Beruflich Dokumente

Kultur Dokumente

Technical Fly Ash Improves Workability Bulletin

Hochgeladen von

Afifah FauziOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Technical Fly Ash Improves Workability Bulletin

Hochgeladen von

Afifah FauziCopyright:

Verfügbare Formate

Technical

5 Fly Ash Improves Workability

Bulletin

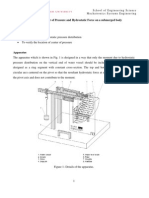

BLEMISHES IN CONCRETE, TYPICALLY CALLED vibration. Figure 1 shows the remarkable difference in time and

ROCK POCKETS, are indicative of concrete without suitable energy required for consolidation of plain and fly ash concretes.

workability, even though the slump may be judged to be Great benefits can be obtained when using more completely

acceptable. Rock pockets indicate a separation of the paste from consolidating fly ash concrete in areas of difficult placement

the coarse aggregate in the concrete mix. Concrete where rock pockets and other placing defects often

must be cohesive even at high slumps to maintain its occur. Engineers understand the effectiveness of

homogeneous character and avoid segregation and Though it is never using fly ash concrete in tall thin walls, such as

costly rock pockets. Fly ash offers this feature specified, workability is those used in water tanks. They know they have a

without extra cost. better chance of getting the dense, void free

one of the most critical concrete they have specified when fly ash is

Reduced Water of Convenience. characteristics of included in the mix.

Approximately 25 pounds (three gallons) of water concrete. Workability

are normally required to hydrate 100 pounds of refers to the ease of Paste Volume Increases.

cement1. A normal concrete mix will generally handling, placing and The specific gravity of fly ash is lighter than cement.

contain twice the required amount of water to finishing of fresh or When replacing fly ash on a pound for pound basis,

hydrate the cement enough to facilitate handling the result is a greater solid volume of cementitious

plastic concrete. Use

and placing of the concrete. This additional water, fines. Proportioning concrete mixtures with only

called water of convenience, increases slump but of fly ash can greatly water-reducing admixtures results in a greatly

at the cost of decreased cohesiveness. Water of enhance workability. diminished volume of cementitious fines. In effect,

convenience is reduced when fly ash is added to the this amounts to taking cement out of the mix and

mix because the plasticizing action results in a 2% to replacing it with sand and gravel. The strengths may

10% water reduction in the plastic concrete to produce the be acceptable, but the workability may not be. Proportioning

same level of slump as plain concrete. Reduced water of performance concrete with fly ash virtually guarantees a greater

convenience at the same level of slump makes for more cohesive solid volume of cementitious materials, which in itself helps

concrete and decreases the occurrence of costly segregation. promote cohesiveness and workability. Cementitious fines are

very important to the contractor who finishes flatwork. These

fines are necessary to allow proper leveling, sealing, and

densification of the surface. Fly ash spheres help ease the

contractors job by lubricating the surface, making it much easier

and faster to finish the job.

In lean mixes, or where aggregates are deficient in fines, an

increase in the volume of paste and an improvement in

consistency will be advantageous for workability and may also

increase strength by allowing more complete compaction.2

Economical Mixture.

Pound for pound, no other solid material improves the

workability, strength, and other properties of a concrete mix like

fly ash can, resulting in the most economical of mixtures. Placing

and finishing concrete becomes easier because of the improved

workability from the spherically shaped fly ash particles. Lower

slump concrete can be placed more easily (and at lower water

content) because of the plasticity provided by fly ash spheres.

Segregation and bleeding are reduced because of to the

increased cohesiveness of fly ash concrete, so form finish and

sharpness of detail are enhanced. And coarse, clean sands can be

Figure 1: Typical VEBE Time vs Slump

used in concretes utilizing fly ash and still have good workability.

Greater Consolidation.

Fly ash concrete is actually more workable than plain cement 1

Highway Research Board, Bulletin 284, Fly Ash in Concrete, January

concrete at equivalent slump. The VEBE test measures the time 1960, p. 27.

and energy necessary for consolidation of concrete under 2

Central Electricity Generating Board, Application of PFA in Concrete and

Cement, RIBA Products Data, London, March 1982

For more information or answers to questions about the use of fly ash in specific

applications, contact your nearest Headwaters Resources Technical Sales 10701 S. River Front Parkway, Suite 300

Representative or call 1-888-236-6236. South Jordan, UT 84095

www.flyash.com

Das könnte Ihnen auch gefallen

- Chapter - 1 1.1 General TheoryDokument44 SeitenChapter - 1 1.1 General TheoryVenkat Deepak SarmaNoch keine Bewertungen

- Unit IVDokument3 SeitenUnit IVSRPC CIVILNoch keine Bewertungen

- It's A Paper For ConcreteDokument5 SeitenIt's A Paper For ConcreteManojkumarNoch keine Bewertungen

- Irjet V6i31363Dokument7 SeitenIrjet V6i31363Afshana bashNoch keine Bewertungen

- Possibilities of Pervious Concrete Application inDokument11 SeitenPossibilities of Pervious Concrete Application inSaurabh PawarNoch keine Bewertungen

- Topic 2.7 Fresh ConcreteDokument44 SeitenTopic 2.7 Fresh ConcreteDEBRA DEIRDRE S. ONONG DEBRA DEIRDRE S. ONONGNoch keine Bewertungen

- Unit 5 Workability and Fresh Concrete I: StructureDokument12 SeitenUnit 5 Workability and Fresh Concrete I: StructureFredrick ChombaNoch keine Bewertungen

- CPP Pervious RoadDokument4 SeitenCPP Pervious Roadatharv paritNoch keine Bewertungen

- Types of lightweight concrete, their advantages and disadvantagesDokument6 SeitenTypes of lightweight concrete, their advantages and disadvantagesMohd ShafiqNoch keine Bewertungen

- BGTECH-1 - Topic 1-Concrete and MasonryDokument7 SeitenBGTECH-1 - Topic 1-Concrete and MasonryChristian Sam VillegasNoch keine Bewertungen

- Flexible Concrete ReportDokument25 SeitenFlexible Concrete ReportGowtham Kichcha50% (4)

- EABASSOC Lightweight Foamed ConcreteDokument4 SeitenEABASSOC Lightweight Foamed ConcreteMălíķ ĂsfęnđýårNoch keine Bewertungen

- ArticledesignandconstructionofliquidtightconcretestrucDokument3 SeitenArticledesignandconstructionofliquidtightconcretestrucalbertoxinaNoch keine Bewertungen

- Proj CH 2 AttaDokument9 SeitenProj CH 2 AttaAsghar Hussain Shah S/o Zubair Shah MS Engg. Management (Swat Campus)Noch keine Bewertungen

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsDokument2 SeitenConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsPrasantaNoch keine Bewertungen

- TDS Conplast WL India3Dokument2 SeitenTDS Conplast WL India3rajni phNoch keine Bewertungen

- 2 PBDokument8 Seiten2 PBArief BudimanNoch keine Bewertungen

- VERSATILE FOAM CONCRETEDokument5 SeitenVERSATILE FOAM CONCRETEnandanaNoch keine Bewertungen

- Week 1Dokument3 SeitenWeek 1Dhave Airen DomingoNoch keine Bewertungen

- Experimental Investigation On Maximum Strength of Pervious Concrete Using Different Size of AggregatesDokument3 SeitenExperimental Investigation On Maximum Strength of Pervious Concrete Using Different Size of AggregatesNatarajan SaravananNoch keine Bewertungen

- Batch 2 Project Report 2022Dokument52 SeitenBatch 2 Project Report 2022B M MeghashreeNoch keine Bewertungen

- Construction and Building Materials: Bradley J. Putman, Andrew I. NeptuneDokument6 SeitenConstruction and Building Materials: Bradley J. Putman, Andrew I. NeptunemargarethsmNoch keine Bewertungen

- Blended Concrete ReviewDokument5 SeitenBlended Concrete Reviewbaba pappuNoch keine Bewertungen

- Assignment: Department of Civil Engineering Wah Engineering CollegeDokument4 SeitenAssignment: Department of Civil Engineering Wah Engineering Collegeashani khanNoch keine Bewertungen

- Emerging Lecture FourDokument39 SeitenEmerging Lecture Fourizim izimNoch keine Bewertungen

- 2017.04 DiscForum NatarajaDokument3 Seiten2017.04 DiscForum NatarajaJohn GiannakopoulosNoch keine Bewertungen

- Conplast SP500 KL: High Perfor Mance Water Reducing and Superplasticising AdmixtureDokument2 SeitenConplast SP500 KL: High Perfor Mance Water Reducing and Superplasticising AdmixtureSankar VNoch keine Bewertungen

- Concrete Specifications For Agriculture: Factors Affecting The Quality of ConcreteDokument4 SeitenConcrete Specifications For Agriculture: Factors Affecting The Quality of ConcreteRajesh SuraypallyNoch keine Bewertungen

- Bendable Concrete PDFDokument14 SeitenBendable Concrete PDFKunal Bathija100% (24)

- Foam Concrete: A Lightweight Building MaterialDokument36 SeitenFoam Concrete: A Lightweight Building MaterialamitNoch keine Bewertungen

- Ijet V4i3p19 PDFDokument6 SeitenIjet V4i3p19 PDFInternational Journal of Engineering and TechniquesNoch keine Bewertungen

- Cellular Lightweight Concrete Blocks 2022Dokument17 SeitenCellular Lightweight Concrete Blocks 2022DEEPAK H LNoch keine Bewertungen

- Lecture 2A Fresh ConcreteDokument13 SeitenLecture 2A Fresh ConcreteNarte, Angelo C.Noch keine Bewertungen

- Cellular Light Weight ConcreteDokument35 SeitenCellular Light Weight ConcreteUTP gamingNoch keine Bewertungen

- Rheological Characterization of HGMDokument10 SeitenRheological Characterization of HGMronak pandyaNoch keine Bewertungen

- Experimental Study of Self-Compacted Concrete Using Foundry SandDokument5 SeitenExperimental Study of Self-Compacted Concrete Using Foundry SandDinesh GuptaNoch keine Bewertungen

- Foam Concrete ArticleDokument11 SeitenFoam Concrete ArticleNibbz NibbzcusNoch keine Bewertungen

- Self-compacting Concrete Testing and Design MethodsDokument6 SeitenSelf-compacting Concrete Testing and Design Methodsvinay rodeNoch keine Bewertungen

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsDokument2 SeitenConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsRaghavendra GaNoch keine Bewertungen

- Self-Compacting and Self-Curing Concrete With Steel Fiber ReinforcementDokument5 SeitenSelf-Compacting and Self-Curing Concrete With Steel Fiber ReinforcementMichael GelongNoch keine Bewertungen

- BT RSW Final 02Dokument9 SeitenBT RSW Final 02judy ramosNoch keine Bewertungen

- A New Test Method For Porosity Measurements of PortlandDokument6 SeitenA New Test Method For Porosity Measurements of PortlandElias Antunes SantosNoch keine Bewertungen

- Properties of Pervious Concrete Made With Electric Arc Furnace Slag and Alkali-Activated Slag CementDokument11 SeitenProperties of Pervious Concrete Made With Electric Arc Furnace Slag and Alkali-Activated Slag CementMr PolashNoch keine Bewertungen

- Chapter-1: Department of Civil Engg, CBITDokument26 SeitenChapter-1: Department of Civil Engg, CBITShashidhara TVNoch keine Bewertungen

- Drenante g9Dokument16 SeitenDrenante g9Joel Alfonso Manurung100% (1)

- Concrete: Basic Ingredients of ConcreteDokument11 SeitenConcrete: Basic Ingredients of Concretecass0608Noch keine Bewertungen

- 44V YoganandandB BhattacharjeeDokument9 Seiten44V YoganandandB BhattacharjeeFear FathanNoch keine Bewertungen

- Study On Compressive Strength of Self Compacting Concrete Using Various Propotions of Steatite PowderDokument5 SeitenStudy On Compressive Strength of Self Compacting Concrete Using Various Propotions of Steatite PowderBharath BharathNoch keine Bewertungen

- The Impact of Using Polymer Impregnated Porous ConcreteDokument7 SeitenThe Impact of Using Polymer Impregnated Porous Concreteikitan20050850Noch keine Bewertungen

- Underwater Concrete Technologies in Marine ConstructionDokument5 SeitenUnderwater Concrete Technologies in Marine ConstructionHoney SinghNoch keine Bewertungen

- Flow Test of Self Compacting Concrete Using V-Funnel TestDokument14 SeitenFlow Test of Self Compacting Concrete Using V-Funnel TestIJRASETPublicationsNoch keine Bewertungen

- 1.14 Fiber-Reinforced ConcretesDokument1 Seite1.14 Fiber-Reinforced ConcretesSardarNoch keine Bewertungen

- Final ManuscriptDokument52 SeitenFinal ManuscriptJosef James CawagasNoch keine Bewertungen

- Prediction of Strength Parameters For Cellular Light Weight Concrete by Using Fly Ash As Partial Replacement of CementDokument5 SeitenPrediction of Strength Parameters For Cellular Light Weight Concrete by Using Fly Ash As Partial Replacement of CementInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Pervious Concrete Using Basalt Fibre for Increased StrengthDokument14 SeitenPervious Concrete Using Basalt Fibre for Increased StrengthShubham PachlingNoch keine Bewertungen

- Strength Study On Fiber Reinforced Self-Compacting Concrete With Fly Ash and GGBFSDokument5 SeitenStrength Study On Fiber Reinforced Self-Compacting Concrete With Fly Ash and GGBFSSchool of EngineersNoch keine Bewertungen

- Research Paper On Floating ConcreteDokument7 SeitenResearch Paper On Floating ConcreteppsivanNoch keine Bewertungen

- Chapter-1: Partial Replacement of Natural Aggregate With Bethamcherla Stone Dust and Recycled AggregateDokument66 SeitenChapter-1: Partial Replacement of Natural Aggregate With Bethamcherla Stone Dust and Recycled AggregatepatanelakathNoch keine Bewertungen

- Miadata 15Dokument3 SeitenMiadata 15Hamza LarnaoutNoch keine Bewertungen

- Perimeter dan luas sektor dan kawasan berlorekDokument1 SeitePerimeter dan luas sektor dan kawasan berlorekWan Naliza Wan JaafarNoch keine Bewertungen

- Brochure EO PDFDokument1 SeiteBrochure EO PDFAfifah FauziNoch keine Bewertungen

- Monthly External Trade Statistics May 2018Dokument7 SeitenMonthly External Trade Statistics May 2018Afifah FauziNoch keine Bewertungen

- Mechanical Properties of Concrete Incorporating High Volumes of Fly Ash From Sources in The U.S.Dokument10 SeitenMechanical Properties of Concrete Incorporating High Volumes of Fly Ash From Sources in The U.S.Afifah FauziNoch keine Bewertungen

- Analyzing Road Junction Capacity and Level of ServiceDokument6 SeitenAnalyzing Road Junction Capacity and Level of ServiceAfifah FauziNoch keine Bewertungen

- DR Choo POTS South Africa 2011 PDFDokument57 SeitenDR Choo POTS South Africa 2011 PDFAfifah FauziNoch keine Bewertungen

- Mitigation SedimentationDokument37 SeitenMitigation SedimentationAfifah FauziNoch keine Bewertungen

- Investigations of Portland Cement MortarsDokument39 SeitenInvestigations of Portland Cement MortarsAfifah FauziNoch keine Bewertungen

- SWM Penang PDFDokument57 SeitenSWM Penang PDFAfifah FauziNoch keine Bewertungen

- C 618 - 00 - Qzyxoc0wmaDokument4 SeitenC 618 - 00 - Qzyxoc0wmaAfifah FauziNoch keine Bewertungen

- Compressive Strength of Mortar Containing Ferronickel SlagDokument6 SeitenCompressive Strength of Mortar Containing Ferronickel SlagAfifah FauziNoch keine Bewertungen

- CaCO3 Whisker Modified Engineered Cementitious Co 2017 Construction and BuilDokument8 SeitenCaCO3 Whisker Modified Engineered Cementitious Co 2017 Construction and BuilAfifah FauziNoch keine Bewertungen

- CAL2 Section 3 LA Rev2 PDFDokument11 SeitenCAL2 Section 3 LA Rev2 PDFAfifah FauziNoch keine Bewertungen

- Introduction To Management Concepts (Compatibility Mode)Dokument20 SeitenIntroduction To Management Concepts (Compatibility Mode)Afifah FauziNoch keine Bewertungen

- The Planning Guidelines For Environmental Noise Limits and ControlDokument34 SeitenThe Planning Guidelines For Environmental Noise Limits and ControlRamona AbrNoch keine Bewertungen

- Santamarina Cho 2001Dokument8 SeitenSantamarina Cho 2001Afifah FauziNoch keine Bewertungen

- 6c. Chapter 5-Critical Path (Part 3)Dokument21 Seiten6c. Chapter 5-Critical Path (Part 3)Afifah FauziNoch keine Bewertungen

- Comparison of Pavement SurfaceDokument7 SeitenComparison of Pavement SurfaceAfifah FauziNoch keine Bewertungen

- Center of Pressure and Hydrostatic Force On A Submerged Body-RevDokument7 SeitenCenter of Pressure and Hydrostatic Force On A Submerged Body-RevAnkit MittalNoch keine Bewertungen

- Comparison of Pavement SurfaceDokument6 SeitenComparison of Pavement Surfacevijay kumarNoch keine Bewertungen

- CAL2 Section 3 LA Rev2 PDFDokument11 SeitenCAL2 Section 3 LA Rev2 PDFAfifah FauziNoch keine Bewertungen

- Comparison of Pavement SurfaceDokument6 SeitenComparison of Pavement Surfacevijay kumarNoch keine Bewertungen

- CAL2 Section 3 LA Rev2 PDFDokument11 SeitenCAL2 Section 3 LA Rev2 PDFAfifah FauziNoch keine Bewertungen

- Center of Pressure and Hydrostatic Force On A Submerged Body-RevDokument7 SeitenCenter of Pressure and Hydrostatic Force On A Submerged Body-RevAnkit MittalNoch keine Bewertungen

- Why Is This Important For BuildingsDokument25 SeitenWhy Is This Important For BuildingsAfifah FauziNoch keine Bewertungen

- Soil Mechanics TestsDokument9 SeitenSoil Mechanics TestsAfifah FauziNoch keine Bewertungen

- Green Building Materials 2Dokument5 SeitenGreen Building Materials 2Afifah FauziNoch keine Bewertungen

- Determination of Consistency of Standard Cement PasteDokument3 SeitenDetermination of Consistency of Standard Cement PasteAfifah FauziNoch keine Bewertungen

- Soil Mechanics TestsDokument9 SeitenSoil Mechanics TestsAfifah FauziNoch keine Bewertungen

- Pump Selection GuideDokument12 SeitenPump Selection GuideLeok Tang100% (2)

- Cable LadderDokument164 SeitenCable Ladderalfonso.parkerNoch keine Bewertungen

- Fire: en 13501 The European Standard Owacoustic Ceilings Reaction To Fire Fire ResistanceDokument12 SeitenFire: en 13501 The European Standard Owacoustic Ceilings Reaction To Fire Fire Resistanceradubotinesteanu100% (3)

- (PDF) Design Standards - CONFERENCE BUILDINGS, EXHIBITION & RESEARCH BUILDINGS - Muath Humaid - Academia - Edu PDFDokument110 Seiten(PDF) Design Standards - CONFERENCE BUILDINGS, EXHIBITION & RESEARCH BUILDINGS - Muath Humaid - Academia - Edu PDFatchaya gopalsamyNoch keine Bewertungen

- Steam Room Construction & Generator Sizing GuideDokument2 SeitenSteam Room Construction & Generator Sizing GuideasdthuNoch keine Bewertungen

- Construction of District Court Complex Electrical WorksDokument76 SeitenConstruction of District Court Complex Electrical WorkssunilrauloNoch keine Bewertungen

- Detailed Lesson Plan in Grade 8 EIMDokument5 SeitenDetailed Lesson Plan in Grade 8 EIMMark Edison Mirando100% (7)

- PERI UP Rosett For The Use On The Constr. Jobsite.Dokument28 SeitenPERI UP Rosett For The Use On The Constr. Jobsite.YUSAK ABDILLAHNoch keine Bewertungen

- Experimental and Numerical Investigations On Seismic Responses of Reinforced Concrete Structures Considering Strain Rate EffectDokument15 SeitenExperimental and Numerical Investigations On Seismic Responses of Reinforced Concrete Structures Considering Strain Rate EffectIon SococolNoch keine Bewertungen

- Highway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsDokument75 SeitenHighway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsAyman KandeelNoch keine Bewertungen

- Earthquake Base Shear Calculation for 3-Story Office BuildingDokument4 SeitenEarthquake Base Shear Calculation for 3-Story Office Buildinggendadeyu552625100% (1)

- ArchitecturalDokument1 SeiteArchitecturalAr. Via Yu BasaNoch keine Bewertungen

- Floor plan layout and dimensionsDokument1 SeiteFloor plan layout and dimensionskennysawegNoch keine Bewertungen

- 2022 23 Secme Balsa Bridge Contest RulesDokument4 Seiten2022 23 Secme Balsa Bridge Contest RulesgernNoch keine Bewertungen

- New COADokument15 SeitenNew COAAhadNurParagNoch keine Bewertungen

- Pressure VesselsDokument63 SeitenPressure Vesselsكرار نعيمNoch keine Bewertungen

- Bosch Pe Injection PumpDokument59 SeitenBosch Pe Injection PumpDavies Emmanuel100% (1)

- Mercer Valve 1400 Series BrochureDokument8 SeitenMercer Valve 1400 Series BrochureAnonymous 7GuboLxjQNoch keine Bewertungen

- Hanlan UpdateDokument6 SeitenHanlan Updaterobert_trewarthaNoch keine Bewertungen

- Essel Ludhiana Talwandi Toll Roads PVT Limited-03!06!2014Dokument4 SeitenEssel Ludhiana Talwandi Toll Roads PVT Limited-03!06!2014Jagadeesh YathirajulaNoch keine Bewertungen

- River Training and Protection WorksDokument8 SeitenRiver Training and Protection Worksnandi_scrNoch keine Bewertungen

- SPLM - Construction Pre-Planning PDFDokument11 SeitenSPLM - Construction Pre-Planning PDFJommarVocalTagalogNoch keine Bewertungen

- Domestic building regulations contents guideDokument618 SeitenDomestic building regulations contents guidedncservices100% (1)

- Domestic Gas PipingDokument2 SeitenDomestic Gas Pipingvalentinlupascu33Noch keine Bewertungen

- DMW 3305 30116 1 3305 602 - Is00Dokument1 SeiteDMW 3305 30116 1 3305 602 - Is00nuramirah2023Noch keine Bewertungen

- Cost Estimation Manual For Low Rise Buildings: Acfl NymsDokument5 SeitenCost Estimation Manual For Low Rise Buildings: Acfl Nymsjhomel garciaNoch keine Bewertungen

- Advanced Problems in Bridge ConstructionDokument298 SeitenAdvanced Problems in Bridge Constructionjohn beeNoch keine Bewertungen

- Architect Urban Designer ResumeDokument4 SeitenArchitect Urban Designer ResumeNakshatra SenNoch keine Bewertungen

- Filltros para MP Excavadora Cat 320 B-BL-5GWDokument3 SeitenFilltros para MP Excavadora Cat 320 B-BL-5GWJosé GonzalezNoch keine Bewertungen

- Degadur® 420 and Degadur® 526Dokument5 SeitenDegadur® 420 and Degadur® 526申易Noch keine Bewertungen