Beruflich Dokumente

Kultur Dokumente

Manual Shutdown LPG

Hochgeladen von

Yoga NugrahaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manual Shutdown LPG

Hochgeladen von

Yoga NugrahaCopyright:

Verfügbare Formate

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

P.OP-SS-OPS-03

Prepared by Reviewed by Approved by

01 Maret 2017 01 Maret 2017 01 Maret 2017

Operation Supervisor Operation Superintendent O & M Manager

This document is property of PT TITIS SAMPURNA

All external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

Doc. No. : P.OP-SS-OPS-03

PROCEDURE Rev. : 0

Date : 01 Maret 2017

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

RIWAYAT PERUBAHAN DOKUMEN

REVISION HISTORY

Bagian Detail Perubahan Alasan Perubahan Tgl Perubahan Nomor Tanda

Dokumen Details of Revision Reason of Revision Date of revision Revisi Tangan

Section No.rev Signed

First Issue 22 Agustus 2011 0

4 Penambahan Klausul Penambahan 01 Juni 2012 1

ISO 14001 : 2004 pada Implementasi ISO

referensi. 14001 : 2004 pada

sistem mutu.

4 Perubahan Klausul ISO Transisi ke ISO 01 Maret 2017 0

9001 : 2015 dan 14001 : 9001:2015 dan

2015 pada referensi. 14001 : 2015

This document is property of PT TITIS SAMPURNA

All external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

|page 2 of 11

Doc. No. : P.OP-SS-OPS-03

PROCEDURE Rev. : 0

Date : 01 Maret 2017

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

DAFTAR ISI

TABLE OF CONTENTS

Cover dan Lembar Pengesahan (cover and authorization sheet)_________________________ 1

Riwayat Perubahan (revision history)_______________________________________________ 2

Daftar Isi (table of contents)_____________________________________________________ 3

Tujuan (objective)_____________________________________________________________ 4

Ruang Lingkup (scope)__________________________________________________________ 4

Definisi (definition)_____________________________________________________________ 4

Referensi (reference)___________________________________________________________ 5

Tanggung Jawab (responsibilities)_________________________________________________ 5

Prosedur (procedures) __________________________________________________________ 6

Dokumen terkait (related documents)_____________________________________________ 11

This document is property of PT TITIS SAMPURNA

All external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

|page 3 of 11

Doc. No. : P.OP-SS-OPS-03

PROCEDURE Rev. : 0

Date : 01 Maret 2017

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

1. TUJUAN (OBJECTIVE)

Prosedur ini untuk memberi panduan tata cara shutdown secara manual di LPG Plant Limau

Timur.

This procedure is to give guidance to manually shutdown procedures in LPG Plant Limau Timur.

2. RUANG LINGKUP (SCOPE)

Prosedur ini meliputi aktivitas Bypass Feed Gas dan kondesat ke off spec tank V-(510D),

pengaturan inlet, mematikan Refrigeration Compressor hingga pengaturan valve-valve.

This procedure involves the activity Feed Gas By pass and condensate into each tank, setting the

"opening" inlet-inlet, shutdown the Refrigeration Compressor until setting "opening" the valve-

valve.

3. DEFINISI (DEFINITION)

Manual shutdown adalah mematikan plant secara sengaja / diperintahkan / instruksi karena

tujuan tertentu.

4. REFERENSI (REFERENCE)

ISO 9001:2015 : Klausul 8.5. Produksi dan Penyediaan Pelayanan

Clause 8.5 Production and service provision

: Klausul 8.5.1 Pengendalian Produksi dan Penyediaan Pelayanan

Clause 8.5.1 Control of production and service provision

OHSAS 18001 : 2007 : Klausul 4.4.6 Pengendalian Operasional

Clause 4.4.6 Operational Control

ISO 14001 : 2015 : Klausul 8.1 Pengendalian Operasional

Clause 8.1 Operational Control

This document is property of PT TITIS SAMPURNA

All external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

|page 4 of 11

Doc. No. : P.OP-SS-OPS-03

PROCEDURE Rev. : 0

Date : 01 Maret 2017

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

5. TANGGUNG JAWAB (RESPONSIBILITIES)

5.1 Superintendent bertanggung jawab atas kelancaran proses shutdown di LPG Plant.

Superintendent is responsible for the smooth process of shutdown in the LPG Plant

5.2 Supervisor Operation bertanggung jawab memastikan proses manual shutdown ini sesuai

prosedur yang sudah ditetapkan.

Operations Supervisor is responsible for ensuring the manual shutdown process according to

the procedure has been established

5.3 Semua petugas yang terlibat dalam proses manual shutdown ini harus ikut bertanggung

jawab atas keselamatan plant berikut didalamnya

All officers involved in this manual shutdown, should be partly responsible for plant safety in

it follow

This document is property of PT TITIS SAMPURNA

All external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

|page 5 of 11

Doc. No. : P.OP-SS-OPS-03

PROCEDURE Rev. : 0

Date : 01 Maret 2017

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

6. PROSEDUR

No Flowchart Deskripsi Penanggung Jawab Dok.terkait

/Alat

Petugas memindahkan product LPG

Pemindahan dari LPG Tank On Spec (V-510

LPG dan A/B/C) dan mengalihkan hasil proses

1 Kondesat Operation

LPG ke V-510D (TK-507/506) ke LPG

Tank Off Spec (V-510 D).

Kemudian menurunkan RPM

Penurunan RPM Refrigeration Compressor secara

Operation

2 Refrigeration bertahap dari RPM 1100 sampai 700

Compressor (posisi idle).

Petugas membuka valve bypass Gas

Pembukaan Inlet sehingga feed gas dari proses

3 valve bypass gas mengalir ke Pupuk Sriwijaya Operation

inlet

Palembang (PUSRI).

Closing valve

Kemudian menutup Valve Inlet ke

4 inlet proses. Operation

Petugas membuka valve discharge

Recyle Compressor yang menuju ke

Pengaturan

valve discharge

Outlet Pusri dan tutup valve

5 discharge Recycle Compressor yang Operation

RC

menuju ke Inlet proses, turunkan

speed dan matikan.

Lakukanlah Sirkulasi internal

Dehydration Package Unit (DHP) :

a. Buka Valve dari Discharge Pompa

6 MEG (P-460 A/B) menuju ke Operation

Sirkulasi DHP Flash Drum (V-461)

b. Tutup Valve dari Discharge

Pompa MEG (P-460 A/B) yang

A This document is property of PT TITIS SAMPURNA

All external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

|page 6 of 11

Doc. No. : P.OP-SS-OPS-03

PROCEDURE Rev. : 0

Date : 01 Maret 2017

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

No Flowchart Deskripsi Penanggung Jawab Dok.terkait

/Alat

menuju ke poroses Gas/Gas

Exchange (E-401) dan Gas Chiller

(E-402).

A c. Turunkan setting temperatur

Reboiler.

Kemudian lakukan Refrigeration

Compressor manual shut down :

a. Setelah 15 menit Refrigeration

Compressor jalan dengan posisi

idle speed maka tekan push

button untuk shutdown.

b. Tutup valve suction dan discard

Compressor Refrigeration

Refrigeration c. Matikan pompa Lube Oil

Comp. dimatikan Compressor (P-440 A/B)

d. Tutup valve fuel system, starter

7 line, Lube Oil, Jacket Water dan Operation

Intercooler.

e. Matikan pompa propane (P-

441) sebagai media pendingin

Lube Oil Compressor. Tutuplah

Inlet dan outlet pompa

tersebut.

f. Tutup Valve Outlet Gas Lube Oil

Return yang menuju ke

Refrigeration Compressor

g. Tutup valve line propane to Ac

Cooler

Penurunan Turunkan setting temperature Hot

Temperatur Oil Heater dan posisikan pada sisi

8 Low Fire. Operation

This document is property of PT TITIS SAMPURNA

All external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

|page 7 of 11

Doc. No. : P.OP-SS-OPS-03

PROCEDURE Rev. : 0

Date : 01 Maret 2017

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

No Flowchart Deskripsi Penanggung Jawab Dok.terkait

/Alat

Mematikan Petugas mematikan pompa Reflux Operation

9 Pompa P-421A/B Accumulator (P-421 A/B).

Bukalah valve dari vessel vessel

Pembukaan

10 menuju ke flare header untuk Operation

Vessel-Vessel

menjaga agar tidak over pressure.

Proses Selesail Proses manual Shutdown selesai

11

This document is property of PT TITIS SAMPURNA

All external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

|page 8 of 11

Doc. No. : P.OP-SS-OPS-03

PROCEDURE Rev. : 0

Date : 01 Maret 2017

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

6.PROCEDURES

No Flowchart Deskripsi Penanggung Jawab Dok.terkait

/Alat

Operator move the LPG product

Transfered from Tank LPG On Spec (V-510 A / B

LPG and / C) and condensate (TK-507/506) to

1 Operation

Condesat

LPG Tank Off Spec (V-510 D).

Decrease RPM

Then decrease RPM of Refrigeration Operation

Refrigeration

2 Compressor gradually from 1100 to

Compressor

700 RPM (idle position).

Operator open the Inlet Gas bypass

Open valve valve so that the feed gas from the

3 bypass gas inlet process flow to PT. Pupuk Sriwijaya Operation

Palembang (PUSRI).

Closing valve

Then close the Inlet Valve to the

4 inlet process. Operation

Operator open discharge Recyle

Compressor valve which toward to

Setting

discharge RC

the Outlet Pusri and close the

5 Operation

valve discharge Recycle Compressor valve

which toward to Inlet process

Do internal circulation to

Dehydration Package Unit (DHP) :

a. Open the Valve form Discharge

6 Pompa MEG (P-460 A/B) toward Operation

Circulated DHP

the Flash Drum (V-461)

b. Close the Valve from Discharge

This document is property of PT TITIS SAMPURNA

All external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

A

|page 9 of 11

Doc. No. : P.OP-SS-OPS-03

PROCEDURE Rev. : 0

Date : 01 Maret 2017

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

No Flowchart Deskripsi Penanggung Jawab Dok.terkait

/Alat

MEG Pump (P-460 A/B) which

toward to Gas process/Gas

Exchange (E-401) and Gas Chiller

(E-402).

A

d. Step down the setting

temperature of Reboiler.

Then do manual shutdown

Refrigeration Compressor :

a. after 15 minute Refrigeration

Compressor run with idle speed

condition, then press push

button for shutdown.

b. Open inlet valve and Compres

sor Refrigeration outlet

Refrigeration c. Turn off the pump of Lube Oil

Comp. dimatikan Compressor (P-440 A/B)

7 Operation

d. Close fuel system valve, starter

line, Lube Oil, Jacket Water dan

Intercooler.

e. Turn off the pump of propane (P-

441) as cooling media of Lube Oil

Compressor. Close the Inlet dan

outlet of the pump.

f. Close the Valve Outlet of Gas

Lube Oil Return which toward to

Refrigeration Compressor

Decrease Step down the setting of

8 Temperature temperature Hot Oil Heater and Operation

adjust at Low Fire position.

Turn off Operator turn off the Reflux

P-421A/B Pump Accumulator pump(P-421 A/B). Operation

9

This document is property of PT TITIS SAMPURNA

B external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

All

|page 10 of 11

Doc. No. : P.OP-SS-OPS-03

PROCEDURE Rev. : 0

Date : 01 Maret 2017

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

MANUAL SHUTDOWN LPG PLANT LIMAU TIMUR

No Flowchart Deskripsi Penanggung Jawab Dok.terkait

/Alat

Open Vessels Open the valve of vessels which Operation

10 toward to flare header for keep

against over-pressure.

Manual Shutdown was completed

11 Process

completed

7. DOKUMENT TERKAIT (RELATED DOCUMENT)

7.1 WI Fuel Gas Conditioning Unit (FGCU) LPG PLANT LMT (WI.OP-SS-OPS-01)

7.2 WI Air Instrument Compressor LPG PLANT LMT (WI.OP-SS-OPS-02)

7.3 WI Refrigeration Compressor LPG PLANT LMT (WI.OP-SS-OPS-03)

7.4 WI Power Generator (WI.OP-SS-OPS-04)

7.5 WI Ajax Compressor LPG PLANT LMT (WI.OP-SS-OPS-05)

7.6 WI Hot Oil Heater LPG PLANT LMT (WI.OP-SS-OPS-06)

7.7 WI DHP Glycol Unit LPG PLANT LMT (WI.OP-SS-OPS-07)

7.8 WI Transfer Glycol Dari Sump Tank LPG PLANT LMT (WI.OP-SS-OPS-08)

7.9 WI Daur Ulang Lpg Off Spec LPG PLANT LMT (WI.OP-SS-OPS-09)

7.10 WI Transfer Condensat LPG PLANT LMT (WI.OP-SS-OPS-10)

7.11 WI PLC View LPG PLANT LMT (WI.OP-SS-OPS-11)

7.12 WI Flow Computer 3020 LPG PLANT LMT (WI.OP-SS-OPS-12)

This document is property of PT TITIS SAMPURNA

All external communication, reproduction, publication should be authorized by PT TITIS SAMPURNA

|page 11 of 11

Das könnte Ihnen auch gefallen

- Active Directory FactsDokument171 SeitenActive Directory FactsVincent HiltonNoch keine Bewertungen

- List of People in Playboy 1953Dokument57 SeitenList of People in Playboy 1953Paulo Prado De Medeiros100% (1)

- Preventing OOS DeficienciesDokument65 SeitenPreventing OOS Deficienciesnsk79in@gmail.comNoch keine Bewertungen

- Guideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling FacilityDokument117 SeitenGuideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling Facilityshahjada100% (1)

- Natural Gas Pipeline Flow Calculations Course Content 2-23-16Dokument32 SeitenNatural Gas Pipeline Flow Calculations Course Content 2-23-16WereGaruruNoch keine Bewertungen

- Company Profile PT - PHE-WMODokument30 SeitenCompany Profile PT - PHE-WMOHendri Anur100% (2)

- GP 47-10 - Glycol Dehydration and RegenerationDokument10 SeitenGP 47-10 - Glycol Dehydration and RegenerationandhucaosNoch keine Bewertungen

- 03 DTK DWG Pid 001 P&id Final 1 NodeDokument1 Seite03 DTK DWG Pid 001 P&id Final 1 NodeAnnisaNoch keine Bewertungen

- Hitt PPT 12e ch08-SMDokument32 SeitenHitt PPT 12e ch08-SMHananie NanieNoch keine Bewertungen

- Jurnal LNGDokument17 SeitenJurnal LNG123habib123fikriNoch keine Bewertungen

- Schematic Diagram NSB-NSODokument18 SeitenSchematic Diagram NSB-NSOandriNoch keine Bewertungen

- Procurement List Year 2022 - Pep CepuDokument2 SeitenProcurement List Year 2022 - Pep Cepumarketing kinaryaNoch keine Bewertungen

- Legend Sheet P&ID For As-Built - Drafting On 20210722-4Dokument1 SeiteLegend Sheet P&ID For As-Built - Drafting On 20210722-4Ludi D. LunarNoch keine Bewertungen

- Sop-003-Rvp of Crude Oil LPG and NGLDokument8 SeitenSop-003-Rvp of Crude Oil LPG and NGLAmnaKamranNoch keine Bewertungen

- Study of Risk Perception and Potfolio Management of Equity InvestorsDokument58 SeitenStudy of Risk Perception and Potfolio Management of Equity InvestorsAqshay Bachhav100% (1)

- Spe Workshop: Brownfield Optimisation and Marginal Asset DevelopmentDokument20 SeitenSpe Workshop: Brownfield Optimisation and Marginal Asset DevelopmentPrimaresa UtamaNoch keine Bewertungen

- Integrated Assurance - Checklist DetailsDokument438 SeitenIntegrated Assurance - Checklist DetailsSyed AhmadNoch keine Bewertungen

- 00.field Overview&Production Process JOB PPEJ (Publish)Dokument56 Seiten00.field Overview&Production Process JOB PPEJ (Publish)Gyra LuthmanaNoch keine Bewertungen

- BMH-FED-SYN-00-L0-DS-001 - Datasheet For Manual Valve - Rev A - ANDokument20 SeitenBMH-FED-SYN-00-L0-DS-001 - Datasheet For Manual Valve - Rev A - ANAfif FadhliNoch keine Bewertungen

- ATLAS HONDA Internship ReportDokument83 SeitenATLAS HONDA Internship ReportAhmed Aitsam93% (14)

- 2 140716021917 Phpapp01Dokument87 Seiten2 140716021917 Phpapp01LK AnhDungNoch keine Bewertungen

- Jetty Modification - Upd 250417Dokument86 SeitenJetty Modification - Upd 250417Deni Yudha PermanaNoch keine Bewertungen

- Work Schedule Cleaning TANKER - PT AKR NILAMDokument1 SeiteWork Schedule Cleaning TANKER - PT AKR NILAMnhariwijayaNoch keine Bewertungen

- Fossil Hydrocarbons: Chemistry and TechnologyVon EverandFossil Hydrocarbons: Chemistry and TechnologyBewertung: 3 von 5 Sternen3/5 (1)

- LPG Finishd Abiola Faluyi FinalDokument19 SeitenLPG Finishd Abiola Faluyi FinalAmir O. OshoNoch keine Bewertungen

- ICSS For Gathering Station Jatiasri (Common Safety)Dokument7 SeitenICSS For Gathering Station Jatiasri (Common Safety)Dwiayu LastaryNoch keine Bewertungen

- Pertamina PitchDokument20 SeitenPertamina Pitchsupport busdevNoch keine Bewertungen

- TSB Gas Development ProjectDokument24 SeitenTSB Gas Development ProjectMarlon Moncada100% (2)

- Repair Procedure Patching Welded 42-L-P1-1404A TLA AREA - SENIPAH FIELDDokument13 SeitenRepair Procedure Patching Welded 42-L-P1-1404A TLA AREA - SENIPAH FIELDFerdie OSNoch keine Bewertungen

- Chapter 3 - Gas Gathering Transportation - V2 (Part 1)Dokument34 SeitenChapter 3 - Gas Gathering Transportation - V2 (Part 1)Qieya SaniNoch keine Bewertungen

- Bongkot Field 20 Year AnniversaryDokument8 SeitenBongkot Field 20 Year AnniversaryAnonymous ntK705RtNoch keine Bewertungen

- Gas Line Packing Calculations PDFDokument2 SeitenGas Line Packing Calculations PDFRBZNoch keine Bewertungen

- Design of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerDokument6 SeitenDesign of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerHoàng KakaNoch keine Bewertungen

- Gas For Energy Transition: Presented at High Level Summit On Human Capital Development Toward Net Zero EmissionDokument12 SeitenGas For Energy Transition: Presented at High Level Summit On Human Capital Development Toward Net Zero Emissionmineral geologistNoch keine Bewertungen

- MSDS PVC PDFDokument4 SeitenMSDS PVC PDFRegian Fajar AriesandiNoch keine Bewertungen

- Indonesian Government Regulation For MeteringDokument4 SeitenIndonesian Government Regulation For MeteringirfanNoch keine Bewertungen

- 2 PPT Sumpal Compression Project Copy PasteDokument6 Seiten2 PPT Sumpal Compression Project Copy PasteboypardedeNoch keine Bewertungen

- Ayie FileDokument19 SeitenAyie FileRudy RaymondNoch keine Bewertungen

- Air Blowing ProcedureDokument11 SeitenAir Blowing ProcedureBhayu Eka AnggitaNoch keine Bewertungen

- Term of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4Dokument7 SeitenTerm of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4tiantaufik100% (1)

- MSDS SFM-4728, FlexoilDokument5 SeitenMSDS SFM-4728, FlexoilLeddy ZakarunaNoch keine Bewertungen

- CV Ani Puspita Sari - Process Eng PDFDokument6 SeitenCV Ani Puspita Sari - Process Eng PDFAgung PartadirtjaNoch keine Bewertungen

- Bentu and Korinci PSCDokument1 SeiteBentu and Korinci PSCSuhendraNoch keine Bewertungen

- Problematic Processes For Hot TappingDokument2 SeitenProblematic Processes For Hot Tapping최승원Noch keine Bewertungen

- Company Profile MEPI 2010Dokument28 SeitenCompany Profile MEPI 2010MiraNoch keine Bewertungen

- Fiber Optics Used To Support Reservoir Temperature Duri SteamfloodSPE-93240-MSDokument9 SeitenFiber Optics Used To Support Reservoir Temperature Duri SteamfloodSPE-93240-MSM Galih Adi SamuderaNoch keine Bewertungen

- Offshore North West Java (ONWJ) Block at Java Sea - Mande BlogDokument4 SeitenOffshore North West Java (ONWJ) Block at Java Sea - Mande BlogwidiNoch keine Bewertungen

- Full Thesis PDFDokument109 SeitenFull Thesis PDFTanjib Rahman NiloyNoch keine Bewertungen

- D0307 (MECH) Painting Procedure For Boiler Steel Structure - Rev 0Dokument18 SeitenD0307 (MECH) Painting Procedure For Boiler Steel Structure - Rev 0Surya Darma100% (1)

- PDFDokument162 SeitenPDFMuslim SiregarNoch keine Bewertungen

- Chapter 00 PengantarDokument8 SeitenChapter 00 PengantarPutu Indra MahatrisnaNoch keine Bewertungen

- Data PipaDokument9 SeitenData PipaediabcNoch keine Bewertungen

- Flash Skim Vessel Descr.Dokument5 SeitenFlash Skim Vessel Descr.vanashley1Noch keine Bewertungen

- TA-16-073-MP-016 Prosedur Pemeriksaan Kondisi Pressure Vessel Dan Inner Parts PDFDokument4 SeitenTA-16-073-MP-016 Prosedur Pemeriksaan Kondisi Pressure Vessel Dan Inner Parts PDFDjuangNoch keine Bewertungen

- INTRODUKSI HAZOPS Project TBBM AmpenanDokument30 SeitenINTRODUKSI HAZOPS Project TBBM AmpenanSyklik DataNoch keine Bewertungen

- Laporan Hyrant and Springkle System R3Dokument44 SeitenLaporan Hyrant and Springkle System R3Wacoman RazanNoch keine Bewertungen

- Checklist SkkpiDokument27 SeitenChecklist SkkpiarisNoch keine Bewertungen

- Carbon Capture, Utilization & StorageDokument18 SeitenCarbon Capture, Utilization & Storagebiblioteca mailfenceNoch keine Bewertungen

- Penjelasan Duri FieldDokument4 SeitenPenjelasan Duri FieldAdi KalebNoch keine Bewertungen

- RDMP Ru V Balikpapan: Piping and Instrument Diagram Plant No. 8 - Hydrogen Unit Battery Limits Process LinesDokument1 SeiteRDMP Ru V Balikpapan: Piping and Instrument Diagram Plant No. 8 - Hydrogen Unit Battery Limits Process Linesdian yuristiaNoch keine Bewertungen

- Natural Gas Odorization UnitDokument3 SeitenNatural Gas Odorization Unitsushant shirsatNoch keine Bewertungen

- TechnicalDokument3 SeitenTechnicalbmanojkumar16Noch keine Bewertungen

- Fat - Functional Factory Acceptance Test Procedure For Flare and Burn Pit Packages 2600-PK-001 / 2600-PK-002 / 2600-PK-003Dokument8 SeitenFat - Functional Factory Acceptance Test Procedure For Flare and Burn Pit Packages 2600-PK-001 / 2600-PK-002 / 2600-PK-003kami safaviNoch keine Bewertungen

- Materi Feed & Product Spesification 2013 (And)Dokument65 SeitenMateri Feed & Product Spesification 2013 (And)Yustinus KrisnaNoch keine Bewertungen

- Terminal LPG Refrigated Tanjung SekongDokument9 SeitenTerminal LPG Refrigated Tanjung SekongBacti BactiarNoch keine Bewertungen

- 4.SOP Emergency Shut DownDokument5 Seiten4.SOP Emergency Shut DownDodik NugrohoNoch keine Bewertungen

- Unit 13 - Business Hotels and Sales ConferencesDokument24 SeitenUnit 13 - Business Hotels and Sales ConferencesMiguel Angel Escoto CanoNoch keine Bewertungen

- Tate Modern London, Pay Congestion ChargeDokument6 SeitenTate Modern London, Pay Congestion ChargeCongestionChargeNoch keine Bewertungen

- Allplan 2006 Engineering Tutorial PDFDokument374 SeitenAllplan 2006 Engineering Tutorial PDFEvelin EsthefaniaNoch keine Bewertungen

- Interest Rates and Bond Valuation: All Rights ReservedDokument22 SeitenInterest Rates and Bond Valuation: All Rights ReservedAnonymous f7wV1lQKRNoch keine Bewertungen

- XI STD Economics Vol-1 EM Combined 12.10.18 PDFDokument288 SeitenXI STD Economics Vol-1 EM Combined 12.10.18 PDFFebin Kurian Francis0% (1)

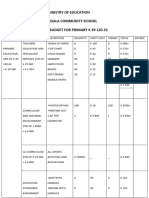

- Ministry of Education Musala SCHDokument5 SeitenMinistry of Education Musala SCHlaonimosesNoch keine Bewertungen

- Stock Prediction SynopsisDokument3 SeitenStock Prediction SynopsisPiyushPurohitNoch keine Bewertungen

- Application of ARIMAX ModelDokument5 SeitenApplication of ARIMAX ModelAgus Setiansyah Idris ShalehNoch keine Bewertungen

- Different Software Life Cycle Models: Mini Project OnDokument11 SeitenDifferent Software Life Cycle Models: Mini Project OnSagar MurtyNoch keine Bewertungen

- Agoura Hills DIVISION - 6. - NOISE - REGULATIONSDokument4 SeitenAgoura Hills DIVISION - 6. - NOISE - REGULATIONSKyle KimNoch keine Bewertungen

- Toa Valix Vol 1Dokument451 SeitenToa Valix Vol 1Joseph Andrei BunadoNoch keine Bewertungen

- Sign Language To Speech ConversionDokument6 SeitenSign Language To Speech ConversionGokul RajaNoch keine Bewertungen

- Fracture and FatigueDokument15 SeitenFracture and FatigueZou JiaweiNoch keine Bewertungen

- Vicente, Vieyah Angela A.-HG-G11-Q4-Mod-9Dokument10 SeitenVicente, Vieyah Angela A.-HG-G11-Q4-Mod-9Vieyah Angela VicenteNoch keine Bewertungen

- Brief Curriculum Vitae: Specialisation: (P Ea 1. 2. 3. Statistical AnalysisDokument67 SeitenBrief Curriculum Vitae: Specialisation: (P Ea 1. 2. 3. Statistical Analysisanon_136103548Noch keine Bewertungen

- Vodafone M2M Integrated M2M Terminals Overview BrochureDokument4 SeitenVodafone M2M Integrated M2M Terminals Overview BrochureJamie JordanNoch keine Bewertungen

- Intelligent Smoke & Heat Detectors: Open, Digital Protocol Addressed by The Patented XPERT Card Electronics Free BaseDokument4 SeitenIntelligent Smoke & Heat Detectors: Open, Digital Protocol Addressed by The Patented XPERT Card Electronics Free BaseBabali MedNoch keine Bewertungen

- Residential BuildingDokument5 SeitenResidential Buildingkamaldeep singhNoch keine Bewertungen

- ArpitResumeISM PDFDokument1 SeiteArpitResumeISM PDFchethan rNoch keine Bewertungen

- CavinKare Karthika ShampooDokument2 SeitenCavinKare Karthika Shampoo20BCO602 ABINAYA MNoch keine Bewertungen

- Pega AcademyDokument10 SeitenPega AcademySasidharNoch keine Bewertungen

- Sales Manager Latin AmericaDokument3 SeitenSales Manager Latin Americaapi-76934736Noch keine Bewertungen

- Te 1569 Web PDFDokument272 SeitenTe 1569 Web PDFdavid19890109Noch keine Bewertungen

- ACM2002D (Display 20x2)Dokument12 SeitenACM2002D (Display 20x2)Marcelo ArtolaNoch keine Bewertungen