Beruflich Dokumente

Kultur Dokumente

2a. Specs For Valves - IA

Hochgeladen von

Praveen KasrottaranOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2a. Specs For Valves - IA

Hochgeladen von

Praveen KasrottaranCopyright:

Verfügbare Formate

Residential & Commercial Tower on Plot No.

345-883, Volume-II Part-1

Burj Khalifa, Dubai Mechanical Works Specifications

Pipe Size Horizontal Piping (Meters) Vertical Piping (Meters)

(mm) Steel Copper uPVC Steel Copper uPVC

100-125 4.0 3.7 1.5 5.0 4.0 3.0

150 5.2 4.0 2.0 6.0 5.0 3.5

200 5.5 5.0

250. 6.0 5.5

300 7.0 6.0

350 7.5

a) Spacing does not apply where span calculations are made or where concentrated loads

are placed between supports, such as flanges, valves, specialties, etc.

b) All spacing length are in meter.

c) For pipes 450 and 600 dia. the spacing of supports shall be minimum 3 meters. Contractor

shall submit complete support details, weights required, span, etc. for Engineers approval.

Contractor shall use factory made steel plate inserts in RCC to supports the pipe works.

A/C contractor to coordinate with Civil Contractor for the location and details.

7.10 Plastic pipework shall be supported using the pipework Manufacturer's standard support

clip as detailed in the Schedule of Manufacturers.

7.11 Horizontal mild steel pipework shall be supported individually by clevis type hangers or

roller hangers, where indicated.

7.12 Vertical steel pipework shall be provided with pipe alignment as recommended by supplier

and with pipe anchors at locations as agreed with the Engineer.

7.13 All chilled water pipe supports shall be galvanized.

7.14 Copper pipework where fixed against brick or dense concrete block walls shall be

supported using polished cast brass build-in brackets.

7.15 Build-in brackets shall be long shank type, when pipework is to insulated or where the finish

to the wall surface is greater than 15 mm, elsewhere build-in brackets shall be the short

shank type.

7.16 Copper pipework in exposed positions where fixed against lightweight hollow block or other

patent walls or partitions, shall be supported using polished cast brass screw-on brackets.

7.17 All chilled water pipework services shall be supported around the insulation and not directly

around the pipework. Care shall be taken to ensure the integrity of vapor sealing is not

damaged in any way.

7.18 It shall be noted that in certain cases it will be necessary to adopt a combination of the

support methods indicated, and when supports are required to be detailed to suit special

site conditions or requirements, then these details shall be submitted to the Consultant for

approval. Anti-vibration supports shall be fitted at all locations where pipework vibration is

likely to be a problem.

8.0 VALVES

8.1 Valves shall be provided and installed where required for the purpose of circulation control

and isolation. Valves shall be of full bore size to suit the mains into which they are installed.

8.2 All castings shall be clean close-grained metal, free from rough projections. Screwed valves

shall have heavy hexagon reinforcement threads, ample length threads and heavy shoulder

to prevent over entry of pipes. Flanged valves shall have the flanges flat faced and of

MEP Contract Works M/150

ARCH GROUP

P. O. Box 38390, Dubai, UAE

Residential & Commercial Tower on Plot No. 345-883, Volume-II Part-1

Burj Khalifa, Dubai Mechanical Works Specifications

thickness conforming to the appropriate specifications for the respective services and

drilled off-centre.

8.3 Valves shall have pressure rating as necessary for the service indicated on the drawing.

Samples must be provided for inspection of the manufacturing methods.

8.4 Gate valves for sizes up to 50 mm, shall be bronze or dezincification resistant copper alloy

according to EN 1982, non-rising stem, screwed bonnet, one-piece wedge, female

threaded ends according to ISO 228.

The casting shall have large hexagon section at all threads to permit gripping to prevent

line distortion during installation.

Pressure rating shall be 16 bar.

8.5 Isolating valves sizes 65mm dia. and above shall be butterfly valves, cast iron body, tapped,

full lug body, 16 bar rated, SS316 shaft, SS304 disc, EPDM seat extended onto flange face,

Fusion bonded epoxy coating to BS5155: EN593/MSS SP-67. End connections in

accordance with EN1092-2.

Manual lever actuator with memory stop for sizes NPS 150MM and below, weatherproof

worm gear Operator for valves NPS 200mm and above. Valves in excess of 2.4m above

floor shall be provided with chain wheel.

Valves on pipe connection to HEX & pump shall be rated for 20 bar.

8.6 Globe valves size 50mm dia. and below shall be bronze or dezincification resistant copper

alloy according to EN 1982, screwed bonnet and renewable dynamic disk.

8.7 Globe valves 65 mm and up shall be bronze trimmed iron body valves rated for 16 bar, with

outside screw and yoke, bolted bonnet, guide feature for disc seating.

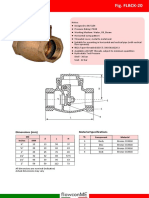

8.8 Check valves up to size 50 mm shall be bronze or Dezincification resistant alloy, screwed

ends, "Y" pattern with screwed access cap, PTFE/metal or metal/metal seating, positive

seating two-piece swivel disc, rated at 16 bar or 25 bar to system pressure requirement.

8.9 Check valves size 65 mm to 100mm shall be double door cast iron or ductile iron body, 16

bar or 25 bar rated, rotating SS304 disc with flexible hinge assembly, and bolted access.

Check valves above 100mm shall be cast iron or ductile iron body, silent check, double

door style, spring actuated, SS304 disc, rated for 16 bars or 25 bar.

8.10 Balancing Valves (double regulating) up to size 50mm dia. shall be of bronze body or

dezincification resistant copper alloy according to EN 1982, globe construction with EPDM

seat rings. Handwheel shall be heat resistant Polyamide. Female Threaded ends PN20.

Valves shall have differential pressure readout ports across valve seat area. Read out ports

shall be fitted with internal EPT insert and check valve. Valve bodies shall have 6MM NPT

tapped drain / purge port. Valves shall have memory stop feature to allow valve to be closed

for service and then reopened to set point without disturbing balance position.

All valves shall have calibrated nameplate to assure specific valve setting. Valves shall be

leak tight at full rated working pressure. All valves shall be provided with molded insulation

to permit access for balance and read out.

8.11 Balancing valves (double regulating) size 65mm dia. and above shall be of heavy duty cast

iron EN-GJL-250 (GG 25), flanged construction with PN16 flanged connections suitable up

to 16 bar working pressure.

Valves size 65 and 80mm dia. shall have a globe construction with EPDM seat rings. Valves

size 100mm dia. and above shall be fitted with a bronze or dezincification resistant copper

alloy seat, and disc with EPDM seal insert, and stainless steel stem. Valves shall have

memory stop feature to allow valve to be closed for service and then reopened to set point

without disturbing balance position. All valves shall have calibrated nameplate to assure

specific valve setting. Valves shall be leak tight at full rated working pressure. All valves

MEP Contract Works M/151

ARCH GROUP

P. O. Box 38390, Dubai, UAE

Residential & Commercial Tower on Plot No. 345-883, Volume-II Part-1

Burj Khalifa, Dubai Mechanical Works Specifications

shall be provided with moulded insulation to permit access for balance and read out.

8.12 On / Off Control valves up to and including NPS 50mm.

Three piece, full port carbon steel body, SS316 ball and stem threaded ends, TFE seats

and seals, "0" ring, lever handle.

8.13 Balancing flow control valves - up to 300mm.

i) Service: Chilled water manual operation.

ii) Valve size: shall be equal to full line size, as indicated on drawings.

iii)Construction: Cast iron bodies, stainless steel stem and seat, enc plated plug.

iv) 16 bar rated flanged.

v) All valves shall come with hand wheel operator, calibrated flow setting scale, and

pressure taps.

vi) Maximum static and differential operating pressure shall be as per system

requirements.

8.14 Valves up to and including size 50mm shall be bronze body or dezincification resistant

copper alloy according to EN 1982 with screwed ends. Valves size 65mm and above shall

be cast iron body bronze trim with flanged ends.

8.15 PICV- Pressure independent control valve

a) Factory fabricated of type, body material, and pressure class based on maximum

pressure and temperature rating of piping system, unless otherwise indicated.

b) The valve is a combination of balancing valve and control valve and differential pressure

control valve and shall be able to control the flow independent of the system pressure

fluctuation.

c) All PICVs should have test points for purpose of flow measurement based on Kv-

methodology.

i) DN15-50: Valve body shall be made from bronze or dezincification resistant copper

alloy according to EN 1982.

ii) DN65-150: Valve body shall be made in ductile iron equivalent to EN-GJS-400-15

according to EN 1563.

iii) The membrane shall be Hydrogenated Nitrile Butadiene Rubber (HNBR) or EPDM

and spring in stainless steel.

iv) Insert: Glass-reinforced PSU/POM/PPS

v) DN15-25: Valve plug shall be PPS (polyphenylsulphide)

vi) DN32-50: Valve plug shall be bronze or dezincification resistant copper alloy

according to EN 1982

vii) DN65-150: Valve plug shall be stainless steel

d) Accuracy: The control valves shall accurately control the flow from 0 to 100% full rated

flow with an operating pressure differential range of 5 to 50 PSID across the valve or

as per actual maximum differential pressure in current application.

The flow accuracy shall be 10% combination of manufacturing tolerances and

pressure variations.

e) Leakage: 0.01% of Maximum Flow per ANSI/FCI 70-2, Class 4.

f) Pressure rating shall be PN16 (or as per system pressure requirement, whichever is

higher).

g) The valve should be adjustable, balancing and control valve with integral differential

pressure control, i.e. a step-less, pre-settable balancing and control valve with an

adjustable Kvs.

MEP Contract Works M/152

ARCH GROUP

P. O. Box 38390, Dubai, UAE

Residential & Commercial Tower on Plot No. 345-883, Volume-II Part-1

Burj Khalifa, Dubai Mechanical Works Specifications

h) The PICVs shall have Equal Percentage Modified (EQM) characteristics. Linear

characteristic PICVs shall not be acceptable.

i) The actuator shall be from the same manufacturer as the valve, integrally mounted to

the valve at site.

j) The use of pressure independent valves piped in parallel to achieve the rated coil flow

shall be permitted, subject to prior approval from Engineer. Actuators shall be

electronically programmed to permit sequencing the flow with a single control output

point. The use of external devices to permit sequencing is not acceptable.

k) The valves, where used for FAHUs and HEXs, should have test points for the purpose

of flow measurement based on computerized KV methodology or an external display of

current valve flow, maximum valve flow, input signal, feedback signal and operational

directional direction shall be available. If the PICV cannot provide flow rate

measurement using KV methodology, the contractor shall provide an orifice plate along

with each PICV for FAHUs and HEXs.

l) Actuator shall have visual position indicator, stroke adaptation, suitable for 0 to 50 deg

C, shall have adequate force/torque to work within the operating range of the differential

pressure required for the application, and be rated minimum IP54.

m) The IP rating of the actuator for DN15-25 should remain IP54 in any position.

n) The actuator shall be supplied by the control valve manufacturer to ensure compatibility.

o) Actuators shall be 0-10 V DC modulating motor type.

p) The manufacturer shall warrant on supplied components for a period of 2 years from

the date of system handing over to Owner.

q) The PICV shall be manufactured in Europe/North America. Certificates of origin shall

be provided by valve manufacturer/supplier.

9.0 STRAINERS

9.1 Strainers shall be full line size located ahead of all pumps and in locations as indicated on

drawings and shall be rated for 16 bar or system pressure, whichever is higher. Bodies

shall be brass, screwed body, "Y" type, up to 50 mm size with 37% open mesh SS 304

metal screen, and 1.4 mm diameter holes.

9.2 For sizes 65 MM and above, Iron body, flanged, "Y" type bolted cover flange, tapped blow-

off outlet, 37% open mesh SS 304 screen, with 1.4 mm diameter holes.

10.0 GAUGES AND ACCESSORIES

10.1 Wet service thermometers shall be straight shank liquid fill insertion type. They shall have

a stem length of 80 mm and a scale length of 225 mm, and the capability of adjusting the

angle of the scale to the stem. Provide copper or brass separable wells for each

thermometer.

10.2 Air service thermometers shall be straight shank liquid fill insertion type. They shall have a

stem length of 150 mm and a scale length of 225 mm, and the capability of adjusting the

angle of the scale to the stem.

10.3 Pressure gauges shall have 100 mm diameter cast Aluminium case, black figures, forged

brass sockets with phosphor bronze bushed rotary type movement and Bourdon tube.

Gauges shall be complete with impulse dampening insert and T-handle gauge cock.

10.4 Where the line size is 100 mm or less the gauge is to be installed into a tree branch, with

reducers. For sizes above 125 mm a "threadolet" weld-on connection may be used, subject

to proper procedures and requirements of the welding specifications.

10.5 Range of gauges shall be selected such that the operating point is approximately midway

of the range in selected gauge.

MEP Contract Works M/153

ARCH GROUP

P. O. Box 38390, Dubai, UAE

Das könnte Ihnen auch gefallen

- SPEC For Chilled Water Pipework and FittingsDokument4 SeitenSPEC For Chilled Water Pipework and FittingsonspsnonsNoch keine Bewertungen

- Sprinkler ESFRDokument4 SeitenSprinkler ESFRGustavo Torres CabañasNoch keine Bewertungen

- JetVent Centrifugal Induction Fans for Car Parks & Smoke ControlDokument16 SeitenJetVent Centrifugal Induction Fans for Car Parks & Smoke ControlHellen MartinssonNoch keine Bewertungen

- ITE EC C Code LanguageDokument39 SeitenITE EC C Code LanguagespotNoch keine Bewertungen

- Fire Safety Requirements For Ductless Jet Fans System in Car ParksDokument10 SeitenFire Safety Requirements For Ductless Jet Fans System in Car ParksVishwajeet SinghNoch keine Bewertungen

- Compact Fans For AC and DC 2014 enDokument268 SeitenCompact Fans For AC and DC 2014 enParasuraman SundaravelNoch keine Bewertungen

- En 12101-2 SHEV-Info EnglishDokument21 SeitenEn 12101-2 SHEV-Info EnglishStefanSevastianNoch keine Bewertungen

- ESCS PresentationDokument20 SeitenESCS Presentationzar niNoch keine Bewertungen

- Aec Collection Comparison Matrix enDokument1 SeiteAec Collection Comparison Matrix enCharlesNoch keine Bewertungen

- M E Room DimensionsDokument3 SeitenM E Room DimensionsPujayantha KumarNoch keine Bewertungen

- Pressure-Differential-Systems 2015 01 en WebDokument20 SeitenPressure-Differential-Systems 2015 01 en WebMohammad Faizul ZainudinNoch keine Bewertungen

- PICV Pressure Independent Control Valve Saves Energy & CostDokument1 SeitePICV Pressure Independent Control Valve Saves Energy & Costpsn_kylmNoch keine Bewertungen

- PPwO - Participant Guide PDFDokument31 SeitenPPwO - Participant Guide PDFAbdullah HasanNoch keine Bewertungen

- Ec Axial Fan W3g800gu2501 EngDokument5 SeitenEc Axial Fan W3g800gu2501 EngmacmottaNoch keine Bewertungen

- Cascade Refrigeration System "For Blood Storage"Dokument4 SeitenCascade Refrigeration System "For Blood Storage"International Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- ESFR Pendent SprinklerDokument6 SeitenESFR Pendent SprinklerNikhil RajanNoch keine Bewertungen

- innovative refrigeration pipe sizing chartDokument2 Seiteninnovative refrigeration pipe sizing chartDedi KartiwaNoch keine Bewertungen

- Refrigeration ClassificationDokument29 SeitenRefrigeration ClassificationSakhawat Hossain SumonNoch keine Bewertungen

- EC Fan Application Note - EMERSONDokument8 SeitenEC Fan Application Note - EMERSONlouie mabiniNoch keine Bewertungen

- Evolving Design Chiller PlantDokument7 SeitenEvolving Design Chiller PlantMohsin KhanNoch keine Bewertungen

- Specifications Report - HighlightedDokument19 SeitenSpecifications Report - HighlightedBogdan CarjanNoch keine Bewertungen

- Balancing and flow control valves quick reference guideDokument47 SeitenBalancing and flow control valves quick reference guideRami ReddyNoch keine Bewertungen

- Acph 2022Dokument15 SeitenAcph 2022VENKAT100% (1)

- Section 13915-SpecDokument25 SeitenSection 13915-SpecMrbudakbaekNoch keine Bewertungen

- BOSS™ Pressurisation Units and Expansion Vessels PDFDokument16 SeitenBOSS™ Pressurisation Units and Expansion Vessels PDFRIFASNoch keine Bewertungen

- Variable Speed Chillers With PicvDokument1 SeiteVariable Speed Chillers With PicvPradeep SukumaranNoch keine Bewertungen

- Technical Data PRIHODADokument32 SeitenTechnical Data PRIHODAAlex PotaNoch keine Bewertungen

- ACE Solar Water HeaterDokument17 SeitenACE Solar Water HeatercrazybozinusNoch keine Bewertungen

- As 4429-1999 Methods of Test and Rating Requirements For Smoke-Spill FansDokument9 SeitenAs 4429-1999 Methods of Test and Rating Requirements For Smoke-Spill FansSAI Global - APACNoch keine Bewertungen

- Acgs 2017Dokument490 SeitenAcgs 2017FS100% (1)

- VAD Variable Area Desuperheaters: Desuperheater OverviewDokument6 SeitenVAD Variable Area Desuperheaters: Desuperheater OverviewLucasZanaNoch keine Bewertungen

- 'Protecting Escape Routes - Smoke Shafts V Pressurisation' - Means of Escape - Fire Safety MagazineDokument6 Seiten'Protecting Escape Routes - Smoke Shafts V Pressurisation' - Means of Escape - Fire Safety MagazineAnonymous NGXdt2BxNoch keine Bewertungen

- Kavalani Hvac R Catalogue 2015Dokument32 SeitenKavalani Hvac R Catalogue 2015Anoop Jacob KunnappuzhaNoch keine Bewertungen

- Design Points For Negative PressureDokument23 SeitenDesign Points For Negative PressureShohei Namjoon LetoNoch keine Bewertungen

- Wise CatalogDokument177 SeitenWise CatalogHatim IshakNoch keine Bewertungen

- Lokring I Single Ring 01.07.2013Dokument58 SeitenLokring I Single Ring 01.07.2013Sandra Mabel Leguizamon100% (1)

- Fan Coil Hose Catalogue ArsenflexDokument8 SeitenFan Coil Hose Catalogue ArsenflexcecotheoneNoch keine Bewertungen

- JFE - Line PipeDokument63 SeitenJFE - Line Pipebee4manuNoch keine Bewertungen

- Distance From Sprinkler To HangerDokument1 SeiteDistance From Sprinkler To Hangerahmaborashed100% (1)

- Nfpa Smoke Barriers 12.9Dokument6 SeitenNfpa Smoke Barriers 12.9Ingénieur ÉlectriqueNoch keine Bewertungen

- Catalogue CF For CTI 2.00 15dec2015Dokument104 SeitenCatalogue CF For CTI 2.00 15dec2015X-flies0% (1)

- A Novel Use of HYSYS To Design An Industrial Refrigeration SystemDokument7 SeitenA Novel Use of HYSYS To Design An Industrial Refrigeration SystemaadamxNoch keine Bewertungen

- Expansion Joint System PDFDokument12 SeitenExpansion Joint System PDFG.SWAMINoch keine Bewertungen

- Air Distribution System Case StudyDokument16 SeitenAir Distribution System Case Studytmy3dataNoch keine Bewertungen

- Chilled Water System Introduction, MyanmarDokument20 SeitenChilled Water System Introduction, MyanmaracmvorgNoch keine Bewertungen

- Duct Leakage TesterDokument8 SeitenDuct Leakage TesterJay PresleyNoch keine Bewertungen

- Twi CrossflowDokument8 SeitenTwi CrossflowDota NgNoch keine Bewertungen

- AX Series Installation and Operating InstructionsDokument32 SeitenAX Series Installation and Operating InstructionsrkssNoch keine Bewertungen

- SANITARY1 Lecture 2019 PDFDokument72 SeitenSANITARY1 Lecture 2019 PDFArnold ApostolNoch keine Bewertungen

- WADokument28 SeitenWADota NgNoch keine Bewertungen

- Explosion Proof Axial Fan CertificateDokument7 SeitenExplosion Proof Axial Fan CertificateShahlan AnuarNoch keine Bewertungen

- Oman Cable Over Head Cable Spec 20-4Dokument34 SeitenOman Cable Over Head Cable Spec 20-4harishpandyanNoch keine Bewertungen

- De Super HeaterDokument2 SeitenDe Super HeatergateauxboyNoch keine Bewertungen

- SeAH KoreaDokument37 SeitenSeAH KoreaThuận LêNoch keine Bewertungen

- ASHRAE 199711 Deh and Cooling Loads From Vent AirDokument6 SeitenASHRAE 199711 Deh and Cooling Loads From Vent Airkkod11Noch keine Bewertungen

- The Royal Atlantis WSP Usa IBI Project No 38188 IFC - 22 March 2017Dokument7 SeitenThe Royal Atlantis WSP Usa IBI Project No 38188 IFC - 22 March 2017MY PCNoch keine Bewertungen

- VALVESDokument9 SeitenVALVESMohamad ChaudhariNoch keine Bewertungen

- FIRE FIGHTING SPECIFICATIONSDokument25 SeitenFIRE FIGHTING SPECIFICATIONSSudipto KumarNoch keine Bewertungen

- D-5) Piping InstallationDokument8 SeitenD-5) Piping InstallationfbellimamNoch keine Bewertungen

- FCU Flexible ConnectorDokument2 SeitenFCU Flexible ConnectorMohamed MostafaNoch keine Bewertungen

- 31 FLBCK-20Dokument1 Seite31 FLBCK-20Praveen KasrottaranNoch keine Bewertungen

- Derivatives Guide PDFDokument22 SeitenDerivatives Guide PDFBskkamNoch keine Bewertungen

- VAV Fundamentals Belimo Speaker Ahmed KhatibDokument24 SeitenVAV Fundamentals Belimo Speaker Ahmed Khatibheartbreakkid132Noch keine Bewertungen

- Testing and Commissioning Procedure For Air-Conditioning, Refrigeration, VentilationDokument247 SeitenTesting and Commissioning Procedure For Air-Conditioning, Refrigeration, VentilationPraveen KasrottaranNoch keine Bewertungen

- VAV Fundamentals Belimo Speaker Ahmed KhatibDokument24 SeitenVAV Fundamentals Belimo Speaker Ahmed Khatibheartbreakkid132Noch keine Bewertungen

- 819590gdi79 Gasoline Direct InjectionDokument19 Seiten819590gdi79 Gasoline Direct InjectionRavindra JillepalliNoch keine Bewertungen

- Dialysis PowerpointDokument10 SeitenDialysis Powerpointapi-266328774Noch keine Bewertungen

- CSR 620 Commissioning Manual A4-5285CDokument40 SeitenCSR 620 Commissioning Manual A4-5285CNguyễn Xuân Lộc86% (7)

- Physical GEOGRAPHY - TIEDokument432 SeitenPhysical GEOGRAPHY - TIEnassorussi9Noch keine Bewertungen

- The CardiacDokument7 SeitenThe CardiacCake ManNoch keine Bewertungen

- Image Authentication ENFSIDokument43 SeitenImage Authentication ENFSIIolanda OprisanNoch keine Bewertungen

- Myo Cny 2023 MenuDokument12 SeitenMyo Cny 2023 Menulihanyong17Noch keine Bewertungen

- Philips Solar+LED Marketing StrategyDokument15 SeitenPhilips Solar+LED Marketing StrategyrejinairNoch keine Bewertungen

- Plastic RecyclingDokument14 SeitenPlastic RecyclingLevitaNoch keine Bewertungen

- PTM Kel 4 (English)Dokument10 SeitenPTM Kel 4 (English)A'an Al FikriNoch keine Bewertungen

- AbolethDokument3 SeitenAbolethjlewis_4Noch keine Bewertungen

- Adoption ApplicationDokument3 SeitenAdoption ApplicationwriterhildNoch keine Bewertungen

- Adverse Drug Reactions in A ComplementaryDokument8 SeitenAdverse Drug Reactions in A Complementaryrr48843Noch keine Bewertungen

- Game Informer September 2013Dokument104 SeitenGame Informer September 2013Igor IvkovićNoch keine Bewertungen

- Regenerative Braking System: An Efficient Way to Conserve EnergyDokument31 SeitenRegenerative Braking System: An Efficient Way to Conserve EnergyPRAVIN KUMAR NNoch keine Bewertungen

- Watson Studio - IBM CloudDokument2 SeitenWatson Studio - IBM CloudPurvaNoch keine Bewertungen

- VNL-Essar Field Trial: Nairobi-KenyaDokument13 SeitenVNL-Essar Field Trial: Nairobi-Kenyapoppy tooNoch keine Bewertungen

- DIRECTORS1Dokument28 SeitenDIRECTORS1Ekta ChaudharyNoch keine Bewertungen

- Derivatives and Foreign Currency: Concepts and Common TransactionsDokument28 SeitenDerivatives and Foreign Currency: Concepts and Common TransactionsElle PaizNoch keine Bewertungen

- Module 3 - Subsequent To AcquisitionDokument8 SeitenModule 3 - Subsequent To AcquisitionRENZ ALFRED ASTRERONoch keine Bewertungen

- Appeal Tax Procedure (Malaysia)Dokument2 SeitenAppeal Tax Procedure (Malaysia)Zati TyNoch keine Bewertungen

- Rajani Panchal Phone: - 0279642567Dokument4 SeitenRajani Panchal Phone: - 0279642567Phillip JohnsonNoch keine Bewertungen

- March 17, 2017 - Letter From Dave Brown and Megan McCarrin Re "Take Article Down" - IRISH ASSHOLES TODAY!Dokument459 SeitenMarch 17, 2017 - Letter From Dave Brown and Megan McCarrin Re "Take Article Down" - IRISH ASSHOLES TODAY!Stan J. CaterboneNoch keine Bewertungen

- Module 3 FP Client AssessmentDokument54 SeitenModule 3 FP Client AssessmentJhunna TalanganNoch keine Bewertungen

- Cardboard Dream HouseDokument1 SeiteCardboard Dream Houseapi-630719553Noch keine Bewertungen

- Beginning of Agriculture Northern Vindhyas Middle Gangetic PlainsDokument17 SeitenBeginning of Agriculture Northern Vindhyas Middle Gangetic Plainsakshat aggarwal100% (1)

- 04 Vendor Registration TrainingDokument16 Seiten04 Vendor Registration TrainingAhmad Ramin AbasyNoch keine Bewertungen

- 5 Hunger of The PineDokument39 Seiten5 Hunger of The PinedraconeitNoch keine Bewertungen

- Project Proposal ApprovedDokument2 SeitenProject Proposal ApprovedRonnel BechaydaNoch keine Bewertungen

- Emily Act 3 GraficoDokument13 SeitenEmily Act 3 Graficoemily lopezNoch keine Bewertungen

- BSC6900 UMTS Hardware Description (V900R017C10 - 01) (PDF) - enDokument224 SeitenBSC6900 UMTS Hardware Description (V900R017C10 - 01) (PDF) - enmike014723050% (2)