Beruflich Dokumente

Kultur Dokumente

Lift

Hochgeladen von

aparajita malhotraCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lift

Hochgeladen von

aparajita malhotraCopyright:

Verfügbare Formate

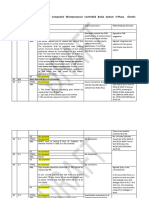

+16400mm

R.C.C. LINTEL 250 X 150MM.

COUNTER WEIGHT

500.0

+14050mm

350.0

GUIDE

FRICTION SHEAVE +13200mm

3 ROPES @ 12.5 mm DIA. EACH 10MM DIA. ANCHOR BOLT. FRICTION SHEAVE

2000.0

500.0

3 ROPES @ 12.5 mm DIA. EACH

OF CAR GUIDE

1200.0

8MM DIA. BOLTED JOINTS. MACHINE SUPPORTING

ISMC 125 X 65

2200.0

230 MM THK. BRICK WALL. +10050mm 2.5MM THK. M.S. PLATE.

500MM WIDE VENTILATOR. 60MM DIA. ROLLERS.

1330.0

4000.0

500.0

MACHINE SUPPORTING

ISMC 125 X 65

17190.0

850.0

500.0

10MM THK. M.S. RAILS.

+6900mm

575

ELEVATOR ROOM

ELEVATOR ELECTRICAL

POWER SWITCH.

800 CONTROLS. 2.5MM THK. M.S. PLATE FIXED

1200.0

150.0

TO SHUTTER.

1000.0

700.0

+3750mm 20MM THK. GYPSUM SHUTTER.

LAMINATED WITH 2MM S.S.

1750 TOP CLEARANCE

COUNTER WEIGHT GUIDE

TERRACE FLOOR

500.0

2850.0

ground level. 2.5MM THK. HAIRLINE

500.0

S.S.SHEET.

OF CAR GUIDE

GUIDE RAILS. 20 mm THK. FLOORING.

+600mm

LIFT ROOM PLAN

230.0

500 X 150 mm R.C.C. BEAM.

ALUMINIUM FOOTBOARD

PROFILE. 115mm THK. BRICK WALL.

M.S. ANGLES TO FIX 12 mm THK. PLASTER. B

KEY SECTION THE FOOTBOARD.

150.0

2200.0 250 X 150 mm R.C.C. LINTEL.

150.0

150MM THK. R. RC.C. SHEAR WALL. 10MM DIA. ANCHOR BOLT. 18 GAUGE HAIRLINE

2080 CLEAR ENTRANCE

STAINLESS STEEL

10MM THK. M.S. LIFT CAGE.

ISMC 75 X 40 COUNTER ELEVATOR CONTROLS.

100.0

200.0 200.0 WEIGHT GUIDE RAIL.

1500 CAGE INSIDE 10 MM THK. M.S. LIFT DETAIL AT A AND B

14530 CLEAR LIFT WELL HEIGHT

CAGE.

745

2000.0

1620.0

2MM THK. HAIRLINE S.S. SHEET. 100.0 100.0

ISMC 150 X 75

548.0 452.0 ELEVATOR SHAFT

1800 DIST. BETWEEN BRACKETS LIFT

150 MM THK. R.C.C.

478.0 478.0 ENTRANCE

SHEAR WALL.

ISA 70 X 50 FIXING

800

578.0

150.0

A

100.0

JUNCTION BOX . 100.0 ANGLE.

150.0

550.0 452.0

2100.0

100.0

180

s.s.hairline

252.0

230 M THK. BRICK WORK. laminated shutters

100.0 ISA 50X50

15 MM THK CERAMIC ANGLE CLEAT.

1000.0

TILE CLAD FIXING BOLT.

150.0 1900.0 150.0

finished floor level.

LIFT WELL AND CAR PLAN DETAIL AT C

150.0 1900.0 150.0 DOOR ELEVATION

LIFT SYSTEM

2080 CLEAR ENTRANCE

150.0

2700

100.0

20.0

ELECTRIC HYDRAULIC

180.0

KEY DESIGN 650.0 650.0 LIFT

MACHINE ABOVE BUILDING 255.0

191.0

ENTRANCE

670.0

CONSIDERATIONS FOOTPRINT

1:1 ROPED

(VARIABLES AFFECTING LIFT CAR ABOVE 33

150.0

150.0

ELEVATORS SYSTEM SPRING

1770.0

350.0

DESIGN)

MACHINE ABOVE

2:1 ROPED

1. NO.OF FLOORS TO BE

175

180

SERVED LIFT CAR FRAME OF STEEL

1230 PIT DEPTH

ENTRENCE CHANNELS.

180

2. FLOOR TO FLOOR

LOBBY 525.0

900.0

MACHINE BELOW DISTANCE JUNCTION BOX .

150.0

300.0

1:1 ROPED 3. POPULATION OF EACH

700.0

FLOOR PIT FLOOR LVL.

500.0

4.

5.

LOCATION OF BUILDING

SPECIALIZED

M.S. LADDER FOR LIFT

PIT.

SECTION SHOWING

SERVICES WITHIN THE

LIFT WELL EDGE

160.0

BUILDING.

250.0

6. TYPE OF BUILDING

7.

OCCUPANCY.

MAXIMUM PEAK KEY PLAN OF BUILDING LIFT PIT PLAN BEAM HOISTWAY SECTION AA'

DEMAND IN

PASSENGERS PER FIVE WITH LIFT LOCATION

MINUTE PERIOD.

SCALE 1:250

SIGN &

LIFT

DATE : NAME : NIKHIL NAIR

STAMP

ROLL NO : SUBJECT : BUILDING TECHNLOGY

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ticket: Terms & ConditionsDokument1 SeiteTicket: Terms & ConditionsJetesh DevgunNoch keine Bewertungen

- Nautical Stories - NapoleonicDokument5 SeitenNautical Stories - Napoleonic2nd Dragoon100% (1)

- 8-Week ReportDokument2 Seiten8-Week ReportAKNoch keine Bewertungen

- Gta Vice City CheatbookDokument73 SeitenGta Vice City CheatbookDolly Panchal100% (3)

- Cimc Flat Rack ManualDokument14 SeitenCimc Flat Rack Manualjuan.vargas.calle6904Noch keine Bewertungen

- HD2 PAP GB Otokar Gamme-Interurbain PLQ 19Dokument28 SeitenHD2 PAP GB Otokar Gamme-Interurbain PLQ 19JimJakNoch keine Bewertungen

- Charges Applicable Towards Delivery Order: Examination D/ODokument8 SeitenCharges Applicable Towards Delivery Order: Examination D/Oev TruongNoch keine Bewertungen

- Locomotives of India - Wikipedia, The Free EncyclopediaDokument31 SeitenLocomotives of India - Wikipedia, The Free Encyclopediasassyboy4uNoch keine Bewertungen

- Q5 Case JetBlueDokument4 SeitenQ5 Case JetBlueAhmed SayedNoch keine Bewertungen

- Owner'S Manual: Read This Manual Carefully Before Operating This VehicleDokument100 SeitenOwner'S Manual: Read This Manual Carefully Before Operating This Vehicleigor petrovskiNoch keine Bewertungen

- RPD Daily Incident Report 5/27/22Dokument8 SeitenRPD Daily Incident Report 5/27/22inforumdocsNoch keine Bewertungen

- PR Sava Intensa Uhp 26102009 English F Upd Tcm2382-72613Dokument3 SeitenPR Sava Intensa Uhp 26102009 English F Upd Tcm2382-72613mac1677Noch keine Bewertungen

- Hanjin LocalchagreDokument5 SeitenHanjin LocalchagreTrần Minh CườngNoch keine Bewertungen

- Unit - I: GPS FundamentalsDokument125 SeitenUnit - I: GPS Fundamentalsapi-3828816Noch keine Bewertungen

- Failure of Jet AirwaysDokument8 SeitenFailure of Jet AirwaysGayatri PoojaryNoch keine Bewertungen

- A Guide On Good Practice To Boost Energy Efficiency in Central and South Eastern Europe-EUDokument92 SeitenA Guide On Good Practice To Boost Energy Efficiency in Central and South Eastern Europe-EUOner AltınsoyNoch keine Bewertungen

- OB5 Transmission InfoDokument98 SeitenOB5 Transmission InfoRobert Moreau95% (21)

- Vehicle Inertia Calculation EnglishDokument4 SeitenVehicle Inertia Calculation EnglishdwiudNoch keine Bewertungen

- SubwaymapnyDokument1 SeiteSubwaymapnyMilica TodorovicNoch keine Bewertungen

- Pestaño v. Spouses SumayangDokument9 SeitenPestaño v. Spouses SumayangAlexandra Nicole SugayNoch keine Bewertungen

- History of The Serene Republic: Venetian Wing Lion On The Pediment of The St. Mark Basilica, VeniceDokument28 SeitenHistory of The Serene Republic: Venetian Wing Lion On The Pediment of The St. Mark Basilica, VeniceEric LefrançaisNoch keine Bewertungen

- Transportation System Notes (ALE Review)Dokument6 SeitenTransportation System Notes (ALE Review)Jehan MohamadNoch keine Bewertungen

- hsg94 PDFDokument40 Seitenhsg94 PDFbtjajadiNoch keine Bewertungen

- Volkswagen Tiguan Brochure 2016Dokument30 SeitenVolkswagen Tiguan Brochure 2016Sajjad Anwar100% (1)

- C20793-15843CN SMV 15-1200B Machine CardDokument2 SeitenC20793-15843CN SMV 15-1200B Machine CardAbas AbasariNoch keine Bewertungen

- Draft Specfication of 3 PH BRAKE SYSTEM PDFDokument32 SeitenDraft Specfication of 3 PH BRAKE SYSTEM PDFGold FlakeNoch keine Bewertungen

- Automotive AerodynamicDokument105 SeitenAutomotive AerodynamicDevansh SrivastavaNoch keine Bewertungen

- MMVDokument42 SeitenMMVHardik PatelNoch keine Bewertungen

- Crown SP 3500 Stock Picker Lift Truck Operator's Manual PDFDokument22 SeitenCrown SP 3500 Stock Picker Lift Truck Operator's Manual PDFVüsal 1Noch keine Bewertungen

- UntitledDokument26 SeitenUntitledsuyash dugarNoch keine Bewertungen