Beruflich Dokumente

Kultur Dokumente

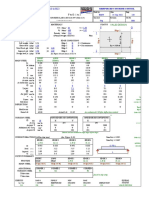

Beam Design As Per AISC - ASD - 9thED - Modified

Hochgeladen von

Arif RusyanaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Beam Design As Per AISC - ASD - 9thED - Modified

Hochgeladen von

Arif RusyanaCopyright:

Verfügbare Formate

VOLUME PAGE

CLIENT SHEET NO

SUBJECT DRAWING NO

REFERENCES COMPUTER CHKD BY DATE

Section Properties W12X26

Analysis Loadout Area, A 7.650 in2 49.4

Load Case No. DKNOR+A4 Depth, d 12.220 in 31.0

Allowable Stress Factor 1.000 Web Thickness,tw 0.230 in 0.6

Fx ( kN ) 0.01 Flange Width, bf 6.490 in 16.48

Fy ( kN ) (MicroSAS Fz) 0.00 Flange thickness,tf 0.380 in 0.965

Fz ( kN ) (MicroSAS Fy) 51.22 2nd Moment Area,Iyy 204.000 in4 8491

Mx ( kN-cm ) 0.00 2nd Moment Area,Izz 17.300 in 4

720

My ( kN-cm ) (MicroSAS Mz) 5266.30 rT 1.720 in 4.4

Mz ( kN-cm ) (MicroSAS My) 0.00 Yield Stress, Fy 345.0 MPa 34.5

Ly ( m ) 4.11

Lz ( m ) 4.11

Ky 1.00

Kz 1.00

Cmy 1.000

Cmz 1.000

E ( kN/cm ) 2

21000.00 Box Plate Properties (2 Nos)

Cb 1.000 Plate thick. (tp) (None=0) 0.00 in 0.0

Plate depth (dp) 0.00 in 0.0

z Wide-Flange Area 0.00 in 2

0.0

2nd Moment Area,Iyy 0.00 in4 0.0

Box Plate 2nd Moment Area,Izz 0.00 in4 0.0

Yield Stress, Fy 0.00 MPa 0.0

y y

Box Plate

NEW SECTION I.R. 0.74

z

Notes : 1. See bottom and next page for detail calculations.

2. Compressive force is negetive

3. For box section, the assumptions are:

a. Allowable stresses are calculated based on Wide-Flange section criteria.

b. Determination of compact or non-compact section is based on Wide-Flange

section criteria.

1. CHECKS AGAINST AISC TABLE B5.1

a. bf / 2tf = 8.54 < 65 / sqrt( Fy ) = 9.19 Note : Fy is in ksi.

< 95 / sqrt( Fy ) = 13.43 Section is Compact

b. fa / Fy = 0.000

d/t = 53.13 < 640 / sqrt ( Fy ) = 90.48

1 of 6 Printed on 11/10/2017 08:18:20 BeamDesignRev.0

VOLUME PAGE

CLIENT SHEET NO

SUBJECT DRAWING NO

REFERENCES COMPUTER CHKD BY DATE

c. h / tw = 49.83 < 760 / sqrt ( Fb ) = 174.94 Member is a beam.

2. ACTUAL STRESSES

Overall Section Properties

Area 7.65 in2 49.4 cm2 ry 13.12 cm

2nd Moment Area,Iyy 204 in4 8491 cm4 rz 3.82 cm

2nd Moment Area,Izz 17 in4 720 cm4

Section Modulus, Syy 33 in3 547 cm3

Section Modulus, Szz 5.33E+00 in3 8.74E+01 cm3

Axial, fa = Fx/A : 0.00 kN/cm2 = 0.002 MPa = 0.00

Shear, fv = Fy/Ay + Fz/Az + Mx.tw/R : 3.01 kN/cm2 = 30.1 MPa = 4.37

Inplane Bending, fby = My/Sy : 9.63 kN/cm2 = 96.3 MPa = 13.96

Outplane Bending, fbz = Mz/Sz : 0.000 kN/cm2 = 0.0 MPa = 0.00

3. ALLOWABLE AXIAL, Fa

Member is in tension, therefore

Fa = 0.60 Fy . . . . AISC D1

20.70 kNscm

4. ALLOWABLE BENDING ( Major Axis), Fby

Lb ( m ) Lc ( m )

4.110 > 1.771 . . . AISC F1-2

Cb = 1.000

Fby = 0.38 Fy . . . AISC F1-5 Note : L / rT = 94.1

13.01 kN/cm 2

L d / Af = 8.0E+02

5. ALLOWABLE BENDING ( Minor Axis), Fbz

Fbz = 0.75 Fy . . . AISC F2-1 for Compact Sections

25.88 kN/cm2

6. ALLOWABLE SHEAR STRESS, Fv

Fv = 0.40 Fy . . . AISC F4-1

13.80 kN/cm 2

7. INTERACTION RATIO

Axial Tension and Bending

fa / Fa = 0.00 <--- Not Applicable

fa / Ft + fby / Fby + fbz / Fbz . . . AISC H2-1

I.R. = 0.000 + 0.740 + 0.000 = 0.740 . . . AISC H2-1

2 of 6 Printed on 11/10/2017 08:18:20 BeamDesignRev.0

VOLUME PAGE

CLIENT SHEET NO

SUBJECT DRAWING NO

REFERENCES COMPUTER CHKD BY DATE

I.R. = 0.218 . . . Based on Shear Stress Only.

3 of 6 Printed on 11/10/2017 08:18:21 BeamDesignRev.0

cm2

cm

cm

cm

cm

cm4

cm4

cm

kN/cm2

cm

cm

cm2

cm4

cm4

kN/cm2

4 of 6 Printed on 11/10/2017 08:18:21 BeamDesignRev.0

Member is a beam.

ksi

ksi

ksi

ksi

5 of 6 Printed on 11/10/2017 08:18:21 BeamDesignRev.0

6 of 6 Printed on 11/10/2017 08:18:21 BeamDesignRev.0

Das könnte Ihnen auch gefallen

- Culvert DesignDokument64 SeitenCulvert DesignJemicah YumenaNoch keine Bewertungen

- Comparison Between Static and Dynamic Analysis of Elevated Water TankDokument10 SeitenComparison Between Static and Dynamic Analysis of Elevated Water TankA RafiNoch keine Bewertungen

- Store Steel Structure Analysis & DesignDokument12 SeitenStore Steel Structure Analysis & DesignAnonymous T7v17KhnwcNoch keine Bewertungen

- View Topic - LOAD COMBINATION - (0.9) Dead Load + (1Dokument11 SeitenView Topic - LOAD COMBINATION - (0.9) Dead Load + (1Bajrang GuptaNoch keine Bewertungen

- 6.5 Design of Precast Protection Slab 6.5.1 Materials: Job: Made by Sheet No. Total Sh. Set No. Date Rev. No. Job NoDokument47 Seiten6.5 Design of Precast Protection Slab 6.5.1 Materials: Job: Made by Sheet No. Total Sh. Set No. Date Rev. No. Job NobalaramNoch keine Bewertungen

- Seismic Forces CalculationDokument112 SeitenSeismic Forces CalculationFAIZAN AHMEDNoch keine Bewertungen

- NMDC Limited, Hyderabad Slurry Pipeline, Iron Ore Beneficiation Plant, Pellet Plant and Water Pipeline ProjectDokument25 SeitenNMDC Limited, Hyderabad Slurry Pipeline, Iron Ore Beneficiation Plant, Pellet Plant and Water Pipeline ProjectAmit SinghNoch keine Bewertungen

- 271XX33 Box Culvert Two CellDokument29 Seiten271XX33 Box Culvert Two CellAjay PolraNoch keine Bewertungen

- Slab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)Dokument12 SeitenSlab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)shiv kumarNoch keine Bewertungen

- WIND LOAD CALCULATION FOR GABLE FRAMESDokument1 SeiteWIND LOAD CALCULATION FOR GABLE FRAMESvk100% (1)

- Structural - Analysis - Skid A4401 PDFDokument94 SeitenStructural - Analysis - Skid A4401 PDFMohammed Saleem Syed Khader100% (1)

- Gpp2 Pe 030 RPT 00002 - r1 B.S. Shelter Design Report CommentsDokument47 SeitenGpp2 Pe 030 RPT 00002 - r1 B.S. Shelter Design Report Commentsisaacjoe77Noch keine Bewertungen

- Shear CheckDokument22 SeitenShear CheckAJAY SHINDENoch keine Bewertungen

- 1.1 Subject Information: Statical Calculation For Masonry Abutment DesignDokument10 Seiten1.1 Subject Information: Statical Calculation For Masonry Abutment DesignabadittadesseNoch keine Bewertungen

- Project Delhi Metro BC17 Wall Panel Flexural Crack Width CalculationDokument10 SeitenProject Delhi Metro BC17 Wall Panel Flexural Crack Width CalculationpsconsultantsNoch keine Bewertungen

- Sleeper - Is456Dokument21 SeitenSleeper - Is456arit bhattacharyaNoch keine Bewertungen

- Steel Design LatestDokument52 SeitenSteel Design LatestAhsan HabibNoch keine Bewertungen

- Purlin DesignDokument10 SeitenPurlin Designitissa INGENIERIANoch keine Bewertungen

- Stiffnesses of Equivalent Springs Along Various Degrees of FreedomDokument9 SeitenStiffnesses of Equivalent Springs Along Various Degrees of FreedomAnjana SureshNoch keine Bewertungen

- Vertical Equation Foundation-Spread Sheet PDFDokument6 SeitenVertical Equation Foundation-Spread Sheet PDFmassive85Noch keine Bewertungen

- Design of AquaductDokument76 SeitenDesign of AquaductGaurav Sharma100% (1)

- Base Plate, Anchor & Foundation (Pipe)Dokument39 SeitenBase Plate, Anchor & Foundation (Pipe)nizardsouissiNoch keine Bewertungen

- Design of Three Span Steel Composite FlyoverDokument85 SeitenDesign of Three Span Steel Composite FlyoverStructural SpreadsheetsNoch keine Bewertungen

- Le160978 C WW SW DC 3220Dokument31 SeitenLe160978 C WW SW DC 3220PK RELHANNoch keine Bewertungen

- Summary of IS 3370 Detailing RequirementsDokument2 SeitenSummary of IS 3370 Detailing RequirementsKanaiyalal N. ShethNoch keine Bewertungen

- Wind Velocity/Pressure Calculation (As Per Api RP 2A 21 Edition)Dokument5 SeitenWind Velocity/Pressure Calculation (As Per Api RP 2A 21 Edition)shadab521Noch keine Bewertungen

- Shear Connection I-SecDokument36 SeitenShear Connection I-SecRaveendra Babu CherukuriNoch keine Bewertungen

- Wing Plate BucklingDokument2 SeitenWing Plate BucklingSai SushankNoch keine Bewertungen

- 70R_TRACKED LOAD DISPERSION CALCULATIONSDokument17 Seiten70R_TRACKED LOAD DISPERSION CALCULATIONSHimal KafleNoch keine Bewertungen

- Design Calculation For Watch Tower - R00 - 20200615Dokument3 SeitenDesign Calculation For Watch Tower - R00 - 20200615Raviraj Thorat100% (1)

- Spliced ColumnsDokument5 SeitenSpliced ColumnsALPHYL BALASABASNoch keine Bewertungen

- 150 VV 1010 Davit CalculationDokument3 Seiten150 VV 1010 Davit Calculationdraj1875977Noch keine Bewertungen

- Design of Self Supporting Steel Chimney For Wind Loads As Per India StandardsDokument41 SeitenDesign of Self Supporting Steel Chimney For Wind Loads As Per India StandardsREVATHY GOPALNoch keine Bewertungen

- Structural Design Summary For 12X20Meter Steel Structure: ClientDokument9 SeitenStructural Design Summary For 12X20Meter Steel Structure: ClientmanojNoch keine Bewertungen

- Substructure Final PDFDokument34 SeitenSubstructure Final PDFSushmit Sharma100% (1)

- Composites Combine Technocrats PVT LTD, J Kumar Infrastructure Pvt. LTDDokument12 SeitenComposites Combine Technocrats PVT LTD, J Kumar Infrastructure Pvt. LTDTitus PraveenNoch keine Bewertungen

- PT Gunanusa Utama Fabricators: Calculation SheetDokument25 SeitenPT Gunanusa Utama Fabricators: Calculation Sheetriandi100% (1)

- RCC Abutment - 67.738 MDokument11 SeitenRCC Abutment - 67.738 MSn SatyanarayanaNoch keine Bewertungen

- Design of Cantilever Slab As Per Is 456 2000Dokument2 SeitenDesign of Cantilever Slab As Per Is 456 2000dhanasekaran33% (3)

- Laterally Loaded Pile - Sand, Depth of Fixity As Per IS Code For Bored Cast in Situ PilesDokument3 SeitenLaterally Loaded Pile - Sand, Depth of Fixity As Per IS Code For Bored Cast in Situ PilesKanaiyalal N. ShethNoch keine Bewertungen

- 200 THK Grade Slab-50kn Variable Load-With FibreDokument7 Seiten200 THK Grade Slab-50kn Variable Load-With FibreFazilat Mohammad Zaidi0% (1)

- Braking Test: Vehicle Laboratory 2Dokument20 SeitenBraking Test: Vehicle Laboratory 2Steven SullivanNoch keine Bewertungen

- Column Base Plate (Fixed Type)Dokument13 SeitenColumn Base Plate (Fixed Type)KM YapNoch keine Bewertungen

- Report and DesignDokument53 SeitenReport and Designkiran raghukiranNoch keine Bewertungen

- 2 Cell Box CulvertDokument22 Seiten2 Cell Box Culvertabhijeet sahuNoch keine Bewertungen

- Capacities of UB SectionsDokument48 SeitenCapacities of UB SectionsRohan KarandeNoch keine Bewertungen

- Connection design shear and tension capacityDokument1 SeiteConnection design shear and tension capacitySuman NakarmiNoch keine Bewertungen

- 3 Analysis and Design of Deck SlabDokument14 Seiten3 Analysis and Design of Deck SlabAshish BhoiNoch keine Bewertungen

- HSS Flange Plate Moment Connection - Temporary SteelDokument9 SeitenHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNoch keine Bewertungen

- GratingDokument2 SeitenGratingAnand3101Noch keine Bewertungen

- Stability CheckDokument2 SeitenStability ChecksaravananNoch keine Bewertungen

- Vibration analysis of tall towers as per standardsDokument6 SeitenVibration analysis of tall towers as per standardsvamsiNoch keine Bewertungen

- Base Plate DesignDokument19 SeitenBase Plate DesignLeah Ann ManuelNoch keine Bewertungen

- Design of Box CulvertDokument21 SeitenDesign of Box CulvertAnirbanBhattacharjeeNoch keine Bewertungen

- Gantry Girder DesignDokument6 SeitenGantry Girder DesignpandianNoch keine Bewertungen

- Welded & Pinned Connection Design CalculationDokument14 SeitenWelded & Pinned Connection Design CalculationPrakash Singh RawalNoch keine Bewertungen

- Inco-Engg. Calculation Sheet: Prepared By: DateDokument1 SeiteInco-Engg. Calculation Sheet: Prepared By: DateRama PrasadNoch keine Bewertungen

- RCC95 Continuous Beams (Tables)Dokument8 SeitenRCC95 Continuous Beams (Tables)Felicia GhicaNoch keine Bewertungen

- RCC95 Continuous Beams (Tables)Dokument9 SeitenRCC95 Continuous Beams (Tables)Murthy GunaNoch keine Bewertungen

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Dokument5 SeitenF To G: 1 To 2: Spreadsheets To BS 8110 & EC298675Noch keine Bewertungen

- Quick Snap Guide To LightingDokument217 SeitenQuick Snap Guide To LightingArif RusyanaNoch keine Bewertungen

- Dica 1005Dokument54 SeitenDica 1005api-3856359Noch keine Bewertungen

- PT REKAYASA Cathodic Protection System Material ListDokument1 SeitePT REKAYASA Cathodic Protection System Material ListArif RusyanaNoch keine Bewertungen

- Hydroelectric Power Plant Electrical DesignDokument118 SeitenHydroelectric Power Plant Electrical DesignKyaw Thu100% (3)

- Deepwater Riser Solutions for Harsh EnvironmentsDokument3 SeitenDeepwater Riser Solutions for Harsh EnvironmentsArif RusyanaNoch keine Bewertungen

- Progress Table - Steel ErectionDokument2 SeitenProgress Table - Steel ErectionArif RusyanaNoch keine Bewertungen

- Cathodic Calculation (SACP)Dokument9 SeitenCathodic Calculation (SACP)Arif RusyanaNoch keine Bewertungen

- Beam Design Chapter 9 BDokument19 SeitenBeam Design Chapter 9 BjdfdfererNoch keine Bewertungen

- Spreadsheets To BS 8110: Flight 5Dokument1 SeiteSpreadsheets To BS 8110: Flight 5Arif RusyanaNoch keine Bewertungen

- ICCP Design Calculation and Material List for 15m Deep FW PipelineDokument11 SeitenICCP Design Calculation and Material List for 15m Deep FW PipelineArif RusyanaNoch keine Bewertungen

- 60.1507.01 Ionizing RadiationDokument97 Seiten60.1507.01 Ionizing RadiationArif Rusyana100% (1)

- Bracing For StabilityDokument74 SeitenBracing For Stabilityaravindtank100% (2)

- Digital Photography CourseDokument17 SeitenDigital Photography Coursesrii47Noch keine Bewertungen

- Pipeline Design and ConstructionDokument86 SeitenPipeline Design and ConstructionArnela Hodzic100% (1)

- Material SS 304LDokument2 SeitenMaterial SS 304LAhSangCheeSangNoch keine Bewertungen

- (Ebooks) 80 Things You Never Knew About PhotoshopDokument10 Seiten(Ebooks) 80 Things You Never Knew About Photoshoprose166Noch keine Bewertungen

- 03 Waves, Design Condition and BreakersDokument16 Seiten03 Waves, Design Condition and BreakersArif RusyanaNoch keine Bewertungen

- Close Up Photography PDFDokument6 SeitenClose Up Photography PDFFlorin IacobNoch keine Bewertungen

- Mepc 139 PDFDokument18 SeitenMepc 139 PDFArif RusyanaNoch keine Bewertungen

- Berkeley CatamaranDokument88 SeitenBerkeley CatamaranHabib MukminNoch keine Bewertungen

- Dulux Epoxy Holding Primer Two Pack - R580-2058Dokument3 SeitenDulux Epoxy Holding Primer Two Pack - R580-2058Arif RusyanaNoch keine Bewertungen

- Strut & Tie ModelDokument67 SeitenStrut & Tie Modelahmed adel100% (9)

- Concrete Block Sizes & ShapesDokument12 SeitenConcrete Block Sizes & Shapesecruz_yhwhNoch keine Bewertungen

- Section Modulus - of BeamDokument15 SeitenSection Modulus - of BeamArif RusyanaNoch keine Bewertungen

- Galvanite: Technical Data SheetDokument4 SeitenGalvanite: Technical Data SheetBiju_PottayilNoch keine Bewertungen

- Progress Steel StructureDokument4 SeitenProgress Steel StructureArif RusyanaNoch keine Bewertungen

- Steel Pipe: Electric Resistance Welded (ERW) Pipe Product SpecificationsDokument7 SeitenSteel Pipe: Electric Resistance Welded (ERW) Pipe Product SpecificationsRantau FarmNoch keine Bewertungen

- Standard Berat BajaDokument2 SeitenStandard Berat BajaPaul PerkinNoch keine Bewertungen

- Hilti Fastening Chemical PDFDokument101 SeitenHilti Fastening Chemical PDFNovancyNoch keine Bewertungen

- Jacket Denting Calculation Rev.0Dokument87 SeitenJacket Denting Calculation Rev.0Arif RusyanaNoch keine Bewertungen

- Taherizadeh, AboozarDokument12 SeitenTaherizadeh, AboozarRajmandir SidhuNoch keine Bewertungen

- No17c-Bundle-H250x250-R13-BS EP-4InteriorColumn-B2 6, C2 6-Rev3Dokument50 SeitenNo17c-Bundle-H250x250-R13-BS EP-4InteriorColumn-B2 6, C2 6-Rev3Nguyễn Duy QuangNoch keine Bewertungen

- Analysis of Tensile Test of Mild Steel Using Finite Element MethodDokument5 SeitenAnalysis of Tensile Test of Mild Steel Using Finite Element MethodLaxmanNoch keine Bewertungen

- Mechanics of Micro Electromechanical Systems (MEMS) : (A Brief Overview.)Dokument53 SeitenMechanics of Micro Electromechanical Systems (MEMS) : (A Brief Overview.)Pulkit ChaudhariNoch keine Bewertungen

- CH 17 Slides 10th Ed SI Cabos de AçoDokument26 SeitenCH 17 Slides 10th Ed SI Cabos de AçoAlexandre LaraNoch keine Bewertungen

- Summary FSWDokument26 SeitenSummary FSWhazelmyaNoch keine Bewertungen

- DifferentialEquations 02 Strain Disp Eqns 2Dokument8 SeitenDifferentialEquations 02 Strain Disp Eqns 2lipun12ka4Noch keine Bewertungen

- SLRB Design of 7.45m Clear Span For IRC Class A LoadingDokument15 SeitenSLRB Design of 7.45m Clear Span For IRC Class A Loadingpaaji100% (9)

- Introduction To Concrete Technology: April 2015Dokument5 SeitenIntroduction To Concrete Technology: April 2015Jemal IbrahimNoch keine Bewertungen

- Experimental Investigation of Using Papercrete and Recycled Aggregate As A Coarse AggregateDokument10 SeitenExperimental Investigation of Using Papercrete and Recycled Aggregate As A Coarse AggregateInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Experimental Investigation and Nonlinear FE Analysis of Historical Masonry Buildings - A Case StudyDokument38 SeitenExperimental Investigation and Nonlinear FE Analysis of Historical Masonry Buildings - A Case StudyRuben OñateNoch keine Bewertungen

- Dispersion and Alignment of Carbon Nanotubes in Polymer Matrix A ReviewDokument24 SeitenDispersion and Alignment of Carbon Nanotubes in Polymer Matrix A ReviewYovaraj Karunakaran0% (1)

- Rubber: ASTM D412 Tensile Properties of Vulcanized Rubber and Thermoplastic ElastomersDokument2 SeitenRubber: ASTM D412 Tensile Properties of Vulcanized Rubber and Thermoplastic ElastomersPrabhakar KambleNoch keine Bewertungen

- Ae1402 Composite Materials and StructuresDokument23 SeitenAe1402 Composite Materials and Structuresrakhi_chenNoch keine Bewertungen

- Laws of ThermodynamicsDokument54 SeitenLaws of ThermodynamicsElakkiya KarthicNoch keine Bewertungen

- Rock AnchorDokument2 SeitenRock AnchorVijay Kumar100% (1)

- Creep and High Temperature Failure: OutlineDokument6 SeitenCreep and High Temperature Failure: OutlineAravind PhoenixNoch keine Bewertungen

- AR6010 Unit 1Dokument15 SeitenAR6010 Unit 1vgdarchNoch keine Bewertungen

- Stresses and Strains in Composite BarsDokument17 SeitenStresses and Strains in Composite BarsSuresh Khangembam100% (1)

- Assessment of Crack-Like Flaws Example ProblemsDokument35 SeitenAssessment of Crack-Like Flaws Example ProblemsHernán Daza100% (1)

- Module 4Dokument37 SeitenModule 4imbrannNoch keine Bewertungen

- Micromachining Gorilla GlassDokument3 SeitenMicromachining Gorilla GlassFarin MahzabeenNoch keine Bewertungen

- Makrolon 6487 Stress-Strain Data and CurveDokument3 SeitenMakrolon 6487 Stress-Strain Data and Curvekrishnakant gargNoch keine Bewertungen

- L&T Construction, Chennai G-O20002: Subarnarekha - Main Bridge SubstrcutureDokument7 SeitenL&T Construction, Chennai G-O20002: Subarnarekha - Main Bridge SubstrcutureGopu RNoch keine Bewertungen

- Mechanical Engineering-Machine Design MCQDokument22 SeitenMechanical Engineering-Machine Design MCQKarthick Pec MechNoch keine Bewertungen

- Alloys: FerrousDokument8 SeitenAlloys: FerroussunsirNoch keine Bewertungen

- 1994 - Second-Order Generalised Beam TheoryDokument21 Seiten1994 - Second-Order Generalised Beam TheoryJosue LewandowskiNoch keine Bewertungen

- Fundamentals of Casting ProcessesDokument33 SeitenFundamentals of Casting ProcessesIhsan Naufal RidhwanNoch keine Bewertungen

- Work Hardening TheoryDokument8 SeitenWork Hardening TheorycrisNoch keine Bewertungen