Beruflich Dokumente

Kultur Dokumente

Starting & Charging System Guide

Hochgeladen von

Aldo ApazzaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Starting & Charging System Guide

Hochgeladen von

Aldo ApazzaCopyright:

Verfügbare Formate

K ELECTRICAL

B

SECTION

STARTING & CHARGING SYSTEM C

E

CONTENTS

PRECAUTIONS .......................................................... 2 DIAGNOSTIC PROCEDURE 2 ........................... 17 F

Precautions for Supplemental Restraint System MINIMUM SPECIFICATION OF CRANKING

(SRS) AIR BAG and SEAT BELT PRE-TEN- VOLTAGE REFERENCING COOLANT TEM-

SIONER .................................................................. 2 PERATURE ......................................................... 18 G

Wiring Diagrams and Trouble Diagnosis .................. 2 Construction ........................................................... 18

PREPARATION ........................................................... 3 Removal and Installation ........................................ 20

Special Service Tool ................................................. 3 QG18DE .............................................................. 20

H

BATTERY .................................................................... 4 QR25DE .............................................................. 21

How to Handle Battery ............................................. 4 Pinion/Clutch Check ............................................... 21

METHODS OF PREVENTING OVER-DIS- CHARGING SYSTEM ............................................... 22

CHARGE ............................................................... 4 System Description ................................................. 22 I

CHECKING ELECTROLYTE LEVEL .................... 4 Wiring Diagram CHARGE ............................. 23

SPECIFIC GRAVITY CHECK ............................... 5 Trouble Diagnoses with Battery/Starting/Charging

CHARGING THE BATTERY ................................. 6 System Tester ......................................................... 24 J

Trouble Diagnoses with Battery/Starting/Charging DIAGNOSTIC RESULT ITEM CHART ................ 25

System Tester .......................................................... 6 WORK FLOW ...................................................... 26

DIAGNOSTIC RESULT ITEM CHART .................. 8 DIAGNOSTIC PROCEDURE 1 ........................... 27 SC

STARTING SYSTEM .................................................. 9 DIAGNOSTIC PROCEDURE 2 ........................... 28

System Description .................................................. 9 DIAGNOSTIC PROCEDURE 3 ........................... 29

M/T MODEL .......................................................... 9 MALFUNCTION INDICATOR .............................. 30

A/T MODEL ........................................................... 9 Construction ........................................................... 30 L

Wiring Diagram START ................................. 10 Removal and Installation ........................................ 31

M/T MODEL ........................................................ 10 QG18DE .............................................................. 31

A/T MODEL ..........................................................11 QR25DE .............................................................. 32 M

Trouble Diagnoses with Battery/Starting/Charging SERVICE DATA AND SPECIFICATIONS (SDS) ...... 33

System Tester ........................................................ 13 Battery .................................................................... 33

DIAGNOSTIC RESULT ITEM CHART ................ 13 Starter ..................................................................... 33

WORK FLOW ...................................................... 14 Generator ............................................................... 33

DIAGNOSTIC PROCEDURE 1 ........................... 15

Revision: May 2004 SC-1 2003 Sentra

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) AIR BAG and SEAT

BELT PRE-TENSIONER EKS0037L

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Wiring Diagrams and Trouble Diagnosis EKS0037M

When you read wiring diagrams, refer to the following:

GI-13, "How to Read Wiring Diagrams"

PG-2, "POWER SUPPLY ROUTING" for power distribution circuit.

When you perform trouble diagnosis, refer to the following:

GI-10, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES".

GI-26, "How to Perform Efficient Diagnosis for an Electrical Incident"

Revision: May 2004 SC-2 2003 Sentra

PREPARATION

PREPARATION PFP:00002

A

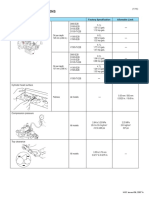

Special Service Tool EKS0037N

Tool number

Description

Tool name B

J-44373 Model 620

Battery/Starting/Charging system

tester

C

E

SEL403X

SC

Revision: May 2004 SC-3 2003 Sentra

BATTERY

BATTERY PFP:AYBGL

How to Handle Battery EKS0037O

CAUTION:

If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

Never add distilled water through the hole used to check specific gravity.

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging

a battery.

The battery surface (particularly its top) should always be kept

clean and dry.

The terminal connections should be clean and tight.

At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as low maintenance

and maintenance-free.

MEL040F

When the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal.

MEL041F

Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

MEL042F

CHECKING ELECTROLYTE LEVEL

WARNING:

Do not allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, do not touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

Revision: May 2004 SC-4 2003 Sentra

BATTERY

Remove the cell plug using a suitable tool.

Add distilled water up to the MAX level. A

MEL043F

D

Sulphation

A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates. E

To determine if a battery has been sulphated, note its voltage

and current when charging it. As shown in the figure, less cur-

rent and higher voltage are observed in the initial stage of F

charging sulphated batteries.

A sulphated battery may sometimes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

G

lowed by a battery capacity test.

SEL709E

SPECIFIC GRAVITY CHECK H

1. Read hydrometer and thermometer indications at eye level.

2. Use the following chart to correct your hydrometer reading

according to electrolyte temperature. I

SC

MEL042FA

Hydrometer Temperature Correction

L

Battery electrolyte temperature C (F) Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

M

60 (140) 0.024

54 (130) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70) 0.004

16 (60) 0.008

10 (50) 0.012

4 (40) 0.016

1 (30) 0.020

7 (20) 0.024

Revision: May 2004 SC-5 2003 Sentra

BATTERY

Battery electrolyte temperature C (F) Add to specific gravity reading

12 (10) 0.028

18 (0) 0.032

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

1.110 - 1.130 Completely discharged

CHARGING THE BATTERY

CAUTION:

Do not quick charge a fully discharged battery.

Keep the battery away from open flame while it is being charged.

When connecting the charger, connect the leads first, then turn on the charger. Do not turn on the

charger first, as this may cause a spark.

If battery electrolyte temperature rises above 60C (140F), stop charging. Always charge battery

at a temperature below 60C (140F).

Charging Rates

Amps Time

50 1 hour

25 2 hours

10 5 hours

5 10 hours

Do not charge at more than 50 ampere rate.

NOTE:

The ammeter reading on your battery charger will automatically decrease as the battery charges. This indi-

cates that the voltage of the battery is increasing normally as the state of charge improves. The charging amps

indicated above refer to initial charge rate.

If, after charging, the specific gravity of any two cells varies more than .050, the battery should be

replaced.

Trouble Diagnoses with Battery/Starting/Charging System Tester EKS0037P

CAUTION:

When working with batteries, always wear appropriate eye protection.

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be

done as a set from start to finish.

If battery surface charge is detected while testing, the tester will prompt you to turn on the headlights to

remove the surface charge.

If necessary, the tester will prompt you to determine if the battery temperature is above or below 0C

(32F). Choose the appropriate selection by pressing the up or down arrow button, then press ENTER to

make the selection.

Revision: May 2004 SC-6 2003 Sentra

BATTERY

1. Turn off all loads on the vehicle electrical system. Clean or repair

as necessary. A

2. Visually inspect the battery, battery terminals and cable ends

with ignition switch in OFF position.

NOTE: B

The contact surface between the battery terminals, cable ends

and tester leads must be clean for a valid test. A poor connec-

tion will prevent testing and a CHECK CONNECTION mes-

C

sage will appear during the test procedures. If this occurs, clean

the battery post and terminals, reconnect them and restart the

test. SEL404X

3. Connect the red tester lead clamp to the positive battery termi- D

nal, and the black to the negative terminal.

4. The tester will turn on automatically. Using the arrow keys,

select IN-VEHICLE on the tester and then press the ENTER E

key.

SEL405X

H

5. Locate the battery type and rating stamped or written on the top

case of the battery to be tested.

NOTE: I

The battery type and rating will have either of the following.

CCA: Cold Cranking Amps (490 CCA, 550 CCA, etc.)

JIS: Japanese Industrial Standard. J

Battery is stamped with a number such as:

80D26L: 80 (rank of output), D (physical size-depth), 26 (width

in cm). The last character L (post configuration) is not input into

SC

the tester.

The tester requires the rating for the battery be entered exactly SEL406X

as it is written or stamped on the battery. Do not attempt a CCA

conversion for JIS stamped batteries. JIS must be input directly. L

6. Using the arrow and ENTER keys alternately, select the battery type and rating.

NOTE:

The tester lists five choices; CCA, JIS, IEC, DIN, and EN. Only use CCA or JIS. M

7. Press ENTER to begin the test. Diagnosis results are dis-

played on the tester. Refer to SC-8, "DIAGNOSTIC RESULT

ITEM CHART" .

SEL407X

Revision: May 2004 SC-7 2003 Sentra

BATTERY

8. Press ENTER, then test output code is displayed. Record the

test output code on the repair order.

9. Toggle back to the DIAGNOSTIC SCREEN for test results.

NOTE:

If necessary, the tester will ask the user to determine if the

battery has just been charged. Choose the appropriate selec-

tion by pressing the up or down arrow button and then press

the ENTER button to make the selection.

When testing a battery installed in a vehicle that has recently

been driven, select BEFORE CHARGE.

SEL576X

If the battery has just been slow charged due to a CHARGE

& RETEST decision by the tester, and the tester asks the user BEFORE CHARGE/AFTER

CHARGE, select AFTER CHARGE.

DIAGNOSTIC RESULT ITEM CHART

Diagnostic item Service procedure

Battery is OK. Refer to SC-6, "Trouble Diagnoses with Battery/Starting/Charging System

GOOD BATTERY

Tester" .

Replace battery.

Before replacing battery, clean the battery cable clamps and battery posts. Perform battery

REPLACE BATTERY

test again with Battery/Starting/Charging system tester. If second test result is Replace Bat-

tery, then do so. Perform battery test again to confirm repair.

Replace the battery. Perform battery test again with Battery/Starting/Charging system tester

BAD CELL-REPLACE

to confirm repair.

Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.) Per-

GOOD-RECHARGE

form battery test again with Battery/Starting/Charging system tester.

Perform the slow battery charging. (Initial rate of charge is 10A for 12 hours.)

Perform battery test again with Battery/Starting/Charging system tester to confirm repair.

CHARGE & RETEST NOTE:

If the tester asks the user BEFORE CHARGE/AFTER CHARGE, select AFTER

CHARGE.

Revision: May 2004 SC-8 2003 Sentra

STARTING SYSTEM

STARTING SYSTEM PFP:23300

A

System Description EKS0037Q

M/T MODEL

Power is supplied at all times: B

through 40A fusible link (letter c , located in the fuse and fusible link box)

to ignition switch terminal B.

With the ignition switch in the START position, power is supplied: C

from ignition switch terminal St

to clutch interlock relay terminal 5.

With the ignition switch in the ON or START position, power is supplied: D

through 10A fuse [No. 20, located in the fuse block (J/B)]

to clutch interlock relay terminal 1.

E

When the clutch pedal is depressed, ground is supplied to clutch interlock relay terminal 2 through the clutch

interlock switch and body grounds E7 and E37.

The clutch interlock relay is energized and power is supplied:

from terminal 3 of the clutch interlock relay F

to terminal S of the starter motor windings.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates. G

A/T MODEL

Power is supplied at all times: H

through 40A fusible link (letter c , located in the fuse and fusible link box)

to ignition switch terminal B.

With the ignition switch in the START position, power is supplied: I

from ignition switch terminal St

to park/neutral position relay terminal 5

J

With the ignition switch in the ON or START position, power is supplied:

through 10A fuse [No. 20, located in the fuse block (J/B)]

to park/neutral position relay terminal 1. SC

With the selector lever in the P or N position, ground is supplied:

to park/neutral position relay terminal 2

through park/neutral position switch. L

The park/neutral position relay is energized and power is supplied:

from ignition switch terminal St

through park/neutral position relay terminals 5 and 3 M

to terminal S of the starter motor windings.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

Revision: May 2004 SC-9 2003 Sentra

STARTING SYSTEM

Wiring Diagram START EKS0037R

M/T MODEL

WKWA0159E

Revision: May 2004 SC-10 2003 Sentra

STARTING SYSTEM

A/T MODEL

A

SC

WKWA0160E

Revision: May 2004 SC-11 2003 Sentra

STARTING SYSTEM

WKWA0161E

Revision: May 2004 SC-12 2003 Sentra

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester EKS0037S

A

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to finish.

1. Turn off all loads on the vehicle electrical system. B

2. Perform battery test with Battery/Starting/Charging system

tester. Refer to SC-13, "Trouble Diagnoses with Battery/Starting/

Charging System Tester" . C

3. Press ENTER to begin the starting system test.

E

SEL408X

4. Start the engine.

F

SEL409X

I

5. Diagnosis result is displayed on the tester. Refer to SC-13,

"DIAGNOSTIC RESULT ITEM CHART" .

J

NOTE:

If the starter performs normally but the engine does not start,

perform engine diagnosis.

SC

For intermittent NO CRANK or NO STARTER OPERA-

TION incidents, refer to SC-17, "DIAGNOSTIC PROCE-

DURE 2" .

L

SEL410X

DIAGNOSTIC RESULT ITEM CHART M

Diagnostic item Service procedure

CRANKING VOLTAGE NORMAL Go to WORK FLOW, SC-14, "WORK FLOW" .

CRANKING VOLTAGE LOW Go to WORK FLOW, SC-14, "WORK FLOW" .

Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.) Per-

CHARGE BATTERY form battery test again with Battery/Starting/Charging system tester. Refer to SC-13, "Trouble

Diagnoses with Battery/Starting/Charging System Tester" .

Before replacing battery, clean the battery cable clamps and battery posts. Perform battery

test again with Battery/Starting/Charging system tester. Refer to SC-13, "Trouble Diagnoses

REPLACE BATTERY

with Battery/Starting/Charging System Tester" . If second test result is REPLACE BAT-

TERY, then do so. Perform battery test again to confirm repair.

Revision: May 2004 SC-13 2003 Sentra

STARTING SYSTEM

WORK FLOW

SEL411X

*1 SC-6 *2 SC-18 *3 SC-15

*4 SC-17

Revision: May 2004 SC-14 2003 Sentra

STARTING SYSTEM

DIAGNOSTIC PROCEDURE 1

Check B Terminal Circuit A

1. CHECK POWER SUPPLY FOR STARTER MOTOR B TERMINAL B

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

C

3. Turn the ignition switch OFF.

4. Check that the starter motor connector E202 terminal B (B/Y) connection is clean and tight.

5. Check voltage between starter motor connector E202 terminal B (B/Y) and ground using a digital circuit

D

tester.

LSC037

OK or NG H

OK >> GO TO 2.

NG >> Check harness between the battery and the starter motor for open circuit.

2. CHECK BATTERY CABLE CONNECTION QUALITY (VOLTAGE DROP TEST) I

1. Check voltage between starter motor connector E202 terminal B (B/Y) and battery positive terminal using

a digital circuit tester. J

SC

M

LSC038

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter motor for poor continuity.

Revision: May 2004 SC-15 2003 Sentra

STARTING SYSTEM

3. CHECK STARTER MOTOR GROUND CIRCUIT (VOLTAGE DROP TEST)

1. Check voltage between starter motor case and battery negative terminal using a digital circuit tester.

LSC039

OK or NG

OK >> Starter motor B terminal circuit is OK. Further inspection is necessary. Refer to SC-14, "WORK

FLOW" .

NG >> Check the starter motor case and ground for poor continuity.

Revision: May 2004 SC-16 2003 Sentra

STARTING SYSTEM

DIAGNOSTIC PROCEDURE 2

Check S Terminal Circuit A

1. CHECK POWER SUPPLY FOR STARTER MOTOR S TERMINAL B

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

C

3. Turn the ignition switch OFF.

4. Disconnect starter motor connector F53 (QG18DE), F32 (QR25DE) terminal S (B/Y) connector.

5. Check voltage between starter motor connector F53 (QG18DE),

D

F32 (QR25DE) terminal S (B/Y) and ground using a digital cir-

cuit tester.

With the ignition switch : Battery voltage should

E

ON exist

OK or NG

OK >> GO TO 2. F

NG >> Check the following.

40A fusible link (letter c , located in fuse and fusible

link box) WKWA0096E

G

Clutch interlock relay

Park/neutral position relay

Harness for open or short H

2. CHECK S TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

I

1. Connect starter motor connector F53 (QG18DE), F32 (QR25DE) terminal S (B/Y) connector.

2. Check voltage between starter motor connector F53 (QG18DE),

F32 (QR25DE) terminal S (B/Y) and battery positive terminal

using a digital tester. J

With the ignition switch in : Voltage less than 1V

START SC

OK or NG

OK >> Starter motor S terminal circuit is OK. Further inspec-

tion is necessary. Refer to SC-14, "WORK FLOW" . L

NG >> Check harness between the battery and the starter

motor S terminal for poor continuity. WKWA0097E

Revision: May 2004 SC-17 2003 Sentra

STARTING SYSTEM

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERA-

TURE

Voltage V

Engine coolant temperature

QG18DE QR25DE

30C to 20C (22F to 4F) 7.4 8.7

19C to 10C (2F to 14F) 8.2 9.2

9C to 0C (16F to 32F) 9.3 9.6

More than 1C (More than 34F) 9.5 10.0

Construction EKS0037T

WKIA0287E

1. Solenoid through bolts 2. Drive end shield 3. Retainers

4. Pinion assembly 5. Fork lever 6. Bearing pedestal

7. Solenoid switch assembly 8. Seal 9. Locking washers

10. Intermediate bearing 11. Internal gear 12. Cover disc

13. Drive shaft 14. Planetary gears 15. Yoke assembly

16. Armature assembly 17. Brush holder 18. Commutator end shield

19. Closure cap 20. Starter through bolts 21. Closure cap screws

Revision: May 2004 SC-18 2003 Sentra

STARTING SYSTEM

WKWA0066E

1. Gear case 2. Shift lever 3. Plate

I

4. Packing 5. Adjusting plate 6. Magnetic switch assembly

7. Pinion stopper set 8. Pinion assembly 9. Internal gear

J

10. Pinion shaft 11. Planetary gear 12. Packing

13. Yoke 14. Armature 15. Brush holder assembly

16. Rear cover

SC

Revision: May 2004 SC-19 2003 Sentra

STARTING SYSTEM

WKWA0067E

1. Pinion stopper set 2. Pinion assembly 3. Front bracket

4. Shift lever 5. Plate 6. Packing

7. Adjusting plate 8. Magnetic switch assembly 9. Clutch gear

10. Internal gear 11. Gear shaft 12. Planetary gears

13. Ball 14. Center bracket 15. Yoke assembly

16. Armature 17. Brush assembly 18. Rear bracket

Removal and Installation EKS0037U

QG18DE

Removal

1. Disconnect the negative battery terminal.

2. Remove the upper starter mounting bolt.

3. Remove the harness protector from the starter engine room har-

ness.

4. Disconnect the starter harness connectors.

5. Remove the lower starter mounting bolt.

6. Remove the starter.

LSC024

Revision: May 2004 SC-20 2003 Sentra

STARTING SYSTEM

Installation

To install, reverse the removal procedure. A

WSC016

D

QR25DE

Removal E

1. Disconnect the negative and positive battery cables.

2. Remove the engine undercover (M/T) or the air duct, fresh air

intake hose, and air cleaner lid (A/T). F

3. Disconnect the starter harness connectors.

4. Remove the two starter mounting bolts.

5. Remove the starter. G

H

WKWA0065E

Installation

To install, reverse the removal procedure. I

SC

L

WKWA0064E

Pinion/Clutch Check EKS0037V

1. Inspect pinion assembly teeth. M

Replace pinion assembly if teeth are worn or damaged. (Also check condition of ring gear teeth.)

2. Inspect planetary gears/planetary gear teeth.

Replace planetary gears if teeth are worn or damaged. (Also check condition of pinion shaft/drive shaft

gear teeth.)

3. Check to see if pinion assembly locks in one direction and rotates smoothly in the opposite direction.

If it locks or rotates in both directions, or unusual resistance is evident, replace.

Revision: May 2004 SC-21 2003 Sentra

CHARGING SYSTEM

CHARGING SYSTEM PFP:23100

System Description EKS0037W

NOTE:

For vehicles with QR25DE engine, a low tone whistling noise coming from the generator for less than 10 sec-

onds after engine shut down is normal. This is caused by the rotor "slow-down" function. Do not replace the

generator exclusively for this symptom.

The generator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to generator terminal B through:

100A (QG18DE) or 120A (QR25DE) fusible link (letter a , located in the fuse and fusible link box).

Power is supplied at all times to generator terminal S through:

10A fuse (No. 33, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage is

controlled by the IC regulator at terminal S detecting the input voltage. The charging circuit is protected by the

100A (QG18DE) or 120A (QR25DE) fusible link.

The generator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied:

through 10A fuse [No. 30, located in the fuse block (J/B)]

to combination meter terminal 26 (without tachometer) or 41 (with tachometer) for the charge warning

lamp.

Ground is supplied to terminal 13 (without tachometer) or 19 (with tachometer) of the combination meter

through terminal L of the generator. With power and ground supplied, the charge warning lamp will illuminate.

When the generator is providing sufficient voltage with the engine running, the ground is opened and the

charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

Revision: May 2004 SC-22 2003 Sentra

CHARGING SYSTEM

Wiring Diagram CHARGE EKS0037X

SC

WKWA0004E

Revision: May 2004 SC-23 2003 Sentra

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester EKS0037Y

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to finish.

1. Turn off all loads on the vehicle electrical system.

2. Perform battery and starting system test with Battery/Starting/

Charging system tester.

3. Press ENTER to begin the charging system test.

4. Start engine.

SEL417X

5. Press ENTER until LOADS OFF REV ENGINE 5 SEC is dis-

played.

6. Raise and hold the engine speed at 1,500 to 2,000 rpm for about

5 seconds, then return the engine to idle.

Once the increase in engine rpm is detected, press ENTER to

continue.

NOTE:

If after 30 seconds an increase in engine idle speed is not

detected, RPM NOT DETECTED will display.

Some engines may have a higher idle initially after starting,

particularly when the engine is cold. The tester may detect SEL418X

this without any other action being taken. If this occurs, con-

tinue on with the testing process. The final results will not be affected.

7. The tester now checks the engine at idle and performs the

DIODE/RIPPLE check.

8. When complete, the tester will prompt you to turn on the follow-

ing electrical loads.

Heater fan set to highest speed. Do not run the A/C or wind-

shield defroster.

Headlamp high beam

Rear window defogger

NOTE:

Do not run the windshield wipers or any other cyclical loads. SEL419X

9. Press ENTER to continue.

SEL420X

Revision: May 2004 SC-24 2003 Sentra

CHARGING SYSTEM

10. Raise and hold the engine speed at 1,500 to 2,000 rpm for about

5 seconds, then return the engine to idle. Once the increase in A

engine rpm is detected, press ENTER to continue.

NOTE:

If after 30 seconds an increase in engine idle speed is not B

detected, RPM NOT DETECTED will be displayed. Press

ENTER to restart the test.

C

SEL421X

D

11. Diagnostic result is displayed on the tester. Refer to SC-25,

"DIAGNOSTIC RESULT ITEM CHART" .

E

G

SEL422X

12. Press ENTER then test output code is displayed. Record the H

test output code on the repair order.

13. Toggle back to the DIAGNOSTIC SCREEN for test results.

I

SC

SEL577X

DIAGNOSTIC RESULT ITEM CHART

Diagnostic item Service procedure L

CHARGING SYSTEM NORMAL Charging system is normal and will also show DIODE RIPPLE test result.

NO CHARGING VOLTAGE Go to SC-26, "WORK FLOW" .

M

LOW CHARGING VOLTAGE Go to SC-26, "WORK FLOW" .

HIGH CHARGING VOLTAGE Go to SC-26, "WORK FLOW" .

DIODE RIPPLE NORMAL Diode ripple is OK and will also show CHARGING VOLTAGE test result.

Replace the generator. Perform DIODE RIPPLE test again using Battery/Starting/Charging

EXCESS RIPPLE DETECTED

system tester to confirm repair.

DIODE RIPPLE NOT DETECTED Go to SC-26, "WORK FLOW" .

Revision: May 2004 SC-25 2003 Sentra

CHARGING SYSTEM

WORK FLOW

WKIA3128E

Revision: May 2004 SC-26 2003 Sentra

CHARGING SYSTEM

DIAGNOSTIC PROCEDURE 1

Check L Terminal Circuit A

1. CHECK L TERMINAL CONNECTION B

Check to see if L terminal is clean and tight.

OK or NG

C

OK >> GO TO 2.

NG >> Repair L terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test.

D

2. CHECK L TERMINAL CIRCUIT

1. Disconnect E35 connector from generator.

E

2. Apply ground to connector E35 terminal L (Y/R) with the ignition switch in the ON position.

LSC042

OK or NG I

OK >> Replace the generator. Confirm repair by performing complete Battery/Starting/Charging system

test.

NG >> Check the following. J

10A fuse [No. 30, located in fuse block (J/B)]

CHARGE lamp

Harness for open or short between combination meter and fuse SC

Harness for open or short between combination meter and generator

Revision: May 2004 SC-27 2003 Sentra

CHARGING SYSTEM

DIAGNOSTIC PROCEDURE 2

Check B Terminal Circuit

1. CHECK B TERMINAL CONNECTION

Check to see if B terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair B terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test.

2. CHECK GENERATOR B TERMINAL CIRCUIT

Check voltage between generator connector E34 terminal B (B/L) (QG18DE), (W) (QR25DE) and ground

using a digital circuit tester.

LSC043

OK or NG

OK >> GO TO 3.

NG >> Check the following.

100A (QG18DE), 120A (QR25DE) fusible link (letter a , located in fuse and fusible link box)

Harness for open or short between generator and fusible link

3. CHECK B TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

Check voltage between generator connector E34 terminal B (B/L) (QG18DE), (W) (QR25DE) and battery pos-

itive terminal using a digital circuit tester.

LSC044

OK or NG

OK >> Replace the generator. Confirm repair by performing complete Battery/Starting/Charging system

test.

NG >> Check harness between the battery and the generator for poor continuity.

Revision: May 2004 SC-28 2003 Sentra

CHARGING SYSTEM

DIAGNOSTIC PROCEDURE 3

Check S Terminal Circuit A

1. CHECK S TERMINAL CONNECTION B

Check to see if S terminal is clean and tight.

OK or NG

C

OK >> GO TO 2.

NG >> Repair S terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test.

D

2. CHECK GENERATOR S TERMINAL CIRCUIT

Check voltage between generator connector E35 terminal S (G/B) and ground using a digital circuit tester.

E

H

LSC045

OK or NG

OK >> GO TO 3. I

NG >> Check the following.

10A fuse (No. 33, located in fuse and fusible link box)

Harness for open or short between generator and fuse J

3. CHECK S TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

Check voltage between generator connector E35 terminal S (G/B) and battery positive terminal using a digital SC

circuit tester.

LSC046

OK or NG

OK >> Replace the generator. Confirm repair by performing complete Battery/Starting/Charging system

test.

NG >> Check harness between the battery and the generator for poor continuity.

Revision: May 2004 SC-29 2003 Sentra

CHARGING SYSTEM

MALFUNCTION INDICATOR

The IC regulator warning function activates to illuminate CHARGE warning lamp, if any of the following

symptoms occur while generator is operating:

Excessive voltage is produced.

No voltage is produced.

Construction EKS0037Z

WKWA0068E

1. Pulley assembly 2. Front cover 3. Front bearing

4. Retainer 5. Rotor 6. Slip ring

7. Stator 8. Fan guide 9. IC regulator assembly

10. Diode assembly 11. Packing 12. Rear cover

Revision: May 2004 SC-30 2003 Sentra

CHARGING SYSTEM

WKIA0136E

1. Pulley assembly 2. Front cover 3. Front bearing

I

4. Retainer 5. Rotor 6. Slip ring

7. Stator 8. Fan guide 9. IC regulator assembly

J

10. Diode assembly 11. Packing 12. Rear cover

Removal and Installation EKS00380

QG18DE SC

Removal

1. Disconnect the negative battery terminal.

2. Remove the front/right-side engine undercover. L

3. Remove the drive belt.

4. Disconnect the A/C compressor harness connector.

5. Remove the four A/C compressor mounting bolts. M

6. Slide the A/C compressor forward and support it.

7. Remove the two generator lower mounting bolts.

8. Disconnect the generator harness connectors.

9. Remove the generator upper bracket. LSC019

10. Remove the generator.

Revision: May 2004 SC-31 2003 Sentra

CHARGING SYSTEM

Installation

To install, reverse the removal procedure.

LSC018

QR25DE

NOTE:

A low tone whistling noise coming from the generator for less than 10 seconds after engine shut down is nor-

mal. This is caused by the rotor "slow-down" function. Do not replace the generator exclusively for this symp-

tom.

Removal

1. Disconnect the negative battery cable.

2. Remove the front/right-side engine undercover.

3. Remove the drive belt.

4. Disconnect the generator harness connectors.

5. Disconnect the engine ground wire from the top mount.

6. Remove the generator upper and lower mount bolts.

7. Set the generator aside and remove the generator top mount.

8. Slide the generator out and remove.

LKWA0051E

Installation

To install, reverse the removal procedure.

LKWA0052E

Revision: May 2004 SC-32 2003 Sentra

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) PFP:00030

A

Battery EKS00381

Application QG18DE QR25DE

Type GR.21R (BCI) GR.24R (BCI) B

Capacity (20 HR) minimum V-AH 12-49 12-63

Cold cranking current A

356 @ -18C (0F) 550 @ -18C (0F) C

(For reference value)

Starter EKS00382

D

Application QG18DE QR25DE

Mitsubishi

Mitsubishi M000T87085ZC

Manufacturer Hitachi S114-900 M000T60781ZC

E

M/T models A/T models

Type Reduction gear type Reduction gear type

System voltage 12V 12V F

Terminal voltage 11V 11V

No-load Current 90A Max. 90A Max.

G

Revolution 2,600 rpm Min. 2,500 rpm Min.

Minimum diameter of commutator 32.1 mm 28.8 mm

Minimum length of brush 10.7 mm 5.5 mm 7.0 mm H

15.0 - 20.4 (1.53 - 2.08 kg, 18.3 - 24.8 (1.87 - 2.53 kg,

Brush spring tension 11.5 N (1.17 kg, 2.58 lb)

3.37 - 4.59 lb) 4.11 - 5.58 lb)

Clearance between pinion front edge and pinion I

1.8 mm 0.5 - 2.0 mm

stopper

Generator EKS00383

J

Application QG18DE QR25DE

LR180-769 LR1100-734

Type

HITACHI SC

Nominal rating 12V-80A 12V-110A

Ground polarity Negative

L

Minimum revolution under no-load (When 13.5 volts is applied) 1,000 rpm 950 rpm

23A/1,300 rpm 35A/1,300 rpm

Hot output current (When 13.5 volts is applied) 66A/2,500 rpm 83A/2,500 rpm

79A/5,000 rpm 95A/5,000 rpm M

Regulated output voltage 14.1 - 14.7V

Minimum length of brush 6 mm (0.236 in)

Brush spring pressure 1.000 - 3.432 N (0.102 - 0.350 kg, 0.225 - 0.772 lbs)

Slip ring minimum outer diameter 26.0 mm (1.024 in)

Rotor (Field coil) resistance 2.67 ohms 2.31 ohms

Revision: May 2004 SC-33 2003 Sentra

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: May 2004 SC-34 2003 Sentra

Das könnte Ihnen auch gefallen

- SC PDFDokument36 SeitenSC PDFRony CentenoNoch keine Bewertungen

- Starting & Charging System: SectionDokument36 SeitenStarting & Charging System: SectionDiego496Noch keine Bewertungen

- SC PDFDokument38 SeitenSC PDFROSILENE PASSOSNoch keine Bewertungen

- SC PDFDokument32 SeitenSC PDFLino Bello RezamanoNoch keine Bewertungen

- Starting & Charging System: SectionDokument32 SeitenStarting & Charging System: SectionLino Bello RezamanoNoch keine Bewertungen

- Starting & Charging System: SectionDokument30 SeitenStarting & Charging System: SectionBrian BobbNoch keine Bewertungen

- Starting & Charging System Troubleshooting GuideDokument26 SeitenStarting & Charging System Troubleshooting GuideJagdeep Sekhon100% (2)

- Starting & Charging System: SectionDokument36 SeitenStarting & Charging System: Sectionmuki461100% (1)

- Nissan-X-Trail 2005Dokument36 SeitenNissan-X-Trail 2005ryanto wawan noviarnoNoch keine Bewertungen

- ELECTRICAL & POWER CONTROL TIPSDokument29 SeitenELECTRICAL & POWER CONTROL TIPSgiancarlo sanchezNoch keine Bewertungen

- Starting & Charging System: SectionDokument40 SeitenStarting & Charging System: SectionNeil MundowaNoch keine Bewertungen

- Charging System: SectionDokument25 SeitenCharging System: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Bateria MotorDeArranque Alternador Nissan VersaDokument34 SeitenBateria MotorDeArranque Alternador Nissan VersaHumberto Vega SanchezNoch keine Bewertungen

- Starting & Charging System: SectionDokument32 SeitenStarting & Charging System: SectionSonia GarciaNoch keine Bewertungen

- Charging System: SectionDokument24 SeitenCharging System: Sectionwilder0l0pezNoch keine Bewertungen

- ELECTRICAL & POWER CONTROL SYSTEMSDokument23 SeitenELECTRICAL & POWER CONTROL SYSTEMSDozer KamilNoch keine Bewertungen

- 2007 Nissan Frontier 18Dokument42 Seiten2007 Nissan Frontier 18Mardelis cisnerosNoch keine Bewertungen

- Electrical & Power Control Charging System GuideDokument24 SeitenElectrical & Power Control Charging System GuideNapiNoch keine Bewertungen

- CHG PDFDokument23 SeitenCHG PDFronaldNoch keine Bewertungen

- ELECTRICAL & POWER CONTROL SYSTEM OVERVIEWDokument22 SeitenELECTRICAL & POWER CONTROL SYSTEM OVERVIEWIvan A. VelasquezNoch keine Bewertungen

- Charging System: SectionDokument23 SeitenCharging System: SectionederengNoch keine Bewertungen

- SC Nissan Sentra B16Dokument35 SeitenSC Nissan Sentra B16Alex HernandezNoch keine Bewertungen

- PCSDokument96 SeitenPCSluis CebergNoch keine Bewertungen

- Starting & Charging System: SectionDokument34 SeitenStarting & Charging System: Sectionjokim mnroNoch keine Bewertungen

- Steering Control System: SectionDokument22 SeitenSteering Control System: SectionAgustin Borge GarciaNoch keine Bewertungen

- Nissan Titan Power Control SystemDokument98 SeitenNissan Titan Power Control SystemDaniel Aguirre100% (2)

- Steering Control System: SectionDokument19 SeitenSteering Control System: SectionalexNoch keine Bewertungen

- Power Supply, Ground & Circuit Elements: SectionDokument64 SeitenPower Supply, Ground & Circuit Elements: SectiontecnicofigueroaNoch keine Bewertungen

- Steering Control System: SectionDokument21 SeitenSteering Control System: SectionTESA MOTORSNoch keine Bewertungen

- SC PDFDokument32 SeitenSC PDFCarlos Eduardo ZelidonNoch keine Bewertungen

- Steering Control System Diagnosis GuideDokument19 SeitenSteering Control System Diagnosis GuidemanualNoch keine Bewertungen

- CHG PDFDokument15 SeitenCHG PDFMisha KulibaevNoch keine Bewertungen

- STC PDFDokument34 SeitenSTC PDFМиша ШаулаNoch keine Bewertungen

- Charging System: SectionDokument33 SeitenCharging System: SectionsKardoNoch keine Bewertungen

- Charging System: SectionDokument30 SeitenCharging System: SectioncesarNoch keine Bewertungen

- Charging System: SectionDokument28 SeitenCharging System: SectionPetter VillarroelNoch keine Bewertungen

- Charging System: SectionDokument34 SeitenCharging System: SectionHakob AdamyanNoch keine Bewertungen

- Driver Information System: SectionDokument56 SeitenDriver Information System: SectionminaryNoch keine Bewertungen

- Charging System: SectionDokument30 SeitenCharging System: SectionIvan A. VelasquezNoch keine Bewertungen

- Power Control System: SectionDokument100 SeitenPower Control System: SectiontecnicofigueroaNoch keine Bewertungen

- Steering Control System Diagnosis GuideDokument23 SeitenSteering Control System Diagnosis GuideLuis Alfonso Ortiz ESpinosaNoch keine Bewertungen

- STEERING CONTROL SYSTEM SECTIONDokument23 SeitenSTEERING CONTROL SYSTEM SECTIONDiego496Noch keine Bewertungen

- Fuente de Alimentación, Tierra y Elementos de CircuitoDokument74 SeitenFuente de Alimentación, Tierra y Elementos de Circuitoastroboy2666Noch keine Bewertungen

- Sentra CircuitDokument69 SeitenSentra CircuitMed KevlarNoch keine Bewertungen

- Charging System: SectionDokument30 SeitenCharging System: SectionZona Educación Especial ZacapaoaxtlaNoch keine Bewertungen

- Driver Information System: SectionDokument37 SeitenDriver Information System: SectionAnonymous 64HDY7IiN0Noch keine Bewertungen

- Power Supply, Ground & Circuit Elements: SectionDokument75 SeitenPower Supply, Ground & Circuit Elements: SectionemenelikNoch keine Bewertungen

- Acs-Auto Cruise Control SystemDokument24 SeitenAcs-Auto Cruise Control SystemDouglas CruzNoch keine Bewertungen

- Electrical Starting & Charging System Troubleshooting GuideDokument27 SeitenElectrical Starting & Charging System Troubleshooting GuideSteven AmadorNoch keine Bewertungen

- Auto Cruise Control System: SectionDokument24 SeitenAuto Cruise Control System: SectionKatya FirsenkoNoch keine Bewertungen

- Steering Control System: SectionDokument21 SeitenSteering Control System: SectionjapaxploseNoch keine Bewertungen

- Power Supply, Ground & Circuit Elements (Section PG)Dokument75 SeitenPower Supply, Ground & Circuit Elements (Section PG)Gleydson Bahiense RamosNoch keine Bewertungen

- 2014-Nissan-Pathfinder POWER CONTROL SYSTEMDokument85 Seiten2014-Nissan-Pathfinder POWER CONTROL SYSTEMgerardogmoralesNoch keine Bewertungen

- Di PDFDokument46 SeitenDi PDFROSILENE PASSOSNoch keine Bewertungen

- Electrical & Charging System GuideDokument29 SeitenElectrical & Charging System Guidejoeldqcgh29Noch keine Bewertungen

- Charging System: SectionDokument29 SeitenCharging System: SectionRuhu royNoch keine Bewertungen

- 2010 Nissan Sentra 27Dokument66 Seiten2010 Nissan Sentra 27Jhonatan Zamora SolisNoch keine Bewertungen

- Electrical Circuit OverviewDokument67 SeitenElectrical Circuit OverviewHanselPerezAguirreNoch keine Bewertungen

- Power Control System: SectionDokument34 SeitenPower Control System: Sectionenrique revecoNoch keine Bewertungen

- F4a41 - F4a42 - W4a42 - F4a51 - F5a51Dokument4 SeitenF4a41 - F4a42 - W4a42 - F4a51 - F5a51Aldo Apazza100% (2)

- D905 D1105 V1505 D1105-T V1505-TDokument1 SeiteD905 D1105 V1505 D1105-T V1505-TAldo ApazzaNoch keine Bewertungen

- Diesel Engine: 05-E3B SERIES, 05-E3Bg SeriesDokument130 SeitenDiesel Engine: 05-E3B SERIES, 05-E3Bg SeriesAldo ApazzaNoch keine Bewertungen

- EmDokument196 SeitenEmJeff KleinNoch keine Bewertungen

- Jacobsen - d1105 PartsDokument72 SeitenJacobsen - d1105 Partstheunauthorised0% (1)

- BL PDFDokument120 SeitenBL PDFAldo ApazzaNoch keine Bewertungen

- AJUSTES Y TORQUE MOTORES KUBOTA SERIE D (EPA Tier 2)Dokument17 SeitenAJUSTES Y TORQUE MOTORES KUBOTA SERIE D (EPA Tier 2)Julio GuerreroNoch keine Bewertungen

- Omm KubotaDokument38 SeitenOmm KubotaHafizhKiranaNoch keine Bewertungen

- Diesel Engine: 05-E3B SERIES, 05-E3Bg SeriesDokument130 SeitenDiesel Engine: 05-E3B SERIES, 05-E3Bg SeriesAldo ApazzaNoch keine Bewertungen

- AJUSTES Y TORQUE MOTORES KUBOTA SERIE D (EPA Tier 2)Dokument17 SeitenAJUSTES Y TORQUE MOTORES KUBOTA SERIE D (EPA Tier 2)Julio GuerreroNoch keine Bewertungen

- At PDFDokument760 SeitenAt PDFAldo ApazzaNoch keine Bewertungen

- Ec PDFDokument1.864 SeitenEc PDFAldo ApazzaNoch keine Bewertungen

- RF PDFDokument18 SeitenRF PDFAldo ApazzaNoch keine Bewertungen

- PG PDFDokument56 SeitenPG PDFAldo ApazzaNoch keine Bewertungen

- WW PDFDokument10 SeitenWW PDFAldo ApazzaNoch keine Bewertungen

- Check your wheels and tires for road noise issuesDokument6 SeitenCheck your wheels and tires for road noise issuesAldo ApazzaNoch keine Bewertungen

- SB PDFDokument12 SeitenSB PDFAldo ApazzaNoch keine Bewertungen

- SRS System Precautions and ProceduresDokument56 SeitenSRS System Precautions and ProceduresAldo ApazzaNoch keine Bewertungen

- Se PDFDokument6 SeitenSe PDFAldo ApazzaNoch keine Bewertungen

- Starting & Charging System GuideDokument34 SeitenStarting & Charging System GuideAldo ApazzaNoch keine Bewertungen

- Ps PDFDokument28 SeitenPs PDFAldo ApazzaNoch keine Bewertungen

- RaxDokument10 SeitenRaxtomallor101Noch keine Bewertungen

- MT PDFDokument190 SeitenMT PDFAldo ApazzaNoch keine Bewertungen

- MTC PDFDokument92 SeitenMTC PDFAldo ApazzaNoch keine Bewertungen

- Di PDFDokument56 SeitenDi PDFAldo ApazzaNoch keine Bewertungen

- LT PDFDokument48 SeitenLT PDFAldo ApazzaNoch keine Bewertungen

- Rsu PDFDokument14 SeitenRsu PDFAldo ApazzaNoch keine Bewertungen

- Engine Lubrication GuideDokument22 SeitenEngine Lubrication GuideAldo ApazzaNoch keine Bewertungen

- Ma PDFDokument38 SeitenMa PDFAldo ApazzaNoch keine Bewertungen

- Parking Brake System: SectionDokument4 SeitenParking Brake System: SectionAldo ApazzaNoch keine Bewertungen

- 416E Backhoe Loader Maintenance ScheduleDokument4 Seiten416E Backhoe Loader Maintenance ScheduleSain MezaNoch keine Bewertungen

- Coduto10 9Dokument3 SeitenCoduto10 9bagmassNoch keine Bewertungen

- Section A: Service Manual - 506C, 506CHL, 508C LoadallsDokument8 SeitenSection A: Service Manual - 506C, 506CHL, 508C Loadallsmauricio carmona67% (3)

- 4.1.5 Newton's Laws of MotionDokument30 Seiten4.1.5 Newton's Laws of MotionjleodennisNoch keine Bewertungen

- Productdata 1LDokument23 SeitenProductdata 1Lsharif_alNoch keine Bewertungen

- Cek Item SapDokument30 SeitenCek Item Sapiduy emailsNoch keine Bewertungen

- Kershaw Scorpion RS64 DL RampDokument3 SeitenKershaw Scorpion RS64 DL Rampcamelia_pirjan5776Noch keine Bewertungen

- ERP Regulation 2281-2016Dokument50 SeitenERP Regulation 2281-2016Bianca-Elena LupuNoch keine Bewertungen

- Module 2Dokument59 SeitenModule 2PSkotsNoch keine Bewertungen

- Moment and Centre of gravity-CIE NOTESDokument7 SeitenMoment and Centre of gravity-CIE NOTESJennieNoch keine Bewertungen

- Terminal Blocks ABBDokument36 SeitenTerminal Blocks ABBalishaikh12Noch keine Bewertungen

- Chapter 3Dokument17 SeitenChapter 3Mintesnot TadeleNoch keine Bewertungen

- Archimedes and BuoyancyDokument2 SeitenArchimedes and Buoyancyromaehab201912Noch keine Bewertungen

- Owner'S Manual & Competition Handbook Competition HandbookDokument164 SeitenOwner'S Manual & Competition Handbook Competition HandbookAgape SniperNoch keine Bewertungen

- Positive Displacement PumpDokument43 SeitenPositive Displacement Pumpvenkeeku100% (2)

- A40hpv08completemanual PDFDokument215 SeitenA40hpv08completemanual PDFEbin RiazNoch keine Bewertungen

- Thermography ReportDokument9 SeitenThermography ReportsandrositohangNoch keine Bewertungen

- PDF - Download - GEA - Flex-Geko PDFDokument16 SeitenPDF - Download - GEA - Flex-Geko PDFEvangelos SotiriouNoch keine Bewertungen

- Kr451 Nepiro Ergo PR enDokument4 SeitenKr451 Nepiro Ergo PR enForum PompieriiNoch keine Bewertungen

- Sisweb Sisweb Techdoc Techdoc Print PageDokument4 SeitenSisweb Sisweb Techdoc Techdoc Print PageGustavo PereiraNoch keine Bewertungen

- Modelling, Identification and Control of A 2 DOF Helicopter PrototypeDokument6 SeitenModelling, Identification and Control of A 2 DOF Helicopter PrototypeosdacavNoch keine Bewertungen

- Eni Blasia S 220Dokument2 SeitenEni Blasia S 220Fajar EkoNoch keine Bewertungen

- A Mechanical Engineer S Handbook by ONGC PDFDokument303 SeitenA Mechanical Engineer S Handbook by ONGC PDFshujad77Noch keine Bewertungen

- Simple Machines TestDokument7 SeitenSimple Machines TestAlyanna CrisologoNoch keine Bewertungen

- Modern Bulk Storage Tanks Design & ManufacturingDokument2 SeitenModern Bulk Storage Tanks Design & ManufacturingSCALE Ingeniería y ConstrucciónNoch keine Bewertungen

- Product CatalogDokument106 SeitenProduct CatalogAri AzadNoch keine Bewertungen

- Pressure Testing ChecklistDokument3 SeitenPressure Testing Checklistjerin100% (3)

- FINNPOWER P Series Manual PDFDokument33 SeitenFINNPOWER P Series Manual PDFMaulanna Ibrohiim50% (2)

- Power Transformer Design, Manufacturing and TestingDokument19 SeitenPower Transformer Design, Manufacturing and TestingAbd ALRahmanNoch keine Bewertungen

- Low Pressure Pumps: Installation and Start-Up InstructionDokument12 SeitenLow Pressure Pumps: Installation and Start-Up InstructionsmithworkNoch keine Bewertungen