Beruflich Dokumente

Kultur Dokumente

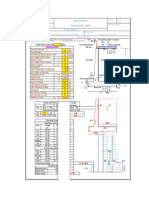

Ground Floor Axis 3 B-3

Hochgeladen von

Nazar Bazaraa0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

20 Ansichten1 SeiteSteel details by NAZAR BAZARAA

Originaltitel

Ground Floor Axis 3 B-3 (1)

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenSteel details by NAZAR BAZARAA

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

20 Ansichten1 SeiteGround Floor Axis 3 B-3

Hochgeladen von

Nazar BazaraaSteel details by NAZAR BAZARAA

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

GENERAL NOTES:

B-3 Side view B-3 Top view

scale 1:20 scale 1:20 1. ALL DIMENSIONS ARE IN MMS UNLESS

OTHERWISE NOTED.

2. ALL MAIN CONNECTIONS BETWEEN BEAMS

AND COLUMNS SHALL BE BOLTED AS PER

DESIGNER RECOMMENDATION FOR

STRUCTURES SUBJECTED TO VIBRATIONS

FROM INSTALLED ROTATING EQUIPMENT AS

PUMPS OR COMPRESSORES.

3. ALL BOLTS HIGH STRENGTH FRIVTION GRIP

BOLTS IN ACCORDANCE WITH AISC A325.

ALL WASHERE ARE PER AISC.

4. USING IMPACT GUN WITH STANDARD

TORQUE MACHINE FOR SNAG TIGHT.

5. ALL HOLES ARE 3MM GREATER THAN BOLT

DIAMETER OR 81 INCH.

HOLES ARE 25.4MM DIA

6. ALL ANGEL CLEAT HOLES CAN BE

STAGGERED FOR EASY ERECTION PURPOSE

WHERE APPLICABLE. THIS IS FOR IMPACT

GUN SOCKET INSERTION.

HOLES ARE 25.4MM DIA 7. BOLT EQUIVALENT DIAMETER:

16MM = 85 INCH

20MM= 43 INCH

HOLES ARE 22.2MM DIA

22MM= 87 INCH

24MM= 1 INCH

8. ALL WELDING WORK SHALL CONFORM TO

F B-3 Isometry SE 1:50 AWS D1.1.

9. ALL WELDS ARE STRUCTURAL WELD E60XX

AND E70XX. QUALIFIED WELDERS AND

FINAL B-3 4@7 Front view WELDING PROCEDURE TO BE PREPARED

scale 1:20

PRIOR TO INSTALLATION.

10. ALL HORIZONTAL FLOOR BRACING ARE

WELDED TO GUSSET PLATES BY 4MM SIZE

FILLET WELD TO BEAM WEB.

11. ALL BOLTS HOLES SHALL BE REAMED TO

REMOVE ANY EXCESS COATING BUILD UP.

12. MINIMUM ANGLE CLEAT THICKNESS AND

GUSSET PLATES IS 10MM UNLESS NOTED

OTHERWISE

13. FOR BEAM TO COLUMN WEB CONNECTIONS

ON BOTH SIDES, IT IS RECOMMENDED TO

INSTALL TEMPORAIRLY SUPPORT FOR FIRST

BEAM ERECTION BOLTS.

14. ALL STEEL TO BE CLEANED WITH

COMPRESSED AIR AND EPOXY PRIME

COATING BEFORE INSTALLATION. ANY

DAMAGE TO PAINT SHALL BE REPAIRED BY

TOUCH UP PAINT.

15.

Das könnte Ihnen auch gefallen

- 225R 99Dokument41 Seiten225R 99farhadamNoch keine Bewertungen

- 214 77Dokument14 Seiten214 77Didier Angel Lopez RinconNoch keine Bewertungen

- 224 2R-92 PDFDokument12 Seiten224 2R-92 PDFfarhadamNoch keine Bewertungen

- ISE Chartered Membership Exam Report January 2017Dokument7 SeitenISE Chartered Membership Exam Report January 2017Nazar BazaraaNoch keine Bewertungen

- Dynamic Analysis and Structural Design of Turbine Generator FoundationsDokument12 SeitenDynamic Analysis and Structural Design of Turbine Generator FoundationsGowrishankar1987100% (1)

- Cold-Formed Steel Portal Frame Joints A ReviewDokument17 SeitenCold-Formed Steel Portal Frame Joints A ReviewNazar BazaraaNoch keine Bewertungen

- Flat Slab Design To BS8110 PDFDokument17 SeitenFlat Slab Design To BS8110 PDFNazar BazaraaNoch keine Bewertungen

- First and Second Beams Framing LayoutDokument1 SeiteFirst and Second Beams Framing LayoutNazar BazaraaNoch keine Bewertungen

- Flat Slab Design To BS8110 PDFDokument17 SeitenFlat Slab Design To BS8110 PDFNazar BazaraaNoch keine Bewertungen

- Buildings 09 00038Dokument13 SeitenBuildings 09 00038Nazar BazaraaNoch keine Bewertungen

- Wind Resistant HousingDokument16 SeitenWind Resistant HousingNazar BazaraaNoch keine Bewertungen

- Lysaght Design Guide Wind Classification May 2017Dokument8 SeitenLysaght Design Guide Wind Classification May 2017Nazar BazaraaNoch keine Bewertungen

- STR FST (A) 04 18Dokument1 SeiteSTR FST (A) 04 18Nazar BazaraaNoch keine Bewertungen

- STR FST (A) 05 18Dokument1 SeiteSTR FST (A) 05 18Nazar BazaraaNoch keine Bewertungen

- Squarefooting CalculatorDokument2 SeitenSquarefooting CalculatorNazar BazaraaNoch keine Bewertungen

- Base Plate Hea280 Base PlateDokument1 SeiteBase Plate Hea280 Base PlateNazar BazaraaNoch keine Bewertungen

- N11702S1Dokument8 SeitenN11702S1Nazar BazaraaNoch keine Bewertungen

- STR FST (A) 001 18Dokument1 SeiteSTR FST (A) 001 18Nazar BazaraaNoch keine Bewertungen

- First Floor Framing Key Str1002Dokument1 SeiteFirst Floor Framing Key Str1002Nazar BazaraaNoch keine Bewertungen

- First Floor Axis 2 D-2Dokument1 SeiteFirst Floor Axis 2 D-2Nazar BazaraaNoch keine Bewertungen

- Bracing Connection UP TO LEVEL +104.450Dokument1 SeiteBracing Connection UP TO LEVEL +104.450Nazar BazaraaNoch keine Bewertungen

- Base Plate HEA280 BASE PLATE PDFDokument1 SeiteBase Plate HEA280 BASE PLATE PDFNazar BazaraaNoch keine Bewertungen

- Base Plate Hea280 Base PlateDokument1 SeiteBase Plate Hea280 Base PlateNazar BazaraaNoch keine Bewertungen

- Ground Floor Axis 3 C-3Dokument1 SeiteGround Floor Axis 3 C-3Nazar BazaraaNoch keine Bewertungen

- Finite Element Method Introduction for Mechanics ProblemsDokument23 SeitenFinite Element Method Introduction for Mechanics ProblemsNazar BazaraaNoch keine Bewertungen

- Gui User PDFDokument224 SeitenGui User PDFNazar BazaraaNoch keine Bewertungen

- Ground Floor Axis 3 D-3Dokument1 SeiteGround Floor Axis 3 D-3Nazar BazaraaNoch keine Bewertungen

- Ground Floor Axis 3 C-3Dokument1 SeiteGround Floor Axis 3 C-3Nazar BazaraaNoch keine Bewertungen

- TheoryDokument1.166 SeitenTheorymodestboy110Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Extruder E9-1200e Brochure en LRDokument4 SeitenExtruder E9-1200e Brochure en LRspnasurde2013Noch keine Bewertungen

- Whitepaper IOTAplus 1 1Dokument10 SeitenWhitepaper IOTAplus 1 1Eugenius BreidenNoch keine Bewertungen

- Listado de Juegos para PC Con EmuladorDokument5 SeitenListado de Juegos para PC Con EmuladorMarcelo IbañezNoch keine Bewertungen

- Mariah Carey - Endless Love (Duet With Luther Vandross)Dokument10 SeitenMariah Carey - Endless Love (Duet With Luther Vandross)ndutpesekNoch keine Bewertungen

- Dan's ResumeDokument2 SeitenDan's Resumedwels002Noch keine Bewertungen

- Replace Hallscrew Compressor PartsDokument10 SeitenReplace Hallscrew Compressor PartsIsmail CesurNoch keine Bewertungen

- Judul AnimeDokument2 SeitenJudul AnimeLucky PrasetyoNoch keine Bewertungen

- Tape Op 131 Subscriber 243028Dokument76 SeitenTape Op 131 Subscriber 243028ZenergiaNoch keine Bewertungen

- Armis - Hyper-V Virtual Appliance Configuration Guide Rev FDokument14 SeitenArmis - Hyper-V Virtual Appliance Configuration Guide Rev FHuynh KimNganNoch keine Bewertungen

- 88H Manual - IdiposDokument8 Seiten88H Manual - IdiposErfan OktafianNoch keine Bewertungen

- NATIONAL ARTISTS TheaterDokument35 SeitenNATIONAL ARTISTS Theatersheila100% (2)

- Script For News ReportDokument2 SeitenScript For News ReportAbdul Rahim OmarNoch keine Bewertungen

- Boarding Pass PDFDokument2 SeitenBoarding Pass PDFSilviuGabrielNoch keine Bewertungen

- LawnGardenCostCalculatorDokument1 SeiteLawnGardenCostCalculatorThineswary SivakumarNoch keine Bewertungen

- SAS Airline ReceiptDokument1 SeiteSAS Airline Receiptshauvik07Noch keine Bewertungen

- Quizzes - Chapter 15 - Accounting For CorporationsDokument6 SeitenQuizzes - Chapter 15 - Accounting For CorporationsAmie Jane Miranda100% (3)

- Guide 1 A1.2Dokument4 SeitenGuide 1 A1.2Nasly Paola Castillo PerezNoch keine Bewertungen

- Google CS First Coding Projects PDFDokument4 SeitenGoogle CS First Coding Projects PDFMelanie FainNoch keine Bewertungen

- TYBOX H en OriginalDokument2 SeitenTYBOX H en OriginalNunoArturNoch keine Bewertungen

- Asus ZenBook Duo UX481FA vs. Asus ZenBook Pro 15 UX535LH WindowsTipDokument1 SeiteAsus ZenBook Duo UX481FA vs. Asus ZenBook Pro 15 UX535LH WindowsTipNicTubeNoch keine Bewertungen

- Microfonos DigitalesDokument12 SeitenMicrofonos DigitalespabloNoch keine Bewertungen

- Social Media ProjectDokument8 SeitenSocial Media Projectapi-577380081Noch keine Bewertungen

- LickNRiff Tabs FullDokument401 SeitenLickNRiff Tabs Fullsda100% (7)

- Falkenbach - Ultima ThuleDokument3 SeitenFalkenbach - Ultima ThuleKronos TattooNoch keine Bewertungen

- MP2550-3350 Ordering InfoDokument4 SeitenMP2550-3350 Ordering InfoCheffley WhiteNoch keine Bewertungen

- Manual GogogateDokument27 SeitenManual Gogogatedenis miguelNoch keine Bewertungen

- Broncolor Download Brochures Power-Packs Senso en 01Dokument18 SeitenBroncolor Download Brochures Power-Packs Senso en 01Mie DtsNoch keine Bewertungen

- Design of Retaining Wall Type1 As Per ACI-318-95Dokument3 SeitenDesign of Retaining Wall Type1 As Per ACI-318-95DIRACLTDANoch keine Bewertungen

- Dakota Cole: The Peak Human Martial ArtistDokument2 SeitenDakota Cole: The Peak Human Martial ArtistasdEFNoch keine Bewertungen

- Necromunda - Chart of ChartsDokument5 SeitenNecromunda - Chart of ChartscockybestgirlNoch keine Bewertungen