Beruflich Dokumente

Kultur Dokumente

Bolt Strength PDF

Hochgeladen von

hlsimonOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bolt Strength PDF

Hochgeladen von

hlsimonCopyright:

Verfügbare Formate

Technical Data

Strength of Bolts, Screw Plugs, and Dowel Pins

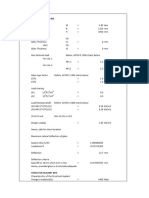

Bolt strength Unwin safety factor based on tensile strength

Pt Axial tensile load kgf

1When a bolt takes the tensile load Repeated load

bthe bolts yield stresskgfmm2 Material Static load Impact load

t the bolts allowable stresskgfmm2 Pulsating Reversed

PttAs1 tbsafety factor Steel 3 5 8 12

As Effective bolt area mm2 Cast iron 4 6 10 15

d2t42

Asd24 Copper, soft metals 5 5 9 15

d Bolts effective diametershaft diameter

mm

Standard strength Standard strengthThe yield strength for ductile materials

Allowable stress

Safety factor The breaking stress for brittle materials

Example The correct size is required for a socket head cap screw to take a repeat loadpulsatingwith P= 200 kgf.

The materials of a socket head cap screw are: SCM435, 3843HRC, strength category of 12.9.

Using formula

1 The yield stress for a strength category of 12.9 isb112kgfmm2

AsPtt The allowable stresstbsafety factorsafety factor of 5 from the above table

20022.4 1125

8.9mm2 22.4kgfmm2

A bolt with an effective area larger that this is

2

required, and a 14.2mm M5 would be selected. The bolt endurance strengthFor screws, the endurance strength is 2 million times use.

Although, if we take into consideration the endurance Effective Strength category

Bolt size bolt area 12.9 10.9

strength, looking at the strength category of 12.9, we would choice the M6 with

As Endurance strength Allowable load Endurance strength Allowable load

an allowable load of 213kgf.

mm2 kgfmm2 kgf kgfmm2 kgf

M 4 8.78 13.1 114 9.1 79

2 For stripper bolts for example which take the impact load, the size is decided M 5 14.2 11.3 160 7.8 111

from the endurance strength.Likewise for a load of 200kgf, the stripper bolt M 6 20.1 10.6 213 7.4 149

would be SCM435, 3338HRC, with a strength category of 10.9. M 8 36.6 8.9 326 8.7 318

M10 58 7.4 429 7.3 423

In the table to the right, the allowable load for load over 200kgf for a strength M12 84.3 6.7 565 6.5 548

category of 10.9 is as M8 at 318kgf. Therefore, the MSB10 would be M14 115 6.1 702 6 690

selected, with a screw diameter of 10mm like the M8. Please use dowel pins M16 157 5.8 911 5.7 895

M20 245 5.2 1274 5.1 1250

also to take the shearing load.

M24 353 4.7 1659 4.7 1659

Screw plug strength Endurance strength is an edited excerpt taken from the measured values of

the endurance limit for small screws, bolts, and meter screws for nutsYamamoto.

Allowable load P is required for screw plug MSW30 to take an impact load.The

MSW30S45C, the tensile strength b of 3443HRC is 65kgf / mm2 .

M

When the root diameter section of

Shear area Aroot diameter d1L

the MSW is ruptured due to Root diameter d1

root diameter d1MP

shearing strain, AMPL301.512

P

1074mm2

the allowance load P tA

Yield stress0.9tensile strength b0.96558.2

3.9107.4

Shear stress 0.8 X yield stress

4190kgf

46.6

Allowable shear stress tshear stresssafety factor 12

46.6123.9kgfmm2 P

When the tap is made of soft material,

an allowable shear is required from the root diameter of the female screw.

Dowel pin strength

The correct size for a dowel pin is required in order for it to hold repeated shear

weightpulsatingof 800kfg.Material of the dowel pin is SUJ2, hardness of 58HRC.

PA

The applicable yield stress of SUJ2 b120kgfmm2

D24

Allowable shear strengthb0.8safety factor

D 4P

1200.85

48003.1419.2 19.2kgfmm2

Use dowel pins so that screw parts have no loading.

7.3

A size of D8 or more is selected for a MS dowel pin.

Also, the tools and stock etc can be reduced if the size of the dowel pin is consistently large.

Everything noted here are only examples of strengths. In actual practice, the hole pitch precision, the perpendicular angle of the hole, surface

coarseness, circularity, the plate materials, parallelism, whether its tempered or not, the precision of the injection molding machine, production

quantity, tool wear, etc must be taken into consideration. Therefore these values should only be used as a guide.These are not guaranteed figures.

1135 1136

Das könnte Ihnen auch gefallen

- Bolt, Screw Plug and Dowel Pin Strength Technical DataDokument1 SeiteBolt, Screw Plug and Dowel Pin Strength Technical DatahlsimonNoch keine Bewertungen

- ستيل ستركشرDokument73 Seitenستيل ستركشرAws SamaNoch keine Bewertungen

- Bolt Strength PDFDokument1 SeiteBolt Strength PDFSilambarasi MurugesanNoch keine Bewertungen

- Typical Anchor BoltsDokument33 SeitenTypical Anchor BoltslucianduNoch keine Bewertungen

- Comments Marked in Grade Slab Design For 20T/m2 Also Applicable For This Document. UpdateDokument2 SeitenComments Marked in Grade Slab Design For 20T/m2 Also Applicable For This Document. UpdateElancheliyan0% (2)

- Timber - Example Calculation - RoymechDokument4 SeitenTimber - Example Calculation - RoymechDavid O'MearaNoch keine Bewertungen

- Steel One Linear NotesDokument102 SeitenSteel One Linear NotesUtkarsh KumarNoch keine Bewertungen

- Week 3-Design of One Way SlabDokument4 SeitenWeek 3-Design of One Way SlabMAYHAY, ADRIAN PAULNoch keine Bewertungen

- 200 THK Grade Slab-50kn Variable Load-With FibreDokument7 Seiten200 THK Grade Slab-50kn Variable Load-With FibreFazilat Mohammad Zaidi0% (1)

- ESR ST - DesignDokument33 SeitenESR ST - DesignTarkeshwar Lal SrivastavaNoch keine Bewertungen

- 10T SWL Spreader Bar R2-Fos2.0Dokument8 Seiten10T SWL Spreader Bar R2-Fos2.0Snr Designer JayaNoch keine Bewertungen

- Structural Cals For UCWDokument11 SeitenStructural Cals For UCWShubham SoniNoch keine Bewertungen

- Us - 12e - pr1271 Screw Plug StrengthDokument1 SeiteUs - 12e - pr1271 Screw Plug StrengthrenebbNoch keine Bewertungen

- Brinell Hardness Test: Name: Amishasharon Rajavijai Sahidha Roll Number: 111120011Dokument7 SeitenBrinell Hardness Test: Name: Amishasharon Rajavijai Sahidha Roll Number: 111120011Amisha SharonNoch keine Bewertungen

- DIN 743 shaft calculation programDokument38 SeitenDIN 743 shaft calculation programAndrei BotNoch keine Bewertungen

- ACI318 Flat Slab DesignDokument5 SeitenACI318 Flat Slab DesignSyed FaheemNoch keine Bewertungen

- SRB DesignDokument3 SeitenSRB DesignRam LangheNoch keine Bewertungen

- Spreader Beam: ASME BTH-1: InputsDokument17 SeitenSpreader Beam: ASME BTH-1: InputsGokul AmarnathNoch keine Bewertungen

- 1) Basic Data: Design of Cantilever Beam As Per IS 456-2000Dokument4 Seiten1) Basic Data: Design of Cantilever Beam As Per IS 456-2000khaniskhan03Noch keine Bewertungen

- Design of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2Dokument5 SeitenDesign of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2khaniskhan03Noch keine Bewertungen

- COLUMNDokument3 SeitenCOLUMNGaneshalingam Ramprasanna2Noch keine Bewertungen

- Calcs for Concrete Industrial Ground Floor DesignDokument3 SeitenCalcs for Concrete Industrial Ground Floor DesignRuemu Godwin InikoriNoch keine Bewertungen

- Flat Bracing Design EC3Dokument1 SeiteFlat Bracing Design EC3David O'MearaNoch keine Bewertungen

- Flat Bracing Design EC3Dokument1 SeiteFlat Bracing Design EC3David O'MearaNoch keine Bewertungen

- Concrete Industrial Ground Floor Slab Desig1Dokument3 SeitenConcrete Industrial Ground Floor Slab Desig1Mahata PriyabrataNoch keine Bewertungen

- Austempered Ductile Iron Offers Superior Strength, Toughness & DurabilityDokument14 SeitenAustempered Ductile Iron Offers Superior Strength, Toughness & DurabilitylucianoNoch keine Bewertungen

- Advanced Design of Steel Structure: Civil Engineering Department, NUCES, Lahore PakistanDokument23 SeitenAdvanced Design of Steel Structure: Civil Engineering Department, NUCES, Lahore Pakistansyed muneeb haiderNoch keine Bewertungen

- Ribbed SlabsDokument10 SeitenRibbed SlabsAlemayehu DargeNoch keine Bewertungen

- Coupler Tensile Strength TestDokument1 SeiteCoupler Tensile Strength TestShahril ZainulNoch keine Bewertungen

- 2x10 - 47ms - R1 - Connection DesignDokument8 Seiten2x10 - 47ms - R1 - Connection DesignPradip NikamNoch keine Bewertungen

- Zamac-5 Is ZDC-1Dokument1 SeiteZamac-5 Is ZDC-1atul sachanNoch keine Bewertungen

- School of Engineering: J. Toby MottramDokument9 SeitenSchool of Engineering: J. Toby Mottrambravo deltafoxNoch keine Bewertungen

- School of Engineering: J. Toby MottramDokument9 SeitenSchool of Engineering: J. Toby MottramIghalo osedebamen DanielNoch keine Bewertungen

- Lecture 9 - Concrete Beam ReinforcementDokument21 SeitenLecture 9 - Concrete Beam ReinforcementKhaled AlregebNoch keine Bewertungen

- Assignment No 2Dokument2 SeitenAssignment No 2Abhishek BordoloiNoch keine Bewertungen

- Ch-27.11 Hardness TestDokument24 SeitenCh-27.11 Hardness TestasjfgauojfgfNoch keine Bewertungen

- Hl707 Adicg CR 001 r0 (Load Out Ramp)Dokument8 SeitenHl707 Adicg CR 001 r0 (Load Out Ramp)dheeraj SureshNoch keine Bewertungen

- Calculation SheetDokument2 SeitenCalculation SheetSamwailNoch keine Bewertungen

- Design Data: Design of Floor Slab ContinousDokument12 SeitenDesign Data: Design of Floor Slab ContinousMohit VermaNoch keine Bewertungen

- Design of axially loaded base plateDokument4 SeitenDesign of axially loaded base plateKumar Prasanna HNNoch keine Bewertungen

- Indian Institute of Technology, Guwahati: Laboratory SheetDokument6 SeitenIndian Institute of Technology, Guwahati: Laboratory SheetKamini GoyalNoch keine Bewertungen

- Design of Timber BeamsDokument14 SeitenDesign of Timber BeamsGhaafil Fitnah100% (2)

- Steel Staircase DesignDokument6 SeitenSteel Staircase DesignMario FeghaliNoch keine Bewertungen

- Proper Bolt Axial Tightening ForceDokument1 SeiteProper Bolt Axial Tightening ForcePrabhu SelvaRajNoch keine Bewertungen

- Design of LRB Isolatros For Seismic Resistant: Amer Hassan, Ahmed SaeedDokument3 SeitenDesign of LRB Isolatros For Seismic Resistant: Amer Hassan, Ahmed SaeedSaniaNoch keine Bewertungen

- Eurocode Weld and Bolt Info 11 - Joints - HandoutDokument2 SeitenEurocode Weld and Bolt Info 11 - Joints - HandoutKishore KumarNoch keine Bewertungen

- Walkway Support Structure DesignDokument6 SeitenWalkway Support Structure Designaakash prabhuNoch keine Bewertungen

- DESIGN OF DOUBLY REINFORCED BEAMDokument13 SeitenDESIGN OF DOUBLY REINFORCED BEAMLikith Gowda MNoch keine Bewertungen

- Casing Design Jimmy WangDokument160 SeitenCasing Design Jimmy WangAhmed Ali AlsubaihNoch keine Bewertungen

- Print 2Dokument4 SeitenPrint 2COMEDY NEPALNoch keine Bewertungen

- Design of Diaphragm Word FileDokument3 SeitenDesign of Diaphragm Word Fileparas rahangdaleNoch keine Bewertungen

- Composite Deck Technical Manual: 3WH-36 Hi FormDokument33 SeitenComposite Deck Technical Manual: 3WH-36 Hi FormVinod Kumar ReddyNoch keine Bewertungen

- Loading : Solid MechanicsDokument22 SeitenLoading : Solid MechanicsAKYNoch keine Bewertungen

- Lect 18Dokument18 SeitenLect 18Gaurav AgarwalNoch keine Bewertungen

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresVon EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresBewertung: 4 von 5 Sternen4/5 (1)

- U.S. Army Explosives and Demolitions HandbookVon EverandU.S. Army Explosives and Demolitions HandbookNoch keine Bewertungen

- A Short Course in Foundation EngineeringVon EverandA Short Course in Foundation EngineeringBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Strength of Materials: Theory and ExamplesVon EverandStrength of Materials: Theory and ExamplesBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Ice Load (Ref Only)Dokument121 SeitenIce Load (Ref Only)hlsimonNoch keine Bewertungen

- Pt A, Ch 2, App 3 Thickness Measurements Acceptance CriteriaDokument25 SeitenPt A, Ch 2, App 3 Thickness Measurements Acceptance CriteriahlsimonNoch keine Bewertungen

- Task 2 Writing TechniqueDokument1 SeiteTask 2 Writing TechniquehlsimonNoch keine Bewertungen

- Capral Mill CatalogueDokument130 SeitenCapral Mill CataloguehlsimonNoch keine Bewertungen

- HANDBOOK Master PDFDokument245 SeitenHANDBOOK Master PDFSRARNoch keine Bewertungen

- Products Handbook PDFDokument175 SeitenProducts Handbook PDFhlsimonNoch keine Bewertungen

- Products Handbook PDFDokument175 SeitenProducts Handbook PDFhlsimonNoch keine Bewertungen

- 36men LB With Davit PDFDokument2 Seiten36men LB With Davit PDFhlsimonNoch keine Bewertungen

- Beam Design Formulas With Shear and MomentDokument20 SeitenBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Leg StrengthDokument1 SeiteLeg StrengthhlsimonNoch keine Bewertungen

- Quick Release HookDokument1 SeiteQuick Release HookhlsimonNoch keine Bewertungen

- Rules and Regulations For Classification of FOIDokument2 SeitenRules and Regulations For Classification of FOIhlsimonNoch keine Bewertungen

- Readme PDFDokument203 SeitenReadme PDFdeepak_dce_meNoch keine Bewertungen

- Radius of Gyration Calculations ExplainedDokument12 SeitenRadius of Gyration Calculations Explainedsailorgeorge1100% (1)

- Bolt Tightening TorqueDokument10 SeitenBolt Tightening Torquekb7401100% (1)

- GHS Training Book OverviewDokument84 SeitenGHS Training Book OverviewKelvin XuNoch keine Bewertungen

- ReadmeDokument11 SeitenReadmehlsimonNoch keine Bewertungen

- Gratings CatalogDokument33 SeitenGratings CatalogLupul50Noch keine Bewertungen

- Beam Element MeshDokument11 SeitenBeam Element MeshhlsimonNoch keine Bewertungen

- Container InfoDokument7 SeitenContainer InfoWasipfcNoch keine Bewertungen

- Offshore Support Vessels 2013: Rules For Building and ClassingDokument16 SeitenOffshore Support Vessels 2013: Rules For Building and ClassinghlsimonNoch keine Bewertungen

- AirWinch CatalogDokument92 SeitenAirWinch CataloghlsimonNoch keine Bewertungen

- OI Rules E-Jan18 PDFDokument130 SeitenOI Rules E-Jan18 PDFhlsimonNoch keine Bewertungen

- Fric-Resistance of Randomly Oscillating SurfacesDokument8 SeitenFric-Resistance of Randomly Oscillating SurfaceshlsimonNoch keine Bewertungen

- OI Rules E-Jan18 PDFDokument130 SeitenOI Rules E-Jan18 PDFhlsimonNoch keine Bewertungen

- Design Guide For Ship Structural DetailsDokument142 SeitenDesign Guide For Ship Structural DetailsReza Babri83% (6)

- Abs 129 - Commentary On The Criteria To Adapt The Safehull System To Fpso Applications - May 2004Dokument118 SeitenAbs 129 - Commentary On The Criteria To Adapt The Safehull System To Fpso Applications - May 2004hlsimonNoch keine Bewertungen

- Design Guide For Ship Structural DetailsDokument142 SeitenDesign Guide For Ship Structural DetailsReza Babri83% (6)

- Accidental LoadDokument56 SeitenAccidental Loadcarrimonn11Noch keine Bewertungen

- Design Guide For Ship Structural DetailsDokument142 SeitenDesign Guide For Ship Structural DetailsReza Babri83% (6)

- Opening ChecklistDokument75 SeitenOpening Checklistsujay13780100% (1)

- New COADokument15 SeitenNew COAAhadNurParagNoch keine Bewertungen

- Submittal Cover Portada de Ficha Tecnica: MPS 01-05 Process SewerDokument3 SeitenSubmittal Cover Portada de Ficha Tecnica: MPS 01-05 Process SewerJosé ArgüelloNoch keine Bewertungen

- Highway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsDokument75 SeitenHighway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsAyman KandeelNoch keine Bewertungen

- BS StandardsDokument13 SeitenBS StandardsShyam Prasad K S100% (3)

- BFab/2 EC 8-0+0(U) W 1.5 mm DatasheetDokument1 SeiteBFab/2 EC 8-0+0(U) W 1.5 mm DatasheetGerente OperacionesNoch keine Bewertungen

- Tree Cutting MethodDokument14 SeitenTree Cutting MethodBienSabadoNoch keine Bewertungen

- TQ Plumbing - Jaim - FinalDokument14 SeitenTQ Plumbing - Jaim - FinalJoanna Fe JaimNoch keine Bewertungen

- Alberta Building Code Guide to Energy Efficient Home ConstructionDokument45 SeitenAlberta Building Code Guide to Energy Efficient Home ConstructionAl7amdlellah100% (2)

- Design and Construction of Confined Masonry Houses in IndonesiaDokument20 SeitenDesign and Construction of Confined Masonry Houses in IndonesiaRAIMUNDO SUHERDINNoch keine Bewertungen

- Clamp Assembly PDFDokument1 SeiteClamp Assembly PDFPhap NguyenNoch keine Bewertungen

- Health and Safety Manual - Company TemplateDokument22 SeitenHealth and Safety Manual - Company TemplateArun VenkatNoch keine Bewertungen

- Why choose CNB bearings: Customized, factory direct, quality assuranceDokument61 SeitenWhy choose CNB bearings: Customized, factory direct, quality assuranceNguyen HungNoch keine Bewertungen

- Volume Loss in Shallow TunnellingDokument14 SeitenVolume Loss in Shallow TunnellingAida RafrinNoch keine Bewertungen

- Bosch Pe Injection PumpDokument59 SeitenBosch Pe Injection PumpDavies Emmanuel100% (1)

- Community With Shipping Container HousesDokument11 SeitenCommunity With Shipping Container HousesSaki Saki SakiNoch keine Bewertungen

- Catálogo EC200DDokument912 SeitenCatálogo EC200DCasa da Madeira100% (1)

- MEngC Presentation (U San Kyu)Dokument56 SeitenMEngC Presentation (U San Kyu)Anonymous 5XPWdQcu100% (1)

- KM Practicum - Ega - Build or DieDokument4 SeitenKM Practicum - Ega - Build or DieEgaMallariNoch keine Bewertungen

- Manual EN HydraCell Pump D04 G04Dokument20 SeitenManual EN HydraCell Pump D04 G04Nhã PhanNoch keine Bewertungen

- 1397087072193-Approved Material List AMLDokument3 Seiten1397087072193-Approved Material List AMLIsmed PrajanegaraNoch keine Bewertungen

- Triptico InglesDokument3 SeitenTriptico InglesMARIANGEL .A SALDIVIIANoch keine Bewertungen

- TECAPEI Natural (Sabic Ultem 1000 Series) 14Dokument1 SeiteTECAPEI Natural (Sabic Ultem 1000 Series) 14kgrier8966Noch keine Bewertungen

- Brick Layout Parapet: 15 CM Setback From First Floor Brick WallDokument3 SeitenBrick Layout Parapet: 15 CM Setback From First Floor Brick WallGeorgy OommenNoch keine Bewertungen

- C2!6!455 Grout and Adhesive Rev.BDokument50 SeitenC2!6!455 Grout and Adhesive Rev.BAreaya mahetemNoch keine Bewertungen

- Edward Resume 102908Dokument2 SeitenEdward Resume 102908edwardblanco03Noch keine Bewertungen

- Base PlateDokument34 SeitenBase PlaterohitnrgNoch keine Bewertungen

- 8-1324-7 Pipe Class FC-7Dokument2 Seiten8-1324-7 Pipe Class FC-7Fredy Vázquez VelázquezNoch keine Bewertungen

- Ensival Moret PumpsDokument5 SeitenEnsival Moret PumpsBenicio Joaquín Ferrero Brebes0% (1)

- Design Offshore Structures CourseDokument2 SeitenDesign Offshore Structures CoursekarthickmectrNoch keine Bewertungen