Beruflich Dokumente

Kultur Dokumente

Astm A105

Hochgeladen von

Raphael Lino0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

59 Ansichten1 Seiteastm

Originaltitel

ASTM A105

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenastm

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

59 Ansichten1 SeiteAstm A105

Hochgeladen von

Raphael Linoastm

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

fh A 105/A 105M

B16.47 Large Diameter Steet Flanges”

25 ASME Boiler and Pressure Vessel Code:

Section IX Welding Qualifications”

2.6 API Standards:

‘API-600 Flanged and Butt-Welding-End Steel Gate Valves

‘API-602 Compact Design Carbon Steel Gate Valves for

Refinery Use™

3. Ordering Information

3.1. See Specification A 961

3.1.1 Additional requirements (see 12.2).

4, General Requirements

4.1. Product furnished to this specification shall conform to

the requirements of Specification A 961, including any supple~

‘mentary requirements that are indicated in the purchase order.

Failure to comply withthe requirements of Specification A 961

constitutes nonconformance with this specification, In case of

‘4 conflict between the requirements of this specification and

Specification A 961, this specification shall prevail,

‘4.2 Except as permitted by Section 6 in Specification A 961,

the finished product shall be a forging as defined in the

‘Terminology Section of Specification A 788,

5. Heat Treatment

5.1. Heat treatment is not a mandatory requirement of this

specification except for the following piping components:

‘1.1 Flanges above Class 300,"

5.1.2 Flanges of special design where the design pressure at

tie design temperature exceeds the pressure-temperature rat-

ings of Class 300, Group 1.1,

'.1.3 Flanges of special design where the design pressure or

design temperature are not known,

5.14 Piping components other than flanges which meet

both of the following eriteria: () over NPS 4 and (2) above

Class 300, and

5.1.5 Piping components of Special Class" other than

flanges which meet both ofthe following criteria: (1) over NPS

4 and (2) when the working pressure at the operating tempera

ture exceeds the tabulated values for Special Class 300, Group,

MW

5.2. Heat treatment, when required by 5.1 shall be annealing,

normalizing, or normalizing and tempering or quenching and

tempering in accordance with Specifiation A 961

6. Chemical Composition

6.1 The steel shall conform to the chemical requirements

specified in Table 1.

6.2 Steels 1o which lead has been added shall not be used.

7. Mechanical Properties

7.1. The material shall conform to the mechanical property

requirements prescribed in Table 2 and Table 3.

* allem American Pete Ise, 2101 St NW, Wesingtn,

* For definition of Class 300, soe ASME B16.

For defton of pci as tee ASME B1S38

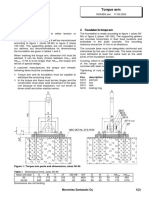

TABLE 1 Chemical Requirements

[Non—For each reduction of 0.01 % below the specified carbon

maximum (0.35%), am increase oF 0.06 % manganese above the specified

tnaximur (1.05%) wil be permite upto a maximum oF 135

a —— a_i ae

Caton 035 max

Nanganese 30-105

Prosser 35 mse

Suter 540 mae

‘iron 010-035

Copper 640 maw

Note 620 mart

Chromium 030 mare

Wetyosenan 812 man?

Comb a2 man

exceed 100%.

‘ne sien tvenum and molederum sha not exces 0.2%

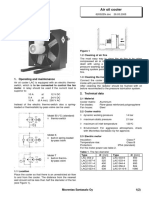

TABLE 2 Mechanical Requirements

“rales, mn, pa IPL 79 ooo 85)

‘Yl seg, min (PSI 35 000 [250]

Eangpton 2. 50 en ri

Base meimun engaion forma [7.9 »

‘Su oerin thokras, spe.

nen standard rund Bane Sm goge ng 2

‘ale popectonaly Sed specimen Wi he SBOE

‘ath enue to AD uso

ors test aston for 882 nn (08-1) 150°

Gaerence in wal theknss bal Ye 9)

tome sve neva sarge

Reduction of ree, min. %® a0

Hartree, Ha; max 1

Deter oy eth te 0.2% oft met othe 05% exnsonande

“Se Table 3 or compte rin vals.

round spacers ony

TABLE 3_ Computed Minimum Values

Wal Tease Elonaten a Pn 5

= = mmm

eos 73 a0

yolo2s") ra paso

‘40250; 6a ao

(0219) 56 2550

10.18) a 200

‘ya(0.88) 40 ne

‘ei0128) 32 200

Pacey 2a iso

ye (.062) ie 200

"Nae —Theabor able ges comets inmoeloreaton vues ie each

‘got ann scent noua ter a eases Pet

‘otewing eatin

E

sr + 15.00

where:

E

Tr

clongetion in 2 in, or $0 mm, %, and

‘actual thickness of specimen, in. [mm].

7.2. For normalized, normalized and tempered, or quenched

and tempered forgings, the central axis of the test specimen

shall correspond to the 1/4 T plane or deeper position, where T

is the maximam heat-treated thickness of the represented

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Awwa Hdpe PDFDokument37 SeitenAwwa Hdpe PDFRaphael LinoNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Corrosion Protection and StorageDokument3 SeitenCorrosion Protection and StorageRaphael LinoNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- 5 - Equivalencia de Normas PERNOSDokument1 Seite5 - Equivalencia de Normas PERNOSRaphael LinoNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- L3206en PDFDokument2 SeitenL3206en PDFRaphael LinoNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- enDokument2 SeitenenRaphael LinoNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- MDI 120EN - Safety GuideDokument6 SeitenMDI 120EN - Safety GuideRaphael LinoNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Mdi 110en PDFDokument2 SeitenMdi 110en PDFRaphael LinoNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Lubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationDokument9 SeitenLubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationRaphael LinoNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Pressure Lubrication Unit Connections: 1. GeneralDokument2 SeitenPressure Lubrication Unit Connections: 1. GeneralRaphael LinoNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Assembly Report: Gear Unit: Manuf. Number: DriveDokument1 SeiteAssembly Report: Gear Unit: Manuf. Number: DriveRaphael LinoNoch keine Bewertungen

- Use and Maintenance of Gear UnitDokument4 SeitenUse and Maintenance of Gear UnitRaphael LinoNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Use and Maintenance of Gear UnitDokument4 SeitenUse and Maintenance of Gear UnitRaphael LinoNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Corrosion Protection and StorageDokument3 SeitenCorrosion Protection and StorageRaphael LinoNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- MDI 165EN - InstallingDokument5 SeitenMDI 165EN - InstallingRaphael LinoNoch keine Bewertungen

- M062210 Part ListDokument4 SeitenM062210 Part ListRaphael LinoNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- L3206en PDFDokument2 SeitenL3206en PDFRaphael LinoNoch keine Bewertungen

- M062210 Tech SpecDokument1 SeiteM062210 Tech SpecRaphael LinoNoch keine Bewertungen

- MDI 120EN - Safety GuideDokument6 SeitenMDI 120EN - Safety GuideRaphael LinoNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Mdi 110enDokument2 SeitenMdi 110enRaphael LinoNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- M062210 - Manual Cover SheetDokument1 SeiteM062210 - Manual Cover SheetRaphael LinoNoch keine Bewertungen

- enDokument1 SeiteenRaphael LinoNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- L3206ENDokument2 SeitenL3206ENRaphael LinoNoch keine Bewertungen

- 2577910.dimensional DrawingDokument1 Seite2577910.dimensional DrawingRaphael LinoNoch keine Bewertungen

- Safety Valve Durgo: 2. Ensure The Valve FunctionsDokument1 SeiteSafety Valve Durgo: 2. Ensure The Valve FunctionsRaphael LinoNoch keine Bewertungen

- enDokument2 SeitenenRaphael Lino100% (1)

- Visual Differential Pressure Indicator: Type FPC V 10 VMDokument1 SeiteVisual Differential Pressure Indicator: Type FPC V 10 VMRaphael LinoNoch keine Bewertungen

- enDokument2 SeitenenRaphael LinoNoch keine Bewertungen

- SHP-Shaft Driven Pump: 1. GeneralDokument1 SeiteSHP-Shaft Driven Pump: 1. GeneralRaphael LinoNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- enDokument2 SeitenenRaphael LinoNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)