Beruflich Dokumente

Kultur Dokumente

Introducttion To Quality and Performance Excellence

Hochgeladen von

Sharmaine FranciscoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Introducttion To Quality and Performance Excellence

Hochgeladen von

Sharmaine FranciscoCopyright:

Verfügbare Formate

INTRODUCTION TO QUALITY AND PERFORMANCE EXCELLENCE Process Approach

System Approach in Management

DEFINING QUALITY Continual Improvement

Perfection Factual Approach to Decision Making

Fast delivery Mutually Beneficial Supplier Relationships

Providing a good, usable product

Consistency CUSTOMER FOCUS

Eliminating waste Customer is the principal judge of quality

Doing I right the first time Organizational must build relationships with customers and increase

Delighting or pleasing customers customer engagement

Total customer service and satisfaction Organizations must understand customer needs and obtain feedback

Compliance with policies and procedures Customers are internal and external

CUSTOMER-FOCUSED PRACTICES

FORMAL DEFINITION OF QUALITY

Researching and understanding customer needs and expectations

The totality of features and characteristics of a product or service that

Ensuring that goods and services are linked to customer needs and

bears on its ability to satisfy given needs American Society for Quality

expectations

- Fitness for use

Communicating customer needs and expectations throughout the

- Meeting or exceeding customer expectations

organization

- Conformance to specifications

Measuring customer satisfaction and using the results to improve

Systematically managing customer relationships; and

PERFORMANCE EXCELLENCE

Ensuring a balanced approach between satisfying customers and other

An integrated approach to organizational performance

stakeholders

management that results in

- Delivery of ever-improving value to customers and LEADERSHIP

stakeholders, contributing to organizational sustainability Leadership is the responsibility of top management

- Improvement of overall organizational effectiveness and Senior leaders should be role models for the entire organizations

capabilities, and As organization cannot sustain quality initiatives without strong

- Organizational and personal learning leadership

IMPORTANCE OF QUALITY LEADERSHIP PRACTICES

The buzzword among business in the 1980s and 1990s Considering the needs of all stakeholders in decisions

Quality problems still abound in many industries, such as automotive Establishing a clear vision of the organizations future

Consumer expectations are high Setting challenging goals and targets

Weve made dependence on the quality of our technology a part of life Creating and sustain shared values, fairness, and ethics at all levels of

Joseph Juran the organization

Establishing trust and eliminating fear

HISTORY OF QUALITY ASSURANCE Providing workers with adequate resources, training and freedom to

Quality assurance in Ancient China make customer-focused decisions, and

Skilled craftsmanship during Middle Ages Inspiring, encouraging and recognizing workers contributions

Industrial Revolution: rise of inspection and separate quality departments

INVOLVEMENT OF PEOPLE

Early 20th Century: Statistical methods at Bell System

A companys success depends increasingly on the knowledge, skills,

Quality control during World War II

and motivation of its workforce

Post-war Japan: Evolution of Quality Management

Engagement workers have a strong emotional bond to their

Quality awareness in U.S manufacturing industry during 1980s:from

organization, are actively involved in and committed to their work, feel

Little Q to Big Q Total Quality Management

that their jobs are important, know that their opinions and ideas have

Malcolm Baldrige National Quality Award (1987)

value, and often go beyond their immediate responsibilities for the good

Cynicism and criticism among some business executives of the organization

Emergence of quality management in service industries, government, Empowerment having the authority to make decisions

health care, education, and non-profits

A sincere belief and trust in people

Evolution of Six Sigma

Current and future challenge: maintain commitment to performance TEAMWORK

excellence Vertical teamwork between top management and lower-level

employees

PRINCIPLES, PRACTICES, AND TECHNIQUES

Horizontal teamwork within work groups and across functional lines

Principles are the foundation of the philosophy (often called cross-functional teams)

Practices are activities by which the principles are implemented Interorganizational partnerships with suppliers and customers

Techniques are tools and approaches that help managers and

employees make the practices effective PEOPLE-FOCUSED PRACTICES

Understand the key factors that drive workforce engagement,

QUALITY MANAGEMENT PRINCIPLES satisfaction, and motivation

Customer Focus Design and manage work and jobs to promote engagement

Leadership

Involvement of People

Create an environment that ensures and improves workplace health, Delighters/exciters new or innovative features that customers do not

safety, and security expect. The presence of such unexpected features, if valued, leads to

Develop an effective performance management system high perceptions of quality

Assess workforce engagement and satisfaction

PRACTICES FOR CONTINUAL IMPROVEMENT

Assess workforce capability and capacity needs

Deploying a systematic approach to continual improvement across the

Make appropriate investments in development and learning

organization

Manage career progression and succession planning

Providing the workforce with training in the methods and tools of

PROCESS APPROACH continual improvement

A process is a sequence of activities that is intended to achieve some Making continual improvement of products, processes, and systems an

result objective for every individual

Establishing goals to guide, and measures to track, continual

PROCESS-FOCUSED PRACTICES improvement, and

Systematically defining processes that create desired outcomes; Recognizing and acknowledging improvements

establishing clear responsibility and accountability for managing key

processes FACTUAL APPROACH TO DECISION MAKING

Analyzing and measuring of the capability of processes Organizations need good performance measures to drive strategies and

Identifying the interfaces of key activities within and between the change, manage resources, and continuously improve

functions of the organization - Data and information support analysis at all levels

Focusing on the factors such as resources, methods, and materials that - Typical measures:

will improve processes; and 1. Product and process outcomes

Evaluating risks, consequences, and impacts of activities on customers, 2. Customer-focused outcomes

suppliers and other stakeholders 3. Workforce-focused outcomes

4. Leadership and governance outcomes, and

SYSTEMS APPROACH TO MANAGEMENT 5. Financial and market outcomes

Synthesis means looking at an organization as a whole and building on

key business attributes, including core competencies, strategic DATA DRIVEN PRACTICES

objectives, action plans, and work systems Ensuring that data and information are sufficiently accurate and reliable

Alignment means ensuring consistency of plans, processes, measures, Making data accessible to those who need it

and actions across the organization Analyzing data and information using valid methods, and

Integration builds on alignment, so that the individual components of the Making decisions and taking action based on factual analysis, balanced

organizational system operate in a fully interconnected manner and with experience and intuition

deliver anticipated results

MUTUALLY BENEFICIAL SUPPLIER RELATIONSHIPS

SYSTEMS APPROACH PRACTICES Suppliers include not only companies that provide materials and

Designing the organization to achieve its objectives in the most effective components, but also distributors, transportation companies, and

and efficient way information, health care and education providers

Understanding the interdependencies between processes Key suppliers might provide unique design, technology, integration, or

Developing approaches that harmonize and integrate processes marketing capabilities that are not available within the business and,

Providing a clear understanding of the roles and responsibilities therefore can be critical to achieving such strategic objectives as lower

necessary for achieving objectives and reducing cross-functional costs, faster time-to-market, and improved quality

barriers

SUPPLIER MANAMGEMENT PRACTICES

Understanding organizational capabilities, defining how specific

Recognizing the strategic importance of suppliers in accomplishing

activities and processes should operate, and

business objectives, particularly minimizing the total cost of ownership

Continually improving the system through measurement and evaluation

Identifying and selecting key suppliers, developing win-win relationships

CONTINUAL IMPROVEMENT that balance short-term gains with long-term considerations

Continual Improvement incremental and breakthrough improvement Establishing trust through openness and honesty, thus leading to mutual

Several Types of Improvement advantages

- Improving Products and Services: enhancing value to the Pooling expertise and resources with partners

customer through new and improved products and services Having clear and open communication that information and future plans

- Improving Work Process: improving productivity and operational Establishing joint development and improvement activities, and inspiring

performance through better work processes and reductions in encouraging

errors, defects and waste Recognizing improvements and achievements of suppliers

- Improving flexibility, responsiveness, and cycle time

- Improving organizational management processes through learning

KANO MODEL

Dissatifiers - those needs that are expected in a product or service.

Such items generally are not stated by customers but are assumed as

given.

Satisfiers needs that customers say they want. Fulfilling these needs

creates satisfaction

Das könnte Ihnen auch gefallen

- Francisco, Sharmaine M. - Insight About Future Is BrightDokument1 SeiteFrancisco, Sharmaine M. - Insight About Future Is BrightSharmaine FranciscoNoch keine Bewertungen

- What Is Culture - 7 Aspects of CultureDokument42 SeitenWhat Is Culture - 7 Aspects of CultureSharmaine Francisco60% (5)

- Human Rights in The PhilippinesDokument2 SeitenHuman Rights in The PhilippinesSharmaine FranciscoNoch keine Bewertungen

- Thank You LetterDokument2 SeitenThank You LetterSharmaine FranciscoNoch keine Bewertungen

- Thank You LetterDokument1 SeiteThank You LetterSharmaine FranciscoNoch keine Bewertungen

- Edited Case StudiesDokument6 SeitenEdited Case StudiesSharmaine FranciscoNoch keine Bewertungen

- Atty. Rosalie J. Dela Cruz-CadaDokument1 SeiteAtty. Rosalie J. Dela Cruz-CadaSharmaine FranciscoNoch keine Bewertungen

- Thank You LetterDokument1 SeiteThank You LetterSharmaine FranciscoNoch keine Bewertungen

- A Project Proposal For The Federation Year 2018-2019 Prepared byDokument23 SeitenA Project Proposal For The Federation Year 2018-2019 Prepared bySharmaine FranciscoNoch keine Bewertungen

- FEU CertDokument1 SeiteFEU CertSharmaine FranciscoNoch keine Bewertungen

- Chapter 1 Test BankDokument33 SeitenChapter 1 Test BankSharmaine FranciscoNoch keine Bewertungen

- Course Adviser, System Analysis and Design: ND ND ND NDDokument1 SeiteCourse Adviser, System Analysis and Design: ND ND ND NDSharmaine FranciscoNoch keine Bewertungen

- Chapter 4 HWDokument1 SeiteChapter 4 HWSharmaine FranciscoNoch keine Bewertungen

- FEU CertificateDokument1 SeiteFEU CertificateSharmaine FranciscoNoch keine Bewertungen

- ImmunityDokument1 SeiteImmunitySharmaine FranciscoNoch keine Bewertungen

- Theme of The Year: "But You Are A Chosen Race, A Royal Priesthood, A Holy Nation, A People of His Own."Dokument1 SeiteTheme of The Year: "But You Are A Chosen Race, A Royal Priesthood, A Holy Nation, A People of His Own."Sharmaine FranciscoNoch keine Bewertungen

- Men's Badminton - SinglesDokument1 SeiteMen's Badminton - SinglesSharmaine FranciscoNoch keine Bewertungen

- Iabf Sportsfest 2017 - 2018Dokument6 SeitenIabf Sportsfest 2017 - 2018Sharmaine FranciscoNoch keine Bewertungen

- Against CloningDokument1 SeiteAgainst CloningSharmaine FranciscoNoch keine Bewertungen

- Far Eastern University - Junior Philippine Institute of Accountants SponsorsDokument3 SeitenFar Eastern University - Junior Philippine Institute of Accountants SponsorsSharmaine FranciscoNoch keine Bewertungen

- The IslandDokument2 SeitenThe IslandSharmaine FranciscoNoch keine Bewertungen

- Energy and MetabolismDokument1 SeiteEnergy and MetabolismSharmaine FranciscoNoch keine Bewertungen

- Streptococcus Thermophilus (Probiotic) : A Strain You WantDokument2 SeitenStreptococcus Thermophilus (Probiotic) : A Strain You WantSharmaine FranciscoNoch keine Bewertungen

- Digestion and ExcretionDokument1 SeiteDigestion and ExcretionSharmaine FranciscoNoch keine Bewertungen

- ManagementDokument5 SeitenManagementSharmaine FranciscoNoch keine Bewertungen

- Solar Powered SmartphoneDokument13 SeitenSolar Powered SmartphoneSharmaine FranciscoNoch keine Bewertungen

- 1 Bora Wan ResortDokument33 Seiten1 Bora Wan ResortSharmaine Francisco100% (1)

- Far Eastern Univrsity Cost Accounting CanvassDokument8 SeitenFar Eastern Univrsity Cost Accounting CanvassSharmaine FranciscoNoch keine Bewertungen

- Whats The Best Diet For HumansDokument26 SeitenWhats The Best Diet For HumansSharmaine FranciscoNoch keine Bewertungen

- Case Study: Mitsubushi Montero Sport (Sua)Dokument5 SeitenCase Study: Mitsubushi Montero Sport (Sua)Sharmaine Francisco50% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SONET - SDH OC192 - STM64 PICs With XFP (T4000 Router) - Sonet SDH Support - Juniper NetworksDokument4 SeitenSONET - SDH OC192 - STM64 PICs With XFP (T4000 Router) - Sonet SDH Support - Juniper NetworksDhanyasriNoch keine Bewertungen

- Ardina Car Care - Brochure 2013Dokument40 SeitenArdina Car Care - Brochure 2013alexpuhaNoch keine Bewertungen

- 10 Bibliografia Adjunta Iso - 6888 - 3Dokument6 Seiten10 Bibliografia Adjunta Iso - 6888 - 3Jen UculmanhaNoch keine Bewertungen

- 911 Calls Data Capstone Project .HTMLDokument15 Seiten911 Calls Data Capstone Project .HTMLJohn BerardiNoch keine Bewertungen

- Jis G3444Dokument19 SeitenJis G3444Tanvir HasanNoch keine Bewertungen

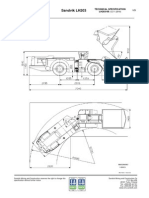

- LH 203Dokument3 SeitenLH 203Angels Córdova Alegría100% (1)

- AngloGold Ashanti Geologist PDFDokument1 SeiteAngloGold Ashanti Geologist PDFashfa ulyaNoch keine Bewertungen

- Camera ReferenceDokument22 SeitenCamera ReferenceblekokNoch keine Bewertungen

- Anuj Project FileDokument38 SeitenAnuj Project FileamaranandminzNoch keine Bewertungen

- 010 Evac Ejector UnitsDokument6 Seiten010 Evac Ejector UnitsMichael CorderoNoch keine Bewertungen

- DRG100-120 - Operator Manual - IDRG02 - 03GB PDFDokument290 SeitenDRG100-120 - Operator Manual - IDRG02 - 03GB PDFNicolas MoyanoNoch keine Bewertungen

- Epson TM t82Dokument2 SeitenEpson TM t82lalukurniawanNoch keine Bewertungen

- GAIL (India) Ltd. Sample Programming Placement Paper Level1Dokument12 SeitenGAIL (India) Ltd. Sample Programming Placement Paper Level1placementpapersampleNoch keine Bewertungen

- Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced PlasticsDokument6 SeitenTensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced PlasticsPablo AlcázarNoch keine Bewertungen

- MQX Rtos PDFDokument23 SeitenMQX Rtos PDFcadornetti100% (1)

- Specifications Infusion Pump TE-135Dokument2 SeitenSpecifications Infusion Pump TE-135Muhammad Iqwan Mustaffa100% (1)

- Type CDokument9 SeitenType CxxxxxNoch keine Bewertungen

- Lecture2 VHDL For SynthesisDokument82 SeitenLecture2 VHDL For SynthesisVimalNoch keine Bewertungen

- B 35Dokument2 SeitenB 35Parashuram ChauhanNoch keine Bewertungen

- SLP TX420Dokument2 SeitenSLP TX420Estrellita BelénNoch keine Bewertungen

- Important Emissions Recall: UB4 Evaporative Emissions CanisterDokument2 SeitenImportant Emissions Recall: UB4 Evaporative Emissions CanisterAyman RiyadhNoch keine Bewertungen

- PT Amman Mineral Nusa Tenggara Batu Hijau Project SpecificationDokument14 SeitenPT Amman Mineral Nusa Tenggara Batu Hijau Project Specificationelia nugraha adiNoch keine Bewertungen

- Design of Experiment QuestionDokument3 SeitenDesign of Experiment QuestionvmgobinathNoch keine Bewertungen

- Vivek Paul Engineer (Tech.) KLG Systel LTDDokument61 SeitenVivek Paul Engineer (Tech.) KLG Systel LTDFirasat AliNoch keine Bewertungen

- Hitachi ZX65USB 6 Mini Excavator KS EN438EUDokument20 SeitenHitachi ZX65USB 6 Mini Excavator KS EN438EUAkhmad SebehNoch keine Bewertungen

- MSS SP-6 2012Dokument7 SeitenMSS SP-6 2012ISRAEL PORTILLO100% (1)

- Js4n2nat 4Dokument2 SeitenJs4n2nat 4tingNoch keine Bewertungen

- CiscoDokument42 SeitenCiscoSergio Julian Sivincha QuispeNoch keine Bewertungen

- PXE Modes of Operation White Paper V1.0Dokument7 SeitenPXE Modes of Operation White Paper V1.0Davide ToniniNoch keine Bewertungen

- Get Approved HVAC Shop DrawingsDokument4 SeitenGet Approved HVAC Shop DrawingsManibalanNoch keine Bewertungen