Beruflich Dokumente

Kultur Dokumente

440 KG Cement Content

Hochgeladen von

Isaiahogeda0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

140 Ansichten1 SeiteConcrete Mix Data

Originaltitel

440 Kg Cement Content

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenConcrete Mix Data

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

140 Ansichten1 Seite440 KG Cement Content

Hochgeladen von

IsaiahogedaConcrete Mix Data

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

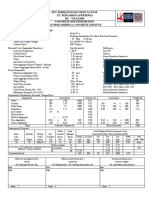

Civicon LTD CONCRETE MIX DESIGN Doc.

CIV-T-QAC-00144

Project Code CON070-01 C32/40 Concrete

REHABILITATION OF G-SECTION Date 14-03-2017

KPA G-SECTION MATERIALS LAB Max Aggregates 20mm

Class 32/40 MPa Cement Type CEM I 42.5 N

Charact. Strength 1.3 (28d) 52 MPa Source of Course Aggregates Mwache / Jaribuni

Max. Nominal Agg. Size 20 mm Source of fine aggregates Malindi

Max. Cement Content 480 Kg/m3 Admixture Type X-Mix WRA

Min. Cement Content 400 Kg/m3 Maximum w/c 0.5

Target Slump 10030 mm Use in the works Batching plant trial mix

CALCULATION

Cement (Kg/m3) 440 Av. Spec. Grav. of Agg. (g/cm3) 2.686

w/c 0.5 Total Aggregates (Kg) 1705

Free water (L) 220 Theor. Density of Mix (g/cm3) 2.388

Air (%) 1.1 Aggregate Cement Ratio 3.875

Admixture (%) 1.6 Specific Gravity of cement (g/cm3) 3.06

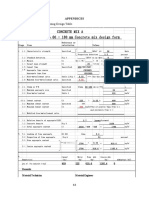

AGGREGATE PROPORTION BY WEIGHT FOR 1m3 OF CONCRETE (BS 882:1992)

Sieve 20 10 6 Mix Specification

50

37.5 100 100

25 100 100

20 94.1 97.9 95 100

14 41.6 100 81.5

10 1.1 91.1 74.4

5 12.3 100 51.9 35 55

2.0 1.0 97.5 41.7

0.6 66.7 27.4 10 35

0.3 17.4 8.9

0.15 3.1 1.1 0 8

Size (mm) % Sp. Grav. Kg Abs.

Micro Fibres 0.29 0.91 5 0.0

20 34.5 2.706 590 0.7

10 17.3 2.666 295 1.0

River Sand 48 2.619 820 0.6

CONCRETE PROPORTIONS FOR 1m3 OF CONCRETE

Micro Fibres 20mm 10mm River Sand Cement Water Admixture

kg kg kg kg kg L L

5 590 295 820 440 213 7.04

Slump At

Water Used 15 45 Conc. Temp C Date of Batching

Actual w/c 30 60 Air Temp. C Time of Batching

CONCRETE PROPORTIONS PER TRIAL MIX

Micro Fibres 20mm 10mm River Sand Cement Water Admixture

kg kg kg kg kg L L

0.14 15.93 7.97 22.14 11.88 5.75 0.19

Das könnte Ihnen auch gefallen

- C40 Concrete Mix DesignDokument2 SeitenC40 Concrete Mix DesignIsaiahogeda50% (2)

- Concrete Mix Design: Structural Element VARIOUSDokument28 SeitenConcrete Mix Design: Structural Element VARIOUSAlfred PatrickNoch keine Bewertungen

- Mix Design FormatDokument18 SeitenMix Design FormatChandan MondalNoch keine Bewertungen

- Mix Design by Imtisal Ahmad: Required DataDokument5 SeitenMix Design by Imtisal Ahmad: Required DataAbdullahNoch keine Bewertungen

- Concrete Mix Design: Lab. Trial No. 4 Date: 21/6/2013 Concrete Class 2000 PsiDokument2 SeitenConcrete Mix Design: Lab. Trial No. 4 Date: 21/6/2013 Concrete Class 2000 PsiazharNoch keine Bewertungen

- Test Report: M/S Abhi Engg Corporation PVT LTDDokument61 SeitenTest Report: M/S Abhi Engg Corporation PVT LTDimran khanNoch keine Bewertungen

- Test Report: M/S Abhi Engg Corporation PVT LTDDokument6 SeitenTest Report: M/S Abhi Engg Corporation PVT LTDImran Khan100% (1)

- Concrete Mix Design: Lab. Trial No.7 #2 R Date: 6/7/2013 Concrete Class 4500 PsiDokument2 SeitenConcrete Mix Design: Lab. Trial No.7 #2 R Date: 6/7/2013 Concrete Class 4500 PsiazharNoch keine Bewertungen

- M 30 Concrete Mix Design FinalDokument10 SeitenM 30 Concrete Mix Design FinalRakesh ReddyNoch keine Bewertungen

- Moisture CorrectionDokument34 SeitenMoisture CorrectionShitanshu SinghNoch keine Bewertungen

- M10 PDFDokument3 SeitenM10 PDFranjeet Chikane50% (2)

- M20 Mix DesignDokument1 SeiteM20 Mix DesignSaurav MukherjeeNoch keine Bewertungen

- Circ05 - 2007 Ready Mix ConcreteDokument27 SeitenCirc05 - 2007 Ready Mix ConcreteHaftom TekluNoch keine Bewertungen

- Concrete MixDokument69 SeitenConcrete MixRATNA SINGHNoch keine Bewertungen

- Epc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteDokument4 SeitenEpc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteBengkulu BetonNoch keine Bewertungen

- Plumb Conc.Dokument28 SeitenPlumb Conc.Muhammad AwaisNoch keine Bewertungen

- Mix Design Specification Requirements (A) Class of Concrete C-30Dokument5 SeitenMix Design Specification Requirements (A) Class of Concrete C-30Atm Tjah Radix LoegoeNoch keine Bewertungen

- M25Easycrete, Trial SheetDokument1 SeiteM25Easycrete, Trial Sheetabir senguptaNoch keine Bewertungen

- Recommended Sheet: Authorised Signatory Pg. No. 1 of 5Dokument5 SeitenRecommended Sheet: Authorised Signatory Pg. No. 1 of 5KA25 ConsultantNoch keine Bewertungen

- Concrete MixesDokument4 SeitenConcrete MixesAnonymous 5VwQ0KC3Noch keine Bewertungen

- Concrete Design MixDokument15 SeitenConcrete Design MixM HAFEEZ RAJANoch keine Bewertungen

- Adjustment of Concrete Mix Proportion For Batching Plant: Posco E&CDokument1 SeiteAdjustment of Concrete Mix Proportion For Batching Plant: Posco E&CHasan al MahmudNoch keine Bewertungen

- M45Dokument6 SeitenM45Prakash HitechNoch keine Bewertungen

- Pe Mixed SDN BHD: G.MohanadassDokument1 SeitePe Mixed SDN BHD: G.MohanadassAmi ShafiNoch keine Bewertungen

- Summary of Mix Design Material Description Grade of Concrete M25 RCC M 35 Pile M15 PCC M20 RCC M30 RCC M35 RCC M40 RCC M45 RCC M50 RCCDokument3 SeitenSummary of Mix Design Material Description Grade of Concrete M25 RCC M 35 Pile M15 PCC M20 RCC M30 RCC M35 RCC M40 RCC M45 RCC M50 RCCmeerut nazibabad projectNoch keine Bewertungen

- Mix Design 6000 PsiDokument2 SeitenMix Design 6000 PsiraheelNoch keine Bewertungen

- S/No. Item A/U Qty Density WT of Mix in MT WT of Bitumen in MT WT of Agg in MTDokument5 SeitenS/No. Item A/U Qty Density WT of Mix in MT WT of Bitumen in MT WT of Agg in MTM.E. TECHNOLOGYNoch keine Bewertungen

- 2.1 Tests On Cement: Sr. No. Properties ResultsDokument3 Seiten2.1 Tests On Cement: Sr. No. Properties ResultsBIPL REPORTNoch keine Bewertungen

- Design of Concrete Mix of M30 Grade: Report Prepared ForDokument5 SeitenDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathNoch keine Bewertungen

- Lab. Trial Report: ProjectDokument1 SeiteLab. Trial Report: Projectmahesh naikNoch keine Bewertungen

- Diarab RoadDokument6 SeitenDiarab RoadHishmat EzzelarabNoch keine Bewertungen

- Keya 3.6.2019Dokument15 SeitenKeya 3.6.2019HarDik PatelNoch keine Bewertungen

- Is Mix Design Based On Is 10262 2009Dokument17 SeitenIs Mix Design Based On Is 10262 2009santhu256Noch keine Bewertungen

- Concrete Mix Design: Stage Item Reference or Values CalculationDokument8 SeitenConcrete Mix Design: Stage Item Reference or Values Calculationmanish100% (1)

- M-15 PCCDokument38 SeitenM-15 PCCRaj PandeyNoch keine Bewertungen

- C3037 XC1Dokument1 SeiteC3037 XC1Anka AksoyNoch keine Bewertungen

- LAB REFF 009R1 WG - SKY HOUSE PHASE 2 UPPER INT - Signed PDFDokument1 SeiteLAB REFF 009R1 WG - SKY HOUSE PHASE 2 UPPER INT - Signed PDFShinku No YoruNoch keine Bewertungen

- Mix Design As Per Is 10262-2019 Civil GurujiDokument11 SeitenMix Design As Per Is 10262-2019 Civil GurujiKazi HaqNoch keine Bewertungen

- Concrete Mix Design PDFDokument11 SeitenConcrete Mix Design PDFLERIS PENOTELNoch keine Bewertungen

- M-25 Mix DesignDokument1 SeiteM-25 Mix DesignRøshän Kumar PatelNoch keine Bewertungen

- Mix Design of Cement GroutDokument4 SeitenMix Design of Cement GroutjitendraNoch keine Bewertungen

- Concrete Mixing DesignDokument15 SeitenConcrete Mixing DesignChris ArtecoNoch keine Bewertungen

- Concrete Mix DesignDokument24 SeitenConcrete Mix Designvishnumani3011Noch keine Bewertungen

- Project On Partial Replacement of Cement With Marble PowderDokument8 SeitenProject On Partial Replacement of Cement With Marble PowderYu Paing HanNoch keine Bewertungen

- M25 Mix Design 100 Recycled AggregateDokument9 SeitenM25 Mix Design 100 Recycled AggregateRakesh ReddyNoch keine Bewertungen

- Lcet Lcet: ED How To Calculate Cement, Sand and Coarse Aggregate Quantity in Concrete? EDDokument4 SeitenLcet Lcet: ED How To Calculate Cement, Sand and Coarse Aggregate Quantity in Concrete? EDmanojNoch keine Bewertungen

- Tm-22 m35 RCCDokument19 SeitenTm-22 m35 RCCVeera ManiNoch keine Bewertungen

- M25 (PPC)Dokument2 SeitenM25 (PPC)Jagdev Guleria100% (1)

- M-35 Mix DesignDokument1 SeiteM-35 Mix DesignRøshän Kumar PatelNoch keine Bewertungen

- M25 (PPC)Dokument2 SeitenM25 (PPC)Jagdev GuleriaNoch keine Bewertungen

- M30Easycrete, Trial SheetDokument1 SeiteM30Easycrete, Trial Sheetabir senguptaNoch keine Bewertungen

- Daily MCBC Mar 2024Dokument1 SeiteDaily MCBC Mar 2024Shoubhik MukherjeeNoch keine Bewertungen

- Self-Compacting Concrete (SCC)Dokument17 SeitenSelf-Compacting Concrete (SCC)Ritika BansalNoch keine Bewertungen

- Mix Design Calculation M50Grade: For Nirvana SiteDokument1 SeiteMix Design Calculation M50Grade: For Nirvana SiteAnkur DalalNoch keine Bewertungen

- Self Compacting Concrete SCCDokument17 SeitenSelf Compacting Concrete SCC8790922772100% (1)

- m25 Mix DesignDokument7 Seitenm25 Mix Design98675Noch keine Bewertungen

- Mix Design (Aci - Method)Dokument14 SeitenMix Design (Aci - Method)Bengkulu BetonNoch keine Bewertungen

- Concrete Mix Design As Per IS Code - 10262: 2019Dokument11 SeitenConcrete Mix Design As Per IS Code - 10262: 2019Ravikant YadavNoch keine Bewertungen

- Concret Mix Design: Quality Conrol LaboratoryDokument17 SeitenConcret Mix Design: Quality Conrol LaboratoryRabnawaz ImamNoch keine Bewertungen

- Did Muhammad Exist?: New Book Reveals Stunning Truth About Origins of IslamDokument2 SeitenDid Muhammad Exist?: New Book Reveals Stunning Truth About Origins of IslamIsaiahogedaNoch keine Bewertungen

- BA 15 SketchDokument1 SeiteBA 15 SketchIsaiahogedaNoch keine Bewertungen

- Invitation To TenderDokument12 SeitenInvitation To TenderIsaiahogedaNoch keine Bewertungen

- DelayDokument1 SeiteDelayIsaiahogedaNoch keine Bewertungen

- BR C Shape Code ChartDokument1 SeiteBR C Shape Code ChartAjay NarraNoch keine Bewertungen

- Rainfall Data 2018Dokument12 SeitenRainfall Data 2018IsaiahogedaNoch keine Bewertungen

- Method For Calculating Schedule Delay Considering Weather ConditionsDokument10 SeitenMethod For Calculating Schedule Delay Considering Weather ConditionsAnonymous p2cFoXbjDNoch keine Bewertungen

- Talking of Bidco, We Mean Any Bidco Product Like Premium OilsDokument1 SeiteTalking of Bidco, We Mean Any Bidco Product Like Premium OilsIsaiahogedaNoch keine Bewertungen

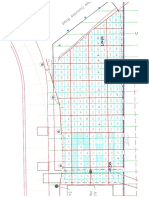

- Con070 01 R02 304 0150Dokument1 SeiteCon070 01 R02 304 0150IsaiahogedaNoch keine Bewertungen

- Analysis of Cube Crushing StrengthDokument1 SeiteAnalysis of Cube Crushing StrengthIsaiahogedaNoch keine Bewertungen

- Code CJM BC q02 Mulji C25rev00Dokument3 SeitenCode CJM BC q02 Mulji C25rev00IsaiahogedaNoch keine Bewertungen

- T 099-90 Moisture Density Relations of SoilsDokument5 SeitenT 099-90 Moisture Density Relations of SoilsIsaiahogedaNoch keine Bewertungen

- Cal Cert For Cube Crusher and Weighing BalanceDokument4 SeitenCal Cert For Cube Crusher and Weighing BalanceIsaiahogedaNoch keine Bewertungen

- CBR MachineDokument2 SeitenCBR MachineIsaiahogedaNoch keine Bewertungen

- 1.1.5 Skip Blanks in Excel - EASY Excel TutorialDokument2 Seiten1.1.5 Skip Blanks in Excel - EASY Excel TutorialIsaiahogedaNoch keine Bewertungen

- 11/1/2017 M05 H-Young Simba Sikaplast M06 H-Young Simba Viscocrete M07 Goldstone Simba SikaplastDokument2 Seiten11/1/2017 M05 H-Young Simba Sikaplast M06 H-Young Simba Viscocrete M07 Goldstone Simba SikaplastIsaiahogedaNoch keine Bewertungen

- Laboratory Tests ResultsDokument14 SeitenLaboratory Tests ResultsIsaiahogedaNoch keine Bewertungen

- Cube BookDokument14 SeitenCube BookIsaiahogedaNoch keine Bewertungen

- 1.1.6 Transpose Data in Excel - EASY Excel TutorialDokument3 Seiten1.1.6 Transpose Data in Excel - EASY Excel TutorialIsaiahogedaNoch keine Bewertungen

- 1.1.1 Fibonacci Sequence in Excel - EASY Excel TutorialDokument2 Seiten1.1.1 Fibonacci Sequence in Excel - EASY Excel TutorialIsaiahogedaNoch keine Bewertungen

- 1.1.3 Comments in Excel - EASY Excel TutorialDokument4 Seiten1.1.3 Comments in Excel - EASY Excel TutorialIsaiahogedaNoch keine Bewertungen

- 1.1.2 Custom Lists in Excel - EASY Excel TutorialDokument3 Seiten1.1.2 Custom Lists in Excel - EASY Excel TutorialIsaiahogedaNoch keine Bewertungen

- #1 Excel Tutorial On The Net - Excel EasyDokument5 Seiten#1 Excel Tutorial On The Net - Excel EasyIsaiahogedaNoch keine Bewertungen

- Plan Profile FG at 10 M-Oct Rev (1) Plan (1) - 2Dokument1 SeitePlan Profile FG at 10 M-Oct Rev (1) Plan (1) - 2IsaiahogedaNoch keine Bewertungen

- 1.1 Range in Excel - EASY Excel TutorialDokument5 Seiten1.1 Range in Excel - EASY Excel TutorialIsaiahogedaNoch keine Bewertungen

- Collins Reinforcements LTD: ProjectDokument2 SeitenCollins Reinforcements LTD: ProjectIsaiahogedaNoch keine Bewertungen

- Plan Profile FG at 10 M-Oct Rev (1) Plan (1) - 3 PDFDokument1 SeitePlan Profile FG at 10 M-Oct Rev (1) Plan (1) - 3 PDFIsaiahogedaNoch keine Bewertungen

- Good ChalmersDokument128 SeitenGood Chalmersec02160Noch keine Bewertungen

- Unit 6B - PassiveDokument18 SeitenUnit 6B - PassiveDavid EstrellaNoch keine Bewertungen

- Evolution of Management AccountingDokument35 SeitenEvolution of Management AccountingNuqiah Fathiah Seri100% (1)

- ACTIVITY Design - Nutrition MonthDokument7 SeitenACTIVITY Design - Nutrition MonthMaria Danica89% (9)

- Using MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsDokument8 SeitenUsing MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsJancarlo Mendoza MartínezNoch keine Bewertungen

- Demand, Supply, and Market EquilibriumDokument15 SeitenDemand, Supply, and Market EquilibriumAnonymous HBQ86kNoch keine Bewertungen

- SOLVING THE STEADY STATE SOLVER AND UNSTEADY or TRANSIENT SOLVER 2D HEAT CONDUCTION PROBLEM BY USINGDokument3 SeitenSOLVING THE STEADY STATE SOLVER AND UNSTEADY or TRANSIENT SOLVER 2D HEAT CONDUCTION PROBLEM BY USINGGodwin LarryNoch keine Bewertungen

- ASHRAE Final Operating Room 508 PDFDokument13 SeitenASHRAE Final Operating Room 508 PDFSilisteanu AndreiNoch keine Bewertungen

- Manual de Utilizare HUMAX DIGI TV RDSDokument116 SeitenManual de Utilizare HUMAX DIGI TV RDSenamicul50Noch keine Bewertungen

- PTE Writing FormatDokument8 SeitenPTE Writing FormatpelizNoch keine Bewertungen

- Interceptor Specifications FinalDokument7 SeitenInterceptor Specifications FinalAchint VermaNoch keine Bewertungen

- Astm C119-16Dokument8 SeitenAstm C119-16Manuel Antonio Santos Vargas100% (2)

- Management of StutteringDokument182 SeitenManagement of Stutteringpappu713100% (2)

- Gender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected PlaysDokument6 SeitenGender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected Playsতন্ময়Noch keine Bewertungen

- Higher Vapor Pressure Lower Vapor PressureDokument10 SeitenHigher Vapor Pressure Lower Vapor PressureCatalina PerryNoch keine Bewertungen

- Jurnal Direct and Indirect Pulp CappingDokument9 SeitenJurnal Direct and Indirect Pulp Cappingninis anisaNoch keine Bewertungen

- Alan Freeman - Ernest - Mandels - Contribution - To - Economic PDFDokument34 SeitenAlan Freeman - Ernest - Mandels - Contribution - To - Economic PDFhajimenozakiNoch keine Bewertungen

- SchedulingDokument47 SeitenSchedulingKonark PatelNoch keine Bewertungen

- FBISE Grade 10 Biology Worksheet#1Dokument2 SeitenFBISE Grade 10 Biology Worksheet#1Moaz AhmedNoch keine Bewertungen

- Supreme Court Case Analysis-Team ProjectDokument5 SeitenSupreme Court Case Analysis-Team ProjectJasmineA.RomeroNoch keine Bewertungen

- Research in International Business and Finance: Huizheng Liu, Zhe Zong, Kate Hynes, Karolien de Bruyne TDokument13 SeitenResearch in International Business and Finance: Huizheng Liu, Zhe Zong, Kate Hynes, Karolien de Bruyne TDessy ParamitaNoch keine Bewertungen

- Millennium Development GoalsDokument6 SeitenMillennium Development GoalsSasha Perera100% (2)

- 7 Ways To Support Your Babys Learning Today Monti KidsDokument19 Seiten7 Ways To Support Your Babys Learning Today Monti KidsMareim A HachiNoch keine Bewertungen

- MJDF Mcqs - Mixed - PDFDokument19 SeitenMJDF Mcqs - Mixed - PDFAyesha Awan0% (3)

- GSP AllDokument8 SeitenGSP AllAleksandar DjordjevicNoch keine Bewertungen

- Aits 2122 PT I Jeea 2022 TD Paper 2 SolDokument14 SeitenAits 2122 PT I Jeea 2022 TD Paper 2 SolSoumodeep NayakNoch keine Bewertungen

- Week 1-2 Module 1 Chapter 1 Action RseearchDokument18 SeitenWeek 1-2 Module 1 Chapter 1 Action RseearchJustine Kyle BasilanNoch keine Bewertungen

- BQ - Structural Works - CompressedDokument163 SeitenBQ - Structural Works - CompressedLee YuxuanNoch keine Bewertungen

- NHD Process PaperDokument2 SeitenNHD Process Paperapi-122116050Noch keine Bewertungen

- CMS156Dokument64 SeitenCMS156Andres RaymondNoch keine Bewertungen

- By Vaibhav Pandya S R.information Security Consultant M.Tech Solutions (India) PVT - LTDDokument22 SeitenBy Vaibhav Pandya S R.information Security Consultant M.Tech Solutions (India) PVT - LTDtsegay.csNoch keine Bewertungen