Beruflich Dokumente

Kultur Dokumente

Sikadurcrackfix CA

Hochgeladen von

laust69Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sikadurcrackfix CA

Hochgeladen von

laust69Copyright:

Verfügbare Formate

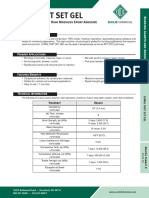

Product Data Sheet

Edition 06.2011/v1

Sikadur Crack Fix

Sikadur Crack Fix

Low-Viscosity and High-Strength Epoxy Resin Injection

Resin, Sealer and Adhesive

Description Sikadur Crack Fix, is a two-component, 100% solids and solvent-free, moisture-tolerant, low-

viscosity, and high-strength multi-purpose epoxy resin.

Where to Use Low pressure injection of cracks in structural concrete, masonry, wood, etc.

Grouting around bolts, dowels, pins and fixings.

Thin layer, high strength adhesive for bonding hardened concrete.

Gravity feeding of cracks in horizontal concrete, masonry, wood etc.

Construction

Sealing interior slabs and exterior above grade slabs.

Advantages Convenient, easy to use single tube cartridge; fits standard caulking gun.

No mess, self-mixing through nozzle.

Low viscosity; allows material to penetrate and seal fine, hairline cracks.

Deep penetration and tenacious crack bonding in structural concrete.

Moisture tolerance: for cant dry cracks and surfaces.

High early-strength development and five times stronger than concrete.

Conforms to current ASTM C881 and AASHTO M-235 specifications.

Technical Data

Packaging 180 mL (6 US fl. oz) Pre-Pack cartridge, 12 per case.

Colour Clear, amber

Yield One cartridge yields approximately 175 - 180 mL (10.7 -11 in3.) of usable resin.

Shelf Life 2 years in original, unopened packaging. Store dry at 4 to 35C (39 to 95F).

Condition product at 15 to 24C (59 to 75F) before using.

Mix Ratio A:B = 2:1 by volume

Properties at 23C (73F) and 50 % R.H.

Viscosity (mixed) Approx. 375 cps

Pot Life (60 g) Approx 25 min

Tack Free Time 4C (39F)* 23C (73F)* 32C (89F)*

3-5 mils 14 - 16 hrs 3 - 3.5 hrs 1.5 - 2 hrs

Compressive Strength ASTM D695, MPa (psi)

Neat

4C (39F)* 23C (73F)* 32C (89F)*

4 hrs - - -

8 hrs - 1.2 (180) 22 (3200)

16 hrs - 31.1 (4500) 43.5 (6300)

1 day - 41.4 (6000) 62.8 (9100)

3 days 27.6 (4000) 62.1 (9000) 72.5 (10 500)

7 days 46.9 (6800) 75.9 (11 000) 72.5 (10 500)

14 days 71.1 (10 300) 82.8 (12 000) 72.5 (10 500)

28 days 85.6 (12 400) 89.7 (13 000) 72.5 (10 500)

* Product cured and tested at the temperatures indicated

Compressive Modulus

7 days 2000 MPa (2.9 x 105 psi)

Tensile Properties ASTM D638

7 days Tensile strength 48.3 MPa (7000 psi)

Elongation at break 6.9%

Flexural Properties ASTM D790

14 days Flexural Strength

(Modulus of Rupture) 75.9 MPa (11 000 psi)

Tangent Modulus of

Elasticity in Bending 2139 MPa (3.6 x 105 psi)

Shear Strength ASTM D732

14 days 33.1 MPa (4800 psi)

Heat Deflection Temperature ASTM D648

14 days, Fiber stress loading =

1.8 MPa (264 psi) 49C (120F)

Bond Strength ASTM C882

(Hardened concrete to hardened concrete)

2 days Moist cure 9.0 MPa (1300 psi)

14 days Moist cure 9.3 MPa (1350 psi)

Water Absorption ASTM D570

7 days 24 hr immersion 0.27%

Sikadur Crack Fix

How to Use

Surface Surfaces must be clean, sound and preferably dry.

Preparation

The crack or void to be grouted or the concrete to be sealed or bonded may be dry or damp, but

must be free of standing water. For optimum performance in terms of penetration and adhesion,

surfaces are best dry.

Remove dust, laitance, grease, curing compounds, impregnations, waxes, foreign particles and

loose friable materials using suitable techniques, including sandblasting or power wire brushing.

Surfaces, cracks and voids must then be cleaned, by suitable means, such as blowing clean with oil

free compressed air or vacuuming to remove all penetration or bond inhibiting material.

Cartridge set-up Remove twist cap and port plug from the top of the cartridge. Press one of the flow restrictors

into the opening. Insert a static mixing nozzle (as supplied) through the twist cap and attach to the

threaded section.

Insert the Sikadur Crack Fix cartridge into a good quality caulking gun. Proceed with a purge of

any air possibly entrapped in the system by pointing the gun upwards and squeezing the trigger. In

order to ensure a uniform blend of the resin components, a second squeeze will be needed to purge

some mixed resin before starting application. The extracted material will be discarded.

Application To pressure inject cracks - Set appropriate injection ports. Bond ports and seal the face of the

Construction

crack with Sika AnchorFix-1 or Sika AnchorFix-3CA/-4CA When the epoxy adhesive and crack

seal has cured, inject Sikadur Crack Fix with slow, steady pressure. When completed, the injection

ports can be knocked off and the adhesive and crack seal ground off to mask the works. Consult

Sika Canada Technical Services for additional information where required.

To anchor bolts, dowels and pins in horizontal surfaces - Annular space around bolt should

not exceed 3 mm (1/8 in). Depth of embedment is typically 10 - 15 times the bolt diameter. Grout

with neat Sikadur Crack Fix, injecting the material into the back of the hole and working upwards,

followed by placing the fixing and rotating it into the filled hole so as to prevent air pockets.

To seal slabs - Spread neat Sikadur Crack Fix over the slab, using a squeegee or roller and allow

the material to penetrate. Remove excess material to prevent a surface film forming. Seal interior

slabs and above grade, exterior slabs only.

To gravity feed cracks - Seal the underside of the slab if the crack reflects right through the depth

of concrete. Inject neat Sikadur Crack Fix into v-notched crack and continue placement until the

crack is completely filled.

Clean Up Uncured material can be removed using Sika Equipment Cleaner. Cured product can only be

removed mechanically. Wash soiled hands and skin thoroughly in hot soapy water or use Sika

Hand Cleaner towels.

Limitations Not suitable for use to seal exterior slabs on grade.

Do not use for injection of cracks under hydrostatic pressure.

Minimum age of concrete must be 21 - 28 days depending on curing and drying conditions.

A wet glistening surface with standing water is not suitable for the application of the material.

Minimum surface and air temperature during application: 4C (39F). Maximum substrate

temperature during application: 35C (95F)

Product is not aesthetic; the colour may alter due to variations in exposure to UV and lighting.

Do not thin material with solvents or modify in any way as this will result in unpredictable results

for which the manufacturer cannot be held responsible.

Not to be injected into cracks greater than 6 mm (1/4 in) in width. Consult Sika Canada Technical

Services for guidance.

Health and Safety For information and advice on the safe handling, storage and disposal of chemical products,

Information users should refer to the product label and the most recent Material Safety Data Sheet

containing physical, ecological, toxicological and other safety-related data.

KEEP OUT OF REACH OF CHILDREN

FOR INDUSTRIAL USE ONLY

The information, and in particular, the recommendations relating to the application and end-use of Sika products, are given in

good faith based on Sikas current knowledge and experience of the products when properly stored, handled and applied under

normal conditions, within their shelf life. In practice, the differences in materials, substrates and actual site conditions are such that

no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability arising out of any legal relationship

whatsoever, can be inferred either from this information, or from any recommendations, or from any other advice offered. The

proprietary rights of third parties must be observed. All orders are accepted subject to our current terms of sale and delivery. Users

should always refer to the most recent issue of the Product Data Sheet for the product concerned, copies of which will be supplied

on request or can be accessed in the Internet under www.sika.ca.

Sika Canada Inc.

Quebec Ontario Alberta 1-800-933-SIKA

601 Delmar Avenue 6915 Davand Drive 18131114th Avenue N.W. www.sika.ca

Pointe-Claire, QC H9R 4A9 Mississauga, ON L5T 1L5 Edmonton, AB T5S 1T8

Tel.: 514-697-2610 Tel.: 905-795-3177 Tel.: 780-486-6111 An ISO 9001 certified company

Fax: 514-697-3087 Fax: 905-795-3192 Fax: 780-483-1580 Pointe-Claire : ISO 14001 certified EMS

Sikadur Crack Fix

Das könnte Ihnen auch gefallen

- RMS b114 - Ground Anchors Updated 2020Dokument59 SeitenRMS b114 - Ground Anchors Updated 2020Darron LeeNoch keine Bewertungen

- Thumb Rules in Building Construction For Civil Engineers - Important Point of Civil Engineering - Construction Thumb Rules - Civil SiteDokument36 SeitenThumb Rules in Building Construction For Civil Engineers - Important Point of Civil Engineering - Construction Thumb Rules - Civil SiteSandeep Kumar100% (2)

- Gazebo Construction ManualDokument40 SeitenGazebo Construction Manualmleul7100% (1)

- PDS Sikacrete Self Consolidating ConcreteDokument4 SeitenPDS Sikacrete Self Consolidating ConcreteJose Serrano de EnamoradoNoch keine Bewertungen

- Design of Precast Concrete Oors in Steel-Framed Buildings. Part 1: Slab DesignDokument5 SeitenDesign of Precast Concrete Oors in Steel-Framed Buildings. Part 1: Slab DesignΤε ΧνηNoch keine Bewertungen

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Dokument4 SeitenF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- HCF PDFDokument68 SeitenHCF PDFSushmit SharmaNoch keine Bewertungen

- Crib WallsDokument26 SeitenCrib WallsChhin Vireak0% (1)

- Civil & Finishing Work B.O.QDokument32 SeitenCivil & Finishing Work B.O.QSagar SharmaNoch keine Bewertungen

- The Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionVon EverandThe Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNoch keine Bewertungen

- Adhesives For Ceramic Tiles - Part 2: Test Methods: Irish Standard I.S. EN 12004-2:2017Dokument10 SeitenAdhesives For Ceramic Tiles - Part 2: Test Methods: Irish Standard I.S. EN 12004-2:2017merxs0% (2)

- Pds CPD Sikadur CrackFix UsDokument2 SeitenPds CPD Sikadur CrackFix UsReab SimanthNoch keine Bewertungen

- Pds CPD Sikadur35HiModLV UsDokument2 SeitenPds CPD Sikadur35HiModLV UsBudhi KurniawanNoch keine Bewertungen

- Pds CPD Sikadur55SLV UsDokument2 SeitenPds CPD Sikadur55SLV UsMikeNoch keine Bewertungen

- SikaAnchorFix3001 PdsDokument4 SeitenSikaAnchorFix3001 PdssaulolmNoch keine Bewertungen

- Sikatop 123 Plus: Polymer-Modified, Cementitious, Non-Sag Mortar, Plus Migrating Corrosion InhibitorDokument2 SeitenSikatop 123 Plus: Polymer-Modified, Cementitious, Non-Sag Mortar, Plus Migrating Corrosion InhibitorMarkNoch keine Bewertungen

- SikaAnchorFix2Arctic PdsDokument4 SeitenSikaAnchorFix2Arctic PdsDragoș SturzoiuNoch keine Bewertungen

- PDS Sika AnchorFix SDokument6 SeitenPDS Sika AnchorFix SdostjanNoch keine Bewertungen

- Sikadur 52: Advanced, Very-Low-Viscosity, Moisture-Tolerant Epoxy Injection AdhesiveDokument2 SeitenSikadur 52: Advanced, Very-Low-Viscosity, Moisture-Tolerant Epoxy Injection Adhesivehendri sukrisnoNoch keine Bewertungen

- Sikadur 42 Gorut Palk LE - CaDokument2 SeitenSikadur 42 Gorut Palk LE - Carobert benavidesNoch keine Bewertungen

- Sikadur 52Dokument2 SeitenSikadur 52JessiNoch keine Bewertungen

- Sikadur - 23 - Lo-Modgel-Pick Proof Epoxy SealantDokument4 SeitenSikadur - 23 - Lo-Modgel-Pick Proof Epoxy SealantDavid RiceNoch keine Bewertungen

- Pds CPD SikaGrout 428FS UsDokument5 SeitenPds CPD SikaGrout 428FS UswilliamNoch keine Bewertungen

- Technical Data: Plastic Steel Putty (A)Dokument4 SeitenTechnical Data: Plastic Steel Putty (A)francisNoch keine Bewertungen

- Masterflow 920 Ans: Epoxy Acrylate (Styrene-Free) Resin Based High Performance Anchoring GroutDokument5 SeitenMasterflow 920 Ans: Epoxy Acrylate (Styrene-Free) Resin Based High Performance Anchoring GroutMuhammad Fadhil ImansyahNoch keine Bewertungen

- 226NDokument2 Seiten226NUmaibalanNoch keine Bewertungen

- Duraplate 8200Dokument4 SeitenDuraplate 8200Carlos VillacrizNoch keine Bewertungen

- Sikagrout®-212: Product Data SheetDokument4 SeitenSikagrout®-212: Product Data SheetrajeevNoch keine Bewertungen

- Sikadur®-32 Hi-Mod: Product Data SheetDokument4 SeitenSikadur®-32 Hi-Mod: Product Data SheetGunga SaileshNoch keine Bewertungen

- Belzona 1121 InstrustionsDokument2 SeitenBelzona 1121 Instrustionssh4kesNoch keine Bewertungen

- Araldite 2011-A/B: Advanced MaterialsDokument6 SeitenAraldite 2011-A/B: Advanced Materialsmehmet kığılıNoch keine Bewertungen

- Sikadur®-32 Hi-Mod: Product Data SheetDokument4 SeitenSikadur®-32 Hi-Mod: Product Data SheetAdrianna ColonaNoch keine Bewertungen

- Sikadur - 42 MP NormalDokument5 SeitenSikadur - 42 MP NormalMochamad TaufikNoch keine Bewertungen

- Accura Clearvue US PDFDokument2 SeitenAccura Clearvue US PDFqualityfreekNoch keine Bewertungen

- Dural Fast Epoxy Gel EuclidDokument3 SeitenDural Fast Epoxy Gel Euclidpayaso1973Noch keine Bewertungen

- Data - Sheet-Non-Shrink Precision Grout 1585-00 PDFDokument2 SeitenData - Sheet-Non-Shrink Precision Grout 1585-00 PDFJeffry Daud BarrungNoch keine Bewertungen

- AralditeDokument7 SeitenAralditeRohit RanaNoch keine Bewertungen

- Sikadur®-301: Product Data SheetDokument4 SeitenSikadur®-301: Product Data SheetHenri DormoyNoch keine Bewertungen

- DuraplateDokument4 SeitenDuraplatelovaldes62Noch keine Bewertungen

- Devcon Plastic Steel Putty ADokument3 SeitenDevcon Plastic Steel Putty AAZLAN ABDULLAINoch keine Bewertungen

- MasterFlow - 410 v1Dokument2 SeitenMasterFlow - 410 v1Anonymous XVEucVMsENoch keine Bewertungen

- Sikagrout 350Dokument3 SeitenSikagrout 350Manuel CardosoNoch keine Bewertungen

- Nap-Gard 7-2504 Gold-Dual Powder System: Technical Data SheetDokument3 SeitenNap-Gard 7-2504 Gold-Dual Powder System: Technical Data Sheetlong chanNoch keine Bewertungen

- Sikadur 42 LeDokument5 SeitenSikadur 42 LekhudhayerNoch keine Bewertungen

- Technical Data: Plastic Steel 5-Minute Putty (SF)Dokument4 SeitenTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNoch keine Bewertungen

- WRC SpecificationDokument2 SeitenWRC SpecificationTrungThanh TranNoch keine Bewertungen

- Sikadur®-42 Grout Pak Multi-Flo: Pre-Proportioned, Epoxy Base Plate, Grouting SystemDokument2 SeitenSikadur®-42 Grout Pak Multi-Flo: Pre-Proportioned, Epoxy Base Plate, Grouting SystemnedNoch keine Bewertungen

- Araldite EP 300 AB - US - eDokument5 SeitenAraldite EP 300 AB - US - echallasnNoch keine Bewertungen

- NS Grout PDFDokument2 SeitenNS Grout PDFRenjithNoch keine Bewertungen

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Dokument4 SeitenAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiNoch keine Bewertungen

- D40 SikaGrout 328Dokument2 SeitenD40 SikaGrout 328Murtada MohamedNoch keine Bewertungen

- Epofine 556 - Finehard 22962Dokument5 SeitenEpofine 556 - Finehard 22962Karishma PrabhuNoch keine Bewertungen

- Sikadur®-31 SBA Normal SetDokument2 SeitenSikadur®-31 SBA Normal Setkvemanak9733Noch keine Bewertungen

- 7727 Auto - Dispensable Glossy White Thermal Transfer Printable PolyimideDokument4 Seiten7727 Auto - Dispensable Glossy White Thermal Transfer Printable Polyimidetoumi amineNoch keine Bewertungen

- Sunmide X-2000-TDSDokument2 SeitenSunmide X-2000-TDSTerrence LaiNoch keine Bewertungen

- Plastic Steel Putty A v3Dokument2 SeitenPlastic Steel Putty A v3feri.ferdianto02Noch keine Bewertungen

- Eastman Copolyester Eastar GN 001Dokument2 SeitenEastman Copolyester Eastar GN 001Josephine NgNoch keine Bewertungen

- 3M Scotch Weld DP 490 PDFDokument4 Seiten3M Scotch Weld DP 490 PDFdilay ünalNoch keine Bewertungen

- DP490 Dwuskładnikowy Klej Strukturalny (TDS) PDFDokument4 SeitenDP490 Dwuskładnikowy Klej Strukturalny (TDS) PDFKrzysztof JososNoch keine Bewertungen

- HojaTecnica Heat Flex Hi Temp 1200Dokument4 SeitenHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONoch keine Bewertungen

- Fosroc Conbextra GP TDSDokument4 SeitenFosroc Conbextra GP TDSmukesh baghelNoch keine Bewertungen

- PS 14 Anchor Bolt TolerancesDokument4 SeitenPS 14 Anchor Bolt TolerancesjebrijaNoch keine Bewertungen

- Five Star Rapid Epoxy GroutDokument2 SeitenFive Star Rapid Epoxy GroutJohnprasannaNoch keine Bewertungen

- Tritan TX1001Dokument2 SeitenTritan TX1001qiongyao cuiNoch keine Bewertungen

- Liquid Epoxy Coating (3M)Dokument5 SeitenLiquid Epoxy Coating (3M)Thamaraikani ManiNoch keine Bewertungen

- HTR Grout: Product DescriptionDokument2 SeitenHTR Grout: Product Descriptionmcdermott22Noch keine Bewertungen

- Basf Masterflow 880 TdsDokument5 SeitenBasf Masterflow 880 TdsvinaykumarNoch keine Bewertungen

- SikaGrout 328Dokument4 SeitenSikaGrout 328Jun ZhuNoch keine Bewertungen

- 32 00 00 Exterior Improvements: 32 01 16 Flexible Paving RehabilitationDokument9 Seiten32 00 00 Exterior Improvements: 32 01 16 Flexible Paving RehabilitationAnonymous Wj1DqbENoch keine Bewertungen

- Construction and Building Materials: Mucteba Uysal, Harun TanyildiziDokument7 SeitenConstruction and Building Materials: Mucteba Uysal, Harun TanyildiziMark WilliamsNoch keine Bewertungen

- AERC8 Ramset-EpconC8 PDSDokument11 SeitenAERC8 Ramset-EpconC8 PDSZilong ZhangNoch keine Bewertungen

- Pripstar 130: SpecificationDokument3 SeitenPripstar 130: SpecificationAnkita Baban GavadeNoch keine Bewertungen

- A Study On The Rigid Pavement Construction Joint and Crack FormationDokument6 SeitenA Study On The Rigid Pavement Construction Joint and Crack FormationAjit P. SinghNoch keine Bewertungen

- Pengaruh Penambahan Serat Bambu Terhadap Kuat Tarik Dan Kuat Tekan BetonDokument6 SeitenPengaruh Penambahan Serat Bambu Terhadap Kuat Tarik Dan Kuat Tekan Betonmuhajir mrbNoch keine Bewertungen

- Sikafloor 225N: UV Resistant Epoxy SystemDokument4 SeitenSikafloor 225N: UV Resistant Epoxy SystemBudhi KurniawanNoch keine Bewertungen

- Building Code Australia ComplianceDokument24 SeitenBuilding Code Australia ComplianceLampard ChenNoch keine Bewertungen

- Catalogo SAP2000 V15Dokument44 SeitenCatalogo SAP2000 V15isanlagNoch keine Bewertungen

- Pinova Vinsol BrochureDokument6 SeitenPinova Vinsol BrochurezodapesssNoch keine Bewertungen

- Concrete DurabilityDokument3 SeitenConcrete DurabilityShuvanjan Dahal100% (1)

- MasterPel SP 4000 - BASF July 2018 - en - NZDokument2 SeitenMasterPel SP 4000 - BASF July 2018 - en - NZDan IonelNoch keine Bewertungen

- Consol Cosmetic: Polymer Modified Portland Cement CoatingDokument2 SeitenConsol Cosmetic: Polymer Modified Portland Cement CoatingCiput MardiantoNoch keine Bewertungen

- Jurnal Beton Ringan StyrofoamDokument8 SeitenJurnal Beton Ringan StyrofoamBudi PriantoroNoch keine Bewertungen

- Full Thesis PDFDokument87 SeitenFull Thesis PDFAli HossainNoch keine Bewertungen

- Bill of Quantities (Boq) For Labor WorkDokument7 SeitenBill of Quantities (Boq) For Labor WorkSiddiqur RahmanNoch keine Bewertungen

- Module 3Dokument17 SeitenModule 3Harshitha j gowdaNoch keine Bewertungen

- Civil Engineering Instruments Cement Concrete Instruments Aggregates Instruments Bitumen Asphalt Equipments Shrinkage Limit SetDokument4 SeitenCivil Engineering Instruments Cement Concrete Instruments Aggregates Instruments Bitumen Asphalt Equipments Shrinkage Limit SetAdeel RasheedNoch keine Bewertungen

- Projet FRCDokument20 SeitenProjet FRCHARSH KUMARNoch keine Bewertungen

- NSPM KonstruksiDokument141 SeitenNSPM Konstruksiredrik irawan100% (2)

- 100 Seated Hostels Building SaharpadaDokument136 Seiten100 Seated Hostels Building SaharpadaMohammed ShahbazNoch keine Bewertungen