Beruflich Dokumente

Kultur Dokumente

Valuable Pump Formulas: 3800 North Carnation Street Franklin Park, IL 60131

Hochgeladen von

cristinelbOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Valuable Pump Formulas: 3800 North Carnation Street Franklin Park, IL 60131

Hochgeladen von

cristinelbCopyright:

Verfügbare Formate

Phone:(847)671-5650

Fax: (847) 671-7686

3800 North Carnation Street cs@semlerindustries,.com

Franklin Park, IL 60131 www.semlerindustries.com

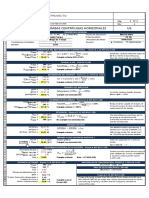

VALUABLE PUMP FORMULAS

Pressure Pipe Velocity Centrifugal Pumps

Feet of Water X 0.4333 = PSI Velocity in Feet GPM x 0.321 Liquid HP: GPM x ft. of Head x Sp. Gr.

(PSI X 2.31)/Sp. Gr. = Feet of Water per Second: Pipe Area in Square Inches 3960

(Ft. Head x Sp. Gr.)/2.31 =PSI Rule of Thumb: Typically, keep pipe velocities Brake HP: GPM x TDH x Sp. Gr.

PSI x 6.9 =kPa around 10 ft/second for good 3960 x Pump Efficiency

results.

ATM x 14.7 =PSI Efficiency BHP

Suction Piping: Generally, have piping in one Overall HP: Motor Efficiency

ATM x 33.9 =Feet of Water

plane from source tank and

ATM x 760 =mm Hg Estimated effects of viscosity on Centrifugal Pumps

have a straight run at least 10

kg/cm2 x 1.42 =PSI times the pipes diameter leading SSU FLOW HEAD EFFICIENCY

Meters of Water x 1.42 =PSI into the pump suction. 35 100% 100% 80%

Bar x 14.5 =PSI Pipe Size: Doubling the diameter of a pipe 500 95% 98% 80%

Inches of Hg x 0.491 =PSI increases its capacity 4 times. 1000 92% 97% 70%

Rotary Positive Displacement Pumps Approximate RPM @ Full Load - for medium sized motors

Poles RPM Sync RPM Sync

Liquid HP: GPM x PSI (60 Hz) Speed (50 Hz) Speed

1714 2 3500 3600 2850 3000

Volumetric Actual GPM 4 1750 1800 1450 1500

Efficiency: Theoretical GPM 6 1150 1200 950 1000

Overall Pump LHP 8 850 900 700 750

Efficiency: BHP Synchronous Speed Frequency(Hz) x 120

Mechanical Overall Pump Efficiency: (no load) Formula RPM= Number of Poles

Volumetric Efficiency

Insulation Class NEMA 1.15 Service Factor Rules of Thumb for Motors

A 1500 C 2210 F A motor develops 1.5 ft-lbs per HP @ 3600 RPM A 3-phase motor draws 1.00 Amp per HP @ 557 Volts

B 1300C 2660 F A motor develops 3.0 ft-lbs per HP @ 1800 RPM A 3-phase motor draws 1.25 Amp per HP @ 460 Volts

F 1550 C 3110 F A motor develops 4.5 ft-lbs per HP@ 1200 RPM A 3-phase motor draws 2.50 Amp per HP @ 230 Volts

H 1800 C 3560 F

HP= Torque (ft-lbs) x RPM

Torque (in lbs) HP x 63,000

Maximum motor temperature including temperature rise plus

5252 RPM

400 C ambient temperature

Particle Size Comparison Atmospheric Pressure Viscosity Affinity Laws for Centrifugal Pumps

Mesh Inch Micron

Altitude in Pressure in Conversions: These formulas can be used to estimate

3250 .0002 6

Feet PSIA SSU* = Centistokes x 4.55 capacity, head and BHP for a pump

1600 .0005 14 speed or impeller diameter when a curve

0 14.70 Degrees Engler* = Centistokes x 0.132

750 .0010 25 Sec. Redwood 1* = Centistokes x 4.05 is not readily available.

100 14.64

325 .0016 40 1 Stoke = 100 Centistokes

300 14.54 1. Flow is directly proportional to the ratio of

250 .0024 62 1 Poise = 100 Centipoises impeller speed:

200 .0029 74 500 14.43 Centistokes = Centipoise/Sp. Gr. GPM1 x RPM2

180 .0033 85 700 14.33 *Where Centistokes are greater than 50 GPM2 =

RPM

150 .0041 100 1,000 14.17 Definitions:

2. Head is directly Proportional to the square of

120 .0046 118 Newtonian fluids are unaffected by shear, e.g.

1,500 13.92 the ratio of impeller speed:

water mineral oil.

100 .0055 149 2,000 13.66 RPM2 2

Non-Netownian fluids are affected by shear Head2 = Head1 x

80 .0070 179 3,000 13.17 RPM1

(5 types).

50 .0117 300 Bingham-Plastic fluids have an exact 3. The HP is directly proportional to the ratio of

4,000 12.69

40 .0150 385 shear point which once exceeded, impeller speed:

5,000 12.23

30 .0200 513 viscosity decreases. RPM 2

7,000 11.34 BHP2 = BHP1 x

24 .0280 718 Pseudo-Plastic fluids have no exact yield point, RPM1

20 .0340 872 10,000 10.11 but instead, viscosity decreases as the 4. Flow is directly proportional to the ratio of

18 .0390 1000 15,000 8.29 magnitude of shear rate increases. impeller diameter:

16 .0450 1154 20,000 6.76 Dilatant fluids viscosity increases as the mag- Impeller Diameter2 2

nitude of the shear rate increases, e.g. printing Flow2 = Flow1 x

14 .0510 1308 25,000 5.45 Impeller Diameter1

ink, candy compounds.

12 .0600 1538 30,000 4.36 5. Head is directly proportional to the square of

Thixotropic fluids decrease in viscosity both in

10 .0750 1923 40,000 2.72 the ratio of Impeller diameter:

relation to the shear magnitude and the period

8 .0970 2488 Impeller Diameter2 2

50,000 1.68 of time subjected to shear. Viscosity might also Head2 = Head1 x

6 .1320 3385 depend on a previous shear condition, e.g. Impeller Diameter1

60,000 1.04

4 .1590 4077 drilling mud, starches, paint. 6. The HP is directly proportional to the cube

2 .2030 5205 Rheopectic fluids increase viscosity both in of the ratio of impeller diameter:

relation to the shear magnitude and the period Impeller Diameter2 2

1 Micron = 10-6 Meters BHP2 = BHP1 x

of time subjected to shear, e.g. some greases. Impeller Diameter1

1 Micron = 3.9 x 10-5 inch

Das könnte Ihnen auch gefallen

- Basic Theory PumpDokument37 SeitenBasic Theory PumpkunkzNoch keine Bewertungen

- Pump Calculations, Pump EquationsDokument3 SeitenPump Calculations, Pump EquationsSpataru Marius0% (2)

- 106.1 Power Measurement TAB BEFORE - COMPONENTSDokument11 Seiten106.1 Power Measurement TAB BEFORE - COMPONENTSHassan GDOURANoch keine Bewertungen

- CalculationsDokument4 SeitenCalculationsVinish HARIDAS NAIRNoch keine Bewertungen

- Hydraulic Power Unit EDokument8 SeitenHydraulic Power Unit EDipankar KhawasNoch keine Bewertungen

- Hvac HintsDokument4 SeitenHvac HintsIsabel VasquezNoch keine Bewertungen

- Performance Curve: e-HSC 3x5x10.5Dokument1 SeitePerformance Curve: e-HSC 3x5x10.5Ndia2007Noch keine Bewertungen

- Electromech BasicDokument51 SeitenElectromech Basicron villanuevaNoch keine Bewertungen

- Conversions Formulas: Visit Our Web SiteDokument1 SeiteConversions Formulas: Visit Our Web SiteKuttappa I GNoch keine Bewertungen

- Cavitation in Pumps and Importance of Calculating Net Positive Suction Head in Preventing ItDokument24 SeitenCavitation in Pumps and Importance of Calculating Net Positive Suction Head in Preventing ItMichael Alex MabaoNoch keine Bewertungen

- 01 - Irrigation PumpsDokument47 Seiten01 - Irrigation PumpsJonesNoch keine Bewertungen

- Centrifugal PumpsDokument7 SeitenCentrifugal Pumpsbb.biancaaborgessNoch keine Bewertungen

- Calculate NPSHfrom Flow Issue 3 - Online-2Dokument1 SeiteCalculate NPSHfrom Flow Issue 3 - Online-2Aviv AL FarisNoch keine Bewertungen

- Pump PerformanceDokument25 SeitenPump PerformanceNguyen ChuyenNoch keine Bewertungen

- Lecture Sheet 3 PDFDokument14 SeitenLecture Sheet 3 PDFMuhammed RazzaqueNoch keine Bewertungen

- 01 HRDokument3 Seiten01 HRamdnazri.80Noch keine Bewertungen

- Voith IPH4-5-6Dokument5 SeitenVoith IPH4-5-6wag008Noch keine Bewertungen

- (Oto-Hui - Com) en - Hydraulic CoursesDokument47 Seiten(Oto-Hui - Com) en - Hydraulic Courseseng_ebrahim_2000100% (1)

- Pump FinalDokument84 SeitenPump Finalpowergops100% (2)

- Pump A10VO DFR PrincipleDokument25 SeitenPump A10VO DFR Principlemaintenance 2kpb100% (1)

- 05 - Formula Sheet - HydraulicsDokument2 Seiten05 - Formula Sheet - Hydraulicsstollermi11Noch keine Bewertungen

- Pumps and Pumping SystemsDokument36 SeitenPumps and Pumping Systemsrizairawan09Noch keine Bewertungen

- Bomba Ziegler Up4 - enDokument8 SeitenBomba Ziegler Up4 - enPillaChantas0% (1)

- Pump CalculationsDokument9 SeitenPump CalculationsMohamad TantawyNoch keine Bewertungen

- 3 PumpDokument19 Seiten3 PumpAzhar SabriNoch keine Bewertungen

- FFB & SFB Conveyor-SizingDokument14 SeitenFFB & SFB Conveyor-SizingAzaharimahadiNoch keine Bewertungen

- Pressure Vessel Sizing Calculation: Project: Al Rayyan Villa MEP Contractor: Lead Cooling Contracting & TradingDokument1 SeitePressure Vessel Sizing Calculation: Project: Al Rayyan Villa MEP Contractor: Lead Cooling Contracting & TradingMohammed JavidNoch keine Bewertungen

- Pump PerformanceDokument33 SeitenPump PerformanceHASSAN MERNoch keine Bewertungen

- Centrifugal Pump Performance CurveDokument6 SeitenCentrifugal Pump Performance CurveManish MishraNoch keine Bewertungen

- Affinity Laws of PumpsDokument5 SeitenAffinity Laws of PumpsselagosNoch keine Bewertungen

- Centrifugal Pump - Expt No .4Dokument17 SeitenCentrifugal Pump - Expt No .4ruikar manojNoch keine Bewertungen

- Voith Gear Pump RecommendationDokument28 SeitenVoith Gear Pump RecommendationcotteNoch keine Bewertungen

- Module 3 - Pump Configuration Specific Speed and Affinity Laws - No AnsDokument17 SeitenModule 3 - Pump Configuration Specific Speed and Affinity Laws - No AnsRoi Vincent AnitNoch keine Bewertungen

- Pump Efficiency ExcelDokument74 SeitenPump Efficiency ExcelSiddharthSaraswat100% (1)

- Pump Horsepower CalculationDokument4 SeitenPump Horsepower CalculationAbigail RuedaNoch keine Bewertungen

- Operation of Centrifugal PumpDokument16 SeitenOperation of Centrifugal PumpvenisamegaNoch keine Bewertungen

- Motor Application FormulasDokument1 SeiteMotor Application FormulasMAJIDM3000Noch keine Bewertungen

- Piston Pump MetarisDokument44 SeitenPiston Pump Metarissml2001100% (3)

- R&R Seremban - Suction PumpDokument3 SeitenR&R Seremban - Suction PumpJeghiNoch keine Bewertungen

- Semler ChartDokument1 SeiteSemler ChartAjit MokalNoch keine Bewertungen

- Roots Atıksu ArımaDokument8 SeitenRoots Atıksu ArımaAndrey GyrychNoch keine Bewertungen

- HdusjDokument46 SeitenHdusjlarasNoch keine Bewertungen

- Week 2 PPD Ipd Problems AnswersDokument26 SeitenWeek 2 PPD Ipd Problems AnswersDarren Ian MaalihanNoch keine Bewertungen

- Pump Performance Test Report: Formula (Example)Dokument2 SeitenPump Performance Test Report: Formula (Example)Serkam PEDNoch keine Bewertungen

- Fmi - Fire ProtectionDokument2 SeitenFmi - Fire ProtectionGia NguyenNoch keine Bewertungen

- HVACR Formulas and SymbolsDokument46 SeitenHVACR Formulas and SymbolsatiqNoch keine Bewertungen

- Design of Pumpset For Mavally Lwss at Thondernad GPDokument1 SeiteDesign of Pumpset For Mavally Lwss at Thondernad GPSweegesh KsNoch keine Bewertungen

- Week13 Turbomachine IDokument24 SeitenWeek13 Turbomachine IMuhammad imranNoch keine Bewertungen

- Slow Down, You're Moving Too FastDokument3 SeitenSlow Down, You're Moving Too Fastcjp6124Noch keine Bewertungen

- Curves Are Approximate, Pump Is Guaranteed For One Set of Conditions Capacity, Head, and PowerDokument4 SeitenCurves Are Approximate, Pump Is Guaranteed For One Set of Conditions Capacity, Head, and PowerMohsin RazaNoch keine Bewertungen

- Pump BasicsDokument118 SeitenPump BasicsVinod GuptaNoch keine Bewertungen

- Brosure Case CX 220C LR-compressedDokument4 SeitenBrosure Case CX 220C LR-compressedindrayunitaNoch keine Bewertungen

- Submittal: Series: HSC, Diesel EngineDokument14 SeitenSubmittal: Series: HSC, Diesel EngineOmar MuqtharNoch keine Bewertungen

- Centrifugal Pump Technical SummaryDokument52 SeitenCentrifugal Pump Technical Summarychaitanya100% (1)

- CH 12 - Pumps & Hydraulic TurbinesDokument20 SeitenCH 12 - Pumps & Hydraulic TurbinesSupervisores ProduccionNoch keine Bewertungen

- Evaluación Cálculo HidráulicoDokument1 SeiteEvaluación Cálculo HidráulicoNoelrmuNoch keine Bewertungen

- Pump & Pressure Drop CalculationDokument42 SeitenPump & Pressure Drop CalculationMuhammad RizkyNoch keine Bewertungen

- Grundfos Isolutions: We Bring More Than PumpsDokument31 SeitenGrundfos Isolutions: We Bring More Than PumpsTasawwur TahirNoch keine Bewertungen

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesVon EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesBewertung: 5 von 5 Sternen5/5 (1)

- What Is A CRN NumberDokument3 SeitenWhat Is A CRN NumbercristinelbNoch keine Bewertungen

- Sample6 FEA Drawing PDFDokument2 SeitenSample6 FEA Drawing PDFcristinelbNoch keine Bewertungen

- Located BearingsDokument106 SeitenLocated BearingscristinelbNoch keine Bewertungen

- Tutorial LimbergDokument1 SeiteTutorial LimbergcristinelbNoch keine Bewertungen

- Guidelines For Pressure Boundary Bolted Flange Joint AssemblyDokument9 SeitenGuidelines For Pressure Boundary Bolted Flange Joint AssemblycristinelbNoch keine Bewertungen

- Cylindrical Roller Bearings: Distributor SearchDokument2 SeitenCylindrical Roller Bearings: Distributor SearchcristinelbNoch keine Bewertungen

- Fig. 2 - Double Direction Angular Contact Thrust Ball BearingDokument1 SeiteFig. 2 - Double Direction Angular Contact Thrust Ball BearingcristinelbNoch keine Bewertungen

- Scheerer Bearing Oil IndustryDokument62 SeitenScheerer Bearing Oil IndustrycristinelbNoch keine Bewertungen

- SKF Angular Contact Ball BearingsDokument2 SeitenSKF Angular Contact Ball BearingscristinelbNoch keine Bewertungen

- Fig. 1 - Single Direction Angular Contact Thrust Ball BearingDokument1 SeiteFig. 1 - Single Direction Angular Contact Thrust Ball BearingcristinelbNoch keine Bewertungen

- Master Bushing - JANKI Oil ToolsDokument6 SeitenMaster Bushing - JANKI Oil ToolscristinelbNoch keine Bewertungen

- Bearing 3Dokument1 SeiteBearing 3cristinelbNoch keine Bewertungen

- Cylindrical Roller Bearings - 2 PDFDokument52 SeitenCylindrical Roller Bearings - 2 PDFcristinelbNoch keine Bewertungen

- PDR BearingDokument11 SeitenPDR BearingcristinelbNoch keine Bewertungen

- Scheerer Bearing Oil IndustryDokument62 SeitenScheerer Bearing Oil IndustrycristinelbNoch keine Bewertungen

- Master Bushing-Insert Bowls - API 7KDokument2 SeitenMaster Bushing-Insert Bowls - API 7KcristinelbNoch keine Bewertungen

- Bowls Bushings AOTDokument2 SeitenBowls Bushings AOTcristinelbNoch keine Bewertungen

- Scheerer Bearing Oil Industry PDFDokument8 SeitenScheerer Bearing Oil Industry PDFcristinelbNoch keine Bewertungen

- Handing Tools CPMCDokument32 SeitenHanding Tools CPMCcristinelb100% (1)

- Master and Casing Bushing - ACEWELDokument8 SeitenMaster and Casing Bushing - ACEWELcristinelb100% (1)

- Eurocode 1: Reference TitleDokument1 SeiteEurocode 1: Reference TitlecristinelbNoch keine Bewertungen

- Master Bushing-Bowls - DENCON ToolDokument5 SeitenMaster Bushing-Bowls - DENCON ToolcristinelbNoch keine Bewertungen

- ASME VIII - Division 1 - Division 2 - Division 3?Dokument1 SeiteASME VIII - Division 1 - Division 2 - Division 3?cristinelbNoch keine Bewertungen

- PDS StructuralEnterprise LTR 0517 LR FDokument7 SeitenPDS StructuralEnterprise LTR 0517 LR FcristinelbNoch keine Bewertungen

- 1980 - Roos - Chem Phys - A Complete Active Space SCF Method (CASSCF) Using A Density Matrix Formulated Super-CI ApproachDokument17 Seiten1980 - Roos - Chem Phys - A Complete Active Space SCF Method (CASSCF) Using A Density Matrix Formulated Super-CI Approachvitoribeiro90Noch keine Bewertungen

- Coatings Word August 2010Dokument52 SeitenCoatings Word August 2010sami_sakrNoch keine Bewertungen

- A Premium Institute For CBSE, NEET & JEEDokument33 SeitenA Premium Institute For CBSE, NEET & JEEZUHAIB KAMALNoch keine Bewertungen

- Unimolecular ReactionDokument16 SeitenUnimolecular ReactionoxyzenNoch keine Bewertungen

- Comprehensive Coordination ChemistryDokument818 SeitenComprehensive Coordination Chemistryrace egrNoch keine Bewertungen

- Becogur enDokument2 SeitenBecogur enRui Felizardo0% (1)

- Effects of Poultry Manure Supplemented by NPK 15-15-15 Fertilizer On Cucumber (Cucumis Sativus L.) Production in Port Harcourt (Nigeria)Dokument7 SeitenEffects of Poultry Manure Supplemented by NPK 15-15-15 Fertilizer On Cucumber (Cucumis Sativus L.) Production in Port Harcourt (Nigeria)tino3528Noch keine Bewertungen

- Unit 4 Study Guide Solutions - Kinetics & ThermoDokument3 SeitenUnit 4 Study Guide Solutions - Kinetics & ThermoPenguin/CatNoch keine Bewertungen

- Improved Procedures For The Genetic Transformation of Rhodobacter CapsulatusDokument1 SeiteImproved Procedures For The Genetic Transformation of Rhodobacter CapsulatusSerena XuNoch keine Bewertungen

- Chemistry 2 Module 3Dokument10 SeitenChemistry 2 Module 3Joshua James Sanguenza RodriguezNoch keine Bewertungen

- Science 7 ExamDokument5 SeitenScience 7 Examangge21Noch keine Bewertungen

- Test Bank For General Chemistry 10th Edition by EbbingDokument56 SeitenTest Bank For General Chemistry 10th Edition by Ebbingcleopatracaig03w5Noch keine Bewertungen

- Techno-Economic Evaluation of Microalgae For Protein - Sari Et Al 2016Dokument9 SeitenTechno-Economic Evaluation of Microalgae For Protein - Sari Et Al 2016Laura Soto SierraNoch keine Bewertungen

- KLEN 2207 Cream CleanerDokument3 SeitenKLEN 2207 Cream CleanerSneha Nagaokar100% (1)

- FaienceDokument15 SeitenFaienceRenata TatomirNoch keine Bewertungen

- General Pharmacology MCQDokument6 SeitenGeneral Pharmacology MCQShrikant ThakurNoch keine Bewertungen

- AlloysDokument4 SeitenAlloyslinguy007Noch keine Bewertungen

- Ceramic Engineering: From Wikipedia, The Free EncyclopediaDokument6 SeitenCeramic Engineering: From Wikipedia, The Free EncyclopediaFaiz AbdullahNoch keine Bewertungen

- Calcium and Magnesium Determinations by EDTA Titrations1 (Soil Science Society of America Journal, Vol. 25, Issue 1) (1961)Dokument3 SeitenCalcium and Magnesium Determinations by EDTA Titrations1 (Soil Science Society of America Journal, Vol. 25, Issue 1) (1961)Heba TahaNoch keine Bewertungen

- AIATS Schedule (2011, 2012)Dokument7 SeitenAIATS Schedule (2011, 2012)goelbharatNoch keine Bewertungen

- Seismic Principles: - Chapter 1Dokument13 SeitenSeismic Principles: - Chapter 1Mahardika Aji KurniawanNoch keine Bewertungen

- Compozitia Smaltului Si DemineralizareaDokument10 SeitenCompozitia Smaltului Si DemineralizareaMadalina Elena TapeleaNoch keine Bewertungen

- Flow Simulation and Static Structural Analysis On Pelton TurbineDokument7 SeitenFlow Simulation and Static Structural Analysis On Pelton TurbineRahul ReddyNoch keine Bewertungen

- Gate 2001Dokument61 SeitenGate 2001api-26818774Noch keine Bewertungen

- Ch. 15 Review AnswersDokument2 SeitenCh. 15 Review AnswersJose PopoffNoch keine Bewertungen

- Measurement System BehaviourDokument48 SeitenMeasurement System BehaviourpitapitulNoch keine Bewertungen

- Concrete ExamDokument26 SeitenConcrete ExamKyra AlesonNoch keine Bewertungen

- Increasing The Performance of Chain Sprocket by Using Cryogenic Treated and Normalizing in Superficial Heat TreatmentDokument25 SeitenIncreasing The Performance of Chain Sprocket by Using Cryogenic Treated and Normalizing in Superficial Heat Treatmentthai avvaiNoch keine Bewertungen

- Food Science Report - GroupDokument23 SeitenFood Science Report - GroupMuhammad Salihin JaafarNoch keine Bewertungen

- OuchterlonyDokument4 SeitenOuchterlonyd_caasi100% (1)