Beruflich Dokumente

Kultur Dokumente

UPVC Storm Water Riser - J2009-005

Hochgeladen von

muhammadukashaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

UPVC Storm Water Riser - J2009-005

Hochgeladen von

muhammadukashaCopyright:

Verfügbare Formate

QA/QC Engineer Construction Manager Project Manager

METHOD STATEMENT

FOR

UPVC STORM WATER RISER

Author: BIMCO

2-APRIL-2009

Prepared by Checked by Reviewed by Approved by

J2009/005_Method Statement_UPVC Storm Water Riser Page 1

Project Name: Oryx Engineering Solutions Center at RLIC

Client: Oryx Engineering Solutions L.L.C.

Main Consultant: Diwan Al Emara Architects, Engineers and Planners

Main Contractor: Al Alia Trading and Contracting Co.

J2009/005_Method Statement_UPVC Storm Water Riser Page 2

S01_ MEP Contract BIMCO

Contents

1. Introduction

2. Scope and Purpose of Method of Statement

3. Objectives

4. Description of Works/Method

4.1. Handing and Storage

4.2. Pre Installation Procedure

4.3. Installation Procedure

4.4. Jointing method (Solvent Cement Welding)

4.5. Water Tightness Test

5. Effectiveness of Construction Drawings

6. Process of Control/Responsibilities

7. List of Main Equipment, Tools, Instruments

8. Health, Safety and Environment Measures

9. Reference Documents

10. Attachments

1.0 Introduction

This Method Statement describe in details the on site installation and testing of

UPVC Storm Water Riser and the requirements of checks to be carried out for Oryx

Engineering Solution Center Project at RLIC.

J2009/005_Method Statement_UPVC Storm Water Riser Page 3

S01_ MEP Contract BIMCO

2.0 Scope and Purpose of Method Statement

This Method Statement covers installation and testing of UPVC storm water riser

work at site. UPVC Pipes and Fittings will be manufactured in accordance with

Doc. No. _____________________________________, and project specification

_________________ and approved drawing.

Materials:

Pipes: 350 mm and smaller size. Unplasticized polyvinyl chloride (UPVC) Pipe

and Fittings: Schedule 40 UPVC DWV pipes and UPVC fittings, with solvent

cement joints, ASTM D2564.

Application:

Location and size of pipes and fittings are as per approved shop drawings.

The works described in this Method Statement covers the installation of UPVC

Pipes and associated fittings such as Tees, Elbows and Reducers, Coupling, Wye,

Double Wye and Roof Drain, etc for storm water riser.

The procedure provides guidance for assessing the activities for installation of

UPVC pipes for storm water riser. This guidance is based on the requirements set

forth in the Safety Requirement Document (SRD) and The Quality Assurance

Program (QAP). Also this Method Statement covered in brief about the installation

procedure with respect to approved shop drawing and the manufacturer

recommendations.

3.0 Objectives

This document provides guidance for the implementation of an effective procedure

for the safe installation of UPVC Storm Water Riser. This includes the following:

The installation of the system: Implementing commitments regarding

the quality of the Installation of UPVC Storm water riser.

Managing and providing supervision and QC to ensure the

installation and related quality control meet the requirements of the

specifications, drawings, and procedures.

Recording all installation and related testing activities.

This procedure will be used, as needed, to provide assurance that construction

J2009/005_Method Statement_UPVC Storm Water Riser Page 4

S01_ MEP Contract BIMCO

4.0 Description of Works/Method

4.1 Handling & Storage

4.1.1 Pipes and fittings will be off loaded in our lay down area prior to

transport to site.

4.1.2 Timber supports of suitable size shall be placed at equal distance

below the pipes.

4.1.3 Pipes shall be stacked on a flat surface free from any sharp objects and

shall be given adequate supports at all times.

4.1.4 Pipes and fittings shall not be stored under direct sun light.

4.1.5 While stacking it shall be ensured that pipes of bigger sizes will be

placed at the bottom and smaller sizes at the top.

4.1.6 Manufacturers recommendations shall be followed, where applicable.

4.1.7 End caps shall be in place until taken out for installation.

4.1.8 Delivery of UPVC pipes and fittings will be checked / inspected by

Contractor QC Engineer to ensure all items on the delivery note are

correct prior to signing. Any shortage or damaged items should be

recorded on the delivery note and reported to the Engineer.

4.2 Preparatory Installation Requirement

4.2.1 All workers to attend Safety induction training on the safe installation

methods by the BIMCO Safety Department.

4.2.2 Ensure that the necessary tools and equipment are available to carry

out the work.

4.2.3 Ensure that all related material (solvent cement, thinner, and cleaner)

are approved make and not expired and are available before carrying

out work.

4.2.4 Prior to commencement of work, areas and access will be inspected to

confirm that installation site area is ready to commence the work, NCI

will be raised.

4.2.5 Site Supervisor and Foreman will carry out a site survey and mark the

route of storm water piping as per approved shop drawings. In the

event that there are any discrepancies or difficulties in executing the

work, these will be brought to notice of Project Engineer for corrective

action.

4.2.6 Coordination with other trades will be carried out while marking the

route of piping.

4.2.7 All relevant documentation (drawings, checklists, method statement,

etc.) and material applicable to particular section of works will be

checked by the Site Engineer / Supervisor prior to commencement of

J2009/005_Method Statement_UPVC Storm Water Riser Page 5

4.3 Installation Procedure

4.3.1. Ensure that the shafts are clear and open. Liase will ATC if necessary.

4.3.2 Ensure that the access for maintenance of pipes in the shaft is provided.

4.3.3 Make sure that the proper working platforms are made for safe working

inside the shaft and all safety PPE are available.

4.3.4 Any cut edges of angles, channels or threaded rods will be painted with

Galvanized Paint/Primer.

4.3.5 Proper materials including pipes, fittings and associated accessories are

withdrawn from stores according to approved shop drawing and good

engineering practices.

4.3.6 Determine the position of supports / hangers for the pipes and mark out on

the concrete surface.

4.3.7 As far as possible, supports for storm water riser shall be fabricated at

BIMCO workshop at site as per approved shop drawing. Fabrication at on

site location will be minimized.

4.3.8 Fix the supports using either self drilling anchor bolts or appropriate size

masonry drill. Ensure threaded rod, angles, clamps, etc are straight, tight

and secure. Only approved support system will be used.

4.3.9 The spacing of the supports for the vertical and horizontal pipes shall be in

accordance with the approved details drawings and applicable standards.

4.3.10 Prior to installation the pipes and fittings will be carefully uplifted by

lifting hoist and will be delivered at correct location.

4.3.11 Pipes are cut to required length and all sharp edges and burrs shall be

removed.

4.3.12 Assemble the pipes and fittings as per approved shop drawing.

4.3.13 Before jointing, the pipes and fittings shall be checked for defects and the

jointing surfaces shall be cleaned thoroughly.

4.3.14 Manufacturers recommendations shall be followed as applicable.

4.3.15 Install the pipes including all accessories as per drawings.

4.3.16 After installation of the pipes, fittings and associated accessories, check

for correct leveling, position and alignment.

4.3.17 Install temporary cap to any open ends of pipes to minimize ingress of

foreign material.

4.4 Jointing Method

Solvent Cement Welding

Ensure that the pipes are cut square before they are joined and that

the inside of pipes is free from any debris.

Spigot and socket to be joined should be carefully examined for

any damage that could create problems in jointing procedure.

The spigot insertion depth to be measured as the depth form the

J2009/005_Method Statement_UPVC Storm Water Riser Page 6

S01_ MEP Contract BIMCO

J2009/005_Method Statement_UPVC Storm Water Riser Page 7

S01_ MEP Contract BIMCO

Lightly roughen the mating surface of the spigot and socket using

emery cloth.

Thoroughly clean again the mating surface using the cleaning fluid

and clean cloth. Ensure that the mating surfaces are clean and dry.

Using recommended size brush, apply an even layer of solvent

cement to the spigot and socket mating surfaces. The cement should be

applied in length wise direction and not in circular motion. For joints

size 3 nominal diameter and above, the cement should be applied

simultaneously to the spigot and socket by two people.

Immediately after applying solvent cement and after ensuring that

the parent pipe is suitable anchored, push the spigot fully home in to the

socket without turning the pipe. The Spigot should be inserted with

steady, continuous motion and held in position from around the mouth of

the socket.

Surplus cement should be cleaned with a dry cloth.

Leave the joint undistributed for five (5) minutes, and then handle

with reasonable care.

4.5 Water Tightness Test

a. Water tightness test is conducted to ensure and prove the tightness of

the joints and ensure there no leaks in the piping system.

b. Ensure that the pipes and fittings are capable of withstanding water

leak test.

c. Water tightness test can be applied to the system in its entirely or in

sections. Once the above is checked and found acceptable, proceed with

the filling water. The system can be filled with water to the point of

overflow. The plugs can be temporarily opened to make sure that all air

has been vented and the water has reached all parts of the system. This is

to ensure that the air form the system is released to avoid the fluctuations

in pressure.

d. Once the water is filled air is vented. All openings in the piping will

be tightly closed from lower end to upper end by pipe plugs or by other

suitable means.

e. No section of pipe or whole system shall be tested to less than the 3

meters of the head of water.

f. Keep the water in the piping or in the portion under the tightness test,

for at least 15 minutes before inspection starts to ensure that joints are

tight at all points.

g. Riser pipe shall be tested in sections of two or three floors at a time

while the system is under pressure; a careful inspection is done on all the

joints by swabbing with a dry tissue.

J2009/005_Method Statement_UPVC Storm Water Riser Page 8

j. Repeat the procedure after attending the leaks (if any).

k. Ensure that the inspections are carried out under similar temperature

conditions to avoid fluctuations in pressure due to variations in ambient

temperature.

l. Record temperature on test sheet.

m. WIR will be raised for witness and inspection.

n. Identification bands/labeling shall be installed before ceiling / wall

closure shall be located at the access panel locations.

5.0 Effectiveness of Construction Drawings

5.1 Determine if the procedures are in conjunction with the pertinent drawings and

attributes are specified and controlled within the limits permitted by the

applicable standard.

5.1.1 Lay out drawing of the Storm Water Riser it is the fundamental

drawing of a storm water riser system.

5.1.2 Installation drawing of the Storm Water Riser system This drawing

shows the location of the supports/hangers.

5.1.3 Support structure drawing This drawing is typical for support

structure as for the Storm Water Riser system supporting.

5.2 Inspection and Recording Requirements

The Engineer should verify that the Supervisor / installer with construction

responsibilities for the Storm Water Riser works is familiar with this Method

Statement and is issued with copies of the inspection checklists.

The Engineer should satisfy procedures provided by QA/QC inspections to

ensure that the storm water riser works meet specified engineering

requirements and drawings. As part of the assessment, the QA/QC Inspection

procedures must ensure a quantitative or qualitative acceptance criteria for

determining the prescribed activities have been accomplished with

satisfactorily level.

The QC inspection personnel, in coordination with site Engineer / Supervisor,

should verify that the quality of the installation of the Storm Water Riser is

within the project design specifications requirements.

J2009/005_Method Statement_UPVC Storm Water Riser Page 9

S01_ MEP Contract BIMCO

5.3 Inspection Guidance

Storm water piping works need to follow strictly established codes and

safety procedures. Care should be taken to ensure that applicable codes and

standards be strictly adhered to during installation.

The Engineer / Supervisor should be familiar with the approved shop

drawings for the Storm Water piping and approved supporting methods

meeting the specification, and must closely coordinate with the construction

provision of other electrical and mechanical services, routings and

elevations; architectural ceiling / headroom levels requirements, and

QA/QC inspection and testing requirements.

Review the implementing procedures and safety standards for installation

provided by the QA/QC. The QA/QC inspectors should verify that the

procedures (1) are approved, and (2) specify the requirements of the design

and/or from the Manufacturers technical manual/s and codes or standards

prescribed by the Client.

5.4 Training and Qualification of Personnel

The Engineer / Supervisor should verify that the safety standards for

sufficient knowledge of the procedures for the installation of \Storm Water

piping. Review any training and qualification records for those individuals

who shall do the task to determine whether they are skilled enough to

follow the procedure before the actual work is carried out. He shall ensure

that the installers are qualified.

6.0 Process of Control/Responsibilities

Project Manager Approving authority for the method

statement

Mandate holder for construction and

responsible for execution of works as per

approved method statement

Construction Manager Review this method statement and

monitor its

Implementation

Mechanical Site Engineer Execute the work

J2009/005_Method Statement_UPVC Storm Water Riser Page 10

S01_ MEP Contract BIMCO

7.0 List of Main equipment, Tools, Instruments

a. Drilling Machine

b. Cutter for UPVC Pipes

c. Tape Measure, plum bob, chalk line, nylon string line

d. Scaffolding

e. Ladder

f. Brush for applying solvent cement

g. Spirit level

h. Test plugs end caps

i. Electric pump (small)

8.0 Health, Safety and Environment Measure

8.1 Preparation

8.1.1 Notify main contractor on the date of delivery.

8.1.2 Ensure all workers involved in the delivery operation put on PPE all

time.

8.1.3 Brief individual worker the roles and responsibilities.

8.1.4 Ensure transporters route is cleared of obstruction.

8.1.5 Ensure designated hoisting area is cleared of obstruction.

8.2 Hoisting

8.2.1 Ensure safe work procedure for lifting operation is observed.

8.2.2 Ensure proper lifting method is being followed.

8.3 Installation

8.3.1 Ensure UPVC pipes for Storm Water Riser have been properly

installed.

8.3.2 Brief individual worker the roles and responsibilities before start the

Work.

8.4 Clean up the work areas

8.4.1 Prevent development of safety hazards.

8.4.2 Remove scrap / waste / balance materials.

8.4.3 Store tools, equipment, and unused materials properly at the end of

the workday.

J2009/005_Method Statement_UPVC Storm Water Riser Page 11

Division Sec. No. Description Version

S01_ MEP Contract BIMCO

8.6 Special Safety Precautions

Use appropriate personal protective equipment (PPE) and follow safe work

practice.

Safety Inspection

It is the responsibility of the Site Engineer and Supervisor to inspect the areas

under their control during complete installation activity. This inspection shall

include the job site cleaning installation and after end of day work.

9.0 Reference Documents

9.1 Specifications and Codes

J2009/005_Method Statement_UPVC Storm Water Riser Page 12

Basic Mechanical Materials and

Methods

Drainage, Waste and Vent Piping

J2009/005_Method Statement_UPVC Storm Water Riser Page 13

Document No. Description Version

9.2 Reference Standards and Publications

J2009/005_Method Statement_UPVC Storm Water Riser Page 14

American Society of Mechanical

ASME B31.9

Engineers

S01_ MEP Contract BIMCO

Uniform Plumbing Code

Description Version

9.3 Attachments

A Inspection and Test Plan

B Inspection Check List

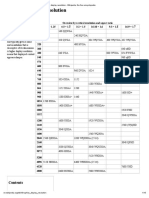

ATTACHMENT A

INSPECTION

AND

TEST PLAN

J2009/005_Method Statement_UPVC Storm Water Riser Page 15

S01_ MEP Contract BIMCO

BIMCO

INSPECTION AND TEST PLAN

Oryx Engineering Solution S01-MEP Works

UPVC STORM WATER RISER

Center at RLIC Report No.

Contractors Name: Al Alia Trad. & Cont. Co. Ref. No.

Package No.: Document No.:

Description of Works: Date:

ACTIVITY

Material Receipt Installation/Alignment Air

Description of

Inspection at Site of Pipes & Fittings & Tightness/Water

Requirements

Store Riser Clamp Support Tightness Test

1 Type of Check Visual Physical Physical

2 Extent of Check Random 100% 100%

Approved Material Approved Shop Approved Shop

Reference Submittal/Manf. Drawing/Specification/ Drawing/

3

Documents Catalogue/Delivery Approved Method Specification/

Note Statement Approved Method

Approved Shop

Approved Material Approved Shop

Drawing/

Acceptance Submittal/Manf. Drawing/Specification/

4 Specification/

Criteria Catalogue/Delivery Approved Method

Approved Method

Note/Test Certificates Statement

Statement

Material Receipt Inspection Request Inspection

5 Format of Records

Inspection (MIR) (WIR)/Checklist Request

6 Verification by - - -

a. BIMCO Inspection Inspection Inspection

b. AT Inspection/Document

Hold Hold

C Review

J2009/005_Method Statement_UPVC Storm Water Riser Page 16

c. Con

Document Review Witness Witness

sultant

d. Reg

- - -

ulatory

Remarks:

Checked by: Inspected by: Inspected by: Witnessed by:

BIMCO Site Engr. BIMCO QA/QC Engr. ATC MEP Engr. Consultant Oryx

ATTACHMENT B

INSPECTION

CHECKLIST

J2009/005_Method Statement_UPVC Storm Water Riser Page 17

S01_ MEP Contract BIMCO

S01_ MEP Contract BIMCO

INSPECTION CHECKLIST

UPVC STORM WATER RISER BIMCO

Oryx Engineering

CL Form No.

Solution Center at RLIC

Contractors Name: Al Alia Trad. & Cont. Drawing Ref. No.:

Package No.: Material Submittal No.:

Description of Works: Prepared by: Date:

Location: Inspection Requested Date: Time:

Inspection Date

ITEM DESCRIPTION Accept Reject Hold

(initials)

A. Materials

a. Pipes Materials

b. Pipe size

c. Fittings

d. Sealant

e. Others

B. Installation

1. Level/Coordinate

2. Method of Installation

3. Pipe Jointing (Solvent

Cement/sealant)

4. Accessories Installation

5. Pipe Supports

6. Riser Clamp & Supports

J2009/005_Method Statement_UPVC Storm Water Riser Page 18

C. Test

1. Water Tightness Test

S01_ MEP Contract BIMCO

2. Air Tightness Test

3. Others

Remarks:

Checked by: Inspected by Inspected by Witness by

BIMCO BIMCO ATC

Consultant Oryx

(Site Engr.) (QA/QC Engr.) (MEP Manager)

Signature

Name

Date

J2009/005_Method Statement_UPVC Storm Water Riser Page 19

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Phase ShifterDokument7 SeitenPhase ShifterNumanAbdullahNoch keine Bewertungen

- PESTLE Analysis - KenyaDokument4 SeitenPESTLE Analysis - KenyaJoseph0% (1)

- T-Spice User's Guide: Release 16.3 June 2015Dokument579 SeitenT-Spice User's Guide: Release 16.3 June 2015Laxmi GuptaNoch keine Bewertungen

- PESTLE Analysis Patanjali Ayurved LTDDokument7 SeitenPESTLE Analysis Patanjali Ayurved LTDvaidehi50% (2)

- A Power Point Presentation On Staad - ProDokument26 SeitenA Power Point Presentation On Staad - ProAbu BindongNoch keine Bewertungen

- HTTP Download - Yamaha.com API Asset File Language En&site Au - YamahaDokument5 SeitenHTTP Download - Yamaha.com API Asset File Language En&site Au - Yamahaericwc123456Noch keine Bewertungen

- 2007 DB Drag FinalsDokument4 Seiten2007 DB Drag FinalsTRELONoch keine Bewertungen

- 10 MM Manifold Mount Solenoid Valve: Product SpecificationsDokument6 Seiten10 MM Manifold Mount Solenoid Valve: Product Specificationshüseyin vururNoch keine Bewertungen

- S9300&S9300E V200R001C00 Hardware Description 05 PDFDokument282 SeitenS9300&S9300E V200R001C00 Hardware Description 05 PDFmike_mnleeNoch keine Bewertungen

- Article 17 Ijaet Volii Issue IV Oct Dec 2011Dokument10 SeitenArticle 17 Ijaet Volii Issue IV Oct Dec 2011Mustapha Maiz Hadj AhmedNoch keine Bewertungen

- Product Responsibilities in RA 03-2017Dokument2 SeitenProduct Responsibilities in RA 03-2017claudedNoch keine Bewertungen

- Micronta 12VDC Power Adapter 273-1653A InstructionsDokument2 SeitenMicronta 12VDC Power Adapter 273-1653A Instructions240GL guyNoch keine Bewertungen

- Syllabus 330C SystemsDokument1 SeiteSyllabus 330C SystemsDANIEL VARGAS RODRIGUEZNoch keine Bewertungen

- Abbbaileyinfi 90Dokument17 SeitenAbbbaileyinfi 90Vipper80Noch keine Bewertungen

- Surge Arresters PP 7Dokument9 SeitenSurge Arresters PP 7gabriela69sNoch keine Bewertungen

- A Neural Network Model For Electric PDFDokument6 SeitenA Neural Network Model For Electric PDFR Adhitya ArNoch keine Bewertungen

- Profile of The Aerospace Industry in Greater MontrealDokument48 SeitenProfile of The Aerospace Industry in Greater Montrealvigneshkumar rajanNoch keine Bewertungen

- 1 Chapter1 Introduction V5.5a1Dokument13 Seiten1 Chapter1 Introduction V5.5a1Alejandro LaraNoch keine Bewertungen

- Graphics Display Resolution - Wikipedia, The Free EncyclopediaDokument15 SeitenGraphics Display Resolution - Wikipedia, The Free EncyclopediaKarun KumarNoch keine Bewertungen

- REA 101 Proteccion de Arco EléctricoDokument64 SeitenREA 101 Proteccion de Arco EléctricoIngJGMNoch keine Bewertungen

- Topic 5 FB Stability PDFDokument26 SeitenTopic 5 FB Stability PDFAbdulrahman NasserNoch keine Bewertungen

- Sports Collection CatalogueDokument31 SeitenSports Collection CataloguesitarazmiNoch keine Bewertungen

- W L 1176Dokument1 SeiteW L 1176shama093Noch keine Bewertungen

- Operator'S Manual: E-Series Ultraviolet Hand LampsDokument9 SeitenOperator'S Manual: E-Series Ultraviolet Hand LampsGuiss LemaNoch keine Bewertungen

- Bloomberg Certification FAQ BMC (Bloomberg Market Concepts) : Goizueta Business LibraryDokument3 SeitenBloomberg Certification FAQ BMC (Bloomberg Market Concepts) : Goizueta Business LibrarySarah Raquel Bozo Herrera100% (1)

- Case StudyDokument80 SeitenCase Studybravo deltafoxNoch keine Bewertungen

- Test Procedure and MethodDokument1 SeiteTest Procedure and MethodkmiqdNoch keine Bewertungen

- Diamond 53 BrochureDokument3 SeitenDiamond 53 Brochuregipanaul100% (1)

- Congelador - Frigidaire GLFC1326FW1 - Man - Eng - PartsDokument7 SeitenCongelador - Frigidaire GLFC1326FW1 - Man - Eng - Partsfelix bazanNoch keine Bewertungen

- How Can The European Ceramic Tile Industry Meet The EU's Low-Carbon Targets A Life Cycle Perspective (Ros-Dosda - España-2018)Dokument35 SeitenHow Can The European Ceramic Tile Industry Meet The EU's Low-Carbon Targets A Life Cycle Perspective (Ros-Dosda - España-2018)juan diazNoch keine Bewertungen