Beruflich Dokumente

Kultur Dokumente

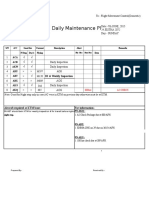

Routine & Preventive Maintenance

Hochgeladen von

vinay9560 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

344 Ansichten8 Seitencontinuous casting routine and preventive maintenance schedule planning

Copyright

© © All Rights Reserved

Verfügbare Formate

XLSX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldencontinuous casting routine and preventive maintenance schedule planning

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

344 Ansichten8 SeitenRoutine & Preventive Maintenance

Hochgeladen von

vinay956continuous casting routine and preventive maintenance schedule planning

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 8

Routine Maintenance Report

Sr.No. Equipment/Part Sub Part Work Description Frequency Fault description Action Taken

water hardness check water hardness 1 week

water bellow check bellow 1 week

1 Primary water line

Instruments (pressure gauge, Check working Every Heat

temp.indicator, pt, Rtd)

check operation, clean,

spray nozzles Every 2 days

2 secondary water line change if reqd.

CI strainer and Basket filter open and clean 1 month

Oil refilling fill tank 50 heats

3 Mould lub. Line fiter cleaning clean filter 1 week

oil flow check 1 week

Casing & cooling jacket clean 2 week

5 Mould jacket Mould tube check, clean 10 heats

oil flow check & set oil flow(if reqd.) 1 week

Return line filter Open & check 1 month

Hose connection check & tight (if reqd.) 2 months

Hydraulic Power Oil level check and refill 1 week

6 pack Hyd. Cylinder clevis Greasing 1 week

Line Pressure Check & set pressure (if reqd) 1 month

Motors Check 1 week

Air drier Check dirt in frl 1 week

7 Pneumatic line Frl (Lubricator) Oil refilling 1 week

Bellow check & replace (if reqd.) 1 week

Motors checking 1 week

W/d & Aux. w/d

8 Gear box Checking & Oiling 1 week

Assembly

Rollers checking & Greasing 1 week

Plummer block check & replace (if reqd.) 1 week

Bearings Greasing & replce (if reqd) 1 week

9 IRT & DRT

Rollers Greasing 1 week

Chain Check, grease 1 week

Guide rollers Check, grease & set 1 week

10 Mould oscillation

Bearings Check, Greasing 1 week

Gear box Oil refilling 1 week

Motors checking 1 week

Adj. Eccentric

11 Assembly

Adj. Eccentric

11 check & tight lock nuts if

Assembly Adjustable nut 1 week

reqd.

stroke length check and set 1 week

check cutting point, set if

Limit switch 1 week

12 Billet Pusher reqd.

Forward & Reverse stroke check Every Heat

13 Tundish car Motors Checking 1 week

Gear box Check & Oiling 1 week

Chain Check, grease 1 week

Wheel Bearings check & Greasing 2 week

Handles check operation Every Heat

14 scale pit clean 3 months

15 Trenches clean 1 months

Checked on Checked by Remarks

Preventive Maintenance Report

Sr.N Equipment/part Sub Part Work Description Frequency Fault description Action Taken

o.

Storage tank clean tank 6 months

1 Primary water line

CI strainer and Basket filter open and clean 2 months

Storage tank clean tank 6 months

2 secondary water line

CI strainer and Basket filter open and clean 2 months

Lubrication tank Clean 4 months

3 Mould lub. Line

Motor & Pump Checking 2 months

4 Al. wire feeder Motor & its connection Checking 2 months

Casing & cooling jacket check & clean 3 months

5 Mould jacket check condition and send for

Mould tube 250 heats

reconditioning (if reqd)

Oil Tank Cleaning 6 months

6 Hydraulic Power pack Hoses check 1 year

Hyd. Cylinder check 1 year

Air drier Check air quality 2 months

Frl Check air quality 2 months

7 Pneumatic line

Flow controller check flow controlling 6 months

Flow meter check 6 months

Check heating, Current taken,

Motors 1 year

Noise level

8 W/d & Aux. w/d

Assembly Gear box Checking heating & noise level 1 year

Rollers Dismantle, clean & check 6 months

Check heating, Current taken,

Motors 1 year

Noise level

9 IRT & DRT

Gear box Checking heating & noise level 1 year

Rollers check& replace if reqd. 6 months

Mould table Check Level & set 6 months

10 Mould oss. Oscillator Frame Check Level & set 6 months

Bearings Check,replce if reqd. 6 months

Gear box Checking heating & noise level 1 year

11 Adjustable Eccentric Check heating, Current taken,

Motors 1 year

Assembly Noise level

11 Adjustable Eccentric

Assembly

Bush check 6 months

Eccentric shaf check 6 months

12 Billet Pusher Bearings check & replace if reqd. 1 year

Motors Checking heating & noise level 1 year

Check heating, Current taken,

Gear box 1 year

13 Tundish car Noise level

Chain check & replace if reqd. 1 year

Wheels check & replace if reqd. 1 year

tive Maintenance Report

Checked on Checked by Remarks

Das könnte Ihnen auch gefallen

- Facility Preventive Maintenance Schedule Template Printable PDFDokument35 SeitenFacility Preventive Maintenance Schedule Template Printable PDFEdmund Yoong100% (3)

- Preventive Maintenance Schedule SampleDokument4 SeitenPreventive Maintenance Schedule SampleAji DwitangoroNoch keine Bewertungen

- Schedule Preventive Maintenance Esm2Dokument52 SeitenSchedule Preventive Maintenance Esm2fitra100% (1)

- Preventive MaintDokument23 SeitenPreventive MaintRavikant PandeyNoch keine Bewertungen

- Corrective MaintenanceDokument12 SeitenCorrective MaintenanceMohammed Nerissa100% (1)

- 52-Week Preventive Maintenance ScheduleDokument21 Seiten52-Week Preventive Maintenance Scheduleguilmar lopez50% (4)

- Operations and Maintenance Preventive Maintenance ChecklistsDokument35 SeitenOperations and Maintenance Preventive Maintenance Checklistssooriya_82100% (14)

- Maintenance Key Performance IndicatorsDokument15 SeitenMaintenance Key Performance Indicatorswhmidi7331100% (3)

- M2 - Preventive Maintenance TechnologyDokument98 SeitenM2 - Preventive Maintenance TechnologyBambang Murtjahjanto100% (1)

- Maintenance Plan 56Dokument47 SeitenMaintenance Plan 56Quannas White50% (2)

- Planned Preventive Maintenance (PPM) WorksheetDokument2 SeitenPlanned Preventive Maintenance (PPM) Worksheetmohsinsafi100% (1)

- Revise Periodic PMS ChecklistDokument21 SeitenRevise Periodic PMS Checklistjherson gravides100% (3)

- Induction Training - MaintenanceDokument22 SeitenInduction Training - MaintenanceAbhijith SNoch keine Bewertungen

- Maintenance Program For EquipmentsDokument793 SeitenMaintenance Program For EquipmentsJoel AlcantaraNoch keine Bewertungen

- Preventive Maintenance 2015.Dokument11 SeitenPreventive Maintenance 2015.Daniel Krismantoro100% (1)

- Generator ChecklistDokument2 SeitenGenerator Checklistsidney_viegas67% (3)

- Maintenace Planning and Scheduling Handbook 2ndDokument6 SeitenMaintenace Planning and Scheduling Handbook 2ndjfredyv170% (1)

- 01.preventive Maintenance Routine - 24.09.2012Dokument79 Seiten01.preventive Maintenance Routine - 24.09.2012Nurun Nadjihah100% (3)

- Daily Check ListDokument5 SeitenDaily Check Listarghyadeepjana100% (2)

- SOP Operational and Preventive Maintenance ChecklistDokument2 SeitenSOP Operational and Preventive Maintenance ChecklistMasomese Henry Kikile88% (8)

- Preventive Maintenance PlanDokument3 SeitenPreventive Maintenance PlanBalram Ji86% (7)

- Weekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekDokument8 SeitenWeekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekfcfernandoNoch keine Bewertungen

- Form Maintenance-Checklist DailyDokument15 SeitenForm Maintenance-Checklist DailyRomly MechNoch keine Bewertungen

- Planned MaintenanceDokument17 SeitenPlanned MaintenanceAnand Dubey100% (1)

- Weekly Generator Test Log SheetDokument2 SeitenWeekly Generator Test Log SheetVer Bautista86% (7)

- Maintenance ManagementDokument21 SeitenMaintenance ManagementRahul WaghmareNoch keine Bewertungen

- Electrical MaintenanceDokument7 SeitenElectrical MaintenanceKHUSHBOO198450% (2)

- PM-CM Ratio StreamliningDokument11 SeitenPM-CM Ratio StreamliningRene Rey MondiaNoch keine Bewertungen

- Maintenance Planning SystemsDokument55 SeitenMaintenance Planning SystemsGyogi MitsutaNoch keine Bewertungen

- Monthly Maintenance Report For Steam GeneratorDokument1 SeiteMonthly Maintenance Report For Steam GeneratorArsalan AhmadNoch keine Bewertungen

- List of MachineDokument11 SeitenList of Machinemohitsharmagzb09Noch keine Bewertungen

- Daily Vehicle Inspection ChecklistDokument2 SeitenDaily Vehicle Inspection ChecklistNgonidzashe Zvarevashe0% (1)

- Energy Saving Equipment ListDokument15 SeitenEnergy Saving Equipment ListMaintenance Circle100% (3)

- Planned Preventive Maintenance - SOPDokument6 SeitenPlanned Preventive Maintenance - SOPzafeer100% (2)

- Total Productive Maintenance (TPM) : Prepared By: M.Ganesh MuruganDokument56 SeitenTotal Productive Maintenance (TPM) : Prepared By: M.Ganesh MuruganPriscila Villas Boas TonãoNoch keine Bewertungen

- BUILDING MAINTENANCE PLAN For121399Dokument87 SeitenBUILDING MAINTENANCE PLAN For121399Sheima Ashour100% (3)

- Customer Service ReportDokument1 SeiteCustomer Service Reportsladjoynwa1Noch keine Bewertungen

- SOP For Machine Maintenance - For UpdateDokument3 SeitenSOP For Machine Maintenance - For UpdatePeracha Engineering60% (5)

- Maintenance ManagementDokument18 SeitenMaintenance ManagementPrasanna KumarNoch keine Bewertungen

- Overhauling Procedure and Report of Generator 12Dokument7 SeitenOverhauling Procedure and Report of Generator 12Swaroop MohapatraNoch keine Bewertungen

- MaintenanceDokument23 SeitenMaintenanceDeepankumar AthiyannanNoch keine Bewertungen

- 02 Maintenance Dept Monthly Report Feb'13Dokument22 Seiten02 Maintenance Dept Monthly Report Feb'13Vinay Kumar100% (3)

- Annual Maintenance Plan and BudgetDokument3 SeitenAnnual Maintenance Plan and BudgetyadiraNoch keine Bewertungen

- Maintenance ChecklistDokument2 SeitenMaintenance ChecklistShreyasi Singh92% (13)

- p2 - 221841 - MAINTENANCE ACMVDokument36 Seitenp2 - 221841 - MAINTENANCE ACMVVin BdsNoch keine Bewertungen

- Preventive MaintenanceDokument3 SeitenPreventive MaintenanceTrilok Singh TakuliNoch keine Bewertungen

- Preventive Maintenance of Dairy Plants and MachineriesDokument13 SeitenPreventive Maintenance of Dairy Plants and MachineriesRonak Rawat100% (3)

- Topic 1 MAINTANANCE Preventive and Breakdown Maintenance ComparisonsDokument6 SeitenTopic 1 MAINTANANCE Preventive and Breakdown Maintenance ComparisonsSrinibas Jena80% (5)

- Daily Maintenance PlanDokument154 SeitenDaily Maintenance PlanDipendra SenNoch keine Bewertungen

- MAINTENANCE PLAN DailyDokument3 SeitenMAINTENANCE PLAN DailyjcNoch keine Bewertungen

- Best Maintenance PracticesDokument8 SeitenBest Maintenance PracticesYuvaraj NithyanandamNoch keine Bewertungen

- Maintenance Planning & SchedulingDokument27 SeitenMaintenance Planning & SchedulingNo HopeNoch keine Bewertungen

- Maintenance PlanDokument28 SeitenMaintenance Plan123habib123fikriNoch keine Bewertungen

- Preventive MaintenanceDokument14 SeitenPreventive Maintenancetristan20100% (6)

- EP-15194-HMGPP Maintenance PlanDokument81 SeitenEP-15194-HMGPP Maintenance Plandebabrata goswami100% (1)

- Monthly Preventive Maintenance ChecklistDokument2 SeitenMonthly Preventive Maintenance ChecklistAlia Marouf90% (10)

- Preventive Maintenance: East Central Integrated SchoolDokument9 SeitenPreventive Maintenance: East Central Integrated SchoolReagan de GuzmanNoch keine Bewertungen

- Maintenance PlanningDokument27 SeitenMaintenance Planningnelson_ferns100% (3)

- Preventive Checklist For Process EquipmentDokument9 SeitenPreventive Checklist For Process EquipmentVishal MehtreNoch keine Bewertungen

- Preventive Sheet 13-02-2023Dokument15 SeitenPreventive Sheet 13-02-2023Vishal MehtreNoch keine Bewertungen

- 1QCCollector NozzleDokument1 Seite1QCCollector Nozzlevinay956Noch keine Bewertungen

- Spray WaterDokument10 SeitenSpray Watervinay956Noch keine Bewertungen

- Impact of Oscillation On Steel SurfaceDokument6 SeitenImpact of Oscillation On Steel Surfacevinay956Noch keine Bewertungen

- 1QC Slide PlateDokument1 Seite1QC Slide Platevinay956Noch keine Bewertungen

- Manual Intermetal Slide Gate System 30 11 10Dokument3 SeitenManual Intermetal Slide Gate System 30 11 10vinay956Noch keine Bewertungen

- FRL (Filter Regulator Lubricator)Dokument4 SeitenFRL (Filter Regulator Lubricator)vinay956Noch keine Bewertungen

- Variable AnalysisDokument5 SeitenVariable Analysisvinay956Noch keine Bewertungen

- Important Elements of SteelDokument14 SeitenImportant Elements of Steelvinay956Noch keine Bewertungen

- Self EvaluationDokument6 SeitenSelf Evaluationvinay956Noch keine Bewertungen

- Important Elements of SteelDokument14 SeitenImportant Elements of Steelvinay956Noch keine Bewertungen

- Elements & Their Effects.Dokument81 SeitenElements & Their Effects.vinay9560% (1)

- Handout On Ratios AnalysisDokument5 SeitenHandout On Ratios Analysisvinay956Noch keine Bewertungen

- Application of Titanium in Aerospace IndustryDokument6 SeitenApplication of Titanium in Aerospace Industryvinay956Noch keine Bewertungen

- Specific Heat CapacityDokument3 SeitenSpecific Heat Capacityvinay956Noch keine Bewertungen

- Not Failure, BT Low Aim Is A Crime.Dokument5 SeitenNot Failure, BT Low Aim Is A Crime.vinay956Noch keine Bewertungen

- Aug 2020 Builders Line Tamil MonthlyDokument48 SeitenAug 2020 Builders Line Tamil MonthlyBuildersLineMonthlyNoch keine Bewertungen

- Cyber Law: Submitted byDokument8 SeitenCyber Law: Submitted bySonu MishraNoch keine Bewertungen

- Upload 1 Document To Download: Ergen DedaDokument3 SeitenUpload 1 Document To Download: Ergen DedakNoch keine Bewertungen

- Median FilteringDokument30 SeitenMedian FilteringK.R.RaguramNoch keine Bewertungen

- Unit 8 - Week 7: Assignment 7Dokument3 SeitenUnit 8 - Week 7: Assignment 7Nitin MoreNoch keine Bewertungen

- MIami Beach City Attorney's DenialDokument7 SeitenMIami Beach City Attorney's DenialDavid Arthur WaltersNoch keine Bewertungen

- New York State - NclexDokument5 SeitenNew York State - NclexBia KriaNoch keine Bewertungen

- General Electric/ Massachusetts State Records Request Response Part 3Dokument673 SeitenGeneral Electric/ Massachusetts State Records Request Response Part 3Gintautas DumciusNoch keine Bewertungen

- Important Terms in ObliconDokument4 SeitenImportant Terms in ObliconAriana Cristelle L. Pagdanganan100% (1)

- Burberry Annual Report 2019-20 PDFDokument277 SeitenBurberry Annual Report 2019-20 PDFSatya PhaneendraNoch keine Bewertungen

- QT1-EVNPMB2-0-NCR-Z-013 Water Treament System of AccommondationDokument3 SeitenQT1-EVNPMB2-0-NCR-Z-013 Water Treament System of AccommondationDoan Ngoc DucNoch keine Bewertungen

- WS-250 4BB 60 Cells 40mm DatasheetDokument2 SeitenWS-250 4BB 60 Cells 40mm DatasheetTejash NaikNoch keine Bewertungen

- Wiring DiagramsDokument69 SeitenWiring DiagramsMahdiNoch keine Bewertungen

- An Analytical Study On Impact of Credit Rating Agencies in India 'S DevelopmentDokument14 SeitenAn Analytical Study On Impact of Credit Rating Agencies in India 'S DevelopmentRamneet kaur (Rizzy)Noch keine Bewertungen

- RFBT - Law On Sales Cont. Week 11Dokument1 SeiteRFBT - Law On Sales Cont. Week 11Jennela VeraNoch keine Bewertungen

- Panch ShilDokument118 SeitenPanch ShilSohel BangiNoch keine Bewertungen

- Personal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553Dokument6 SeitenPersonal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553MirelaRoșcaNoch keine Bewertungen

- Mio Digiwalker c220/c220sDokument32 SeitenMio Digiwalker c220/c220sTNoch keine Bewertungen

- SHPXXX 20 IS XX 13Dokument240 SeitenSHPXXX 20 IS XX 13Geyciane PinheiroNoch keine Bewertungen

- Eastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateDokument6 SeitenEastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateTasheen MahabubNoch keine Bewertungen

- AET Assignment C Kate ThomsonDokument12 SeitenAET Assignment C Kate ThomsonaymenmoatazNoch keine Bewertungen

- Psychological Attitude Towards SafetyDokument17 SeitenPsychological Attitude Towards SafetyAMOL RASTOGI 19BCM0012Noch keine Bewertungen

- Lab 1Dokument8 SeitenLab 1Нурболат ТаласбайNoch keine Bewertungen

- Ibm v3700 Storeage PDFDokument694 SeitenIbm v3700 Storeage PDFJanakackvNoch keine Bewertungen

- Ins200 Assignment Hazardous PlaceDokument10 SeitenIns200 Assignment Hazardous PlaceNur Syafatin Natasya86% (7)

- Manual MIB 303S-13/33Dokument58 SeitenManual MIB 303S-13/33Daniel Machado100% (1)

- Application Form-Nguyen Huy CuongDokument4 SeitenApplication Form-Nguyen Huy Cuongapi-3798114Noch keine Bewertungen

- Subsistence and Travel FormsDokument3 SeitenSubsistence and Travel FormsAnonymous YRLhQY6G6jNoch keine Bewertungen

- Midterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsDokument3 SeitenMidterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsGarp Barroca100% (1)

- TIP - IPBT M - E For MentorsDokument3 SeitenTIP - IPBT M - E For Mentorsallan galdianoNoch keine Bewertungen