Beruflich Dokumente

Kultur Dokumente

CH 18

Hochgeladen von

Amol VaradeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CH 18

Hochgeladen von

Amol VaradeCopyright:

Verfügbare Formate

18

P OTATO/BANANA WAFERS

PRODUCT CODE : 219804001 only for Patato Wafers

QUALITY AND STANDARDS : PFA Regulations and BIS

PRODUCTION CAPACITY : Qty. : 60 MT and Value: Rs. 39 lakhs

MONTH AND YEAR : May, 2003

OF PREPARATION

PREPARED BY : Small Industries Service Institute

65/1, G.S.T. Road, Guindy

Chennai - 600032

Tamil Nadu

INTRODUCTION tonnes. The main banana growing states

are: Tamil Nadu, Maharashtra, Kerala and

In India around 12 million tonnes of Andhra Pradesh. Banana contains about

potato is grown which is about 4% of 20% sugar and reasonable amount of

the total world production. However, the Vitamins A, B and C. This is considered

per capita consumption of potatoes is to be a rich source of energy producing

low. It is estimated that 25% of the food. It is consumed in several forms

potatoes, which are spoiled due to and preparations and amongst which

various reasons such as transportation, Banana wafer is considered to be the

type of packing, non-availability of cold most important item.

storage capacities during harvesting

season, glut in the market etc., could

be saved by making various preserved

MARKET POTENTIAL

potato products. Potato wafer is one of The popularity of snack foods is

such products which has a great growing fast day-by-day and potato and

potential as this is considered as one of banana wafers have emerged as a

the traditional foods of India. Potato potential snack food. A number of

wafers are needed to be made in a organised as well as unorganised groups

scientific manner and under hygienic are already there catering to the needs

conditions. of tea stalls, restaurants, railway stations,

Banana is one of the most important tourist places etc. Still there is a huge

fruits in India and occupies about 27.4 demand to be met for these products in

thousand hectares area with an annual interior and remote places in different

production of about 42.33 thousand parts of the country.

106 P OTATO/BANANA WAFERS

B ASIS AND PRESUMPTIONS TECHNICAL ASPECTS

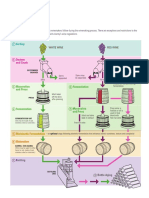

(1) The scheme is based on single Process of Manufacture

shift per day for 300 working Potato Wafers

days in a year at 75% working

efficiency. The potatoes selected for wafers

should be large oval shape free from

(2) Five year period is required for disease and fully matured. They should

achieving full capacity utilisation. have the minimum number of eyes to

(3) Labour wages are as per the rates cut down the losses by trimming. They

prevailing in the area. are washed thoroughly in water and

(4) Interest on Capital Investment @ peeled manually with stainless steel knife

14% p.a. or by means of an abrasive potato

peeling machine. The peelings are

(5) Payback period: 7 years washed away with sprays of water. They

(6) Land cost Rs. 1500 per sq.m are then trimmed and placed in water

to prevent browning. They are sliced 0.4

IMPLEMENTATION SCHEDULE to 0.5 cm. thick in a slicing machine.

The slices are again placed in cold water

A period of 8 months would be whenever there is considerable delay in

required for start of production from the the subsequent operations of blanching.

date of approval of scheme. The break Then slices are kept in water containing

up of the activities with relative time for 0.05% potassium metabisulphite to avoid

each activity is as follows: oxidation. The slices are blanched for 3

to 5 minutes in boiling water and spread

1. Acquisition of land 1 month on trays at the rate of 4.88 kg. to 7.30

2. Preparation of Project 1 month kg. per square metre of tray surface. The

report and SSI Regi- blanched chips are then subjected to

stration hydro-extracting machine (centrifugal) to

3. Financial assistantce 3 months remove excess of water and fried in

from Institutions edible oil at 180-240C, for 3-4 minutes.

The fried potato wafers are then kept

4. Building construction 36 months on the sieve to remove excess of oil,

5. Power Connection 67 months cooled and other ingredients like salts,

6. Acquisition of 67 months spicy mixture is sprayed as per required

machinery taste. Cooled potato wafers are then

7. Installation of Mach- 77 packed in polythene bags and sealed.

inery months

Banana Wafers

8. Appointment of staff 78 months

and labour Firm bananas are washed, peeled and

sliced. The bananas thus prepared are

9. Trial production and 8-8

then dipped in brine water to avoid

shooting problems months

oxidation. Sometimes turmeric powder

10.Commercial 9th month is also used for colouring the banana

Production onwards chips or to improve colour.

P OTATO/BANANA WAFERS 107

The banana chips are fried in Built up Area Size Area (sq.ft.)

vegetable oil and cooled down to the WC and Bath 10' 5' 50 sq.ft.

room temperature. These wafers are then Total 1650 sq.ft.

packed in polythene bags of suitable Cost of Construction 4,12,500

guaze and sizes to prevent spoilage. @ Rs 250 per sq.ft.

Say 4,13,000

Quality Control and Standards

(iii) Machinery and Equipment

Product must meet PFA Regulations.

Sl. Description Qty. Amount

However, BIS Specifications are as No. (In Rs.)

follows: 1. Potato peeler (body and 1 No. 15,000

IS: 4626:1978 chamber of stainless steel)

cap. per charge 15 kg. taking

IS: 2860:1964 3 to 4 minutes complete

IS: 7254:1974 with motor

2. Power operated slicing 1 No. 20,000

Production Capacity (per annum) machine with arrangements

to adjust the thickness of

Quantity : 60 MT slices with motor

Value : Rs. 39,00,000 3. Hydro extractor to extract- 1 No. 10,000

excess of moisture with motor

Motive Power 20 HP 4. Deep fat fryer (oil tank of 1 No. 22,000

stainless steel, electrically

heated, temp. control switch)

Pollution Control

5. Polythene bag sealing machine1 No. 10,000

The unit will not create any pollution 6. Salting drum 1 No. 10,000

problems. However, entrepreneur Total 87,000

should obtain NOC from concerned

Erection and Electrification @ 10% 9,000

State Pollution Control Board.

Aluminum Table, Plastic Carry 14,000

Containers etc.

Energy Conservation

Total 1,10,000

Suitable measures should be adopted

(iv) Furniture and Fixtures 20,000

to use appropriate amount of Fuel and

Electricity. (v) Pre-operative Expenses Amount

(In Rs.)

FINANCIAL ASPECTS Establishment cost, legal expenses,

consultancy fee, Start up expenses

20,000

interest during construction period,

A. Fixed Capital trial run expenses

i) Land 100 sq.mtr. @ Rs. 1500 1,50,000

vi) Fixed Capital Investment Amount (In Rs.)

(ii) Built up Area Size Area (sq.ft.) 1. Land 1,50,000

Production Hall 30' 20' 600 sq.ft. 2. Building 4,13,000

Stores 20' 20' 400 sq.ft. 3. Machinery and Equipment 1,10,000

Finished goods stores 20' 20' 400 sq.ft. 4. Furniture 20,000

Laboratory 10' 10' 100 sq.ft. 5. Pre-operative expenses 20,000

Office 10' 10' 100 sq.ft. Total 7,13,000

108 P OTATO/BANANA WAFERS

B. Working Capital (per month) v) Working Capital Amount (In Rs.)

1. Raw Material 1,90,000

i) Raw Material

2. Staff and Labour 22,425

Particulars Qty. Rate/ Total

3. Utilities 7,000

MT Tonne (In Rs.)

4. Miscellaneous Expenses 10,000

1. Potatoes/Banana 25 3,000 75,000

Total 2,29,425

2. Ground-nut oil 2.5 40,000 1,00,000

3. Flavours, chemicals LS 5,000 C. Total Capital Investment

spices etc.

Amount

4. Packaging material LS 10,000

(In Rs.)

Total 1,90,000 1. Fixed capital 7,13,000

ii) Staff and Labour 2. Working capital (for 3 months) 6,88,275

Total 14,01,275

Particulars No. Salary Amount

(In Rs.) (In Rs.)

1. Manager 1 6000 6,000

FINANCIAL ANALYSIS

2. Sales supervisor 1 3000 3,000 (1) Cost of Production (per annum) Amount

(In Rs.)

3. Clerk 1 2500 2,500

Recurring Expenses 27,53,100

4. Skilled workers 1 2000 2,000

Depreciation on building @ 5% 21,000

5. Unskilled workers 4 1500 6,000

Depreciation on machinery @ 10% 11,000

Total 19,500 Depreciation on furniture @ 20% 4,000

Perquisites @ 15% 2,925 Interest on total capital 1,96,200

investment @ 14%

Total 22,425

Total 29,85,300

iii) Utilities Amount (In Rs.)

(2) Turnover (per annum) Amount (In Rs.)

1. Water 500

Potato/Banana Wafers 60 M.T. 39,00,000

2. Fuel 4,500

@ Rs. 65 Kg

3. Electricity 2,000

Sales Commission @ 10% 3,90,000

Total 7,000

Total 35,10,000

iv) Other Contingent Expenses Amount

(In Rs.) (3) Profit (per annum)

1. Consumable Stores 1,000 = Turnover Cost of Production

= Rs. 35,10,000 29,85,000

2. Maintenance and Repairs 1,000

= Rs. 5,25,000

3. Transportation and Travelling 4,000

(4) Net Profit Ratio

4. Insurance 500

= Profit 100

5. Other Expenses 1,000 Turnover

6. Advertisement and Publicity 2,500 = 5.25 100

35.10

Total 10,000

= 14.96%

P OTATO/BANANA WAFERS 109

(5) Rate of Return Addresses of Machinery and

= Profit 100 Equipment Suppliers

Total Capital Investment

1. M/s. The Metal Box Co. of India

= 5.25 100 Allahabad Bank Building,

14.01

Connaught Circus,

= 37.47% New Delhi-110001.

2. M/s. Revlon Metal Works

(6) Break-even Point 293, Ballasis Road,

Annual Fixed Cost Total (Rs.

Mumbai-400 008.

in Lakhs) 3. M/s. Dornow Food Technology

40% Salaries 1.08

Karl Bornow and Sohy, Kaiser

Fried, Rich Ring, 96, D-4000

40% Utilities 0.34 Dusseldorf, West Germany.

40% Other Contingencies 0.48 4. M/s. Batliboi and Co. Pvt. Ltd.

Total Depreciation 0.36 P.B. No. 190, 4, Fort,

Mumbai-1.

Total Interest 1.96

5. M/s. Textile Machinery

Total 4.22 Corporation Ltd.

Break-even Point

Boiler Factory,

Royal Exchange Palace,

= Annual Fixed Cost 100

Kolkata.

Annual Fixed Cost + Profit

= 4.22 100 Raw Material Suppliers

4.22 + 5.25

= 422 Local Market.

9.47

= 44.56%

= Say 45%

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Trade Atlas - 20-09-2021 - File ID 8046515442Dokument1.155 SeitenTrade Atlas - 20-09-2021 - File ID 8046515442İbrahim ErenNoch keine Bewertungen

- ScriptDokument32 SeitenScriptJudy Marie BogayNoch keine Bewertungen

- Wine GuideDokument4 SeitenWine GuidepankajkhakareNoch keine Bewertungen

- 7 Day Easy Peasy Paleo Meal PlanDokument16 Seiten7 Day Easy Peasy Paleo Meal PlanRuth. Rochelle.Noch keine Bewertungen

- Shopee FileDokument4 SeitenShopee FilechanNoch keine Bewertungen

- EPONYMSDokument12 SeitenEPONYMSLEA BERSABENoch keine Bewertungen

- I Got Drunk and Then PoetryDokument8 SeitenI Got Drunk and Then PoetryAkina LeeNoch keine Bewertungen

- Water That Is Crafted For You. Crafted by You.: #CraftyourwaterDokument43 SeitenWater That Is Crafted For You. Crafted by You.: #Craftyourwatermaxombga100% (1)

- Cbse Class 1 Evs Sample Paper Term 1 Model 1Dokument2 SeitenCbse Class 1 Evs Sample Paper Term 1 Model 1Sunaina RawatNoch keine Bewertungen

- Unit 1 - TestDokument21 SeitenUnit 1 - Testnguyennato2008Noch keine Bewertungen

- Poram Standard Specifications For Processed Palm Oil PDFDokument2 SeitenPoram Standard Specifications For Processed Palm Oil PDFlaboratory ITSI50% (2)

- This Study Resource Was: Market Segmentation, Targeting and PositioningDokument4 SeitenThis Study Resource Was: Market Segmentation, Targeting and PositioningSwati SahNoch keine Bewertungen

- 1ST Term S1 Agricultural ScienceDokument32 Seiten1ST Term S1 Agricultural SciencePeter Omovigho Dugbo89% (9)

- The State of Food Delivery Apps 2021 Condensed FinalDokument19 SeitenThe State of Food Delivery Apps 2021 Condensed FinalHarry BinosNoch keine Bewertungen

- Recipe - Babka Shuk and CookDokument2 SeitenRecipe - Babka Shuk and CookJesseNoch keine Bewertungen

- Rural Infrastructure 1, NewDokument212 SeitenRural Infrastructure 1, NewSameer MahatoNoch keine Bewertungen

- Guest Satisfaction and Restaurant PerformanceDokument15 SeitenGuest Satisfaction and Restaurant PerformanceJoel CarinoNoch keine Bewertungen

- ĐỀ - HSG 8 - 4Dokument7 SeitenĐỀ - HSG 8 - 4Tiếng Anh 7Noch keine Bewertungen

- 200 Soru 1-5 ArasiDokument116 Seiten200 Soru 1-5 ArasiZeynep Neva BoyrazNoch keine Bewertungen

- Cafeteria Menu-VIC Catering Week 12Dokument1 SeiteCafeteria Menu-VIC Catering Week 12Sameer HajelaNoch keine Bewertungen

- Brgy FiestaDokument3 SeitenBrgy FiestaSGwannaB100% (1)

- ST Valentine Worksheet BeginnerDokument2 SeitenST Valentine Worksheet BeginnerHannaNoch keine Bewertungen

- FT Château Troplong Mondot 2015 ENDokument4 SeitenFT Château Troplong Mondot 2015 ENGrégoire CambodgeNoch keine Bewertungen

- LUX - An HUL BrandDokument22 SeitenLUX - An HUL Brandaditig2275% (4)

- A Vegan Diet in KenyaDokument2 SeitenA Vegan Diet in Kenyalarrylico2017Noch keine Bewertungen

- Presented By: A.Suneel Kumar, Veluru Naveen, Nikhil Joseph Alex, Prabhat JhaDokument15 SeitenPresented By: A.Suneel Kumar, Veluru Naveen, Nikhil Joseph Alex, Prabhat JhaAvolupati Suneel kumarNoch keine Bewertungen

- Chocolate Making Equipment and MachineryDokument7 SeitenChocolate Making Equipment and MachineryalbricoNoch keine Bewertungen

- Trouble in Rethem - v1.0 GerdelDokument36 SeitenTrouble in Rethem - v1.0 GerdelMartin100% (1)

- Agrotoxicos Na America Latina PortuguesDokument109 SeitenAgrotoxicos Na America Latina PortuguesAlfredo Luiz CostaNoch keine Bewertungen

- DLPDokument7 SeitenDLPVINUYA, Kurl JoshuaNoch keine Bewertungen