Beruflich Dokumente

Kultur Dokumente

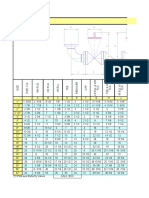

Condensed Induced Waterhammer

Hochgeladen von

Eugenio DurbanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Condensed Induced Waterhammer

Hochgeladen von

Eugenio DurbanCopyright:

Verfügbare Formate

Condensation-Induced W

T he steam pipe started to

vibrate and shake. Don

yelled to Clyde Lets get the Hell

out of here...this things going to blow!

Clyde stuck his head out from where he

was removing insulation beneath the

steam pipe. He heard a loud roar rum-

bling down the steam line like a freight

train coming from the direction of the C-4

manhole. Don was already clamoring up

the exit ladder. Clyde slid from beneath

the maze of pipes and scrambled up

the ladder after him. Don was trying

to break through the Visqueen

plastic sheet that covered the

manhole. It was sealed tight

to prevent asbestos

fibers from escaping.

This is the type of waterhammer that kills

operators.1 It can easily be 100 times more

powerful than conventional waterhammer

driven by steam flow, yet few engineers

and operators understand its cause

By WAYNE KIRSNER, PE,

Kirsner Consulting Engineering, Inc., Atlanta, Ga.

112 HPAC Heating/Piping/AirConditioning January 1999

there, he was able to hoist himself

through the plastic-covered open-

Waterhammer

ing. He emerged with second and

d third degree burns, but otherwise,

he was okay.

Wayne stumbled through the pip-

ing to the other material pass-out.

His first jump was too weak, and he

fell back onto the piping, which by

now was becoming slippery with

A white steam cloud rolled down Bobby nudged past his co- condensing steam. Air temperature

the utilidor from the direction of worker, Wayne, as he made his in the utilidor was approaching 200

C-4 and began to flood the man- way over to the material passout F. Wayne desperately collected

hole. Another worker fleeing the and yelled up through the plastic himself. He knew that this might be

encroaching steam crawled up be- flaps to his boss Shes spinnin his final chance. He groped his way

hind them. Together, they desper- freely. Is it okay to open her up all back up onto the slippery pipes,

ately tore at the stubborn the way? The supervisor was took a breath of the searing air, and

Visqueen seal until it finally gave puzzled, too. No, finally came leapt up again into the plastic-

way, shoved open the steel hatch the muffled response. Better con- covered opening. This time he was

above, and tumbled out into the tinue to open her a little at a time able to hook one elbow above the rim

fresh air. The swelling heat from like we were told to do. About a and, with his life on the line, kick up

the utilidor rose around them. Up minute had elapsed since Bobby through the opening.

top, there was pandemonium. had opened the valve enough to Clyde and Don saw Wayne

Steam was billowing out the C-4 lift it off its seat. As Bobby turned crawl out through the plastic flaps

manhole as well as the manhole back to the valve, a pop was of the material passout. He rose to

theyd just exited. Fire engines heard. Then a moment later, KA- his feet and started screaming for

were arriving. Men were shouting BOOM! Hot water and steam ex- help. His protective clothing was

and trying to figure out who was ploded from the 10 in. valve. A shredded. Loose skin was slough-

still down in the utilidors. Two white cloud of flashing condensate ing off his exposed arms and legs.

other workers, Bobby and Wayne, and steam filled the utilidor with He was badly burned. Clyde yelled

had not gotten out. a suffocating wave of heat. Wayne at passers-by to call an ambulance

Moments earlier, before the acci- was knocked down and stunned as they ushered Wayne away from

dent, Bobby had opened the 10 in. by the scalding water spraying the steaming manholes. Soldiers

gate valve at Manhole C-4 a second from the valve. Egress via the with a knowledge of first-aid

incremental turn. He thought, manhole exit was cut off by steam rushed him to a barracks across

This is strange; the valves hand- spraying from the valve. The only the street and started to apply cold

wheel spun freely. Just 15 min way out appeared to be through packs to his burns and gave him

earlier, hed cracked open the 10 the material passouts constructed cold drinks. Waynes throat was

in. cast iron valve to admit steam into the roof of the utilidor. Bobby beginning to constrict. An ambu-

into the 2200 ft steam line to begin clambered up on top of the pipes lance arrived to rush Bobby and

warming it up. For three weeks and jumped up catching his Wayne to the hospital. As the in-

now, hed been energizing the G- armpits above the opening. From jured workers were being cared

Line at the end of the asbestos

workers shift and had never had

n of s

the system warm up this quickly. It ctio gres

Dire ent pro

usually took about 30 to 45 min. bate

m

a

When the handwheel spun freely, G-1

he understood the lack of friction to

mean that steam pressure on ei-

ther side of the valve had equal- 0 ft

216 G-4

ized, so the warm-up was complete.

He could open the valve the rest of

the way. This seemed too quick

though. Hed better check with his G-9

supervisor before spinning the th Manhole and trap location

Nor

valve all the way open. Isolation valve

C-4

H-1

1 Pipe slope down

Mr. Kirsner wrote the July 1995

HPAC article What Caused the Steam

Accident that Killed Jack Smith. 1 Isometric view of G- and H-Lines (no scale).

January 1999 HPAC Heating/Piping/AirConditioning 113

STEAM ACCIDENT

for, Clyde turned his fury on his gizing the steam line daily. For the Abatement began at Manhole G-

supervisor and screamed, We told three weeks before the accident, 1 and headed south toward C-4 at

you this would happen. this was the procedure. By the be- the rate of 125 ft a day. As abate-

ginning of the laborers workday, ment proceeded down the G-Line,

What happened temperatures in the utilidors were local traps serving the uninsulated

For four weeks, asbestos work- still around 120 F, but with fre- portion of the line were over-

ers had been removing asbestos in- quent breaks to cool off and re-hy- whelmed with condensate during

sulation from the 2200 ft section of drate, conditions were tolerable. the period that the lines were ener-

steam main known as the G-Line Unfortunately, discomfort to gized each day. In the first two

and the 120 ft H-Line (Fig. 1). Like the workers was not the only con- weeks, however, this did not cause

all steam mains at Fort Wain- sequence of removing the insula- a problem. Excess condensate

wright, Alaska, the G- and H-Lines tion from active steam mains that merely rolled down to C-4 on the

ran underground in narrow utili- had gone unforeseen. There was south end and G-1 on the north

dors2 filled with pipe. Originally, also the effect on the steam traps. end. Traps on the south end, still

the contractor had tried to abate At each manhole, a 3/8 in. thermo- serving insulated portions of the

the steam main with the lines en- dynamic trap was installed, ex- line, had adequate capacity to re-

ergized. This proved to be near im- cept C-4, which contained a 1/2 in. move the excess condensate. On

possible for the workers. Utilidor trap. At the systems operating the north end, the steam valve was

temperatures reached 160 F as in- conditions, the 3/8 in. traps could left closed, so trouble was avoided.

sulation was removed from the 325 remove 295 lb of condensate per After two weeks of daily startups

F pipe carrying 80 psig steam. La- hr.3 With 31/2 in. of insulation, 300 without a serious incident, save

borers who had to be suited-up and ft of 12 in. pipe generates 41 lb of some minor waterhammers, asbes-

masked to work in the asbestos- condensate per hr. Thus, for a typ- tos crew operators grew confident

laden environment were passing ical pipe segment, the traps had that startup of the steam line was

out from the heat and/or were quit- better than a 7 to 1 safety factor no big deal.

ting. The contractor was forced to for condensate removal with the By the beginning of the third

seek relief from the owner. A com- line insulated. With the insula- week, insulation removal had

promise was negotiated after the tion removed, however, heat loss reached Manhole G-9. Calcula-

first weeksteam would be de-en- increased by almost a factor of 18 tions showed that at this point the

ergized at midnight before each so that condensate formation rate of condensate being generated

workday, and asbestos abators jumped to 729 lb per hr over 300 ft in the southern section of the G-

would start work at 4:00 AM and of pipe. At this rate of heat loss, Line began to exceed the net capac-

finish by noon at which time steam the 3/8 in. traps had less than one- ity of the traps to remove it. Con-

would be restored. The asbestos re- half the capacity needed to keep densate accumulation during

moval contractor would be respon- up with the condensate produc- steam operation is potentially de-

sible for de-energizing and re-ener- tion. This was not good. structive. But even so, as long as

2 3

condensate is religiously drained

Shallow underground utility tunnels Trap conditions were 80 psig with a everyday before startup, a cata-

capped with removable concrete lids. 10 psig backpressure.

strophic waterhammer accident

might still be averted. The problem

was that condensate wasnt being

Steam drained religiously. The asbestos

Condensate

workers given responsibility for

energizing the steam main daily

C-4 H-1 didnt fully anticipate the danger

inherent in starting up a high-

2 H-Line full of condensate to overflowing. continued on page 116

Steam

South North H-Line

80 psig steam

Steam from G-1

Steam

C-4 bleeder To trap

3 Conditions before C-4 valve opened.

114 HPAC Heating/Piping/AirConditioning January 1999

STEAM ACCIDENT

Condensing steam

entrapped

continued from page 114 Seal forms

pressure steam system with con-

densate in it. They did not rou-

tinely open drain valves to bleed

the system of excess condensate ei- Fig. A

ther at night, when they shut down

the system, or at noon, when they

re-admitted steam through the C-4

valve to re-energize the steam

main. Their belief was that steam

admitted through the C-4 valve Condensate seal

would blow condensate to the far sucked up riser

end of the main at G-1. Thus, in Steam

their view, only the drain at G-1

really needed to be opened at

startup. Accordingly, there was a

tacit understanding that the Fig. B

bleeder valve at G-1 would be

opened daily by the quality control

supervisor for the prime contrac-

tor, and any condensate that was-

nt drained at startup, they appar-

ently thought, would be mopped up

by traps after startup.

As the third week began, the Steam

severity and frequency of water-

hammer began to accelerate.

Residual condensate accumulated

in the steam pipe at C-4 due not Fig. C

only to operation of the uninsu-

lated steam main but also due to

condensate formed at startup that Condensate Collection in Vertical Lines

went undrained. Early in the

third week, heavy banging forced

workers to evacuate the utilidor.

C ondensate will fill a vertical take-off like the H-Line against gravity

if the horizontal line beneath it becomes filled or nearly filled with

condensate. To illustrate this point, I have exaggerated the rise of the

Clyde, one of the more vocal evac- H-Line in the figures below. Fig. A shows steam flowing into all open

uees, warned the abatement su- portions of the steam line and condensing. The condensing steam

pervisor, This thing sounds like causes a reduction in local pressure that induces steam movement to

its ready to explode . . . What are flow in to replace it. If the horizontal section of steam pipe fills or be-

you going to do about it? comes nearly full, a condensate seal forms that isolates the steam

By Wednesday of the third downstream of the seal. Condensing steam in the pocket causes the

week, all the insulation had been pressure to fall. The falling pressure in the isolated steam pocket will

stripped from the G- and H-Lines. then suck up condensate into the pocket to fill the void. The result is

The lines were completely bare. shown in Fig. C.

By the next morning, the day of

the accident, calculations showed

that sufficient condensate had ac- tion, condensate accumulated in Condensate also accumulated

cumulated at C-4 to fill the line the 120 ft long H-Line. Due to a each night in the double-elbow

adjacent to the valve completely design oversight, there was no riser to the south of the C-4 valve

and extend over 300 ft up the drain or trap upstream of the gate (Fig. 3). During the period after

steam line toward G-9.4 In addi- valve at H-1. The contractor, not midnight when the C-4 valve was

4 comprehending the pitch of the H- closed, steam condensed in the

Before the line completely filled, how-

Line, did not realize that conden- uninsulated double-elbow riser

ever, much of the condensate blocking

the steam entrance at C-4 would be sate would accumulate against and came to rest against the south

swept downstream toward G-1 by the the H-1 valve during the three side of the closed valve. From mid-

steam entering through the valve. weeks of on-off steam operation. night until noon the following

Later, it would be swept back as ex- Hence, the line filled with conden- day, enough condensate accumu-

plained later. sate as depicted in Fig. 2. lated to almost fill the riser.

116 HPAC Heating/Piping/AirConditioning January 1999

Condensation-Induced Waterhammer vs.

Conventional Steam Flow

Driven Waterhammer

On the day of the accident,

there was a change in the startup

W aterhammer, according to a

major steam trap manufac-

turers engineering guide, is the

densation-induced waterhammer

is due to the compression of water

by a piston formed by a moving

procedure. To isolate another impact caused by a sudden stop- plug of water. This is the same phe-

steam main for repair work, the ping of a rapidly moving slug of nomena that generates waterham-

contractor needed to energize the water. The guide goes on to ex- mer in a hydronic, single-phase

G-Line early. The asbestos crew plain that: system, i.e., plumbing. The formula

was instructed to start up the G- [Unless] condensate is removed to calculate the magnitude of the

Line 1 hr and 15 min before their from low points...ripples form on maximum pressure pulse is:

quitting time. In addition, but un- the condensate surface...until con-

beknownst to the asbestos crew, densate so restricts steam flow

the contractors quality control that a slug of condensate is carried

supervisor decided to expedite down the main by the steam. The

warm-up in the G-Line by admit- slug of water travels at the speed of

ting steam through the G-1 valve steam (which may be in excess of

at the far end of the G-Line as well 100 mph) until some obstruction is Note that Equation 1 is similar

as through C-4. The G-1 valve was reached...[and]...the slug of water to Equation 2 except that c re-

opened as much as 30 min before is suddenly stopped often with dis- places one v. Whats the relevance

Bobby first cracked open the C-4 astrous results...1 of the speed of sound? The sonic

steam valve. This had the likely The waterhammer described speed squared, c2, is in essence a

effect of sweeping the undrained above is but one type of water- shorthand notation for the ratio of

condensate residing against the hammer. I term it steam flow the stiffness of the material, rep-

G-1 valve on the north end of the driven waterhammer. It describes resented by Youngs Modulous E,

line south to C-4, and completely an impact event where a slug of divided by the density of the ma-

filling the H-Line as shown in the fast moving water strikes a sta- terial, i.e.,

sequence of figures in Sidebar 1. tionary object and gives up its mo-

The situation, then, as Bobby pre- mentum much like an ocean wave c = E /

pared to crack open the C-4 valve striking a sea wall. The formula Clearly, the magnitude of a

15 min before the accident, is for the maximum impact pressure pressure pulse reverberating

shown in Fig. 3. over the target area is: through, for example, a piece of

Subcooled condensate filled the steel compressed upon collision,

steam line on both sides of the C-4 would in some measure be a func-

valve in addition to filling the H- tion of the stiffness of the steel.

Line completely. High-pressure The same is true for water. Hence,

steam admitted through G-1 had the dependence on c is really a de-

pressurized the steam main and For water at 60 lb per cu ft and pendence on E.

was sitting atop the condensate v = 100 mph, Pmax = 279 psi. Lab At 4300 fps, c is roughly two or-

on the north side of C-4. The south experiments indicate that peak ders of magnitude larger than v.

side of the valve was also under pressures for actual events are Thus, the over-pressurization

steam pressure, which based on typically less than the maximum generated by condensation-in-

testimony, was likely slightly less theoretical value.2 duced waterhammer can be 10 to

than that on the north side. Condensation-induced water- 100 times greater than that

Now, put yourself in Bobbys hammer is a different animal. The caused by steam-flow driven wa-

place, except assume you know all pressure pulse generated by a con- terhammer.

the information described above. In

1

your minds eye, you can visualize Sarco Hook-up Designs for Steam & Fluid Systems, 1981.

2

the build-up of condensate shown Neumann & Griffith, Forces on a Pipe Bend Resulting from Clearing a Pool of

in Fig. 3. You figure out, based on Liquid Upstream, PVB-Vol. 224/Fed-Vol. 126, Fluid Transients and Fluid

the ease with which the valves Structure, 1991.

handwheel spun, that there is full

For more information, contact Mr. Kirsner at www.kirsner.org

steam pressure atop the conden-

sate. Ask yourself two questions:

Is this situation dangerous? from moving quickly and thus explains why this type of event is

Some steam people would say, prevent a waterhammer. This is 10 to 100 times more powerful

No, as long as there is no fast- wrong, dead wrong. High-pres- than conventional steam flow

moving steam, theres no danger sure steam in contact with sub- driven waterhammer.

of waterhammer. Opening C-4 cooled condensate is dangerous. What would you have done in

slowly and incrementally should Its a recipe for condensation-in- Bobbys place? If your answer is,

prevent steam or condensate duced waterhammer. Sidebar 2 continued on page 119

January 1999 HPAC Heating/Piping/AirConditioning 117

STEAM ACCIDENT

continued from page 117 Think of the last time you did a pressure steam and excess con-

Id first open the C-4 bleeder belly flop off a diving boardthe densate by making sure steam

valve to drain the condensate, water felt pretty stiff, didnt it? mains are properly trapped, and

youre toast. Although, this is the The specific factors that influ- live steam is kept out of conden-

answer most steam operators ence the severity of a condensa- sate-return systems. Neverthe-

would give, it will trigger the acci- tion-induced waterhammer are: less, it does happen. Condensate

dent. Neither the bleeder valve The steam pressure lines, for instance, are often heard

nor the steam valve can be opened The degree of condensate to pop and bang when steam

without provoking this accident. subcooling squirts into them through traps.

To understand why, its crucial for The presence of non-condens- Why dont the collapsing steam

steam fitters and operators to un- ables left over in the void bubbles destroy condensate

derstand the mechanism of con- The size of the void pipes? They can over time. But,

densation-induced waterhammer. If the steam pressure is high, the shock waves generated are not

the condensate is subcooled, non- catastrophic because the pressure

Condensation-induced condensables are absent, and the in a condensate system is gener-

waterhammer void is large enough for a slug of ally lowon the order of just a

A condensation-induced water water to pick up some velocity. few psi, subcooling is not great,

hammer is a rapid condensation The over-pressure resulting from and the steam bubbles are small.

event. It could also be aptly an event can easily exceed 1000 Of course, high-pressure steam

termed a rapid steam bubble col- psi. This is enough pressure to can contact subcooled condensate

lapse. It occurs when a steam fracture a cast iron valve, blow out in steam lines when something

pocket becomes totally entrapped a steam gasket, or burst an accor- goes wrongfor example, when a

in subcooled condensate. As the dion-type expansion joint. And, in trap assembly becomes plugged

steam gives up its heat to the sur- fact, failure of each of these com- with scale causing a drip leg to fill

rounding condensate and pipe ponents in separate condensation- with condensate. Why dont situa-

walls, steam changes from a va- induced waterhammer accidents tions like this result in destruc-

por to a liquid state. As a liquid, has resulted in operator fatalities. tive, condensation-induced water-

the volume formerly occupied by One might ask at this point, hammer? One reason is pipe

the steam shrinks by a factor But wait, isnt it common for geometry. A steam bubble must

ranging from several hundred to steam and condensate to come become entrapped for there to be a

over a thousand, depending on into contact in a steam system? collapse. In a vertical pipe such as

the saturated steam pressure. Good design and operating prac- a drip leg where steam is above

Likewise, the pressure in the void tice aim to avoid mixing high- the condensate, its difficult to en-

drops to the saturated trap the steam because

vapor pressure of the natural buoyancy tends

surrounding condensate. Condensing steam Heat loss to keep the two fluids sep-

(For example, the satu- Steam arate. 5 In fact, research

rated vapor pressure of experiments show that

condensate at ambient Subcooled condensate Bernoulli Effect its difficult to entrap a

draws up wave

temperature is less than steam void in any pipe

1 psia.) This leaves a Isolated steam sloped downward in the

pocket Wave seals pipe

low-pressure void in the direction of steam flow

space formerly occupied more than 1/2 in. in 1.0 ft.6

by the steam that the Subcooled condensate Steam At slopes less than this,

surrounding condensate, however, and in upwardly

under steam pressure it- sloped pipes, its a differ-

self, will rush in to fill. Collapsing steam ent story.

void

The resulting collision of 80 psig steam

At Fort Wainwright,

condensate generates an 5

over-pressurization that A condensation-induced

reverberates throughout waterhammer is possible if a

the portion of the pipe vertical pipe is drained ex-

BAM! tremely fast.

filled with condensate.

How severe is the over- Rebounding wave 6

Griffith and Silva. Steam

pressurization? Remem- Bubble Collapse Induced

ber that water is virtu- Waterhammer in Draining

ally incompressible. In a 4 Steam entrapment and slug formation in a horizontal Pipes, PVP-Vol. 231, ASME,

collision, it does not give. line. 1992.

January 1999 HPAC Heating/Piping/AirConditioning 119

STEAM ACCIDENT

the pipe slope to C-4 is 1/ 4 in. in stream supply creating a steam boundary layer insulates the

10.0 ftnormal for a steam line. pocket. Ongoing condensation in steam void. On the one hand, the

Thus, the line is nearly horizontal. the isolated steam pocket drops layer prevents rapid condensa-

How does steam become en- the pressure, causing a slug to ac- tion, but on the other, it can allow

trapped when resting atop sub- celerate into the void. a steam void to grow in magnitude

cooled condensate in a nearly hori- The formation of a condensate and potential energy like an over-

zontal line? The sequence below bridge or seal is a necessary condi- expanded balloon. Often times,

explains how (Fig. 4). tion for a rapid condensation there will be no rapid condensa-

Steam residing over sub- event in a horizontal line. Often, tion event if the layer goes undis-

cooled condensate loses heat to however, heat transfer is not turbed. Steam will fill a pipe atop

the condensate and the surround- rapid enough to induce sufficient subcooled condensate without in-

ing pipe, which causes the steam steam flow to seal the pipe and to cident. Minor collapses may occur,

but due to the lack of rapid heat

transfer, they will be mild and go

South North H-Line unnoticed. If, however, the insu-

Expansion lating layer is disturbed in such a

joint Steam way that the layer is breached at

some point, then the local intru-

sion of subcooled condensate can

result in a chain reaction, which

Bleeder valve

To trap

shatters the entire insulating

layer. In a millisecond, the rate of

heat transfer can increase a thou-

sand fold, inducing a rapid steam

5 Steam encroachment as condensate is drained.

influx that seals the pipe and sets

off a rapid condensation event, re-

sulting in condensation-induced

waterhammer. The key, then, to

whether or not an event is initi-

ated depends on the occurrence of

a trigger to cause interface shat-

tering.

Back at the accident

Now, return to Manhole C-4 15

min before the accident. Bobby

had opened the bleeder valve at C-

4 for the first time per a special in-

struction from the quality control

supervisor. He then proceeded to

crack open the C-4 steam valve.

Both of these actions presumably

resulted in condensate draining

Photo 1 The model pictured was constructed to simulate the accident.

from the system on the north side

to condense. The continual loss of cause a rapid steam bubble col- of the C-4 valve. The pipe volume

steam induces fresh steam to flow lapse. In fact, generally, a trig- vacated by the draining conden-

in to replace it. Steam flow over ger is needed to initiate a conden- sate at C-4 drew in steam along

condensate will tend to draw up a sation-induced waterhammer in a the top of the pipe from the north

wave in the condensate via the horizontal line where neither to replace it (Fig. 5). Fifteen min

Bernoulli effect. steam nor condensate is flowing after the first crack, Bobby opened

I f t h e r a t e o f h e a t trans- through the pipe. Thats because the C-4 valve againthis time

fer is rapid enough for a given con- in a non-flowing situation, heat lifting the disk 1/2 in. off its seat.

densate level, the induced steam transfer between the steam and This action accelerated the re-

velocity will draw up a wave high condensate is retarded by a stag- moval of condensate and the ad-

enough to bridge the pipe. nant layer of hot condensate and vance of steam along the top of the

The formation of a bridge non-condensables laid down by pipe toward C-4.

immediately isolates the down- steam as it condenses atop cooler The model pictured in Photo 1

stream steam pocket from the up- condensate. This interphase was constructed to simulate the

120 HPAC Heating/Piping/AirConditioning January 1999

accident. From this point on, Ill As the tongue of steam reached enough to be termed waterham-

describe what we understand to down the nearly horizontal line to- mer events. When the steam fi-

have occurred based on tests with ward C-4, it probably collapsed nally reached the vertical opening

this model and others used to in- several times as seals developed, to the H-Line, the steam licked up

vestigate the accident (Fig. 6). but the collapses were not violent around the corner seeking to flow

up into the H-Line riser. This was

the trigger necessary to set off the

South North event. The tip of the tongue dis-

H-Line tended, then detached, releasing a

Steam bubble containing steam and non-

condensables that rose up into the

vertical H-Line while an equal vol-

ume of subcooled water spilled

C-4 valve

Bleeder valve down into the G-Line. The remain-

To trap

der of the steam tongue quickly

snapped back into the G-Line after

releasing the bubble. The release

South North of the bubble and the exposure to

H-Line the cool condensate assaulted the

Steam

stability of the boundary layer. It

caused a ripple to reverberate

down the length of the steam-con-

densate interfaceperturbing it

and accelerating heat transfer.

Bleeder valve

To trap This could have been sufficient to

trigger the event. It depends on

how much air had seeped into the

system during cooling. As conden-

South North sate continued to drain, steam ad-

H-Line

6 Frame-by-frame animation

of a condensation-induced

waterhammer event.

Bleeder valve

To trap

South North Anchor

H-Line

Wave crashing into void

South

Bleeder valve

To trap

Waterhammer

over-pressure

South North

BAM!

Steam and

Bleeder valve condensate

To trap

7 Illustration of a valves deflection

during the waterhammer event.

January 1999 HPAC Heating/Piping/AirConditioning 121

STEAM ACCIDENT

vanced toward the H- Line open- subcooled condensate, but that it if you cannot be absolutely certain

ing a second time, again peeking is FULL and resting against the that the line has been completely

around the corner, and again re- valve he is about to open. The drained.

leasing a bubble of steam and non- question isIs it possible, given Allowing subcooled conden-

condensables. This time the inter- the circumstances with which sate to flow into a steam-filled line

face shattered. The entrapped hes confronted, to avoid this ac- is more dangerous than admitting

steam pocket collapsed hard, cident? steam into a line with subcooled

whipping a slug of water

from the north into the col-

lapsing void at C-4 with a

load snap. The collision of

the slug with the conden-

sate at C-4 created an over-

pressurization that re-

bounded throughout the

water-filled portion of the

system, including up the H-

Line where Clyde and Don

would have been working.

At Fort Wainwright, the

overpressure caused the

double-elbow riser at C-4

to compress as shown in

Fig. 7. The pipe and valve

flanges twisted in response

to the deflection of the dou-

ble-elbow riser. The twist-

ing flange caused the cast

iron valve body to crack at

the flange neck, causing Photo 2 This shows the actual damage to the valve.

first condensate, then

steam to spray from the valve. The answer is YES. But, theres condensate.

The actual damage to the valve is only one way. Cut the steam off. If you suspect that a pressur-

shown in Photo 2. Dont open the C-4 steam valve. ized steam line is filled with sub-

Dont open the bleeder valve. cooled condensate, dont attempt

Could this accident have been Youve got to exit the manhole and to drain the condensate. Shut the

prevented? close the G-1 steam valve, then steam off first; then, drain the

Of course. Numerous procedu- drain the lines to empty the con- condensate. If you do open a drain

ral blunders should be obvious to densate. This is what must be and the line hammers, close it and

experienced steam operators and done to avoid a condensation-in- get the steam off. The line may

their supervisors as they read duced waterhammer in the situa- continue to hammer until you get

this articlenot the least of tion described. Trying to drain the the steam off.

which is assigning responsibility condensate with high-pressure A mixture of steam above

for startup of a high-pressure steam atop the subcooled conden- subcooled condensate can sit dor-

steam system to untrained as- sate will trigger a rapid condensa- mant in an isolated steam line

bestos workers. But, Im most in- tion event. like a loaded gun awaiting a trig-

terested in putting the question gering event. Opening a valve to

above to the guy whos in the last In conclusion... admit steam or opening a bleeder

line of defensethe steam oper- Heres what I want steamfitters to drain condensate can trigger

ator standing in Bobbys shoes and operators to know: the event. Dont let yourself or

with his hands on the valves High-pressure steam in con- those you supervise inadver -

handwheel just moments before tact with subcooled condensate is tently pull that trigger without

the accident. Suppose from the an unstable and potentially explo- first making sure the gun is un-

feel of the valves handwheel, he sive mixture. loaded. HPAC

surmises that there already Dont admit steam into a line

must be full steam pressure on filled with subcooled condensate.

the steam line, and he believes In fact, always be wary of admit-

not only that the line contains ting steam to any cold steam line

122 HPAC Heating/Piping/AirConditioning January 1999

Das könnte Ihnen auch gefallen

- 1929 MONONOBE On The Determination of Earth Pressure During EartquakesDokument9 Seiten1929 MONONOBE On The Determination of Earth Pressure During EartquakesEugenio DurbanNoch keine Bewertungen

- IEC 61643-22 DraftDokument43 SeitenIEC 61643-22 DraftDinan Ibnu HuseinNoch keine Bewertungen

- 1957 HOUSNER Dynamic Pressures On Accelerated Fluid ContainersDokument21 Seiten1957 HOUSNER Dynamic Pressures On Accelerated Fluid ContainersEugenio Durban100% (1)

- Fire in the Night: The Piper Alpha DisasterVon EverandFire in the Night: The Piper Alpha DisasterBewertung: 4.5 von 5 Sternen4.5/5 (5)

- 1924 OKABE General Theory On Earth Pressure and Seismic Stability of Retaining Wall and Dam ENGLISHDokument47 Seiten1924 OKABE General Theory On Earth Pressure and Seismic Stability of Retaining Wall and Dam ENGLISHEugenio Durban100% (2)

- Tutorial 9Dokument7 SeitenTutorial 9angel lopezNoch keine Bewertungen

- When Removing Insulation Turns Deadly Waterhammer W Kirsner 2019Dokument7 SeitenWhen Removing Insulation Turns Deadly Waterhammer W Kirsner 2019Karel OstenNoch keine Bewertungen

- 34 Ca Naked PDFDokument4 Seiten34 Ca Naked PDFCatalin VelcsovNoch keine Bewertungen

- 71E Reading PDFDokument8 Seiten71E Reading PDFPJ MillerNoch keine Bewertungen

- The Return to the Lost El Dorado: The Lost El Dorado Series, #2Von EverandThe Return to the Lost El Dorado: The Lost El Dorado Series, #2Noch keine Bewertungen

- Technical ErrorDokument11 SeitenTechnical ErroreroteNoch keine Bewertungen

- 16F.Eulogy For ZingaroDokument4 Seiten16F.Eulogy For ZingarocarlNoch keine Bewertungen

- WOPU0815 Feat Singe ValveDokument8 SeitenWOPU0815 Feat Singe ValvePhạm PhátNoch keine Bewertungen

- Activity #5 Identifying Specific VulnerabilitiesDokument3 SeitenActivity #5 Identifying Specific Vulnerabilitiesmary graceNoch keine Bewertungen

- Duxbury Clipper 2011 - 02 - 02Dokument44 SeitenDuxbury Clipper 2011 - 02 - 02Duxbury ClipperNoch keine Bewertungen

- We're Not Afraid To Die...Dokument8 SeitenWe're Not Afraid To Die...vaasoli bhaiNoch keine Bewertungen

- Franklin's Philadelphia ExperimentDokument17 SeitenFranklin's Philadelphia ExperimentHarry KyriakodisNoch keine Bewertungen

- The R-Ll/Dio-Ll/Ctive: Boy ScoutDokument14 SeitenThe R-Ll/Dio-Ll/Ctive: Boy ScoutgwillimwNoch keine Bewertungen

- G3 Volcanic HazardsDokument14 SeitenG3 Volcanic Hazardsmaejesh088Noch keine Bewertungen

- Reading+Lab+ +Final+Reading+Assessment+Fall+2023Dokument3 SeitenReading+Lab+ +Final+Reading+Assessment+Fall+2023qq1421491981Noch keine Bewertungen

- Collector's Edition - A Retrospective of The Past 40 YearsDokument8 SeitenCollector's Edition - A Retrospective of The Past 40 YearsAnonymous PYzK0pDkNoch keine Bewertungen

- Scandinavian Studies Volume 85 Issue 3 2013 (Doi 10.5406/scanstud.85.3.0332) Pernille Hermann - Saga Literature, Cultural Memory, and StorageDokument4 SeitenScandinavian Studies Volume 85 Issue 3 2013 (Doi 10.5406/scanstud.85.3.0332) Pernille Hermann - Saga Literature, Cultural Memory, and StorageMarioMartinPaezNoch keine Bewertungen

- Surviving A Steam Rupture in An Enclosed SpaceDokument3 SeitenSurviving A Steam Rupture in An Enclosed SpaceDenny SaputraNoch keine Bewertungen

- MODULE 7. Water Supply and StorageDokument9 SeitenMODULE 7. Water Supply and StorageLemuel Maliwat DupitasNoch keine Bewertungen

- Full Campaign DebriefingDokument24 SeitenFull Campaign DebriefingcyberquasitNoch keine Bewertungen

- Star of The SeaDokument1 SeiteStar of The SeafreddieNoch keine Bewertungen

- Sept11.NY NYT PDFDokument1 SeiteSept11.NY NYT PDFfiacominiNoch keine Bewertungen

- Series: High Pressure BoilerDokument4 SeitenSeries: High Pressure BoilerRafael CalleNoch keine Bewertungen

- The Man of Steel: Superman and the Poisoned PlanetVon EverandThe Man of Steel: Superman and the Poisoned PlanetBewertung: 4 von 5 Sternen4/5 (5)

- Story 10 - MistDokument20 SeitenStory 10 - MistKonkmanNoch keine Bewertungen

- ComprehensionDokument1 SeiteComprehensionArun PrakashNoch keine Bewertungen

- The Sequence of Deel: e I C An Adventure Location by Michael PrescottDokument2 SeitenThe Sequence of Deel: e I C An Adventure Location by Michael PrescottAlpamys Sultanbek100% (1)

- DOD Film Office File On Ice Station ZebraDokument68 SeitenDOD Film Office File On Ice Station ZebraSpyCultureNoch keine Bewertungen

- STARGATE ATLANTIS Third Path (Legacy book 8)Von EverandSTARGATE ATLANTIS Third Path (Legacy book 8)Bewertung: 5 von 5 Sternen5/5 (1)

- Vocabulary 10TH Final Exam 2ND Term. 2022Dokument6 SeitenVocabulary 10TH Final Exam 2ND Term. 2022Sharick MonsalvoNoch keine Bewertungen

- The Great Stink: A Novel of Corruption and Murder Beneath the Streets of Victorian LondonVon EverandThe Great Stink: A Novel of Corruption and Murder Beneath the Streets of Victorian LondonBewertung: 5 von 5 Sternen5/5 (1)

- Temp WindowDokument17 SeitenTemp WindowEugenio DurbanNoch keine Bewertungen

- Capitulo 1 Introduccion CFD Con Open FoamDokument33 SeitenCapitulo 1 Introduccion CFD Con Open FoamDennys SarangoNoch keine Bewertungen

- 2003 - Lithium Free Surface Flow Experiment ForDokument6 Seiten2003 - Lithium Free Surface Flow Experiment ForEugenio DurbanNoch keine Bewertungen

- 2002 - Thermal-Hydraulic Characteristics of IFMIF Liquid Lithium TargetDokument10 Seiten2002 - Thermal-Hydraulic Characteristics of IFMIF Liquid Lithium TargetEugenio DurbanNoch keine Bewertungen

- 2005 - Surface Wave On High Speed Liquid Lithium Flow ForDokument5 Seiten2005 - Surface Wave On High Speed Liquid Lithium Flow ForEugenio DurbanNoch keine Bewertungen

- 2016 Technical Paper 7Dokument58 Seiten2016 Technical Paper 7Eugenio DurbanNoch keine Bewertungen

- Treatment of Support Friction in Pipe Stress AnalysisDokument6 SeitenTreatment of Support Friction in Pipe Stress AnalysisEugenio DurbanNoch keine Bewertungen

- Fatigue Tests On Flanged AssembliesDokument11 SeitenFatigue Tests On Flanged AssembliesEugenio DurbanNoch keine Bewertungen

- Why Branch Connections FailDokument7 SeitenWhy Branch Connections FailEugenio DurbanNoch keine Bewertungen

- Tuberias Con Agua de RioDokument16 SeitenTuberias Con Agua de RioEugenio DurbanNoch keine Bewertungen

- Toward More Consistent Pipe Stress AnalysisDokument5 SeitenToward More Consistent Pipe Stress AnalysisEugenio DurbanNoch keine Bewertungen

- 2007 - Measurement of Free Surface of Liquid Metal Lithium Jet For IFMIF TargetDokument7 Seiten2007 - Measurement of Free Surface of Liquid Metal Lithium Jet For IFMIF TargetEugenio DurbanNoch keine Bewertungen

- 1997 ArticleDokument13 Seiten1997 ArticleEugenio DurbanNoch keine Bewertungen

- 1977 ArticleDokument29 Seiten1977 ArticleEugenio DurbanNoch keine Bewertungen

- 1963 HOUSNER The Dynamic Behaviour of Water TanksDokument7 Seiten1963 HOUSNER The Dynamic Behaviour of Water TanksEugenio DurbanNoch keine Bewertungen

- 2003 - Lithium Free Surface Flow Experiment ForDokument6 Seiten2003 - Lithium Free Surface Flow Experiment ForEugenio DurbanNoch keine Bewertungen

- 2008 - Numerical Analysis of Free Surface Instabilities in The IFMIF Lithium TargetDokument5 Seiten2008 - Numerical Analysis of Free Surface Instabilities in The IFMIF Lithium TargetEugenio DurbanNoch keine Bewertungen

- 1980 KennedyDokument24 Seiten1980 KennedyEugenio DurbanNoch keine Bewertungen

- 1975 B ArticleDokument35 Seiten1975 B ArticleEugenio DurbanNoch keine Bewertungen

- 1994 - A Survey of Impact Load Analysis in CAESAR II (COADE News)Dokument6 Seiten1994 - A Survey of Impact Load Analysis in CAESAR II (COADE News)Eugenio DurbanNoch keine Bewertungen

- 2004 - Present Status of Beryllide R&D As Neutron MultiplierDokument7 Seiten2004 - Present Status of Beryllide R&D As Neutron MultiplierEugenio DurbanNoch keine Bewertungen

- 150# RF Piping DimensionsDokument255 Seiten150# RF Piping DimensionsFred McGuinnessNoch keine Bewertungen

- GlossaryDokument48 SeitenGlossaryEugenio DurbanNoch keine Bewertungen

- Useful Valve InfoDokument11 SeitenUseful Valve InfoEugenio DurbanNoch keine Bewertungen

- Hydronic Systems: Technologically Advanced and Highly EfficientDokument4 SeitenHydronic Systems: Technologically Advanced and Highly EfficientEugenio DurbanNoch keine Bewertungen

- Pipe ExpansionDokument3 SeitenPipe ExpansionEugenio DurbanNoch keine Bewertungen

- Tiger Bifacial: 445-465 WattDokument2 SeitenTiger Bifacial: 445-465 WattMonster LifeNoch keine Bewertungen

- Module 7 - Ac Parallel Circuits Conyaining InductanceDokument9 SeitenModule 7 - Ac Parallel Circuits Conyaining InductanceMARY JOY MAGAWAYNoch keine Bewertungen

- Unidad #2 Centroids and Centre of GravityDokument37 SeitenUnidad #2 Centroids and Centre of GravityAnna E A. Camaño100% (2)

- D 2283 - 86 R97 - RdiyodmDokument2 SeitenD 2283 - 86 R97 - RdiyodmPrakash MakadiaNoch keine Bewertungen

- WI 06 Pre-FV Version PrEN 15240 Inspection of Airco BuildingsDokument36 SeitenWI 06 Pre-FV Version PrEN 15240 Inspection of Airco BuildingsMericNoch keine Bewertungen

- Experiment 4 Cross Flow Heat ExchangerDokument19 SeitenExperiment 4 Cross Flow Heat Exchangerbeasturs1Noch keine Bewertungen

- EPC Tenants GuideDokument8 SeitenEPC Tenants Guidejoseph durantNoch keine Bewertungen

- Centrifugal Pumps: P.K.Nagarajan SR - Lecturer School of Mechanical and Building Sciences VIT UniversityDokument30 SeitenCentrifugal Pumps: P.K.Nagarajan SR - Lecturer School of Mechanical and Building Sciences VIT UniversityVikas Kumar100% (1)

- Chapter 4Dokument34 SeitenChapter 4Ahmad TahirNoch keine Bewertungen

- Handout No. 11 (Capacitance II) by Odon M. Sanchez C. (Spring Semester 2017)Dokument4 SeitenHandout No. 11 (Capacitance II) by Odon M. Sanchez C. (Spring Semester 2017)AMC PureNoch keine Bewertungen

- LUCB1XBLDokument2 SeitenLUCB1XBLAlex Ruben Alvarez GallardoNoch keine Bewertungen

- GeneralPhysics1 Q2 Module-2 Gravity v5Dokument25 SeitenGeneralPhysics1 Q2 Module-2 Gravity v5rexilldatorNoch keine Bewertungen

- W1 Electric Charge Coulumbs Law Electric Fields and Electric FluxDokument81 SeitenW1 Electric Charge Coulumbs Law Electric Fields and Electric FluxbenamirbrentyuridNoch keine Bewertungen

- Chapter 7 - Gas Steam MediumDokument21 SeitenChapter 7 - Gas Steam MediumAdugna Gosa100% (1)

- Solution Manual Gas Dynamics 3rd Edition James E.A. John Theo G. KeithDokument10 SeitenSolution Manual Gas Dynamics 3rd Edition James E.A. John Theo G. KeithPatnala Susmitha ae17b012Noch keine Bewertungen

- Outdoor Air Switches Selection and Application: 8.25 Thru 800 KV Max. Voltage 600 Thru 5000 Amperes Bulletin 2.3.1-1FDokument18 SeitenOutdoor Air Switches Selection and Application: 8.25 Thru 800 KV Max. Voltage 600 Thru 5000 Amperes Bulletin 2.3.1-1FannymagoNoch keine Bewertungen

- Instruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0160 D, RA 0202 D, RA 0250 D, RA 0302 DDokument32 SeitenInstruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0160 D, RA 0202 D, RA 0250 D, RA 0302 DYunisNoch keine Bewertungen

- Tiger Pro HC JKM515-535M-72HL4-BDVP-A2.1Dokument2 SeitenTiger Pro HC JKM515-535M-72HL4-BDVP-A2.1Parth DaxiniNoch keine Bewertungen

- Surge Filters, Low Current Dinsafe: Technical Information Sheet Sf105Din/ADokument1 SeiteSurge Filters, Low Current Dinsafe: Technical Information Sheet Sf105Din/AjohnarllanNoch keine Bewertungen

- Units ConversionDokument9 SeitenUnits ConversionNoor M KhanNoch keine Bewertungen

- 300W Single Output Battery Charger: SeriesDokument2 Seiten300W Single Output Battery Charger: SeriesCsaba WielandNoch keine Bewertungen

- LM317M DDokument14 SeitenLM317M DVinícius BardellaNoch keine Bewertungen

- Lecture 1 - Rankine Power CyclesDokument5 SeitenLecture 1 - Rankine Power CyclesMuhammad Alam Zaib KhanNoch keine Bewertungen

- Physics 222 Ohm's Law Lab ReportDokument12 SeitenPhysics 222 Ohm's Law Lab ReportEmily Gatlin81% (27)

- EM - I-Assignment - II (NA) - 1Dokument2 SeitenEM - I-Assignment - II (NA) - 1deepakNoch keine Bewertungen

- Siemens Energy Silyzer 09 - HYPOS - Dialog - WagnerDokument20 SeitenSiemens Energy Silyzer 09 - HYPOS - Dialog - WagnerFreyrVoNoch keine Bewertungen

- Exp1 (Final) PDFDokument15 SeitenExp1 (Final) PDFZaidNoch keine Bewertungen

- Semiconductors Properties PDFDokument87 SeitenSemiconductors Properties PDFKarthika SathishNoch keine Bewertungen