Beruflich Dokumente

Kultur Dokumente

Stonclad GR Product Data

Hochgeladen von

Anonymous aii1ilOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stonclad GR Product Data

Hochgeladen von

Anonymous aii1ilCopyright:

Verfügbare Formate

P R O D U C T D ATA

STONCLAD GR

PRODUCT DESCRIPTION

Stonclad GR is an environmentally friendly four-component, trow-

eled, epoxy mortar system utilizing recycled materials and rapidly

PHYSICAL CHARACTERISTICS

renewable soy based components. The system utilizes 25% recy-

cled glass blended with an epoxy resin, amine curing agent and Compressive Strength . . . . . . . . . . . . . . . . . . . . . . . . . .10,000 psi

soy based additives. Stonclad GR can be applied at thickness (ASTM C-579) after 7 days

ranging from 1/8 in./3 mm to 1/4 in./6 mm depending on applica- Tensile Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,750 psi

tion requirements. Stonclad GR cures to an extremely hard, (ASTM C-307)

impact resistant surface which exhibits excellent abrasion, wear Flexural Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4,000 psi

and chemical resistance.

(ASTM C-580)

Flexural Modulus of Elasticity . . . . . . . . . . . . . . . . . .2.0 x 106 psi

(ASTM C-580)

SYSTEM OPTIONS

Hardness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85 to 90

Coatings (ASTM D-2240, Shore D)

To improve cleanability and increase the resistance to damage Impact Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . .>160 in./lbs.

from abrasion and chemical spillages, the following coatings are (ASTM D-2794)

recommended: Stonkote GS4, Stonkote HT4. Abrasion Resistance . . . . . . . . . . . . . . .0.1 gm max. weight loss*

Waterproofing (ASTM D-4060, CS-17)

Where the total system must be waterproof, use of Stonhards Flammability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class 1

Stonproof ME7 membrane system is required, with strict adher- (ASTM E-648)

ence to application instructions. Thermal Coefficient of

Linear Expansion . . . . . . . . . . . . . . . . . . . . . . . .11 x 10-6 in./in.F

Cove Base (ASTM C-531)

To provide for an integral seal at the joint between the floor and Water Absorption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.2%

the wall, cove bases in heights from 2 to 6 in./5 to 15 cm may be (ASTM C-413)

specified. Cure Rate . . . . . . . . . . . . . . . . .24 hours for normal operations

Fiberglass Reinforcement (at 75F/25C)

VOC Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<5 g/L

To provide additional surface strength to the system, a surface

(ASTM D-2369)

veil of fiberglass reinforcement should be installed for areas

exposed to instantaneous temperature changes of greater than

* Test samples finished with one coat of high solids epoxy

100F/38C.

coating

PACKAGING

Stonclad GR is packaged in units for easy handling. Each unit con- Note: The above physical properties were measured in accordance

sists of: with the referenced standards. Samples of the actual floor system,

including binder and filler, were used as test specimens. All sample

2 cartons, each containing: preparation and testing is conducted in a laboratory environment,

6 foil bags of Amine values obtained on field applied materials may vary and certain test

6 poly bags of Resin methods can only be conducted on lab made test coupons.

12 individual bags of aggregate

1 carton containing:

12 bags of pigment

COLOR

COVERAGE Stonclad GR is available in 12 standard colors. Refer to the

Each unit of Stonclad GR will cover approximately 200 sq. Stonclad Color Sheet.

ft./18.58 sq. m of surface at a nominal 1/4 in./6 mm thickness.

SUBSTRATE

STORAGE CONDITIONS Stonclad GR, with the appropriate primer, is suitable for applica-

Store all components of Stonclad GR between 60 to 85F/16 to

tion over concrete, wood, brick, quarry tile, metal or Stonhard

30C in a dry area. Avoid excessive heat and do not freeze. The

Stonset grouts. For questions regarding other possible substrates

shelf life is 3 years in the original, unopened container.

or an appropriate primer, contact your local Stonhard represen-

tative or Technical Service.

SUBSTRATE PREPARATION NOTES

Proper preparation is critical to ensure an adequate bond and Procedures for maintenance of the flooring system during

system performance. The substrate must be dry and properly operations are described in the Stonkleen Floor Cleaning

prepared utilizing mechanical methods. Questions regarding Procedures Brochure.

substrate preparation should be directed to your local Stonhard Specific information regarding chemical resistance is available in

representative or Technical Service. the Stonclad Chemical Resistance Guide.

Safety Data Sheets for Stonclad GR are available on line at

www.stonhard.com under Products or upon request.

PRIMING

A staff of technical service engineers is available to assist with

The use of Standard Primer is necessary for all applications of

installation or to answer questions related Stonhards flooring

Stonclad GR over all substrates except Stonset grouts. Over

products.

Stonset grouts, Stonhards Stonset Primer is used. Please see the

appropriate primer Product Data sheet for details. Requests for technical service or literature can be made

through local sales representatives and offices, or corporate

offices located worldwide.

MIXING The appearance of all floor, wall and lining systems will change

Proper mixing is critical for the product to exhibit the proper over time due to normal wear, abrasion, traffic and cleaning.

application properties, cure properties and ultimate physical Generally, high gloss coatings are subject to a reduction in

properties. gloss, while matte finish coatings can increase in gloss level

Mechanical mixing using a JB Blender (or equivalent 5 gal. pail under normal operating conditions.

mixer) or a larger mortar mixer (e.g., a Baugh 3 Batch Mixer) Surface texture of resinous flooring surfaces can change over

is required. time as a result of wear and surface contaminants. Surfaces

See Stonclad GR Directions for further details. should be cleaned regularly and deep cleaned periodically to

ensure no contaminant buildup occurs. Surfaces should be

APPLYING periodically inspected to ensure they are performing as

DO NOT attempt to install material if the temperature of expected and may require traction-enhancing maintenance to

Stonclad GR components and substrate are not within 60 to ensure they continue to meet expectations for the particular

85F/16 to 30C. The cure time and application properties of area and conditions of use.

the material are severely affected at temperatures outside of

this range.

Material must be applied immediately after mixing.

A suitable screed applicator is used to distribute the mixed

Stonclad GR onto the floor.

Steel finishing trowels are used to compact and smooth the

surface of the material to the required thickness.

Detailed application instructions can be found in the

Stonclad GR Directions.

IMPORTANT:

Stonhard believes the information contained here to be true and accurate as of the date of publication. Stonhard makes no warranty, expressed or implied, based on this literature and assumes no responsibility for conse-

quential or incidental damages in the use of the systems described, including any warranty of merchantability or fitness. Information contained here is for evaluation only. We further reserve the right to modify and change

products or literature at any time and without prior notice.

Rev. 4/16

2016 Stonhard

w w w. s t o n h a r d . c o m

Worldwide Offices:

a brand of

THE

Mexico (52)55.9140.4500 Europe (32)2.720.8982 Africa (27)11.254.5500

STONHARD

USA 800.257.7953

South America (54-3327)44.2222 Middle East (971)4.3470460 Asia (86)21.5466.5118

GROUP

FLOORS FOR EVERY ENVIRONMENT Canada (905)430.3333

Das könnte Ihnen auch gefallen

- 855 Stonchem Product DataDokument3 Seiten855 Stonchem Product DataSky MoonNoch keine Bewertungen

- Stonclad Ur Product DataDokument2 SeitenStonclad Ur Product DatagafarmerdanNoch keine Bewertungen

- Amercoat 68 BSDokument4 SeitenAmercoat 68 BSStephen Francis BothelloNoch keine Bewertungen

- SES Amercoat Dimetcote 9Dokument4 SeitenSES Amercoat Dimetcote 9kamalkashNoch keine Bewertungen

- Amerlock 400 GFADokument4 SeitenAmerlock 400 GFASherif AbdelhameedNoch keine Bewertungen

- Amercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsDokument4 SeitenAmercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsAchraf BoudayaNoch keine Bewertungen

- Amercoat 878: Physical DataDokument2 SeitenAmercoat 878: Physical Dataabdulgafoor54Noch keine Bewertungen

- Amerlock 400GFA High Solids Glassflake Epoxy CoatingDokument4 SeitenAmerlock 400GFA High Solids Glassflake Epoxy CoatingSherif AbdelhameedNoch keine Bewertungen

- 0400GF Amerlock 400 GF PDS PDFDokument4 Seiten0400GF Amerlock 400 GF PDS PDFRenny DevassyNoch keine Bewertungen

- 0400GF Amerlock 400 GF PDSDokument4 Seiten0400GF Amerlock 400 GF PDSRenny DevassyNoch keine Bewertungen

- Amerlock 2C: Fast Drying High Solids Epoxy Product Data/ Application InstructionsDokument4 SeitenAmerlock 2C: Fast Drying High Solids Epoxy Product Data/ Application InstructionsTony KhouryNoch keine Bewertungen

- 0400GF Amerlock 400 GF PDSMay 08Dokument2 Seiten0400GF Amerlock 400 GF PDSMay 08amadan64Noch keine Bewertungen

- Fire Protection PDFDokument474 SeitenFire Protection PDFNizar BouchaalaNoch keine Bewertungen

- Dimecote 9 Inorganic Zinc Silicate CoatingDokument4 SeitenDimecote 9 Inorganic Zinc Silicate Coatingabdulgafoor54Noch keine Bewertungen

- Amercoat 56E Polyamide Epoxy High Solids Tank LiningDokument4 SeitenAmercoat 56E Polyamide Epoxy High Solids Tank LiningMuhammad MustahsinNoch keine Bewertungen

- Amercoat 4801 Glass Flake Vinyl EsterDokument4 SeitenAmercoat 4801 Glass Flake Vinyl Esterilyasmd7Noch keine Bewertungen

- PN78HBCDokument4 SeitenPN78HBCLassadNoch keine Bewertungen

- Stonproof CT5 Product Data - en - USDokument2 SeitenStonproof CT5 Product Data - en - USVentas ExpertisNoch keine Bewertungen

- Nu-Klad 114A: Epoxy Filler Compound Product Data/ Application InstructionsDokument4 SeitenNu-Klad 114A: Epoxy Filler Compound Product Data/ Application InstructionsCad AutocadNoch keine Bewertungen

- Carboguard 891: Selection & Specification DataDokument4 SeitenCarboguard 891: Selection & Specification DataPrakashNoch keine Bewertungen

- Stonkote Gs4 Product Data en UsDokument4 SeitenStonkote Gs4 Product Data en UsWillian Huaraca AyalaNoch keine Bewertungen

- Plasite 9133 Product Data SheetDokument3 SeitenPlasite 9133 Product Data SheetChris StroudNoch keine Bewertungen

- Amercoat 253Dokument4 SeitenAmercoat 253Sherif AbdelhameedNoch keine Bewertungen

- Carboguard 635: Selection & Specification DataDokument5 SeitenCarboguard 635: Selection & Specification DataPrakashNoch keine Bewertungen

- Crestomer, Adhesivo Estructural de Alta ResistenciaDokument3 SeitenCrestomer, Adhesivo Estructural de Alta ResistenciaTommy VargasNoch keine Bewertungen

- Interseal 670 HS EN O-FDokument4 SeitenInterseal 670 HS EN O-Fapde06Noch keine Bewertungen

- Chemflake SpecialDokument5 SeitenChemflake Specialmajmor-1Noch keine Bewertungen

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intertuf - 16 - Eng - A4 - 20150204 PDFDokument4 SeitenE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intertuf - 16 - Eng - A4 - 20150204 PDFShafnur HamdiNoch keine Bewertungen

- Carboguard 890: Selection & Specification DataDokument5 SeitenCarboguard 890: Selection & Specification DataMuthazhagan SaravananNoch keine Bewertungen

- Amerlock 400gfaDokument4 SeitenAmerlock 400gfaKhaled bouhlelNoch keine Bewertungen

- 7) PPG Amercoat 385 - Pds - AiDokument4 Seiten7) PPG Amercoat 385 - Pds - AididbeauNoch keine Bewertungen

- Product Data Sheet: 17008 Brite Galvanize Coating 65% Zinc RichDokument2 SeitenProduct Data Sheet: 17008 Brite Galvanize Coating 65% Zinc RichJORGE HOLGUINNoch keine Bewertungen

- TDS Chemflake Glass Flake SuggestedDokument5 SeitenTDS Chemflake Glass Flake SuggestedShankar Pl GowdaNoch keine Bewertungen

- ChemflakeDokument5 SeitenChemflakeManohar SeetharamNoch keine Bewertungen

- Pennguard InformationDokument2 SeitenPennguard Informationhuynhthanhtamga1981Noch keine Bewertungen

- TDS - Jotamastic 80 - English (Uk) - Issued.26.03.2009Dokument4 SeitenTDS - Jotamastic 80 - English (Uk) - Issued.26.03.2009Joni EfwanNoch keine Bewertungen

- Triflex ™ 3-Layer Combinations: Technical Data SheetDokument2 SeitenTriflex ™ 3-Layer Combinations: Technical Data SheetSantosh JayasavalNoch keine Bewertungen

- Asrene (Hdpe SP4808)Dokument2 SeitenAsrene (Hdpe SP4808)AgusPurwantoNoch keine Bewertungen

- Amercoat 878 HSDokument4 SeitenAmercoat 878 HSMario KoričanNoch keine Bewertungen

- 2750 515-130 enDokument14 Seiten2750 515-130 endouslasNoch keine Bewertungen

- Amerlock 400 Sigmacover 400Dokument6 SeitenAmerlock 400 Sigmacover 400Vijay KumarNoch keine Bewertungen

- Interlac 1 Gris MamaparoDokument4 SeitenInterlac 1 Gris Mamaparowilfran villegasNoch keine Bewertungen

- Interzinc 75V: Zinc-Rich EpoxyDokument4 SeitenInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaNoch keine Bewertungen

- Chemflake Special: Technical Data SheetDokument5 SeitenChemflake Special: Technical Data SheetSalmanNoch keine Bewertungen

- Plasite 4310 PDS 1-06Dokument2 SeitenPlasite 4310 PDS 1-06Gerardo FloresNoch keine Bewertungen

- Jotatemp 1000 Ceramic Technical Data SheetDokument5 SeitenJotatemp 1000 Ceramic Technical Data SheetGurdeep Sungh AroraNoch keine Bewertungen

- C 581 - 00 - Qzu4ms1sruq - PDFDokument7 SeitenC 581 - 00 - Qzu4ms1sruq - PDFAndre CasteloNoch keine Bewertungen

- Tankguard Storage: Technical Data SheetDokument5 SeitenTankguard Storage: Technical Data SheetEngTamerNoch keine Bewertungen

- Tinopoxy Primer - Intermediate Metal CoatingsDokument3 SeitenTinopoxy Primer - Intermediate Metal CoatingsAbed samadsureyft7vewyrNoch keine Bewertungen

- 253 PDS AiDokument4 Seiten253 PDS AiHrvoje RuzicNoch keine Bewertungen

- Sigmazinc 109 HS: Description Principal CharacteristicsDokument4 SeitenSigmazinc 109 HS: Description Principal CharacteristicsАлексейNoch keine Bewertungen

- Jotamastic 87 Aluminium - English (Uk) - Issued.04.01.Dokument4 SeitenJotamastic 87 Aluminium - English (Uk) - Issued.04.01.Mohamed FaragNoch keine Bewertungen

- Sonolastic - NP2 - Polyutherane Caulking SealantDokument6 SeitenSonolastic - NP2 - Polyutherane Caulking SealantOgbedande Awo Orunmila100% (1)

- TDS 48342 Jotatemp 1000 Euk GBDokument5 SeitenTDS 48342 Jotatemp 1000 Euk GBhenryNoch keine Bewertungen

- HereShield TDSDokument5 SeitenHereShield TDSMahdi BagheriNoch keine Bewertungen

- Jotatemp 1000 Ceramic: Technical Data SheetDokument5 SeitenJotatemp 1000 Ceramic: Technical Data Sheetebastien2Noch keine Bewertungen

- Amercoat 37-B-1 / 37-G-1: Product Data/ Application InstructionsDokument4 SeitenAmercoat 37-B-1 / 37-G-1: Product Data/ Application InstructionsTony KhouryNoch keine Bewertungen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- GRP and Buildings: A Design Guide for Architects and EngineersVon EverandGRP and Buildings: A Design Guide for Architects and EngineersNoch keine Bewertungen

- 3 and 4 Point Bend Fixtures, CortestDokument2 Seiten3 and 4 Point Bend Fixtures, CortestzhiqianxuNoch keine Bewertungen

- 2014 Speed Report 025 Fortificação de Alimentos Básicos em MoçambiqueDokument39 Seiten2014 Speed Report 025 Fortificação de Alimentos Básicos em MoçambiqueMauro VieiraNoch keine Bewertungen

- Chapter 2-Operations Strategy in A Global Environment Heizer&rDokument10 SeitenChapter 2-Operations Strategy in A Global Environment Heizer&rfireflyzzzNoch keine Bewertungen

- Rossilator PDFDokument4 SeitenRossilator PDFfaviomarchantNoch keine Bewertungen

- Jaw BrochureDokument12 SeitenJaw Brochuremarcosandia1974Noch keine Bewertungen

- World Steel Prices PDFDokument16 SeitenWorld Steel Prices PDFIAmaeyNoch keine Bewertungen

- Printed Circuit BoardDokument25 SeitenPrinted Circuit Boardchristineparpan100% (7)

- Ingersoll Rand07 00Dokument116 SeitenIngersoll Rand07 00texwan_100% (1)

- Seal Cat PDFDokument44 SeitenSeal Cat PDFkarinaerojasNoch keine Bewertungen

- Lista de AccesoriosDokument8 SeitenLista de AccesoriosRONALDNoch keine Bewertungen

- Kaowool Paper 1260Dokument2 SeitenKaowool Paper 1260praveentienNoch keine Bewertungen

- The Performance Meets The Promise: Vectra Series Models GL & XLDokument12 SeitenThe Performance Meets The Promise: Vectra Series Models GL & XLNicolás Villarin100% (1)

- Gas Metal Arc WeldingDokument3 SeitenGas Metal Arc Weldingvarun100% (1)

- A 276Dokument1 SeiteA 276AnuranjanNoch keine Bewertungen

- Ultimate Compressor Oil (POE)Dokument2 SeitenUltimate Compressor Oil (POE)JimNoch keine Bewertungen

- Technical Specifications (Building)Dokument51 SeitenTechnical Specifications (Building)Richard WestonyNoch keine Bewertungen

- Floor PlansDokument25 SeitenFloor PlansLilian Padios Abiog100% (1)

- Mechanical Relaxation of Residual StressDokument120 SeitenMechanical Relaxation of Residual Stressrginunes9044100% (1)

- Garry Thuer & Hendrik VocksDokument12 SeitenGarry Thuer & Hendrik VocksAsturoSuprojoNoch keine Bewertungen

- Basic Engineering DesignDokument4 SeitenBasic Engineering DesignSopi LabuNoch keine Bewertungen

- Fiberex 408 DataSheetDokument1 SeiteFiberex 408 DataSheetMohammed Abdul NaseerNoch keine Bewertungen

- Wright's Eosin Methylene Blue Solution For MicrosDokument2 SeitenWright's Eosin Methylene Blue Solution For Microspieterinpretoria391Noch keine Bewertungen

- Indian Merchants' ChamberDokument11 SeitenIndian Merchants' ChamberAvinash SahuNoch keine Bewertungen

- Roofing: Single Ply Roofing: Modified Bitumen Plastic Fabrication Civil Engineering Tunnelling FlooringDokument2 SeitenRoofing: Single Ply Roofing: Modified Bitumen Plastic Fabrication Civil Engineering Tunnelling FlooringНенад КнежевићNoch keine Bewertungen

- Technical Development Program For Process Performance Engineers, 2008-2009Dokument20 SeitenTechnical Development Program For Process Performance Engineers, 2008-2009vikubhardwaj9224Noch keine Bewertungen

- Cellular Manufacturing ThesisDokument60 SeitenCellular Manufacturing Thesissdfsdfsadfwsfewe100% (1)

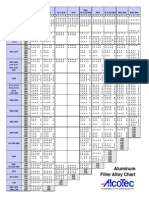

- Aluminum Filler Alloy Selection ChartDokument2 SeitenAluminum Filler Alloy Selection Chartbtgottlieb100% (2)

- Product Design Guide For ForgingDokument31 SeitenProduct Design Guide For ForgingVikram Borkhediya100% (1)

- TDS - Aqua PU Anti-SkidDokument2 SeitenTDS - Aqua PU Anti-SkidHeramb TrifaleyNoch keine Bewertungen

- Block WorkDokument11 SeitenBlock WorkSharad SinghNoch keine Bewertungen