Beruflich Dokumente

Kultur Dokumente

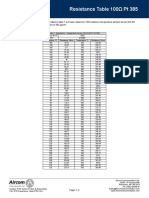

Temperature Correction Table

Hochgeladen von

99912300840831814491Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Temperature Correction Table

Hochgeladen von

99912300840831814491Copyright:

Verfügbare Formate

Temperature Correction Factors

As the service temperature increases, the maximum pressure a hose assembly can withstand decreases.

The material from which the hose is made and the method of fitting attachment (mechanical, soldered, welded,

silver brazed) determine the maximum pressure at which an assembly can be used. By using the factors given

in the chart below, the approximate safe working pressure at elevated temperatures can be calculated for

assemblies with welded or mechanically attached fittings.

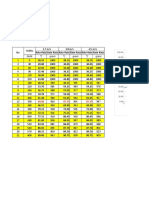

Temp ( 304, 316L 321 Monel Hastelloy

F) Stainless Stainless

Room 1.00 1.00 1.00 1.00

150 .96 .97 .93 .97

200 .92 .94 .90 .94

250 .91 .92 .87 .92

Saturated Steam Pressure To Temperature (PSIG)

300 .86 .88 .83 .91

Saturated Temp ( Saturated Temp ( Saturated Temp (F) 350 .85 .86 .82 .89

Steam F) Steam F) Steam

(PSIG) (PSIG) (PSIG) 400 .82 .83 .79 .87

0 212 150 366 450 460 450 .80 .81 .77 .86

10 238 175 377 475 465 500 .77 .78 .73 .85

20 259 200 388 500 470 600 .73 .74 .72 .84

30 274 225 397 550 480 700 .69 .70 .71 .82

40 287 250 406 600 489 800 .64 .66 .70 .81

50 298 275 414 700 505 900 .62 .79

60 307 300 422 800 520 1000 .60 .78

75 320 325 429 900 534 1100 .58 .75

80 324 350 436 1000 546 1200 .55 .73

90 331 375 442 1250 574 1300 .50 .69

100 338 400 448 1500 606 1400 .44 .65

125 353 425 454 2500 669 1500 .40

Example

Determine if 3/4" annular stainless hose with welded

Saturated Steam fittings is satisfactory for the given operating conditions?

Pressure To

Given:

Temperature (Hg) Maximum operating temperature is 700F.

Saturated Temp ( Maximum operating pressure is 200 PSIG.

Steam F)

Vacuum Computation:

(in. of Hg)

From the Product Specifications table - nominal rated burst

0 pressure for 3/4" with one layer of braid and with welded

fittings is 3200 PSIG.

29.84 20 From Temperature Correction Factors Chart - factor for

stainless at 700F is .70

29.74 32

29.67 40 Rated Burst Pressure: 3200 PSIG x .70 = 2240 PSIG

(rated burst pressure at 700F)

29.39 60 Safe Operating Pressure: 2240 4 = 560 PSIG (using 4:1

safety factor)

28.89 80

Result:

27.99 100 Since the maximum operating pressure for 3/4 one braid

layer at 700F is 560 PSIG the hose will meet the required

26.48 120

operating conditions outlined above.

24.04 140

20.27 160

15.20 180

6.46 200

Das könnte Ihnen auch gefallen

- The Science and Engineering of Thermal Spray CoatingsVon EverandThe Science and Engineering of Thermal Spray CoatingsNoch keine Bewertungen

- Project: (G+4) Hotel Owner: Ato Wondafrash Tesfaye Location: Wolega (Gimbi)Dokument2 SeitenProject: (G+4) Hotel Owner: Ato Wondafrash Tesfaye Location: Wolega (Gimbi)Frezer AmareNoch keine Bewertungen

- Hardness Conversion Table - EDokument1 SeiteHardness Conversion Table - EsachinumaryeNoch keine Bewertungen

- Steel grade 12Х1МФDokument6 SeitenSteel grade 12Х1МФHussien AlsadyNoch keine Bewertungen

- Table For RTD Pt100 (IEC 60751) : - 200 °C To 850 °CDokument1 SeiteTable For RTD Pt100 (IEC 60751) : - 200 °C To 850 °CRafael Bispo De Souza NetoNoch keine Bewertungen

- ESP SelectpumpDokument17 SeitenESP SelectpumpAdam Rohman SAZZYSAQQASASHANoch keine Bewertungen

- 100W 5700kphotometric Test ReportDokument10 Seiten100W 5700kphotometric Test ReportGonzalo LunaNoch keine Bewertungen

- AmpacityDokument3 SeitenAmpacityjkNoch keine Bewertungen

- Mission 3-Pass: Smoke Tube Shell Boiler in Wet Back DesignDokument2 SeitenMission 3-Pass: Smoke Tube Shell Boiler in Wet Back DesignMauricio CarestiaNoch keine Bewertungen

- Characteristics Hytherm 500 Hytherm 600Dokument3 SeitenCharacteristics Hytherm 500 Hytherm 600Cal India -GeneralNoch keine Bewertungen

- Elemental Analysis: Coal Tar Biomass TarDokument4 SeitenElemental Analysis: Coal Tar Biomass TarCesar BerruecoNoch keine Bewertungen

- Aerospace Grade Oils and Greases: Product InformationDokument4 SeitenAerospace Grade Oils and Greases: Product InformationPeter BennetNoch keine Bewertungen

- RTD Resistance Table RT0 C2 0Dokument1 SeiteRTD Resistance Table RT0 C2 0Mothafukin MorrisseyNoch keine Bewertungen

- Estimation HVAC Work 1Dokument3 SeitenEstimation HVAC Work 1Skylink Estimation TeamNoch keine Bewertungen

- Felycian Data, For Optimization of Grinding Circuit111Dokument44 SeitenFelycian Data, For Optimization of Grinding Circuit111Flora PatrickNoch keine Bewertungen

- Sections ArcelorMittal V2016-1Dokument68 SeitenSections ArcelorMittal V2016-1PatrickNoch keine Bewertungen

- KcalDokument5 SeitenKcalanibal chavez zeballosNoch keine Bewertungen

- Datasheet-Sandvik-2rk65hv-En-V2020-12-10 07 - 47 Version 1Dokument3 SeitenDatasheet-Sandvik-2rk65hv-En-V2020-12-10 07 - 47 Version 1tatiana alvarezNoch keine Bewertungen

- Lab Group 2 SpreadsheetDokument9 SeitenLab Group 2 SpreadsheetKavish DayaNoch keine Bewertungen

- Chapter 5. Control Valve Selection: Cast Carbon Steel (ASTM A216 Grade WCC) - WCC Is The Most PopDokument8 SeitenChapter 5. Control Valve Selection: Cast Carbon Steel (ASTM A216 Grade WCC) - WCC Is The Most PopRedzaNoch keine Bewertungen

- Data Sheet: Scrd-Ut SeriesDokument2 SeitenData Sheet: Scrd-Ut SeriesMustafa PardawalaNoch keine Bewertungen

- Hagedorn-Brown CorrelationDokument14 SeitenHagedorn-Brown CorrelationCaesar DimasDwi SaputriNoch keine Bewertungen

- Sepa FlashDokument8 SeitenSepa FlashCamila Shaine BelmonteNoch keine Bewertungen

- Orrcon Steel Chequer PlateDokument1 SeiteOrrcon Steel Chequer PlateOliver HermosaNoch keine Bewertungen

- ProcessPipe PipesDokument6 SeitenProcessPipe PipesANISNoch keine Bewertungen

- Stripping Furnace: Electric MotorDokument2 SeitenStripping Furnace: Electric MotorQrwer SffNoch keine Bewertungen

- Tribo Assignment 4Dokument4 SeitenTribo Assignment 4abdurhman suleimanNoch keine Bewertungen

- Ramill Tech Toolkit 3Dokument9 SeitenRamill Tech Toolkit 3moddysNoch keine Bewertungen

- Area Led Roy AlphaDokument10 SeitenArea Led Roy AlphaPineda SuárezNoch keine Bewertungen

- Konversi Kekerasa Brinell, Vicker, RockwellDokument1 SeiteKonversi Kekerasa Brinell, Vicker, RockwellVeronika SinagaNoch keine Bewertungen

- Line Sizing For Single Phase LiquidDokument12 SeitenLine Sizing For Single Phase LiquidKomal PatelNoch keine Bewertungen

- Unconsolidated Undrained Triaxial Test IDokument48 SeitenUnconsolidated Undrained Triaxial Test ISiti Ulfatun UyunNoch keine Bewertungen

- Inconel Alloy 617 (UNS N06617) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDokument5 SeitenInconel Alloy 617 (UNS N06617) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebJosué Emmanuel Blásquez ContrerasNoch keine Bewertungen

- Section 20: Technical InformationDokument23 SeitenSection 20: Technical InformationMohd Lutfi MahaliNoch keine Bewertungen

- Technical Data Sheet: Stainless Steel: AusteniticDokument4 SeitenTechnical Data Sheet: Stainless Steel: AusteniticdaagiraldogoNoch keine Bewertungen

- Heat Coil CalculationDokument2 SeitenHeat Coil CalculationZhao XuanNoch keine Bewertungen

- Invar ASDokument3 SeitenInvar ASBhagawati Prasad SharmaNoch keine Bewertungen

- Schedule 80 PVC Pipe Dimensions & Pressure RatingsDokument1 SeiteSchedule 80 PVC Pipe Dimensions & Pressure RatingsprathapNoch keine Bewertungen

- DB Sections and BarsDokument69 SeitenDB Sections and BarsJulienNoch keine Bewertungen

- RTD Thermistor Z202030 0NDokument1 SeiteRTD Thermistor Z202030 0NcesarNoch keine Bewertungen

- Chem Displacement LabDokument18 SeitenChem Displacement LabHEHEHENoch keine Bewertungen

- FR 6700 Extended TDS - METRIC 10 2022Dokument1 SeiteFR 6700 Extended TDS - METRIC 10 2022Nyla LaraibNoch keine Bewertungen

- 1.3505 100cr6 PDFDokument1 Seite1.3505 100cr6 PDFmcNoch keine Bewertungen

- Sections and Merchant Bars-ArcelorMittal V2016-1Dokument71 SeitenSections and Merchant Bars-ArcelorMittal V2016-1mojgfdNoch keine Bewertungen

- SL-150W FotometriaDokument10 SeitenSL-150W FotometriaErik Marcelo BarrenecheaNoch keine Bewertungen

- Nitrogen Spreadsheet JR EditDokument20 SeitenNitrogen Spreadsheet JR EditОлександр ЛетюкNoch keine Bewertungen

- ASTM & TBP Vs V DistilledDokument3 SeitenASTM & TBP Vs V DistilledNaufal FasaNoch keine Bewertungen

- Detik C Gram C Gram C GramDokument5 SeitenDetik C Gram C Gram C GramSunset GamingNoch keine Bewertungen

- Experiment 1: Physical Properties of Water ObjectivesDokument12 SeitenExperiment 1: Physical Properties of Water ObjectivesWan XïnNoch keine Bewertungen

- Steam Pipe SizingDokument2 SeitenSteam Pipe SizingONLY PHYSICSNoch keine Bewertungen

- Kabel 3x075 BrandsikkerDokument2 SeitenKabel 3x075 Brandsikkerafie pio pioNoch keine Bewertungen

- Joseph 16 JanDokument6 SeitenJoseph 16 JanRitesh SinghNoch keine Bewertungen

- Malleable Pressure Temperature RatingsDokument1 SeiteMalleable Pressure Temperature RatingsJose Gregorio Prada RodriguezNoch keine Bewertungen

- Emergency Relief Vent: MODEL 2000ADokument8 SeitenEmergency Relief Vent: MODEL 2000ASantiago PeñuelaNoch keine Bewertungen

- Shear Strength ResultDokument14 SeitenShear Strength ResultPrateek Soumya SharmaNoch keine Bewertungen

- BS 3059-1 PDFDokument9 SeitenBS 3059-1 PDFabhiNoch keine Bewertungen

- Quality 100crmo7: Lucefin GroupDokument1 SeiteQuality 100crmo7: Lucefin GroupPaulo ZechinNoch keine Bewertungen

- Aalborg OL: The Large Capacity Modular Boiler PlantDokument2 SeitenAalborg OL: The Large Capacity Modular Boiler Plantthlim19078656Noch keine Bewertungen

- Dyno rs150v2 Spec70mmDokument2 SeitenDyno rs150v2 Spec70mmNajmyrosliNoch keine Bewertungen

- Therminol 55Dokument5 SeitenTherminol 55Dinesh KumarNoch keine Bewertungen

- Shri Naina Devi Aarti English 167Dokument5 SeitenShri Naina Devi Aarti English 167ratt182Noch keine Bewertungen

- 18-MCE-49 Lab Session 01Dokument5 Seiten18-MCE-49 Lab Session 01Waqar IbrahimNoch keine Bewertungen

- KPI AssignmentDokument7 SeitenKPI AssignmentErfan Ahmed100% (1)

- Claim of FactDokument11 SeitenClaim of FactXeb UlritzNoch keine Bewertungen

- The New Order of BarbariansDokument39 SeitenThe New Order of Barbariansbadguy100% (1)

- A P P E N D I X Powers of Ten and Scientific NotationDokument5 SeitenA P P E N D I X Powers of Ten and Scientific NotationAnthony BensonNoch keine Bewertungen

- Safety Bulletin 09 - Emergency Escape Breathing Device - Product RecallDokument2 SeitenSafety Bulletin 09 - Emergency Escape Breathing Device - Product RecallMuhammadNoch keine Bewertungen

- Gis Data Creation in Bih: Digital Topographic Maps For Bosnia and HerzegovinaDokument9 SeitenGis Data Creation in Bih: Digital Topographic Maps For Bosnia and HerzegovinaGrantNoch keine Bewertungen

- Ultra ConductorsDokument28 SeitenUltra ConductorsAnu Kp50% (8)

- Information Systems and Supply Chain ManagementDokument2 SeitenInformation Systems and Supply Chain Managementvipinkandpal86Noch keine Bewertungen

- D&D 5.0 Combat Reference Sheet Move Action: Interact With One Object Do Other Simple ActivtiesDokument2 SeitenD&D 5.0 Combat Reference Sheet Move Action: Interact With One Object Do Other Simple ActivtiesJason ParsonsNoch keine Bewertungen

- I M Com QT Final On16march2016Dokument166 SeitenI M Com QT Final On16march2016Khandaker Sakib Farhad0% (1)

- Analysis of Rates (Nh-15 Barmer - Sanchor)Dokument118 SeitenAnalysis of Rates (Nh-15 Barmer - Sanchor)rahulchauhan7869Noch keine Bewertungen

- Csir Life Sciences Fresh Instant NotesDokument4 SeitenCsir Life Sciences Fresh Instant NotesAlps Ana33% (3)

- HUMSS - Introduction To World Religions & Belief Systems CGDokument13 SeitenHUMSS - Introduction To World Religions & Belief Systems CGAliuqus SirJasper89% (18)

- Job Satisfaction VariableDokument2 SeitenJob Satisfaction VariableAnagha Pawar - 34Noch keine Bewertungen

- Smartfind E5 g5 User ManualDokument49 SeitenSmartfind E5 g5 User ManualdrewlioNoch keine Bewertungen

- G10 Lesson2 DLPDokument13 SeitenG10 Lesson2 DLPAngeles, Mark Allen CNoch keine Bewertungen

- Active Hospital Network List For Vidal Health Insurance Tpa PVT LTD As On 01 Feb 2023Dokument119 SeitenActive Hospital Network List For Vidal Health Insurance Tpa PVT LTD As On 01 Feb 2023jagdeepchkNoch keine Bewertungen

- PDFDokument40 SeitenPDFAndi NursinarNoch keine Bewertungen

- De Thi Hoc Ki 1 Lop 11 Mon Tieng Anh Co File Nghe Nam 2020Dokument11 SeitenDe Thi Hoc Ki 1 Lop 11 Mon Tieng Anh Co File Nghe Nam 2020HiềnNoch keine Bewertungen

- A Comparative Study of Public Private Life Insurance Companies in IndiaDokument5 SeitenA Comparative Study of Public Private Life Insurance Companies in IndiaAkansha GoyalNoch keine Bewertungen

- Lesson 1 3 Transes in Reading in Philippine HistoryDokument17 SeitenLesson 1 3 Transes in Reading in Philippine HistoryNAPHTALI WILLIAMS GONoch keine Bewertungen

- CA21159 MG 8 Digital BookletDokument5 SeitenCA21159 MG 8 Digital BookletcantaloupemusicNoch keine Bewertungen

- СV Nestor RodriguezDokument28 SeitenСV Nestor RodriguezKate BrownNoch keine Bewertungen

- Zomato Restaurant Clustering & Sentiment Analysis - Ipynb - ColaboratoryDokument27 SeitenZomato Restaurant Clustering & Sentiment Analysis - Ipynb - Colaboratorybilal nagoriNoch keine Bewertungen

- Iguard® LM SeriesDokument82 SeitenIguard® LM SeriesImran ShahidNoch keine Bewertungen

- UNIT 5-8 PrintingDokument17 SeitenUNIT 5-8 PrintingNOODNoch keine Bewertungen

- Sale Counter List JuneDokument9 SeitenSale Counter List Junep6a4nduNoch keine Bewertungen

- Perdarahan Uterus AbnormalDokument15 SeitenPerdarahan Uterus Abnormalarfiah100% (1)