Beruflich Dokumente

Kultur Dokumente

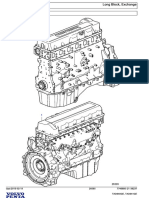

Workshop Manual: Group 20 Technical Data I

Hochgeladen von

Sebastian Jerez UrquietaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Workshop Manual: Group 20 Technical Data I

Hochgeladen von

Sebastian Jerez UrquietaCopyright:

Verfügbare Formate

Workshop Manual I

Group 20 Technical Data 1(0)

TAD940GE, TAD941GE

TAD940VE, TAD941VE, TAD942VE, TAD943VE

TAD950VE, TAD951VE, TAD952VE

Downloaded from www.Manualslib.com manuals search engine

Downloaded from www.Manualslib.com manuals search engine

Technical data

Industrial Engines

TAD940GE, TAD941GE

TAD940VE, TAD941VE, TAD942VE, TAD943VE

TAD950VE, TAD951VE, TAD952VE

Contents

Safety information ................................................ 2

General information ............................................. 5

Technical data ...................................................... 6

General ............................................................... 6

Engine ................................................................ 8

Valve mechanism ............................................... 10

Timing gear ......................................................... 14

Reciprocating components .................................. 16

Lubrication and oil systems................................. 19

Fuel system ........................................................ 22

Inlet and exhaust system .................................... 23

Cooling system ................................................... 24

Engine control system ........................................ 25

Tightening torque ................................................ 27

References to Service Bulletins .......................... 36

Downloaded from www.Manualslib.com manuals search engine

Group 20

Safety information

This workshop manual contains technical data, de- Read the available safety information, General in-

scriptions and repair instructions for the Volvo Penta formation and Repair instructions in the work-

products or product versions noted in the table of con- shop manual before you start to do any service

tents. Make sure that you use the correct workshop work.

literature.

Important

The following special warning signs are used in the Check that the warning or information labels on

workshop manual and on the product. the product are always clearly visible. Replace

labels which have been damaged or painted

WARNING! Warns for the risk of personal injury, over.

major damage to product or property, or serious

malfunctions if the instruction is ignored.

IMPORTANT! Is used to call attention to things Never start the engine without installing the air

which could cause damage or malfunctions to cleaner (ACL) filter. The rotating compressor tur-

product or property. bine in the turbocharger can cause severe inju-

ry. Foreign objects entering the intake ducts can

NOTE! Is used to call attention to important informa- also cause mechanical damage.

tion, to facilitate work processes or operation.

To give you a perspective on the risks which always

need to be observed and precautions which always

Never use start spray or similar products as a

have to be taken, we have noted them below.

starting aid. They may cause an explosion in

the inlet manifold. Danger of personal injury.

Make it impossible to start the engine by cutting

system current with the main switch(es) and

lock it (them) in the off position before starting

service work. Fix a warning sign by the control Only start the engine in a well- ventilated area.

station. When operated in a confined space, exhaust

fumes and crankcase gases must be ventilated

from the engine bay or workshop area.

All service work should normally be done on a

stationary engine. Some work, such as adjust-

ments, need the engine to be running, however. Avoid opening the coolant filling cap when the

Going close to a running engine is a safety risk. engine is hot. Steam or hot coolant can spray

Remember that loose clothes, long hair etc. can out and the system pressure will be lost. When

catch on rotating components and cause severe needed, open the filler cap slowly and release

injury. the pressure in the system. Be extremely care-

If work is done adjacent to a running engine, a ful if a tap, plug or coolant hose has to be re-

careless movement or a dropped tool can lead moved from a hot engine. It is difficult to antici-

to personal injury in the worst case. Take care pate in which direction steam or hot coolant can

to avoid contact with hot surfaces (exhaust spray out.

pipes, turbocharger, charge air pipe, starter

heater etc.) and hot fluids in pipes and hoses in

an engine which is running or has just been

stopped. Reinstall all protective parts removed Hot oil can cause burns. Avoid skin contact with

during service operations before starting the en- hot oil. Ensure that the lubrication system is not

gine. under pressure before carrying out any work.

Never start or operate the engine with the oil fill-

er cap removed, otherwise oil could be ejected.

Downloaded from www.Manualslib.com manuals search engine

Group 20 General instructions

Stop the engine before carrying out operations All fuels, and many chemicals, are flammable.

on the engine cooling system. Do not allow naked flame or sparks in the vicini-

ty. Certain thinners and hydrogen from batteries

can be extremely flammable and explosive

when mixed with air in the right proportions. No

Always use protective glasses or goggles when Smoking! Ensure that the work area is well ven-

carrying out work where there is a risk of splin- tilated and take the necessary safety precau-

ters, grinding sparks, acid splashes or where tions before starting welding or grinding work. Al-

other chemicals are used. Your eyes are ex- ways ensure that there are fire extinguishers at

tremely sensitive, injury could cause blindness! hand when work is being carried out.

Avoid getting oil on your skin! Repeated expo- Make sure that oil and fuel soaked rags, and

sure to oil or exposure over a long period can re- used fuel and oil filters are stored in a safe

sult in the skin becoming dry. Irritation, dryness place. Rags soaked in oil can spontaneously ig-

and eczema and other skin problems can then nite under certain circumstances. Used fuel and

occur. Used oil is more dangerous than fresh oil oil filters are polluting waste and must be hand-

from a health aspect. Use protective gloves and ed to an approved waste management facility

avoid oil soaked clothes and shop rags. Wash for destruction, together with used lubrication oil,

regularly, especially before eating. There are contaminated fuel, paint residue, solvents, de-

special skin creams which counteract drying out greasers and wash residue.

of the skin and make it easier to clean off dirt

after work is completed.

Batteries must never be exposed to open

flames or electric sparks. Do not smoke close

Most chemicals intended for the product (e.g. to the batteries. The batteries generate hydro-

engine and transmission oils, glycol, petrol (gas- gen gas when charged, which forms an explo-

oline) and diesel oil) or chemicals for workshop sive gas when mixed with air. This gas is easily

use (e.g. degreasers, paints and solvents) are ignited and highly volatile. A spark, which can

hazardous. Read the instructions on the product be formed if the batteries are wrongly connect-

packaging with care! Always follow the safety ed, is enough to make a battery explode and

precautions for the product (for example use of cause damage. Do not shift the connections

protective mask, glasses, gloves etc.). Make when attempting to start the engine (spark risk)

sure that other personnel are not exposed to and do not lean over any of the batteries.

hazardous chemicals, for example in the air. En-

sure good ventilation in the work place. Follow

the instructions provided when disposing of

used or leftover chemicals. Never mix up the battery positive and negative

poles when the batteries are installed. Incorrect

installation can result in serious damage to the

electrical equipment. Refer to the wiring dia-

Exercise extreme care when leak detecting on gram.

the fuel system and testing the fuel injector noz-

zles. Use eye protection. The jet from a fuel in-

jector is under very high pressure, and has con-

siderable penetration ability; fuel can force its Always use protective goggles when charging

way deep into body tissues and cause serious and handling the batteries. Battery electrolyte

damage. Danger of blood poisoning (septice- contains sulfuric acid, which is highly corrosive.

mia). Should the battery electrolyte come into contact

with unprotected skin wash off immediately us-

ing plenty of water and soap. If you get battery

acid in your eyes, flush it off at once with a gen-

WARNING! The delivery pipes must under no erous amount of water, and get medical assis-

circumstances be bent. Damaged pipes must be tance at once.

replaced.

Downloaded from www.Manualslib.com manuals search engine

General instructions Group 20

Turn the engine off and turn off the power at the WARNING! Components in the electrical and

main switch(es) before carrying out work on the fuel systems on Volvo Penta products have

electrical system. been designed to minimize the risks of explo-

sion and fire. The engine must not be operated

in environments with adjacent explosive media.

The clutch must be adjusted with the engine

shut off.

Only use the fuels recommended by Volvo Pen-

ta. Refer to the Instruction Book. Use of fuels

that are of a lower quality can damage the en-

The existing lugs on the engine should be used gine. In a diesel engine, poor fuel can cause the

for lifting. Always check that the lifting devises control rod to bind and the engine will over- rev,

are in good condition and that they have the cor- entailing a strong risk of personal injury and ma-

rect capacity for the lift (the weight of the engine chinery damage. Poor fuel can also lead to

plus the reversing gear and extra equipment). higher maintenance costs.

The engine should be lifted with a customized or

adjustable lifting boom for safe handling and to

avoid damaging components on top of the en-

gine. All chains or cables must be parallel to Remember the following when washing with a

each other and should be as square as possible high pressure washer: Never aim the water jet at

to the top of the engine. air filters, seals, rubber hoses or electrical com-

If other equipment connected to the engine has ponents. Never use a high pressure washer for

altered its center of gravity, special lifting devis- engine cleaning.

es may be needed to obtain the correct balance

and safe handling.

Never do any work on an engine which just

hangs from a liftingdevise. The injectors can leak fuel when the engine is

stationary, if the tank is higher than the engine

and the fuel pressure is positive.

Never work alone when heavy components are

to be dismantled, even when safe lifting devises

such as lockable blocks & tackle are used.

When using a lifting devise, two people are usu-

ally required to do the work, one to take care of

the lifting device and another to ensure that

components are lifted clear and not damaged

during the lifting operations.

Always make sure that there is enough space

for disassembly where you are working, with no

risk for personal or material damage.

Downloaded from www.Manualslib.com manuals search engine

Group 20

General information

About the workshop manual Certified engines

This workshop manual contains technical data for the The manufacturer certifies that both new engines and

TAD940GE, TAD941GE, TAD940VE, TAD941VE, those in use, which are certified for national or region-

TAD942VE, TAD943VE, TAD950VE, TAD951VE and al legislation, comply with the environmental require-

TAD952VE engines. ments. Each product must correspond with the unit

The Workshop Manual, Technical Data, contains all used for certification. The following requirements for

the references from the workshop manuals to repair service and spare parts must be complied with, for

instructions for the TAD940GE, TAD941GE, Volvo Penta as a manufacturer to be responsible for

TAD940VE, TAD941VE, TAD942VE, TAD943VE, ensuring that engines in use comply with the stipulat-

TAD950VE, TAD951VE and TAD952VE series. ed environmental requirements:

The Workshop Manual is produced primarily for the

use of Volvo Penta workshops and service techni- Maintenance and service intervals recommended

cians. For this reason the manual presupposes a cer- by Volvo Penta must be complied with.

tain basic knowledge and that the user can carry out Only Volvo Penta Original Spare Parts intended

the mechanical/electrical work described to a general for the certified engine version may be used

standard of engineering competence.

Service related to injection pumps and injectors

Volvo Penta constantly improves its products, so we must always be done by an authorized Volvo Pen-

reserve the right to make modifications without prior ta workshop.

notification. All information in this manual is based on

product data which was available up to the date on The engine must not be converted or modified in

which the manual was printed. Any material changes any way, except for the accessories and service

introduced into the product or service methods after kits which Volvo Penta has approved for the en-

this date are notified by means of Service Bulletins. gine.

Installation changes to the exhaust pipe and the

engine bay air inlet ducts (ventilation ducts) must

not be done without further discussion, since this

could affect exhaust emissions.

Spare parts No seals may be broken by unauthorized person-

nel.

Spare parts for electrical and fuel systems are subject

to various national safety requirements. Volvo Penta The general advice in the instruction book about oper-

Original Spares comply with these requirements. No ation, care and maintenance applies.

damage whatever, occasioned by use of non-original IMPORTANT! When spare parts are needed,

Volvo Penta spares for the product, will be compen- use only Volvo Penta Original Spares.

sated by the warranty offered by Volvo Penta.

Use of non-original spareparts means that AB

Volvo Penta can no longer be responsible for

guaranteeing that the engine complies with the

certified version.

Any damage, injury and/or costs which arise due

to the use of non-original Volvo Penta spares for

the product in question will not be compensated

by Volvo Penta.

Downloaded from www.Manualslib.com manuals search engine

Group 20

Technical data

General

Type designation TAD940GE TAD941GE

Power, Prime/Stand-by See Sales Guide Generating Set Engines

Torque, Prime/Stand-by See Sales Guide Generating Set Engines

Compression ratio 20,2:1 17,4:1

Low idle (rpm) 600-1200 600-1200

High idle (rpm) 1500-1620/1800-1920 1500-1620/1800-1920

No. of valves 24 24

No. of cylinders 6 6

Cylinder bore (mm) 120 120

Stroke (mm) 138 138

3

Swept volume (dm ) 9.36 9.36

Weight, dry (kg) 1015 1015

Weight, wet (kg) 1065 1065

Injection sequence 1-5-3-6-2-4 1-5-3-6-2-4

Type designation TAD940VE TAD941VE TAD942VE TAD943VE

Power See Sales Guide Industrial Diesel Power

Torque See Sales Guide Industrial Diesel Power

Compression ratio 20.2:1 20.2:1 20.2:1 20.2:1

Low idle (rpm) 600 600 600 600

High idle (rpm) 2250 2250 2250 2250

No. of valves 24 24 24 24

No. of cylinders 6 6 6 6

Cylinder bore (mm) 120 120 120 120

Stroke (mm) 138 138 138 138

Swept volume (dm3) 9.36 9.36 9.36 9.36

Weight, dry (kg) 1015 1015 1015 1015

Weight, wet (kg) 1065 1065 1065 1065

Injection sequence 1-5-3-6-2-4 1-5-3-6-2-4 1-5-3-6-2-4 1-5-3-6-2-4

(1 mm = 0.03937 inch)

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Type designation TAD950VE TAD951VE TAD952VE

Power Please refer to the sales literature

Torque Please refer to the sales literature

Compression ratio 20.2:1 20.2:1 20.2:1

Low idle (rpm) 600 600 600

High idle (rpm) 2250 2250 2250

No. of valves 24 24 24

No. of cylinders 6 6 6

Cylinder bore, mm (inch) 120 (4.72) 120 (4.72) 120 (4.72)

Stroke, mm (inch) 138 (5.43) 138 (5.43) 138 (5.43)

Swept volume, dm3 (US quart) 9.36 (9.89) 9.36 (9.89) 9.36 (9.89)

Weight, dry, kg (lb) 1015 (2238) 1015 (2238) 1015 (2238)

Weight, wet, kg (lb) 1065 (2348) 1065 (2348) 1065 (2348)

Injection sequence 1-5-3-6-2-4 1-5-3-6-2-4 1-5-3-6-2-4

Downloaded from www.Manualslib.com manuals search engine

Group 20

Engine

Engine block

Length .................................................................... 967 mm (38.07")

Height, upper block plane - crankcase centerline ... 379 mm (14.92")

Height lower block plane - crankcase centerline ..... 120 mm (4.72")

Crankcase pressure

normal value, irrespective of engine speed ............. max 0.5 kPa (0.07 psi)

Cylinder head

Type ...................................................................... 6-cylinder

Length .................................................................... 996 mm (39.21")

Width ..................................................................... 410 mm (16.14")

Height .................................................................... 135 mm (5.32")

Max. flatness error (base plane) ............................. 0.4 mm (0.0158")

Cylinder head screws

No. of screws ......................................................... 26

Dimension, thread .................................................. M16

Length .................................................................... 200 mm (7.874")

Cylinder liner

Type ...................................................................... Wet, replaceable

Height, total. .......................................................... 250 mm (9.8425")

Sealing surface height above block plane .............. 0.15 - 0.20 mm (0.0059 - 0.0079")

No. of seal rings per cylinder liner .......................... 3

Cylinder bore .......................................................... 120.00 - 120.02 mm (4,72 - 4,73)

Piston

Type ...................................................................... aluminium

Height above engine block plane ............................ 0.15 -0.65 mm (0.0059 - 0.0256")

Diameter, combustion chamber

TAD940GE, TAD940-943VE ............................... 77 mm (3.032")

TAD941GE ......................................................... 78,5 mm (3.090")

TAD950-52VE ..................................................... 77,1 mm (3.035")

Depth, piston bowl

TAD940GE, TAD940-943VE ............................... 15 mm (0.590")

TAD941GE ......................................................... 17,3 mm (0.681")

TAD950-952VE ................................................... 14,6 mm (0.575")

No. of ring grooves ................................................. 3

Front marking ......................................................... Arrow towards front

Gudgeon pin diameter ............................................ 54 mm (2.126")

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Piston rings

Compression rings

Specification:

Quantity ................................................................. 2

Piston ring clearance in groove

upper compression ring ....................................... 0.12 -0.19 mm (0.0047 - 0.0075")

lower compression ring ....................................... 0.09 -0.13 mm (0.0035 - 0.0051")

Piston ring gap, measured at ring opening:

upper compression ring ....................................... 0.35 -0.55 mm (0.013779 - 0.021653")

lower compression ring ....................................... 1.15 -1.3 mm (0.045275 - 0.051181")

Oil scraper ring:

Quantity ................................................................. 1

Width, including spring ........................................... 4.3 mm (0.011811")

Piston ring clearance in groove, ............................. 0.05 -0.10 mm (0.001968 - 0.003937")

Piston ring gap, measured at ring opening .............. 0.35 -0.75 mm (0.013779 - 0.029527")

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Valve mechanism

Valves

Valve head, diameter:

Inlet .................................................................... 38 mm (1.49606")

Exhaust

TAD940-941GE, TAD940-943VE ...................... 38 mm (1.49606")

TAD950-952VE ................................................. 36 mm (1.41732")

Valve stem, diameter:

Inlet .................................................................... 8 mm (0.31496")

Exhaust .............................................................. 8 mm (0.31496")

Valve seat angle (A):

Inlet .................................................................... 29.5

Exhaust .............................................................. 29.5

Seat angle in cylinder head (B):

Inlet .................................................................... 30

Exhaust .............................................................. 30

Dimension between valve head and cylinder head plane:

Inlet .................................................................... min 0.95 mm (0.037401")

Exhaust .............................................................. min 1.25 mm (0.049212")

NOTE! When the valve seats are changed, the valves must be changed at the same time.

Valve clearance, cold engine, setting value:

Inlet .................................................................... 0.2 mm (0.007874")

Exhaust

TAD940-941GE, TAD940-943VE ...................... 0.5 mm (0.019685")

TAD950-952VE ................................................. 0,8 mm (0.031496")

Valve clearance, cold engine, check value:

Inlet .................................................................... 0.15 -0.25 mm (0.005905 - 0.009842")

Exhaust

TAD940-941GE, TAD940-943VE ...................... 0.45 -0.55 mm (0.017716 - 0.021653")

TAD950-952VE ................................................. 0,75 - 0,85 mm (0.029527 - 0.033465")

TAD950-952VE

Clearance, double rocker arm

base circle on camshaft ...................................... using gauge tool

10

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Valve seats

Outer diameter (A)

Standard:

Inlet ....................................................................

TAD940-941GE, TAD940-943VE ...................... 40.0 mm (1.5748")

TAD950-952VE ................................................. 42,0 mm (1.6535")

Exhaust

TAD940-941GE, TAD940-943VE ...................... 41.0 mm (1.61417")

TAD950-952VE ................................................. 40,0 mm (1.5748")

Oversize dimension:

Inlet

TAD940-941GE, TAD940-943VE ...................... 40.3 mm (1.586611")

TAD950-952VE ................................................. 42,3 mm (1.665349")

Exhaust

TAD940-941GE, TAD940-943VE ...................... 41.3 mm (1.625981")

TAD950-952VE ................................................. 40,3 mm (1.586609")

Height (B):

Inlet

TAD940-941GE, TAD940-943VE ...................... 7.3 mm (0.287401")

TAD950-952VE ................................................. 7,4 mm (0.291338")

Exhaust

TAD940-941GE, TAD940-943VE ...................... 7.4 mm (0.291338")

TAD950-952VE ................................................. 6,4 mm (0.251968")

11

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Valve seat bed

Diameter (C) standard:

Inlet

TAD940-941GE, TAD940-943VE ...................... 40.0 mm (1.5748")

TAD950-952VE ................................................. 42,0 mm (1.6535")

Exhaust

TAD940-941GE, TAD940-943VE ...................... 41.0 mm (1.61417")

TAD950-952VE ................................................. 40,0 mm (1.5748")

Diameter (C) oversize dimension:

Inlet

TAD940-941GE, TAD940-943VE ...................... 40.2 mm (1.582674")

TAD950-952VE ................................................ 42,2 mm (1.661412")

Exhaust

TAD940-941GE, TAD940-943VE ...................... 41.2 mm (1.622044")

TAD950-952VE ................................................. 40,2 mm (1.582672")

Depth (D):

Inlet .................................................................... 11.5 mm (0.452755")

Exhaust .............................................................. 11.9 mm (0.468503")

Seat base radius (R):

Inlet .................................................................... max 0.8 mm (0.031496")

Exhaust .............................................................. max 0.8 mm (0.031496")

12

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Valve guides

Length:

Inlet .................................................................... 83.4 mm (3.283458")

Exhaust .............................................................. 83.4 mm (3.283458")

Inner diameter:

Inlet .................................................................... 8 mm (0.31496")

Exhaust .............................................................. 8 mm (0.31496")

Height above cylinder head spring plane:

Inlet .................................................................... 24.50.5 mm (0.964564 0.019685")

Exhaust .............................................................. 16.50.5 mm (0.6496043 0.019685")

Clearance, valve stem - guide:1

Inlet .................................................................... max 0.2 mm (0.007874")

Exhaust .............................................................. max 0.2 mm (0.007874")

1

The dimensions have been calculated for the method of measurement described in the workshop manual (group 21).

Rocker arms

Bearing clearance .................................................. max 0.08 mm

Valve springs

Inlet

Outer valve springs:

Unloaded length .................................................. 73.8 mm (2.905506")

With 590 N (132.6 lbf) loading ............................. 58.4 mm (2.299208")

With 1150 N (258.5 lbf) loading ........................... 45.3 mm

Coilbound length, max ......................................... 39.5 mm (1.555115")

Inner valve spring:

Unloaded length .................................................. 70.5 mm (2.775585")

With 243 N (54.6 lbf) loading ............................... 54.4 mm (2.141728")

With 447 N (100.4 lbf) loading ............................. 41.3 mm (1.625981")

Coilbound length, max ......................................... 36.5 mm (1.437005")

Exhaust

Outer valve springs:

Unloaded length .................................................. 73.8 mm (2.905506")

With 590 N (132.6 lbf) loading ............................. 58.4 mm (2.299208")

With 1150 N (258.5 lbf) loading ........................... 45.3 mm (1.783461")

Coilbound length, max ......................................... 39.5 mm (1.555115")

Inner valve spring:

Unloaded length .................................................. 70.5 mm (2.775585")

With 243 N (54.6 lbf) loading ............................... 54.4 mm (2.141728")

With 447 N (100.4 lbf) loading ............................. 41.3 mm (1.625981")

Coilbound length, max ......................................... 36.5 mm (1.437005")

13

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Timing gear

Timing gear wheels

No. of teeth:

1. Drive gear, crankshaft .......................................... 54

2. Idler wheel, double, outer ...................................... 72

Idler wheel, double, inner ...................................... 56

3. Idler wheel, adjustable .......................................... 73

4. Drive gear, camshaft ............................................ 84

5. Idler wheel, servo pump ........................................ 37

6. Drive wheel, steering servo and fuel feed pump .... 31

7. Drive wheel, air compressor ................................. 42

8. Drive wheel, lubricating oil pump .......................... 23

Gear backlash

min ..................................................................... 0.05 mm (0.001968")

max .................................................................... 0.17 mm (0.006692")

Shaft stub for idler wheel, diameter ........................ 100 mm (3.937")

Bushing for idler wheel, diameter ............................ 100 mm (3.937")

Radial clearance for idler wheel .............................. max 0.05 mm (0.001968")

14

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Camshaft

Check camshaft setting, cold engine and valve clearance =0.

Inlet valve for cylinder 1 at flywheel position 6 ATDC must be open 1.30.3 mm (0.051180.0118").

During the check, you must turn the timing gear in the correct direction (clockwise seen

from the front), to take up all gear flank clearance.

Drive ...................................................................... gear wheel

No of bearings ........................................................ 7

Diameter, bearing journals, standard ...................... 69.97 -70.00 mm (22.754718 - .7559")

NOTE! Only check values, not for machining.

Diameter, bearing journals, undersize dimension

0.25 .................................................................... 69.72 -69.78 mm (2.744876 - 2.747238")

0.50 .................................................................... 69.47 -69.53 mm (2.735033 - 2.737396")

0.75 .................................................................... 69.22 -69.28 mm (2.725191 - 2.727553")

Max. end float ........................................................ 0.24 mm (0.009448")

Max permissible ovality (with new bearings) ........... 0.05 mm (0.001968")

Bearing, max. permissible wear on diameter .......... 0.05 mm (0.001968")

Valve lift:

inlet ..................................................................... 13 mm (0.51181")

outlet (EPG) ........................................................ 12 mm (0.47244")

Permissible wear between base circle

and max. lift ....................................................... max 0.1 mm (0.003937")

Unit injector, stroke ................................................ 13 mm (0.51181")

Camshaft bearings

Camshaft bearing thickness, standard ................... 1.92 mm (0.075590")

Oversize dimension:

0.25 .................................................................... 2.04 mm (0.080314")

0.50 .................................................................... 2.17 mm (0.085432")

0.75 .................................................................... 2.29 mm (0.090157")

15

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Reciprocating components

Crankshaft

Length .................................................................... 1.066 mm (0.041968")

Crankshaft, end float1 .............................................0.100.40 mm (0.00390.0157")

Ovality of main and big end bearings ..................... max 0.01 mm (0.000393")

Taper of main and big end bearings ....................... max 0.02

Runout on center bearing ....................................... 0.15 mm (0.005905")

1

Dimensions refer to oiled components.

Main bearing journal

NOTE! Only check values, not for machining.

Diameter () standard ............................................ 108.0 mm (4.25196")

Undersize dimension:

0.25 mm ............................................................. 107.85 -107.87 mm (4.246054 - 4.246841")

0.50 mm ............................................................. 107.73 -107.75 mm (4.241330 - 4.242117")

0.75 mm ............................................................. 107.60 -107.62 mm (4.236212 - 4.236999")

1.00 mm ............................................................. 107.48 -107.50 mm (4.231487 - 4.232275")

1.25 mm ............................................................. 107.35 -107.37 mm (4.226369 - 4.227156")

Surface finish, main bearing journal ....................... Ra 0.25

Surface finish, radius ............................................. Ra 0.4

Width, main bearing journal (A) standard ................ 42 mm (1.65354")

Oversize dimension:

0.2 mm (thrust bearing 0.1) ................................. 42.17 -42.22 mm (1.660232 - 1.662201")

0.4 mm (thrust bearing 0.2) ................................. 42.37 -42.42 mm (1.668106 - 1.670075")

0.6 mm (thrust bearing 0.3) ................................. 42, 57-42.62 mm (1.65354 - 1.677949")

Fillet radius (R) ....................................................... 4.5 mm (0.177165")

16

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Thrust washers (thrust bearing)

Width (B) standard ................................................. 3.2 mm (0.125984")

Oversize dimension:

0.1 mm ............................................................... 3.2 -3.3 mm (0.125984 - 0.129921")

0.2 mm ............................................................... 3.3 -3.4 mm (0.129921 - 0.133858")

0.3 mm ............................................................... 3.4 -3.5 mm (0.133858 - 0.137795")

Main bearing shells

Outer diameter (C) ................................................. 113 mm (4.44881")

Thickness (D) standard .......................................... 2.5 mm (0.098425")

Oversize dimension:

0.25 mm ............................................................. 2.6 -2.7 mm (0.102362 - 0.106299")

0.50 mm ............................................................. 2.7 -2.8 mm (0.106299 - 0.110236")

0.75 mm ............................................................. 2.8 -2.9 mm (0.110236 - 0.114173")

1.00 mm ............................................................. 2.9 -3.0 mm (0.114173 - 0.11811")

1.25 mm ............................................................. 3.1-3.2 mm (0.122047 - 0.125984")

Radial clearance, main bearings ............................. max 0.11 mm (0.004330")

Big end bearing journal

NOTE! Only check values, not for machining.

Diameter () .......................................................... 88 mm (3.46456")

Undersize dimension:

0.25 mm ............................................................. 87.85 -87.87 mm (3.458654 - 3.459441")

0.50 mm ............................................................. 87.73 -87.75 mm (3.453930 - .3454717")

0.75 mm ............................................................. 87.60 -87.62 mm (3.448812 - 3449599")

1.00 mm ............................................................. 87.48 -87.50 mm (3.444087 - 3.444875")

1.25 mm ............................................................. 87.35 -87.37 mm (3.438969 - 3.439756")

Surface finish, big end bearing journal .................... Ra 0.25

Surface finish, radius ............................................. Ra 0.4

Width (A) ................................................................ 54 mm (2.12598")

Fillet radius (R) ....................................................... 4.5 mm (0.177165")

17

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Big end journal shells

Outer diameter (B) ................................................. 93 mm (3.66141")

Thickness (C) standard .......................................... 2.4 mm (0.094488")

Oversize dimension:

0.25 mm ............................................................. 2.5 -2.6 mm (0.098425 - 0.102362")

0.50 mm ............................................................. 2.6 -2.7 mm (0.102362 - 0.106299")

0.75 mm ............................................................. 2.7 -2.8 mm (0.106299 - 0.110236")

1.00 mm ............................................................. 2.8 -2.9 mm (0.110236 - 0.114173")

1.25 mm ............................................................. 3.0 -3.1 mm (0.11811 - 0.122047")

Diameter, bearing shell seat (D) ............................. 92.85 mm (3.655504")

Con rods

Length, center - center (E) ..................................... 225 mm (8.85825")

Small end bushing, internal diameter (G) ................ 54 mm (2.12598")

End float, con rod - crankshaft1: ............................. max 0.35 mm (0.013779")

Big end bearing, radial clearance 1: ....................... max 0.10 mm (0.003937")

Straightness, max. deviation on 100 mm (3.937")

measured length .................................................... 0.06 mm (0.002362")

Twist, max. deviation on 100 mm (3.937")

measured length .................................................... 0.15 mm (0.005905")

1

Dimensions refer to oiled components.

Marking:

FRONT on the con rod faces forwards.

The con rods and caps are marked in pairs, using a three digit serial number (please refer to the illustration).

Flywheel, installed

Runout (manual gearbox), measurement

radius 150 mm (5.9055") . ...................................... max 0.20 mm (0.007874")

No. of teeth on starter gear ring .............................. 153

Sensor grooves in flywheel .................................... 54 pcs.

Flywheel housing, installed

Runout for mating face against bellhousing. ........... max 0.1 mm (0.003937")

Radial runout for alignment against bellhousing. ..... max 0.05 mm (0.001968")

18

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Lubrication oil systems

TAD940-941GE, TAD940-943VE

Sulfur content in fuel, by weight

< 0.5 % 0.5 1.0 % > 1.0 %1)

Oil grade Oil change interval: Reached first in operation

VDS-3 600 hours / 12 month 300 hours / 12 month 150 hours / 12 month

VDS-2 and ACEA E7 2)

VDS-2 and ACEA E5 2)

VDS-2 and Global DHD-1 2)

VDS-2 and API CI-4 2)

VDS-2 and API CH-4 2)

VDS and ACEA E3 2) 400 hours / 12 month 200 hours / 12 month 100 hours / 12 month

ACEA: E7, E5, E4 200 hours / 12 month 100 hours / 12 month 50 hours / 12 month

API: CI-4, CH-4, CG-4

TAD950-952VE

Sulfur content in fuel, by weight

< 0.3 % 0.3 0.5 % > 0.5 %1)

Oil grade Oil change interval: Reached first in operation

VDS-3 500 hours / 12 month 250 hours / 12 month 125 hours / 12 month

VDS-2 and ACEA E7 2) 250 hours / 12 month 125 hours / 12 month 75 hours / 12 month

VDS-2 and ACEA E5 2)

VDS-2 and Global DHD-1 2)

VDS-2 and API CI-4 2)

VDS-2 and API CH-4 2)

VDS and ACEA E3 2) 125 hours / 12 month 75 hours / 12 month 50 hours / 12 month

ACEA: E7, E5, E4

API: CI-4, CH-4, CG-4

1)

If sulfur content is > 1.0 % by weight, use oil with TBN > 15.

2)

Lubrication oil must comply with both requirements. Note. API: CG-4 or CH-4 can be approved in markets outside Europe (instead of

ACEA A3).

NOTE! Mineral based oil, either fully or semi-synthetic, can be used on condition that it complies with the quality

requirements above.

NOTE! Oil filter must be changed with every oil change.

VDS = Volvo Drain Specification

ACEA = Association des Constructeurs Europenne dAutomobiles

API = American Petroleum Institute

TBN = Total Base Number

19

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Viscosity

Select the viscosity from the adjacent table, for the

appropriate continuous ambient air temperature.

* *Refers to synthetic or semi-synthetic oils.

Oil

Oil change volume, including filters ........................ 35 liter (9.2 US gallon)

Oil pressure

Operating speed (above 1100 rpm) ......................... 300 -550 kPa (43.5-79.7 psi)

Low idle .................................................................. min 270 kPa (39.1 psi)

Oil temperature

Cold engine, engine stopped .................................. ambient temperature

Hot engine, engine running

(coolant temperature 75-95 C) (167-203F) .......... 90-115 C (194-239F)

Lubricating oil pump

Type ...................................................................... Gear driven

No. of teeth, drive wheel ........................................ 23

Oil filter

Full flow filter .......................................................... 2

Turbo filter (By-pass filter) ...................................... 1

20

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

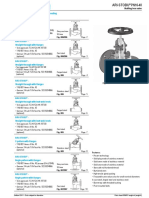

Oil valves

1. Safety valve, lube oil pump

Marking ............................................................. Violet

2. Bypass valve, bypass filter

Spring, free length ............................................. 69 mm (2.71653")

Loaded 13-15 Nm (9.6-11.0 lbf-ft) ...................... 40 mm (1.5748")

3. Bypass valve, oil cooler

Spring, free length ............................................. 63 mm (2.48031")

Loaded 124 Nm (91.4 lbf-ft) ............................... 44 mm (1.73228")

4. Reduction valve, oil pressure

Marking ............................................................. Blue

5. Bypass valve, full flow filter

Spring, free length ............................................. 69 mm (2.71653")

Loaded 13-15 Nm (9.6-11.0 lbf-ft) ...................... 40 mm (1.5748")

6. Opening valve, piston cooling

Spring, free length ............................................. 122 mm (4.80314")

Loaded, 94 Nm (69.3 lbf-ft) ................................ 62 mm (2.44094")

7. Control valve, piston cooling

Spring, free length ............................................. 122 mm (4.80314")

Loaded, 47 Nm (34.6 lbf-ft) ................................ 92 mm (3.62204")

21

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Fuel system

Feed pump

Feed pressure at:

600 r/min ............................................................. min 400 kPa (58.0 psi)

1200 r/min ........................................................... min 400 kPa (58.0 psi)

full load ............................................................... min 400 kPa (58.0 psi)

By-pass valve

Opening pressure ................................................... 400 -550 kPa (58.0-79.7 psi)

Fuel quantity

At low idle and with the engine unloaded, the fuel quantity should be inside area B. The engine should be run in

at least 600 h.

Unit injector

Pre-load: ................................................................ 3-4 spanner flats (0.75 0.1 mm (0.029527 - 0.003937")),

please refer to the illustration.

Tighten the adjustment screw to zero clearance against the camshaft, then turn 3-4 spanner flats.

22

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Inlet and exhaust system

Turbocharger

Manufacturer/type

TAD940GE, TAD940-943VE ............................... 3K/K29

TAD941GE ......................................................... 3K/K31

TAD950-952VE ................................................... Holset

End float, turbine shaft ........................................... max 0.15 mm (0.005905")

Charge air temperature indicator

Cold engine, engine stopped .................................. Ambient temperature

Hot engine, engine running

(coolant temperature 75-95C (167-203F)) .......... 10-30C (18-54F) above ambient temperature

Pressure drop indicator

Pressure drop indicator indication lamp

lights up at a pressure drop of ............................. 5 kPa (0.7 psi)

Boost pressure

1500/1800 r/min.

TAD940GE ............................................................ 230 kPa (33.36 psi)

TAD941GE ............................................................ 250 kPa (36.26 psi)

2100 r/min

TAD940VE ............................................................. 145 kPa (21.03 psi)

TAD941VE ............................................................. 166 kPa (24.08 psi)

TAD942VE ............................................................. 185 kPa (23.83 psi)

TAD943VE ............................................................. 187 kPa (27.12 psi)

TAD950VE ............................................................. 187 kPa (27.12 psi)

TAD951VE ............................................................. 207 kPa (30.02 psi)

TAD952VE ............................................................. 212 kPa (30.75 psi)

23

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Cooling system

General

Pressure cap opens at ........................................... 75 kPa (10.8 psi)

Thermostat

Quantity ................................................................. 1

Opening temperature .............................................. 82C (180F)

Fully open .............................................................. 92C (198F)

Coolant

Type ...................................................................... Volvo Original

Consists of ............................................................ Glycol and corrosion-inhibiting additives

Color ...................................................................... Green

Mix with ................................................................. Water (according to ASTM D4985)

24

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Engine control system

Engine control unit

No. of pins ............................................................. 2 x 36

Sensor

Charge pressure sensor

Check value ........................................................... 1.05-1.30 V at 100 kPa (14.5 psi)

Charge air temperature sensor

Coolant temperature sensor

25

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Inlet temperature sensor

Engine oil temperature sensor

Camshaft sensor

Distance to camshaft ............................................. 0.3 -1.0 mm (0.011811 - 0.03937")

Flywheel sensor

Distance to flywheel ............................................... 0.7 -2.1 mm (0.027559 - 0.082677")

26

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Tightening torque

General tightening torque Nm

M6 standard screw 8.8 ........................................... 10 1.5 (1.1 lbf-ft)

M8 standard screw 8.8 ........................................... 25 4 (18.52.9 lbf-ft)

M10 standard screw 8.8 ......................................... 508 (36.95.9 lbf-ft)

M12 standard screw 8.8 ......................................... 85 15 (62.711.0 lbf-ft)

M14 standard screw 8.8 ......................................... 140 25 (10318.4 lbf-ft)

M16 standard screw 8.8 ......................................... 220 35 (16225.8 lbf-ft)

Only torqued screws can be re-installed.

Torque and angle tightened / plastic limit tightened screws:

8.8 ...................................................................... should not be re-installed

10.9 .................................................................... can be re-installed

12.9 .................................................................... can be re-installed

IMPORTANT! Check screws which are to be re-installed. Damaged screws, with marks of seizure etc. under the

heads, must be scrapped.

Tightening torque group 21: Engine body

Front engine mounting, engine block ...................... 275 45 Nm (20233lbf-ft)

Front engine mounting, front engine pad ................. 150 30 Nm (11122 lbf-ft)

Main bearing caps

Stage 1 ............................................................... 150 20 Nm (11115 lbf-ft)

Stage 2 ............................................................... 120 5 angle tightening

Big end bearing cap

Stage 1 ............................................................... 20 3 Nm (152 lbf-ft)

Stage 2 ............................................................... 35 3 Nm (262 lbf-ft)

Stage 3 ............................................................... 90 5 angle tightening

Stiffening frame ..................................................... 48 8 Nm (356 lbf-ft)

NOTE! Tighten the screws in sequence, from the center and outwards.

27

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Flywheel

NOTE! Make sure that the flange is clean and dry.

NOTE! Tighten the screws in number order, as in the illustration.

Stage 1 ............................................................... 60 5 Nm (444 lbf-ft)

Stage 2 ............................................................... 120 10 angle tightening

Bell housing

NOTE! Apply 2 mm silicone sealer as in the illustration.

28

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

12

1

10

3

8

6 5

7

2

4 9

Vibration damper, camshaft 11

Stage 1 ............................................................... 45 5 Nm (334 lbf-ft)

Stage 2 ............................................................... 90 5 angle tightening

NOTE! Tighten the screws in number order, as in the illustration.

NOTE! The 8.8 screws on the vibration damper must not be re-used.

Housing, crankcase seal ............................. 24 4 Nm (183 lbf-ft)

NOTE! Apply 2mm (0,07874") silicone sealer as in the illustration.

Valve housing. .............................................. 24 4 Nm (183 lbf-ft)

NOTE! Tighten the screws in number order, as in the illustration.

29

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Oil cooler, housing ...................................... 24 4 Nm (183 lbf-ft)

NOTE! Tighten the screws in sequence, from the center and outwards.

Cylinder head

NOTE! Tighten the screws in number order, as in the illustration.

Stage 1 ............................................................... 60 10 Nm (447 lbf-ft)

Stage 2 (check tightening) .................................. 60 10 Nm (447 lbf-ft)

Stage 3 ............................................................... 120 5 angle tightening

Stage 4 ............................................................... 90 5 angle tightening

Core plugs, cylinder head ....................................... 60 10 Nm (447 lbf-ft)

Lock nut, valve adjustment screw .......................... 60 5 Nm (444 lbf-ft)

30

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Bearing caps, camshaft / rocker arm shaft

NOTE! Tighten the screws in stages, to ensure that the rocker arm shaft

comes down without being bent.

Stage 1: Torque screws 1-7 to ............................... 15 3 Nm (112 lbf-ft)

Stage 2: Torque screws 9, 11, 13. ......................... 60 5 Nm (444 lbf-ft)

Start with screw 11.

Stage 3: Torque screws 8, 10, 12, 14. ................... 60 5 Nm (444 lbf-ft)

Stage 4: Loosen screws 9, 11, 13. .........................

Stage 5: Torque screws 9, 11, 13. ......................... 60 5 Nm (444 lbf-ft)

Stage 6: Tighten screws 1-7. ................................. 90 5 angle tightening

Stage 7: Tighten screws 8-14. ............................... 120 5 angle tightening

31

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Apply silicone sealer to the rear edge of the cylinder Tighten the screws in number order.

head and the engine block.

Timing gear plate ......................................... 24 4 Nm (133 lbf-ft)

NOTE! Apply silicone sealer and tighten the screws in number order, as in the illustration.

Timing gear cover, upper ............................ 24 4 Nm (133 lbf-ft)

NOTE! Apply 2 mm (0,07874") silicone sealer as in the illustration.

32

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Timing

1 Drive gear, crankshaft ............................................................. 24 4 Nm (133 lbf-ft)

2 Idler wheel, double gear

Apply thread locking fluid 1161053 to the screws and tighten them in number order, as in the illustration.

Stage 1 ..................................................................................... 35 4 Nm (263 lbf-ft)

Stage 2 ..................................................................................... 60 5 angle tightening

3 Idler wheel, adjustable

Tighten the screws in number order, as in the illustration.

Stage 1 ..................................................................................... 35 4 Nm (263 lbf-ft)

Stage 2 ..................................................................................... 120 5 angle tightening

4 Drive gear, camshaft

Tighten the screws in number order, as in the illustration.

Stage 1 ..................................................................................... 45 5 Nm (334 lbf-ft)

Stage 2 ..................................................................................... 90 5 angle tightening

5 Drive wheel, steering servo and fuel feed pump ................... 100 10 Nm (747 lbf-ft)

6 Drive wheel, air compressor ................................................... 200+50

-0 Nm(148-037 lbf-ft)

33

Downloaded from www.Manualslib.com manuals search engine

Technical data Group 20

Tightening torque group 22: Lubricating system

Oil sump ................................................................ 24 4 Nm (183 lbf-ft)

NOTE! Tighten the screws in sequence, from the center and outwards.

Drain plug, oil sump ............................................... 60 5 Nm (444 lbf-ft)

Bracket, oil pump/main bearing caps ..................... 24 4 Nm (133 lbf-ft)

Oil strainer, retaining screws .................................. 24 4 Nm (183 lbf-ft)

Oil cooler, retaining screws .................................... 27 4 Nm (183 lbf-ft)

Tightening torque group 23: Fuel system

Feed pump - steering servo pump .......................... 24 4 Nm (183 lbf-ft)

Fixing yoke, unit injector (new copper sleeve)

First tightening

Stage 1 ............................................................... 20 5 Nm (154 lbf-ft)

Stage 2 ............................................................... 180 5 angle tightening

Loosen the fastening yoke screw before doing the second tightening.

Second tightening

Stage 1 ............................................................... 20 5 Nm (154 lbf-ft)

Stage 2 ............................................................... 60 5 angle tightening

Fixing yoke, unit injector (re-used copper sleeve)

Stage 1 ............................................................... 20 5 Nm (143 lbf-ft)

Stage 2 ............................................................... 60 5 angle tightening

Locknut for rocker adjuster screw, unit injector

Stage 1 ............................................................... tighten until contact

Stage 2 .............................................................. 45 5 angle tightening

Hollow screw M16 x 1.5 ......................................... 50 8 Nm

Hollow screw M10 x 1 ............................................ 25 4 Nm

34

Downloaded from www.Manualslib.com manuals search engine

Group 20 Technical data

Tightening tourqe group 25, Intake and exhaust system

Inlet pipe ......................................................... 24 4 Nm (183 lbf-ft)

NOTE! Apply 2mm silicone sealer as in the illustration.

Plug, M10 .............................................................. 20 3 Nm (153 lbf-ft)

Pressure/temperature sensor, charge air ................ 12 2 Nm (92 lbf-ft)

Exhaust collector pipe

Stage 1: Tighten the screws until they just touch ...................... 5 1.5 Nm (41 lbf-ft)

Stage 2: Torque screws 1 and 8 ................................................ 10 1.5 Nm (71 lbf-ft)

Stage 3: Torque screws 3 and 10 .............................................. 10 1.5 Nm (71 lbf-ft)

Stage 4: Torque screws 5 and 12 .............................................. 10 1.5 Nm (71 lbf-ft)

Stage 5: Torque screws 2 and 7 ................................................ 48 8 Nm (356 lbf-ft)

Stage 6: Torque screws 4 and 9 ................................................ 48 8 Nm (356 lbf-ft)

Stage 7: Torque screws 6 and 11 .............................................. 48 8 Nm (352 lbf-ft)

Stage 8: Torque screws 1 and 8 ................................................ 48 8 Nm (352 lbf-ft)

Stage 9: Torque screws 3 and 10 .............................................. 48 8 Nm (352 lbf-ft)

Stage 10: Torque screws 5 and 12 ............................................ 48 8 Nm (352 lbf-ft)

35

Downloaded from www.Manualslib.com manuals search engine

Group 20

Reference to Service bulletins

Group No Date Refers to

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

.........................................................................................................................................................................................

36

Downloaded from www.Manualslib.com manuals search engine

Notes

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

Downloaded from www.Manualslib.com manuals search engine

Notes

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

Downloaded from www.Manualslib.com manuals search engine

Report form

Do you have any complaints or other comments about this manual.

Please make a copy of this page, write your comments down and send

them to us. The address is at the bottom. We would prefer you to write in

English or Swedish.

From: ......................................................................

................................................................................

................................................................................

................................................................................

Refers to publication: ................................................................................................................................

Publication No.: .................................. Date of issue: ................................................................................

Proposal/motivation: .................................................................................................................................

.................................................................................................................................................................

.................................................................................................................................................................

.................................................................................................................................................................

.................................................................................................................................................................