type of mechanics for robot, but with same architecture for the

WAX [2,3]. Either MAX or WAX are the microcontroller-based rest to keep its compatibilities with existing DAPS packages.

robots equipped with onboard computer, camera and Some considerable packages are, for example, censors of

microphone with main purpose to simulate telepresence. dangerous gas combined with software based chemical

Because originally these robots were intended for handicapped compound analyzer, vibration censor combined with software

persons. So the main issue is how to recognize the captured based seismograph, and so forth. This is the reason we call it as

images or sounds and interpret them to be useful information for a generic robot.

users. We would like to emphasize that this concept is quite new and

We follow similar approach in developing our LIPI Wireless a breakthrough in robotic (hardware) technology that is actually

Robot (LWR), but with very different purposes [4]. We develop inspired by the habit of open-source communities. Because,

a wirelessly teleoperated robot for more serious tasks requiring most of robots are usually constructed for single particular task.

telepresence for the reason of safety. For example : retrieving According to the above concept, in order to realize high

data directly from nuclear reactors, observations in volcanoes degree of freedom for both users and developers, and to keep

and so on. The LWR is unique in the sense of its ability to full compatibilities in the future developments, let us list

acquire data in almost real-time basis, and to process the data at common characteristics should be fulfilled by LWR :

the robot's local system. Therefore the end-users just need to 1. All aspects are fully controllable wirelessly over web

connect their terminals to any network and then pointing the through TCP/IP protocol.

browser to the assigned address to display the analyzed results 2. Acquired data are stored and processed at the robot's local

as graphs etc. While at same time they can control, also over system independent from external apparatus.

web, the robot's movement, direction etc. 3. The processed data can be retrieved and analyzed by users

In this paper we focus on discussing our original concept on also over web such that no need for additional software

modular wireless robot, and followed with the main system of installation at the user's terminal.

LWR which is responsible for control and monitoring the whole 4. The hardware driven parts are replaced as much as possible

system. Detail discussion on the censors, real-time data with the software driven systems, even in the main unit.

processing, mechanical aspects and its integrated web interface Due to limited space, in the next section we are discussing

will be presented elsewhere. only the microcontroller based hardware to enable data

This paper is organized as follows : first of all we present our acquisition and remote mechanical control. Before going on let

concept, and followed by the design of control and monitoring us mention some benefits in deploying this approach :

Data Acquisition Module

Gain control

networkks Signal Processing :

AGC

- filtering

Microcontroller (Automatic Gain

- integrating, differentiating

Control)

- etc.

I/O port :

- parallel port input selector censors

Ethernet controller

- serial port

- SPI

wirelless router - I2C

- etc..

clients

embedded Actuator :

web-server Interface :

- Motor stepper, DC

- D/A converter

Microcontroller - buzzer Actual Output

- current driver

- voltage, current output

- etc..

- etc..

Feedback :

- censors

- camera

- etc..

Control System Module

Figure 2. The block diagrams for data acquisition and control.

this approach is lack of flexibility and freedom, especially for

those who need to realize special tasks that cannot be

accommodated by the standard libraries. Of course ones could

develop their own libraries to solve this problem. However this

requires more efforts that might be comparable to developing the

hardwares from the scratch. Also, there is a risk of high

Figure 1. The block diagram of three modules in LWR. dependency on certain products which could bind the users

forever. Therefore, we decide to utilize alternative connection

Easy access for end-users regardless the operating system port and develop the hardwares from the scratch to meet specific

used. There is also no need to install any additional software needs of LWR and also to reduce the overall cost as well. We

in terminal accessing the robot. have chosen the parallel and serial ports. Using those ports, there

Overall cost reduction, since most parts work on software- is no need to design nor purchase expensive I/O port. We just

based system. need to plug the devices we have developed into the ports and

High compatibility due to limited proprietary hardwares, and programme them to be anything matches our purposes.

then embedded software, used in the system. Moreover all Importantly, this can be used not only for control, but also for

software-based parts are developed using freely available data acquisition depending on the programme.

open-source softwares. In our case we use Debian Linux for In principle both devices can be integrated in a single

the operating system, Apache for the web-server and some microcontroller. However, to reduce the delays due to the

GNU Public License development languages. limitation of microcontroller, we divide them into two

Highly safe at any untouchable areas of human being, since independent devices. Another reason is for the sake of

the robot is remotely controllable. modularity as mentioned before. Because the censors embedded

in data acquisition module, while the control system is

3. The data acquisition and control modules integrated in main unit together with the embedded computer.

As mentioned in the preceding section, we are focused only We should emphasize that the control system also involves some

on the hardware aspects of data acquisition and control modules. monitoring tasks like feedbacks from the wheels to calculate the

Further discussion is based on the case of LWR as a prototype actual distance, etc. Therefore we use serial port which has

for the current approach. single incoming and outgoing data communication for the

Since there are two main tasks related to hardware in the control system, and parallel port which have multi channels for

system, that is control and data acquisition, we have deployed the data acquisition. Because one in general may attach multi

two microcontroller based devices. This can be seen in Fig. 2. censors for a comprehensive observation.

Both are connected to the PC-based device, either a regular or Now let us discuss the way to control the movement of LWR.

mini computer over serial and parallel ports. Before moving on, Instead of using the images captured by camera which would

we would like to comment on this choice. require complicated and resource wasting image processing, we

Usually, most people tend to use the I/O port by applying a combine together the compass censor and its wheels to

GPIB or data acquisition card due to its reliabilities and recognize the current position. The compass censor provides

modularities. This option provides great benefit for users in information of the actual angle against the North-South pole.

simplifying the whole hardwares and in saving the design time While calculating the rotation of the wheels we can obtain the

as well, since there is no need to design everything from the point-to-point distance. This mechanism is integrated on the web

scratch. Moreover one can further programme and interface it as virtual compass and the footprint of wheels from one point to

with the bundled softwares and its libraries for some popular another. Of course we also attach a small camera on the robot,

low level languages as LabView or Visual Basic. All of these but only for recognizing the actual visualization around the

would enable creating attractive interfaces on the screen and robot.

store the acquired data with much less effort. On the other hand,

Motor Digital

PWM

I2C /

Compass

Left Module

Motor Stepper

Driver Serial I/O uC

To main

controll I/O

Parallel

Censor 1

Port

port

Parallel I/O

Motor Stepper Censor 2

Multiplexer

Built-in

Programable

ADC

Driver

Analog

Serial I/O Gain

Amplifier

from main Motor Censor n

controll I/O uC Right

port

Parallel I/O

Figure 4. Data acquisition module.

Figure 3. Control module.

For the compass censor we have deployed the digital compass

The block diagram for control module is given in Fig.. 3 in module CMPS03. This module produces serial digital output

the simplest case of mechanical robot with regular wheels. This data that can be read by microcontroller either in PWM or I2C

module is responsible only to control the actuator. In this design modes [7]. In the sense of modularity, it might be better to split

we set the motor stepper as an actuator. As an illustration let us this part off the data acquisition module in real application.

concern only two motors as wheels. By using these motors we Because the compass censor should belong to the main unit to

are able to control the robot movement in four directions such as control the robot itself.

turning left and right, moving forward and backward. However The temperature and gases censor are processed by

the electricity current supplied by microcontroller is too small to microcontroller using internal ADC as argued previously. In this

accelerate the motor steppers directly. In order to overcome this design we use microcontroller Atmega8535 from Atmel. Due to

problem, we must use motor driver to amplify the current. One different level of each output of censors, the programmable gain

of the most popular chip suitable for this purpose is ULN2803. amplifier is used. The gain is controlled by microcontroller to

This IC has eight darlington array to amplify the current. By distinguish from which censor the data is taken. It is clear that

using only one parallel port in microcontroller such as simultaneous data retrieval from multiple censors is impossible.

PA,PB,PC or PD, we can control two motors steppers However, by adjusting the sequence of data retrieval from each

simultaneously [5,6]. The following code is used to send a censor, we may obtain data in an appropriate interval for each of

command to microcontroller to move the robot in a particular them. Although this is not a real-time process, concerning the

direction : actual required time interval, that is typically much longer

#include <xxx.h> //it depend on microcontroller used around a minute, we can say that the current system has already

void main() realized a “real-time” data acquisition.

{ We would like to stress that all microcontroller based-

//input port for capturing the command sent by parallel port hardwares above are utilized moreless only for converting the

//can be set depend on capabilities of each microcontroller analog data to be the digital ones. All data filtering are handled

while(1) //loop forever by software embedded in data processing, and then DAPS,

{ module. This point is important since there might be multiple

data=input(); //read command into variable data censors attached in DAPS which require different signal

switch(data) processings. Again, data processing module carries out not only

{ the task of filtering the incoming signals, but also analyzing the

case ‘1’ : turn left; whole data to be understandable results for users as graphs,

case ‘2’ : turn right; tables etc.

case ‘3’ : moving forward;

case ‘4’ : moving backward; 4. Summary

}} We have developed the LIPI Wireless Robot as a typical

} prototype for newly introduced concept of modular wireless

In contrast, the data acquisition module is used to retrieve robot. The robot has unique characteristics adjustable for various

some physical parameters from attached multiple censors for purposes. We argue that LWR is quite efficient and has good

temperature, gases and so forth. As discussed previously, there is total cost-performance due to its modularity and dominant

also another censor related to the control system, that is the software based solutions. The system has complicated aspects

digital compass to acquire the current angle against North-South require further developments, and will be presented elsewhere

pole. Therefore, we have designed to divide the data acquisition like :

module into two parts as shown in Fig. 4. The first one involves Web-based real-time control for robot's movement using

some censors with digital outputs like compass censor. The compass censor and wheel rotation.

other is responsible for censors producing analog outputs such as Web-based software to analyze the acquired data from

temperature and gases censors. particular DAPS packages in real-time basis.

A new or modified algorithms for software-based control on

robot's mechanics.

In the future we also plan to develop another main unit and its

robot. Especially to improve mechanical aspects of LWR to

enable more advanced and smooth movements. Rather than

hardware-based approach, this will be done by utilizing

integrated and software-based algorithms.

Lastly, we would like to announce that the architecture and all

related softwares of LWR will be open for public under GNU

Public License once we consider the system is ready for further

development by open-source communities around the world.

Acknowledgment

This work is partially supported by the Riset Kompetitif LIPI

in fiscal year 2007 under Contract no. 11.04/SK/KPPI/II/2007.

References

[1] A. Ferworn, R. Roque, and I. Vecchia, "MAX: Teleoperated

Dog on the World Wide Web", Proc. of the 2nd International

Workshop on Presence, Colchester, UK, 1999.

[2] A. Ferworn, R. Roque, and I. Vecchia, "MAX: Wireless

Teleoperation via the World Wide Web", Proc. of the 1999

IEEE Canadian Conference on Electrical and Computer

Engineering, Edmonton, Alberta, Canada, 1999.

[3] WAX's webpage, http://ncart.scs.ryerson.ca/wax.

[4] LIPI Wireless Robot, http://robot.teori.fisika.lipi.go.id.

[5] Thomas Braunl, “Embedded Robotic, Mobile Robot Design

and Applications with Embedded System”, Springer, 2003.

[6] Gordon McComb, Myke Predko, “Robot’s Builder

Bonanza”, McGraw-Hill, 2006

[7] Jan Axelson, “The Microcontroller Idea Book”, Lakeview

Research, 1997.

Das könnte Ihnen auch gefallen

- Basic Commands For Powershell: Configuring Windows PowerShell and Working With Basic CommandsDokument14 SeitenBasic Commands For Powershell: Configuring Windows PowerShell and Working With Basic CommandsDr. Hitesh Mohapatra100% (2)

- Search EnginesDokument15 SeitenSearch EnginesRam Sagar MouryaNoch keine Bewertungen

- Classification of ComputersDokument2 SeitenClassification of Computerseduardo acuniaNoch keine Bewertungen

- VinayKumarV MRaghavaCharyulu 129 PDFDokument7 SeitenVinayKumarV MRaghavaCharyulu 129 PDFUpendra VaddeNoch keine Bewertungen

- Scada in Power Distribution SystemsDokument10 SeitenScada in Power Distribution SystemsMike AjayiNoch keine Bewertungen

- Ec1009 Digital Image ProcessingDokument37 SeitenEc1009 Digital Image Processinganon-694871100% (15)

- MCC Bus Bar Sizing CalculationDokument12 SeitenMCC Bus Bar Sizing Calculationerkamlakar223483% (6)

- Philippine ArenaDokument7 SeitenPhilippine ArenaPeachieAndersonNoch keine Bewertungen

- Mautic DocumentationDokument33 SeitenMautic DocumentationDVMSNoch keine Bewertungen

- LTE Self-Organising Networks (SON): Network Management Automation for Operational EfficiencyVon EverandLTE Self-Organising Networks (SON): Network Management Automation for Operational EfficiencySeppo HämäläinenNoch keine Bewertungen

- Nagios Based Enhanced IT Management System: Ahmed D. KORADokument9 SeitenNagios Based Enhanced IT Management System: Ahmed D. KORAkhadirNoch keine Bewertungen

- Case Study Autoclave AutomationDokument8 SeitenCase Study Autoclave AutomationÖZER YILDIRIMNoch keine Bewertungen

- IOT-Intelligent Optimization ToolDokument7 SeitenIOT-Intelligent Optimization ToolEng Amr ElorbanyNoch keine Bewertungen

- FMGaDokument7 SeitenFMGaWilson Roberto Sanchez SolanoNoch keine Bewertungen

- Yokogawa Centum CS3000Dokument43 SeitenYokogawa Centum CS3000Hammad AshrafNoch keine Bewertungen

- Design of Multi-Detrct Surface Algorithm For Home Vacuum Aplication - Mohamad Sahran B. Kamilan - TJ223.P76.M77 2008Dokument27 SeitenDesign of Multi-Detrct Surface Algorithm For Home Vacuum Aplication - Mohamad Sahran B. Kamilan - TJ223.P76.M77 2008Nasir JamshedNoch keine Bewertungen

- MSD - Ha - Case StudyDokument8 SeitenMSD - Ha - Case StudyNIRAJ BHOINoch keine Bewertungen

- 1.3 - Intro System ControlDokument35 Seiten1.3 - Intro System ControlmartinqNoch keine Bewertungen

- Robotics and AutomationDokument130 SeitenRobotics and AutomationtycsdepartmentNoch keine Bewertungen

- PLC m5Dokument14 SeitenPLC m5Goutham KNoch keine Bewertungen

- Research On Web Server Application On Multi-Core Embedded SystemDokument5 SeitenResearch On Web Server Application On Multi-Core Embedded SystemRelaxed EntertainmentNoch keine Bewertungen

- Automated Material Handling System Based On The PLC: Fares Mohmmed Mehdi Hassan, Asaad Musaab Ali YousifDokument5 SeitenAutomated Material Handling System Based On The PLC: Fares Mohmmed Mehdi Hassan, Asaad Musaab Ali YousifAsaad MusaabNoch keine Bewertungen

- CENTUM-History: Enhancing Dcs FunctionsDokument2 SeitenCENTUM-History: Enhancing Dcs Functionssaeedkhalili94Noch keine Bewertungen

- Introducing An Unsupervised Automated Solution For Root Cause Diagnosis in Mobile NetworksDokument16 SeitenIntroducing An Unsupervised Automated Solution For Root Cause Diagnosis in Mobile Networksmary isaakNoch keine Bewertungen

- Evaluacion InstrumentacionDokument5 SeitenEvaluacion InstrumentacionCamila SarabiaNoch keine Bewertungen

- Radisys M-CORD: The Open Platform For Emerging 5G ApplicationsDokument10 SeitenRadisys M-CORD: The Open Platform For Emerging 5G ApplicationsPNG networksNoch keine Bewertungen

- Scheme To Secure Communication of SCADA Master Station and Remote HMI's Through Smart PhonesDokument10 SeitenScheme To Secure Communication of SCADA Master Station and Remote HMI's Through Smart PhonesAdi FangNoch keine Bewertungen

- Design of A SCADA Graphical User Interface For An Industrial ProcessDokument5 SeitenDesign of A SCADA Graphical User Interface For An Industrial ProcessvighneshNoch keine Bewertungen

- Presentation 2Dokument23 SeitenPresentation 2Suda KrishnarjunaraoNoch keine Bewertungen

- MT6603 DMS Unt 3 PDFDokument39 SeitenMT6603 DMS Unt 3 PDFKarthi KeyanNoch keine Bewertungen

- Design On Security Alarming System of Vehicle Terminal EquipmentDokument4 SeitenDesign On Security Alarming System of Vehicle Terminal EquipmentLets TalkNoch keine Bewertungen

- Development of Web-Based SCADA Like Application Using Arduino PlatformDokument5 SeitenDevelopment of Web-Based SCADA Like Application Using Arduino PlatformluckyamruNoch keine Bewertungen

- A Methodology To Design and Prototype Optimized Embedded RobDokument6 SeitenA Methodology To Design and Prototype Optimized Embedded RobHelder Anibal HerminiNoch keine Bewertungen

- HPSR MounaBenMabroukDokument6 SeitenHPSR MounaBenMabroukMouna Ben MabroukNoch keine Bewertungen

- Metro Train Prototype: A Summer Training Report OnDokument34 SeitenMetro Train Prototype: A Summer Training Report OnPooja SharmaNoch keine Bewertungen

- An ATM Switch Control Interface For Quality of Service and ReliabilityDokument12 SeitenAn ATM Switch Control Interface For Quality of Service and ReliabilityWai Phyo AungNoch keine Bewertungen

- ONU Monitoring and Management Employing An In-Band Ethernet Communication in FTTH/X SystemDokument4 SeitenONU Monitoring and Management Employing An In-Band Ethernet Communication in FTTH/X SystemKrishna GNoch keine Bewertungen

- Building Management System: SpecificationsDokument24 SeitenBuilding Management System: SpecificationsDo KhoaNoch keine Bewertungen

- SCADA PaperDokument15 SeitenSCADA Paperprashantbgpatel1Noch keine Bewertungen

- Fuel Management SystemDokument7 SeitenFuel Management SystemShweta KompaNoch keine Bewertungen

- New Microsoft Word DocumentDokument10 SeitenNew Microsoft Word DocumentTejas KadamNoch keine Bewertungen

- E T C S: Lectric Raction Ontrol YstemDokument6 SeitenE T C S: Lectric Raction Ontrol Ystemanon_842648641Noch keine Bewertungen

- A Flexible Real-Time Motor Control System For Robot JointsDokument4 SeitenA Flexible Real-Time Motor Control System For Robot JointsmalleswarararaoNoch keine Bewertungen

- Rtos Based Industrial Wireless Sensor Network ImplementationDokument5 SeitenRtos Based Industrial Wireless Sensor Network ImplementationDolice TakeuNoch keine Bewertungen

- Networking Programmable Logic Controllers: Pneumatic Cylinder Modelling and ControlDokument12 SeitenNetworking Programmable Logic Controllers: Pneumatic Cylinder Modelling and Controlquangvu16Noch keine Bewertungen

- Wireless Cameras Network For IntelligentDokument15 SeitenWireless Cameras Network For IntelligentYellaturi Siva Kishore ReddyNoch keine Bewertungen

- Application of PLC For Elevator Control System: Saurabh Sharma T.Y.Ladakhi A.P.Tiwary Dr. B.B.Pradhan R.PhiponDokument4 SeitenApplication of PLC For Elevator Control System: Saurabh Sharma T.Y.Ladakhi A.P.Tiwary Dr. B.B.Pradhan R.PhiponMohammed SelmanNoch keine Bewertungen

- Supervisory Control and Data Acquisition FOR Automatic Sub-Station ControlDokument9 SeitenSupervisory Control and Data Acquisition FOR Automatic Sub-Station ControlARVINDNoch keine Bewertungen

- Wireless Industrial Automation System Using PythonDokument5 SeitenWireless Industrial Automation System Using PythonRoyce DsouzaNoch keine Bewertungen

- Study On Monitoring and Control System For Rotor Online Dynamic Balancing Based On DSP&FPGADokument4 SeitenStudy On Monitoring and Control System For Rotor Online Dynamic Balancing Based On DSP&FPGAharithNoch keine Bewertungen

- (IJCT-V3I4P8) Authors: Mrs. Sangeetha Lakshmi .G, Ms. Arun Kumari .GDokument9 Seiten(IJCT-V3I4P8) Authors: Mrs. Sangeetha Lakshmi .G, Ms. Arun Kumari .GIjctJournalsNoch keine Bewertungen

- Application of Industrial PLC For Controlling Intelligent Traffic LightsDokument4 SeitenApplication of Industrial PLC For Controlling Intelligent Traffic LightsAFAFNoch keine Bewertungen

- Scada PaperDokument6 SeitenScada PaperhafizgNoch keine Bewertungen

- 1.1. Introduction To Embedded SystemsDokument45 Seiten1.1. Introduction To Embedded SystemsKotagiri AravindNoch keine Bewertungen

- The Last Few Years Have Seen The Emergence of Numerous New WirelessDokument20 SeitenThe Last Few Years Have Seen The Emergence of Numerous New WirelessvaseemalikhanNoch keine Bewertungen

- The Role of PLC and Microcontroller in Manufacturing IndustryDokument6 SeitenThe Role of PLC and Microcontroller in Manufacturing IndustryVania Alodia NNoch keine Bewertungen

- Design and Fabrication of Control Sytems On Production LineDokument4 SeitenDesign and Fabrication of Control Sytems On Production LinegithinjipeterNoch keine Bewertungen

- Monitoring Services For Networks-on-Chips: George Kornaros, Ioannis Papaeystathiou, and Dionysios PnevmatikatosDokument32 SeitenMonitoring Services For Networks-on-Chips: George Kornaros, Ioannis Papaeystathiou, and Dionysios Pnevmatikatosslinc_a82Noch keine Bewertungen

- A Parking Management System Based On Wireless Sensor NetworkDokument10 SeitenA Parking Management System Based On Wireless Sensor NetworkKlarizze GanNoch keine Bewertungen

- Coordinated Targeting of Mobile Sensor Networks For Ensemble Forecast ImprovementDokument5 SeitenCoordinated Targeting of Mobile Sensor Networks For Ensemble Forecast Improvementsmv_veeraNoch keine Bewertungen

- A1-Design of Intelligent Ambulance and Traffic Control Using 8051Dokument54 SeitenA1-Design of Intelligent Ambulance and Traffic Control Using 8051LakshmiNoch keine Bewertungen

- Iot MFG Cbm1Dokument9 SeitenIot MFG Cbm1shobhaNoch keine Bewertungen

- IPANema PDFDokument16 SeitenIPANema PDFE. 17Noch keine Bewertungen

- Substation Load ShareDokument6 SeitenSubstation Load ShareRaghul Ramasamy100% (1)

- The BrightCore ManifestoDokument2 SeitenThe BrightCore ManifestoDrazen BosakNoch keine Bewertungen

- Iot Based Automatic College Gong: S.Arockia Ranjith Kumar, R.Glarwin, M.Gowthamaraj, M.K.Vijayanainar, G.ShunmugalakshmiDokument3 SeitenIot Based Automatic College Gong: S.Arockia Ranjith Kumar, R.Glarwin, M.Gowthamaraj, M.K.Vijayanainar, G.ShunmugalakshmiMohseen SNoch keine Bewertungen

- Hadamard TransformDokument5 SeitenHadamard TransformPhaniendra KundetiNoch keine Bewertungen

- HSI and HSO Units of 80196Dokument6 SeitenHSI and HSO Units of 80196Phaniendra KundetiNoch keine Bewertungen

- RajkamalDokument147 SeitenRajkamalshyamfunnyNoch keine Bewertungen

- Application of SpintronicsDokument12 SeitenApplication of Spintronicsapi-3845765100% (3)

- Physics and Applications of SpintronicsDokument16 SeitenPhysics and Applications of SpintronicsPhaniendra KundetiNoch keine Bewertungen

- Ideal Diode Circuit Analysis StepsDokument4 SeitenIdeal Diode Circuit Analysis StepsPhaniendra KundetiNoch keine Bewertungen

- Vol. XXiv No. 46Dokument64 SeitenVol. XXiv No. 46CohenNoch keine Bewertungen

- Design A Slab For A Room of Size 5mX4m Which Carries A Live Load of 4 KN/m2. Use M20 Concrete QND Fe 415steel For The Design. Take Bearing 300mmDokument3 SeitenDesign A Slab For A Room of Size 5mX4m Which Carries A Live Load of 4 KN/m2. Use M20 Concrete QND Fe 415steel For The Design. Take Bearing 300mmK N RASHMI 2127960Noch keine Bewertungen

- Floor PlansDokument26 SeitenFloor PlansXiaobinn Y OcaNoch keine Bewertungen

- Design of A Ground Level Storage TankDokument8 SeitenDesign of A Ground Level Storage TankcamagnacNoch keine Bewertungen

- CellCommNets SON-LTE WS13 Part1Dokument33 SeitenCellCommNets SON-LTE WS13 Part1Apitan KongcharoenNoch keine Bewertungen

- PacketShaper Release Notes v921Dokument30 SeitenPacketShaper Release Notes v921Noah HeaserNoch keine Bewertungen

- How To Become An HLA Guru in Ashort TimeDokument39 SeitenHow To Become An HLA Guru in Ashort Timeephrem32Noch keine Bewertungen

- Onondaga County Lakeview Amphitheater Conceptual Design Report June 2014Dokument723 SeitenOnondaga County Lakeview Amphitheater Conceptual Design Report June 2014Michelle BreidenbachNoch keine Bewertungen

- Transcede t3k Product BriefDokument2 SeitenTranscede t3k Product Brieftrigunait6288100% (1)

- Macsteel Tube Pipe Catalogue PDFDokument32 SeitenMacsteel Tube Pipe Catalogue PDFgeraldNoch keine Bewertungen

- ST 18Dokument2 SeitenST 18KawadasanNoch keine Bewertungen

- Classical Architecture Originated in Ancient Greece and RomeDokument3 SeitenClassical Architecture Originated in Ancient Greece and RomeKhyla GironNoch keine Bewertungen

- User Manual GH 200 v2.2 ERPDokument112 SeitenUser Manual GH 200 v2.2 ERPMihail Andrei CismaruNoch keine Bewertungen

- CIVIL B Tech Projects - IIT KanpurDokument2 SeitenCIVIL B Tech Projects - IIT Kanpurjayaram miryalaNoch keine Bewertungen

- Ds Esprimo p5730Dokument5 SeitenDs Esprimo p5730Andre GasoNoch keine Bewertungen

- Classiied: Your Local MarketplaceDokument5 SeitenClassiied: Your Local MarketplaceDigital MediaNoch keine Bewertungen

- Principles of LED - The Mesopic Vision - John Rooymans, CroDokument35 SeitenPrinciples of LED - The Mesopic Vision - John Rooymans, Cromark78goNoch keine Bewertungen

- Pre-Chamber RegulatorDokument3 SeitenPre-Chamber RegulatorfahadullahNoch keine Bewertungen

- Naveed Ur Rahman: Curriculum VitaeDokument2 SeitenNaveed Ur Rahman: Curriculum VitaeNaveed ur RahmanNoch keine Bewertungen

- CP PPT 3 (600 Colline Street)Dokument12 SeitenCP PPT 3 (600 Colline Street)Hp King GoodNoch keine Bewertungen

- Memory Management With BitmapsDokument37 SeitenMemory Management With Bitmapssuneerav17Noch keine Bewertungen

- Readme Idrisi SelvaDokument5 SeitenReadme Idrisi SelvaDiego CuencaNoch keine Bewertungen

- Frequently Asked Questions and IT Survival Guide!: Version 2.2 - July 2012Dokument40 SeitenFrequently Asked Questions and IT Survival Guide!: Version 2.2 - July 2012Nikhilesh ShegokarNoch keine Bewertungen

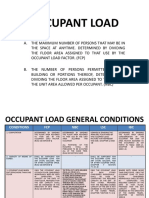

- 02 - Occupant Load General ConditionsDokument5 Seiten02 - Occupant Load General ConditionsLean Liganor100% (1)