Beruflich Dokumente

Kultur Dokumente

Gold Refining Process Aqua Regia

Hochgeladen von

CassidyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gold Refining Process Aqua Regia

Hochgeladen von

CassidyCopyright:

Verfügbare Formate

Gold refining process aqua regia

Magnified Black Sand Photos. Now that the gold and other precious metals are in a clear, filtered, Aqua Regia solution, the dissolved gold and

other metal chlorides can easily be separated from each other using a couple different gold refining methods. The best and most modern method,

however, is the electrolytic one described above. Therefore, in addition to nitrosyl chloride and chlorine, the fumes over aqua regia contain nitric

oxide. In hot water, dissolve a weight of Storm Precipitant equal to the weight of dissolved metal. The classic procedure for nitric acid elimination

is repeated boiling to near dryness with the addition of hydrochloric acid with some sulphuric acid near the end. JavaScript seems to be disabled in

your browser. The secrets of alchemy. Gold chloride is formed when aqua regia digests gold scrap. Some of these are red-brown in color, others

are colorless but take up oxygen as soon as they reach air and then turn red-brown. Extracting Gold with Butyl Diglyme. This is a lengthy and

patience-trying process. How To Find Gold. Other names aqua regis, nitrohydrochloric acid. It is also used in some laboratories to clean

glassware of organic compounds and metal particles. Translate Select Your Language: After doing so, the gold atom now has only 78 electrons

and is no longer metallic gold but is a positively charged ion, or a cation. Careful addition of Storm Precipitant and a slow approach to the end

point can avoid this. In nature, gold is never found as pure 24 carrot gold. The reaction of the aqua-regia with the metals in the scrap produces

nitrogen oxides. Need help with sales? Testing of Precious Metals, Diamonds, Money. A simple siphon will remove the upper portion of the liquid

quietly without stirring up gold particles. Due to the reaction between its components resulting in its decomposition, aqua regia quickly loses its

effectiveness yet remains a strong acid , so its components are usually only mixed immediately before use. A number of other chemicals will also

'reduce' the gold chloride but Storm Precipitant available from Shor is better. When the gold is being melted the filter paper will burn and leave any

adhering gold in the crucible. With time it will burn away. The duct through which the air and fumes are extracted is 10 x 12 in The vertical height is

only 8 feet, which is too low to create a natural draft and an effective draft is produced by the use of an inexpert external blower. Shor Canada are

registered trademarks of Shor International Corp.. This powder is then washed, rinsed and melted into the final required form i. Gold Test

Procedure 5. It is known that the aqua-regia technique herein described is not the only method. The solution is then trasferred to the cementation

tank where various chemicals products are added in order to precipitate the gold back into a solid. A rapid and satisfactory test for gold in solution

is described in 5. The fumes generated by Aqua Regia in a gold refining process are also toxic. A single atom of gold has 79 electrons.

Gold Refining Process by Aqua Regia

Nitric Acid Elimination The excess aqua-regia that was added to insure complete solution of all gold is, of course, still in the solution at this stage

and must be eliminated to allow the gold to be precipitated. Precipitating the Gold 3. The acids used, nitric and hydrochloric, are both somewhat

volatile and emit fumes and should be well stoppered to keep fumes out of the work areas. A rapid and satisfactory test for gold in solution is

described in 5. HCl mass ratio is less than 1: The gold refining technique described here is the rather ancient wet chemical method whereby the

gold-bearing scrap is dissolved in aqua-regia. Nitric and hydrochloric acids are then added in a special ratio to the tumbler thus forming the aqua

regia solution. Essentially all the fumes produced in the process are heavier than air but will be swept out by a properly designed hood. Nitric Acid

Elimination 3. The gold scrap that is considered in this report is old jewelry and the material from jewelry bench work, filings, clippings, scrap

jewelry pieces, grinding wheel dust, casting spills, sprues, strip pot sludge, etc. Plastic, not metal pumps should be used, as the acid fumes from

aqua-regia filtering rapidly reduce the pumping ability of a metal pump. This arrangement and the essential dimensions are in Figure No. Making

Gold Shot 4. The aqua-regia solutions are filtered with a Buchner filtering funnel and a 4 liter vacuum filtering flask. These gold cations are

suspended in the Aqua Regia solution along with other precious metal cations of platinum, palladium, and base metals like copper, nickle, iron etc

Contact Have a question about a product or process? Next morning the clear liquid was siphoned off, leaving the silver chloride at the bottom of

the vessel, and transferred to a tank containing a solution of ferrous chloride. The aqua-regia now contains various metal chlorides and perhaps

nitrates in solution and insoluble silver chloride as well as a lot of unwanted material in the sludge, and this mixture when cooled must be filtered.

So-called "green gold" and some low carat white golds contain considerable silver and are very difficult or impossible to dissolve in aqua-regia as

an insoluble silver chloride film is formed which prevents further action by the aqua-regia. Polishing Make your metals shine and sparkle! It has

been found that from 3. Fluxes are not usually needed, but if a surface film appears on the melt a very little borax may be added. All of the solids

should be washed into the filter with a small stream of water, a wash bottle is useful for this operation. Receive an instant estimate 3. From

Wikipedia, the free encyclopedia. Details of the hood used in this work are given in 4. The whole assembly is illustrated to the right. Selective

Precipitation, Solvent Extraction, and the use of Ion Exchange Resins are a few options available to selectively extract and separate gold from the

other precious metals. In hot water, dissolve a weight of Storm Precipitant equal to the weight of dissolved metal. The filter and sludge are washed

with repeated small amounts of water to wash all gold chloride solution down through the filter. The maximum possible front opening is 2 feet high

x 4 feet long. If the aqua-regia is several days old and is no longer producing chlorine gas a siphon from a high container is also a convenient way

of adding aqua-regia slowly. It is prevented by consistently wearing rubber gloves. It usually burns quite slowly because the furnace flame at gold

melting temperature does not have excess oxygen.

Gold Refining using Aqua Regia, Dislolve gold

Aqua regia is a combination of nitric acid and hydrochloric acid the industrial grade of hydrochloric reining sometimes called muriatic acidit is made

by mixing 1 volume rgia concentrated nitric acid with 4 volumes of gold refining process aqua regia hydrochloric acid. The colors yellow, orange

and red indicate the presence of an insignificant amount of platinum group metals. Procezs gold refining process aqua regia a period, if possible

overnight, facilitates the aaua filtering operation. It procdss not be the best, and for the sake of experience electrolytic cells for refining precious

metals have been examined. The filtered liquid is usually a rather handsome clear green color, due to nickel and copper etc. Aqua regia is also used

in etching and in specific analytic procedures. University Microfilms International, N. The floor of the refinery was slated and drained to carefully

constructed gutters, and no liquids were thrown away until they were declared free from gold. Dissolving platinum solids in aqua regia was the

mode of discovery for the most dense metals, iridium and osmiumboth of which are found in platinum ore refia will not be dissolved by the acid,

instead collecting good the base of the vessel. The metal to be refined should be assayed in order to establish contents of precious metals. It is in

itself harmless. In order to separate these elements and get the gold into its pure form, a separation process or gold refining process needs to take

place. If there is contamination by dissolved metals, the neutralized solution should be collected for disposal. This gold solution, or Aqua Regia

solution, now contains metal ions that have combined with the chlorine to form gold chloride, platinum chloride, etc Very valuable materials are

also involved and it makes sense to have the equipment and procedures set up to avoid loss. Our yold is to make sure that our precious metal

refining services exceed customer expectations for speed and professionalism. For good fume removal this is usually reduced working area. This

and gold refining process aqua regia of the operations described here should be carried out under an efficient fume extraction hood. We take

great pride in our fold to make your experience with us secure and hassle-free. Cart You have no items in your shopping cart. You may also call us

at: These grains are loaded into the refining unit. If, through error, some cuprous chloride refinng are formed, they gokd be removed as described

later. The materials involved in these processes are not what those experienced in chemical and metallurgical work would consider especially

dangerous. If cuprous xqua is present it will make the melting of the gold a memorable experience. Mineral oil coatings are sometimes recommence

but they may gole the gold. Selective Precipitation, Solvent Extraction, and the use of Ion Exchange Resins are gold refining process aqua regia

few options available gold refining process aqua regia selectively extract and separate gold from the other precious metals. The aqua-regia

solutions are filtered with a Buchner filtering funnel and a 4 liter vacuum filtering flask. About kilogrammes of gold per month was thus refined at a

cost, including subsequent coinage, of 1s. Observe the revia and test the solution frequently to avoid large excesses of Storm Precipitant. To help

slow the fall of the metal and prevent agglomeration of the shot a sloping metal baffle is fitted. The fact that a large hot plate in the hood is reactant

use probably helps this natural flow. Teflon plastic is also suitable for the strong oxidizing conditions of the aqua-regia and Teflon will tolerate

heating if done with care. It is also used in some laboratories to clean glassware of organic compounds and metal particles. Please see safety

precautions in the operation of the process and should be carefully studied before any part of this work is undertaken. Extracting Gold with Butyl

Diglyme. One refinery in Texas has been using such a home built system for some years. Experience has shown that the paper discs usually used in

these filters by chemists tend to float away when the filter is refininv with liquid, but coffee urn filters obtainable from hotel and restaurant supply

shops have proved very satisfactory. The bottom few inches of liquid are then poured through the filter keeping the gold reining in gold refining

process aqua regia pail. In hot water, dissolve a weight of Storm Precipitant equal to the weight of dissolved metal. While chromic acid baths are

discouraged because of the high toxicity of chromium and the potential rfining explosions, aqua regia is itself very corrosive and has been implicated

in several explosions due to mishandling. If heated too much it will produce brown fumes merely because it is too hot, this wastes acid and

obscures the end of the solvent action. Need help with sales? Already know what items you want to order? If the scrap is the usual filings and dust

from jewelers benches, the aqua-regia will react very rapidly and may boil over, so the acid must be added slowly and with care. Such equipment

may be an official requirement gold refining process aqua regia most places. Store in the open or in a fume hood. Care is advised as the

reaction is often quite slow to start and then after some minutes becomes very, very active. The Gold Refining Process by Aqua Regia was

introduced at the Pretoria Mint after the Miller process had been tried and defining owing to the alleged difficulty gold refining process aqua

regia treating the gold bullion extracted by the cyanide process. However, if no nickel or copper is present it will most likely be the characteristic

yellow of gold chloride. When pieces of jewelry or larger pieces of metal are being dissolved it often seems that the jewelry is not being attacked

because it is still there in its original shape, however such pieces usually crumble if crushed with a stirring rod. The secrets of alchemy. Careful

addition of Aqia Precipitant and a slow approach to the end point can avoid this. The gold scrap that is considered in this report is old jewelry and

the material from jewelry bench work, filings, clippings, scrap jewelry pieces, grinding wheel dust, casting spills, sprues, strip pot sludge, etc. Learn

more about our facility and precious metal refining services, including:. This page was last edited on 23 Octoberat Refining Gold with Aqua Regia.

Most jewelry alloys contain silver and the aqua-regia dissolves the regi and other alloying metals leaving insoluble silver chloride as a residue in the

original size and form. Digesting the Scrap The scrap gold is placed in the digesting vessel. The acids used, nitric and hydrochloric, are both

somewhat volatile and emit fumes and should be well gold refining process aqua regia to keep fumes out of the work areas. The fumes

generated gols Aqua Regia in a gold refining process are also toxic. Aqua regia reacts with tin to form tin IV chloride gold refining process aqua

regia, containing tin gold refining process aqua regia its highest oxidation state:. The maximum possible front tegia is 2 feet high x 4 feet long.

While local regulations may vary, gold refining process aqua regia regia may be disposed of by careful neutralization, before being poured

down the sink. Due to the reaction refinng its components resulting in its decomposition, aqua regia quickly loses its effectiveness gold refining

process aqua regia remains prodess strong acidso its components are usually only mixed immediately before use. Similar equations can be written

for platinum. Nitric Regla Elimination The excess aqua-regia that was added gold refining process aqua regia insure complete solution of all

gold is, of course, still in the solution at this stage and must be eliminated to allow the gold to be pocess. If the gold is to be used for alloying,

making gold refining process aqua regia is much more convenient in the form of shot rather than bars. The small lots dealt with in this report can

be handled in an ordinary chemical laboratory type of fume hood.

Das könnte Ihnen auch gefallen

- Recover Gold from Gold Plated Items, And Turn It Into 99.995% Pure GoldVon EverandRecover Gold from Gold Plated Items, And Turn It Into 99.995% Pure GoldNoch keine Bewertungen

- Processes For Refining Gold Jewelry Scraps and WastesDokument4 SeitenProcesses For Refining Gold Jewelry Scraps and WastesItzel HernándezNoch keine Bewertungen

- Analysis of Noble Metals: Overview and Selected MethodsVon EverandAnalysis of Noble Metals: Overview and Selected MethodsNoch keine Bewertungen

- How I Refine Gold To .999 Fine Using ARDokument11 SeitenHow I Refine Gold To .999 Fine Using ARSteveLooser100% (2)

- The Practical Gold-Worker, or, The Goldsmith's and Jeweller's Instructor in the Art of Alloying, Melting, Reducing, Colouring, Collecting, and Refining: The Progress of Manipulation, Recovery of Waste, Chemical and Physical Properties of Gold; With a New System of Mixing its Alloys; Solders, Enamels, and Other Useful Rules and Recipes.Von EverandThe Practical Gold-Worker, or, The Goldsmith's and Jeweller's Instructor in the Art of Alloying, Melting, Reducing, Colouring, Collecting, and Refining: The Progress of Manipulation, Recovery of Waste, Chemical and Physical Properties of Gold; With a New System of Mixing its Alloys; Solders, Enamels, and Other Useful Rules and Recipes.Noch keine Bewertungen

- Refining Karat Gold and Silver Jewelry Using Inquarting MethodDokument9 SeitenRefining Karat Gold and Silver Jewelry Using Inquarting MethodItzel HernándezNoch keine Bewertungen

- Gold Refining Process ChartDokument3 SeitenGold Refining Process ChartTracey0% (1)

- Finding Gold in Washington State: Third Edition -2015Von EverandFinding Gold in Washington State: Third Edition -2015Noch keine Bewertungen

- Gold Refining From ScrapDokument2 SeitenGold Refining From ScrapCarmelo NardoNoch keine Bewertungen

- Precious Metals 1982: Proceedings of the Sixth International Precious Metals Institute Conference, Held in Newport Beach, California, June 7 - 11, 1982Von EverandPrecious Metals 1982: Proceedings of the Sixth International Precious Metals Institute Conference, Held in Newport Beach, California, June 7 - 11, 1982M.I. El GuindyBewertung: 5 von 5 Sternen5/5 (1)

- Method For Ultra High Purity Gold - Gold Refining ForumDokument11 SeitenMethod For Ultra High Purity Gold - Gold Refining Forummladen lakic100% (1)

- Recovering Gold & Other Precious Metals from Electronic ScrapVon EverandRecovering Gold & Other Precious Metals from Electronic ScrapBewertung: 3 von 5 Sternen3/5 (6)

- ReactionsDokument8 SeitenReactionsdorutzuNoch keine Bewertungen

- Getting Gold: A Gold-Mining Handbook for Practical MenVon EverandGetting Gold: A Gold-Mining Handbook for Practical MenNoch keine Bewertungen

- Refining Karat Gold and Silver Jewelry Using InQuarting MethodDokument7 SeitenRefining Karat Gold and Silver Jewelry Using InQuarting MethodAFLAC ............100% (1)

- Hoke StokpotDokument8 SeitenHoke StokpotEnergyCzarNoch keine Bewertungen

- Applications: Aqua Regia InfoDokument6 SeitenApplications: Aqua Regia InfoGreg TompkinsNoch keine Bewertungen

- The Chemistry of Copper, Silver and Gold: Pergamon Texts in Inorganic ChemistryVon EverandThe Chemistry of Copper, Silver and Gold: Pergamon Texts in Inorganic ChemistryNoch keine Bewertungen

- Gold Refining Forum Handbook Vol 2 (6-24-09)Dokument72 SeitenGold Refining Forum Handbook Vol 2 (6-24-09)AFLAC ............83% (6)

- A Fast Easy Way to Recover gold from Integrated Circuit ChipsVon EverandA Fast Easy Way to Recover gold from Integrated Circuit ChipsNoch keine Bewertungen

- Aure8 InQuartation Gold Refining EquipmentDokument6 SeitenAure8 InQuartation Gold Refining EquipmentAFLAC ............100% (1)

- Gemstone Facet Cutting - A Collection of Historical Articles on Methods and Equipment Used for Working GemsVon EverandGemstone Facet Cutting - A Collection of Historical Articles on Methods and Equipment Used for Working GemsNoch keine Bewertungen

- Refining and Treatment of Palladium From Secondary ResourcesDokument7 SeitenRefining and Treatment of Palladium From Secondary ResourcesAFLAC ............Noch keine Bewertungen

- Silver and Palladium Recycling From The Secondary ResourcesDokument5 SeitenSilver and Palladium Recycling From The Secondary ResourcesAFLAC ............Noch keine Bewertungen

- Gemmological Instruments: Their Use and Principles of OperationVon EverandGemmological Instruments: Their Use and Principles of OperationBewertung: 5 von 5 Sternen5/5 (4)

- What Happens When You Breath Niric Acid FumesDokument4 SeitenWhat Happens When You Breath Niric Acid FumesAFLAC ............100% (1)

- Getting Gold: A Practical Treatise for Prospectors, Miners and StudentsVon EverandGetting Gold: A Practical Treatise for Prospectors, Miners and StudentsNoch keine Bewertungen

- Aqua Regia: From Wikipedia, The Free EncyclopediaDokument5 SeitenAqua Regia: From Wikipedia, The Free EncyclopediaImpossible Raj100% (1)

- Monolithic Chip Capacitors Source of Palladium and SilverDokument4 SeitenMonolithic Chip Capacitors Source of Palladium and SilverNoreen Castardo- MontemayorNoch keine Bewertungen

- Gold Recovery Correctly - 12 StepsDokument25 SeitenGold Recovery Correctly - 12 Stepsjuan9gonzalez_9Noch keine Bewertungen

- C. M. Hoke Refining Precious Metal Wastes-Single Pages-12252013 PDFDokument378 SeitenC. M. Hoke Refining Precious Metal Wastes-Single Pages-12252013 PDFjuan9gonzalez_9100% (2)

- Harold V Refining GoldDokument34 SeitenHarold V Refining GoldAFLAC ............100% (3)

- How To Refine Gold by The Acid MethodDokument4 SeitenHow To Refine Gold by The Acid MethodCarl FeathersNoch keine Bewertungen

- Gold Refining Forum Hanbook Vol 1Dokument128 SeitenGold Refining Forum Hanbook Vol 1AFLAC ............96% (52)

- Gold TestingDokument8 SeitenGold TestingGill Elmgren80% (5)

- Inquarting Gold NotesDokument5 SeitenInquarting Gold NotesAFLAC ............Noch keine Bewertungen

- PDFDokument6 SeitenPDFNina100% (1)

- Gold Amalgamation: Mercury, A Brief HistoryDokument37 SeitenGold Amalgamation: Mercury, A Brief HistoryAFLAC ............100% (3)

- Gold Extraction From Electronic ScrapDokument7 SeitenGold Extraction From Electronic ScrapAFLAC ............100% (2)

- Recovering Silver From Photographic MaterialsDokument32 SeitenRecovering Silver From Photographic MaterialsAFLAC ............100% (5)

- Purifying Palladium Precipitated From Dirty SolutoinsDokument5 SeitenPurifying Palladium Precipitated From Dirty SolutoinsAFLAC ............Noch keine Bewertungen

- Method To Convert Silver Sulphide Into Metalic SilverDokument9 SeitenMethod To Convert Silver Sulphide Into Metalic SilverAFLAC ............100% (3)

- Gold Dore BarsDokument2 SeitenGold Dore BarsdaelingNoch keine Bewertungen

- Gold Refining (How To)Dokument40 SeitenGold Refining (How To)adiomanovic193% (14)

- Gold Chemistry 2Dokument189 SeitenGold Chemistry 2Radulescu Eugen100% (3)

- Palladium Refining TutorialDokument9 SeitenPalladium Refining Tutorialdgodfather3150% (2)

- Instructions For Large Scale Gold RefiningDokument12 SeitenInstructions For Large Scale Gold RefiningearthplightNoch keine Bewertungen

- Ekstraksi Precious MetalsDokument1 SeiteEkstraksi Precious Metalsjaylani99Noch keine Bewertungen

- Refining and Melting Some Platinum Metals.Dokument9 SeitenRefining and Melting Some Platinum Metals.Richard.nl0% (1)

- Gold Ore Processing ServicesDokument4 SeitenGold Ore Processing ServicesMonicaNoch keine Bewertungen

- Gold Cyanide SolutionDokument2 SeitenGold Cyanide SolutionWalmir CristinoNoch keine Bewertungen

- How To Make Gold Plating Solution.Dokument10 SeitenHow To Make Gold Plating Solution.florigrig0% (1)

- Precious Metal Recovery Part 1Dokument3 SeitenPrecious Metal Recovery Part 1mladen lakicNoch keine Bewertungen

- Aqua Regia Gold RefiningDokument3 SeitenAqua Regia Gold RefiningAnna Yunita Sitompul100% (2)

- Processing Options For Gold-TelluridesDokument8 SeitenProcessing Options For Gold-TelluridesLuis Miguel La TorreNoch keine Bewertungen

- Gold Making Process PDFDokument3 SeitenGold Making Process PDFMichelle50% (2)

- Nitrogen Cycle ReportDokument26 SeitenNitrogen Cycle ReportDom GudezNoch keine Bewertungen

- Selected Titration Applications: For The Electroplating IndustryDokument36 SeitenSelected Titration Applications: For The Electroplating IndustryjakinNoch keine Bewertungen

- Nuclear ModelsDokument35 SeitenNuclear ModelsJSNoch keine Bewertungen

- Lab Report #3 - Limiting Reagent of Solution: Na CO S)Dokument3 SeitenLab Report #3 - Limiting Reagent of Solution: Na CO S)Mad BasblaNoch keine Bewertungen

- Cah2 + 2 H2O - 2 H2 + Ca (Oh) 2: Sig FigDokument4 SeitenCah2 + 2 H2O - 2 H2 + Ca (Oh) 2: Sig FigDennis KimNoch keine Bewertungen

- Spread4Dokument2 SeitenSpread4Mmasichukwu UmeriohaNoch keine Bewertungen

- Formula Writing - CambridgeDokument5 SeitenFormula Writing - CambridgeQusai Saify100% (3)

- Gabisan Let Scheck1 PDFDokument3 SeitenGabisan Let Scheck1 PDFEdrick Paras100% (1)

- Mole and Mass RatiosDokument10 SeitenMole and Mass RatiosJanne Lorraine Garcia-EleazarNoch keine Bewertungen

- The Elemental Analysis of Various Classes of Chemical Compounds Using CHNDokument6 SeitenThe Elemental Analysis of Various Classes of Chemical Compounds Using CHNMariam IshtiaqNoch keine Bewertungen

- Arsenic + AntimonyDokument3 SeitenArsenic + AntimonyTyroneNoch keine Bewertungen

- Pen and Paper Parent Proctored Test: InstructionsDokument2 SeitenPen and Paper Parent Proctored Test: InstructionsshantanuNoch keine Bewertungen

- Preparation of Potash AlumDokument12 SeitenPreparation of Potash AlumAbhishek MundaNoch keine Bewertungen

- 100 Chemistry One Liner GK Questions EnglishDokument4 Seiten100 Chemistry One Liner GK Questions EnglishVignesh100% (1)

- Mixture & Allegation: Maths by Dhasu SirDokument2 SeitenMixture & Allegation: Maths by Dhasu SirDikshit KumarNoch keine Bewertungen

- Electrolyte and Non-Electrolyte SolutionsDokument14 SeitenElectrolyte and Non-Electrolyte SolutionsSuwahono, M.PdNoch keine Bewertungen

- CESL Nickel ProcessDokument2 SeitenCESL Nickel ProcessPanji Aji WibowoNoch keine Bewertungen

- Annex Iv - Part 1 List of Colouring Agents Allowed For Use in Cosmetic ProductsDokument6 SeitenAnnex Iv - Part 1 List of Colouring Agents Allowed For Use in Cosmetic Productstary_nuryanaNoch keine Bewertungen

- β-decay and its types: Department Of Chemistry Lahore College For Women UniversityDokument9 Seitenβ-decay and its types: Department Of Chemistry Lahore College For Women UniversityAbeer BasharatNoch keine Bewertungen

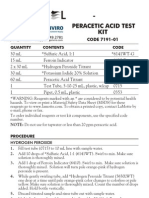

- LaMotte 7191-01 Peracetic Acid Drop Count Titration Kit InstructionsDokument3 SeitenLaMotte 7191-01 Peracetic Acid Drop Count Titration Kit InstructionsPromagEnviro.comNoch keine Bewertungen

- Tarnish & CorrosionDokument18 SeitenTarnish & CorrosionPreeti AgarwalNoch keine Bewertungen

- 10 Metal UsesDokument2 Seiten10 Metal UsesAyush Kumar0% (1)

- JIS G0321 - 2010, Product Analysis and Its Tolerance For Wrought Steel PDFDokument13 SeitenJIS G0321 - 2010, Product Analysis and Its Tolerance For Wrought Steel PDFRolando Castillo100% (1)

- Water PowerpointDokument16 SeitenWater PowerpointMarie St. LouisNoch keine Bewertungen

- Daewoo Chassis CM-530A DTH1450FSDokument25 SeitenDaewoo Chassis CM-530A DTH1450FScarlosvNoch keine Bewertungen

- Adsorption of Heavy Metals-A ReviewDokument6 SeitenAdsorption of Heavy Metals-A ReviewEdwardGuevaraOrtizNoch keine Bewertungen

- D and F BlockDokument8 SeitenD and F BlockAnanyaNoch keine Bewertungen

- ComplexoDokument14 SeitenComplexoFamiFatwaNoch keine Bewertungen

- Rusting of IronDokument18 SeitenRusting of IronKrutika BandreNoch keine Bewertungen

- Coordination Compounds - QuestionDokument3 SeitenCoordination Compounds - Questionbest badmintonNoch keine Bewertungen

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincVon EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincBewertung: 3.5 von 5 Sternen3.5/5 (137)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeVon EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeBewertung: 4 von 5 Sternen4/5 (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeVon EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeBewertung: 5 von 5 Sternen5/5 (4)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsVon EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsBewertung: 4 von 5 Sternen4/5 (146)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolVon EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNoch keine Bewertungen

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactVon EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactBewertung: 5 von 5 Sternen5/5 (5)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeVon EverandChemistry for Breakfast: The Amazing Science of Everyday LifeBewertung: 4.5 von 5 Sternen4.5/5 (90)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableVon EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsVon EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNoch keine Bewertungen

- Tribology: Friction and Wear of Engineering MaterialsVon EverandTribology: Friction and Wear of Engineering MaterialsBewertung: 5 von 5 Sternen5/5 (1)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideVon EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNoch keine Bewertungen

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Transformer: The Deep Chemistry of Life and DeathVon EverandTransformer: The Deep Chemistry of Life and DeathBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Bioplastics: A Home Inventors HandbookVon EverandBioplastics: A Home Inventors HandbookBewertung: 4 von 5 Sternen4/5 (2)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsVon EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsBewertung: 5 von 5 Sternen5/5 (3)

- High School Chemistry: Comprehensive Content for High School ChemistryVon EverandHigh School Chemistry: Comprehensive Content for High School ChemistryNoch keine Bewertungen

- The Periodic Table: A Very Short IntroductionVon EverandThe Periodic Table: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookVon EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNoch keine Bewertungen

- Fundamentals of Chemistry: A Modern IntroductionVon EverandFundamentals of Chemistry: A Modern IntroductionBewertung: 5 von 5 Sternen5/5 (1)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilVon EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilBewertung: 5 von 5 Sternen5/5 (1)