Beruflich Dokumente

Kultur Dokumente

Java Heat

Hochgeladen von

abdallah samadCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Java Heat

Hochgeladen von

abdallah samadCopyright:

Verfügbare Formate

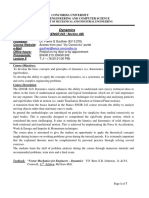

Proceedings of the

5th ASME/JSME Thermal Engineering Joint Conference

March 15-19, 1999, San Diego, California

AJTE99-6229

HEAT TRANSFER CODES FOR STUDENTS IN JAVA

W.J. Devenport,* J.A. Schetz** and Yu. Wang***

Virginia Polytechnic Inst. and State Univ.

Blacksburg, VA

devenport@aoe.vt.edu

Keywords: Heat transfer education, Web-based teaching aids, JAVA.

ABSTRACT

Simple JAVA computer codes for student use solving the T temperature

homework problems in an undergraduate heat transfer text on Te(x) edge temperature distribution

a PC have been developed. JAVA was selected so that the Tw(x) wall temperature distribution

codes could be made available in a platform-independent form u streamwise velocity

on the Internet. At this point, there are four codes for: 1) Ue(x) edge velocity distribution

steady, conduction in two dimensions by finite differences, 2) Uinf freestream velocity

unsteady conduction in two dimensions by finite differences, v transverse velocity

3) laminar boundary layers with heat transfer by an integral x axial and streamwise coordinate

method, and 4) turbulent boundary layers with heat transfer by y transverse coordinate

an integral method. A brief description of each code precedes

*/wdp/dx Clauser pressure gradient parameter

the operating instructions. Also, a default input for a typical

boundary layer thickness

example and results for that case are presented.

* displacement thickness

momentum thickness

c conduction thickness

NOTATION

viscosity

cp specific heat

kinematic viscosity

Cf skin friction coefficient

density

H */ shape factor

w wall shear

k thermal conductivity

Nu Nusselt number

p pressure

INTRODUCTION

Pr Prandtl number In this paper, we present simple JAVA computer codes

qw wall heat flux that are intended for student use solving the homework

r(x) body thickness distribution problems in a standard undergraduate heat transfer text such as

Re Reynolds number Holman (1986) or White (1988) and other similar problems on

s(x) surface distance a PC or Work Station. The JAVA language (see

St Stanton number www.javasoft.com) was selected so that such codes could be

_____________________________________________ made conveniently available in a platform-independent form

*Associate Professor of Aerospace and Ocean Engineering, on the Internet. These codes are not intended for use by

Member ASME working professionals in the field. The goal has been to keep

** J. Byron Maupin Professor of Aerospace and Ocean the formulation, logic and programming as simple as possible

Engineering, Fellow ASME so that the student can easily grasp the flow of the

*** Graduate Student

1 Copyright 1999 by ASME

calculations. Thus, primitive variables (T,u,v); (x,y,t) are one need only pick the length of the flow of interest and the

employed with no transformations. streamwise grid size, dx. That grid must be fine enough to

At this point in the development, there are four separate accurately represent the variations in the boundary conditions

codes for: 1) steady, heat conduction in two dimensions by such as Ue(x), Te(x) and Tw(x).

finite differences, 2) unsteady heat conduction in two

dimensions by finite differences, 3) laminar boundary layers PROGRAM STDYCOND

with heat transfer by an integral method, and 4) turbulent This program treats STeaDY CONDuction heat transfer

boundary layers with heat transfer by an integral method. All in two spatial directions by a numerical method. The thermal

the codes presume constant values of the density and conductivity is taken as constant. Central finite differences are

thermophysical properties, so they are limited to low-speed used to replace the differentials in LaPlaces Equation which

cases with modest temperature differences. A brief description governs such problems. This results in a system of algebraic

of each code precedes the operating instructions. Also, a equations, one at each interior grid point relating the

default input for a typical example and results for that case are temperature at that point to that at four neighboring points.

presented and discussed. The system is solved by the Gauss-Seidel iteration technique.

These codes are meant to relieve the student of the time See Holman (1986) or White (1988) for a description of the

consuming burden of writing, modifying and/or debugging general approach.

numerous FORTRAN or other similar codes during a heat The user can specify either temperature or heat flux as a

transfer course. The hope is to thereby leave sufficient time boundary condition at each grid point on the boundary.

and energy for the working of actual heat transfer problems of A default input set is included for the following problem.

reasonable complexity to build understanding and intuition. Example Steady, 2D Heat Conduction Problem: The problem

The student is not, however, relieved of the burden to think. is steady heat conduction in a 2X1 ellipse of aluminum. The

One should always estimate the answer the computer solution temperature on the top half of the boundary is 100C, and that

is expected to yield. For example, one could use the exact on the bottom half is 50C. What is the temperature pattern in

solution for a simpler heat conduction problem to crudely the interior?

estimate the level of the surface heat flux to be expected in a Solution:

more complicated case. The student is the analyst, not the First, note that the solutions for steady heat conduction

computer, and he or she is responsible for producing and problems with constant properties are actually independent of

interpreting the correct answer. the values of the thermophysical properties; LaPlaces equation

Conduction heat transfer problems require specification doesnt contain any coefficients.

of the geometry and boundary and initial conditions. The 2X1 ellipse is represented in this sample input with a

Thermophysical property values of thermal conductivity, k, relatively coarse grid to keep the file size modest. Look at Fig.

specific heat, cp ,and density, , are needed. Next, the grid 1. When you launch the Applet, the input geometry and

must be created. boundary conditions for the temperature are shown in the

For any boundary layer convection heat transfer window in the lower left-hand corner. The first two entries are

problem, one must specify the fluid through density, , the grid spacings in the x and y directions. This is followed by

conductivity, k, specific heat, cp , and viscosity, , or perhaps four columns of input with x, y and T for each boundary

just kinematic viscosity, . The next information needed point. The 1s in the last column indicate that this is a

would be the freestream velocity Uinf and the inviscid edge temperature boundary condition. (Use 2 for a heat flux

velocity distribution, Ue(x). Also, the wall temperature, Tw(x), boundary condition.) The region and the grid are displayed

or the wall heat transfer distribution and Tinf and Te(x) are above the input panel. The solution is iterative, and the initial

required. guess for the temperature in the interior is given below this

Finally, the computational region and grid must be window. Push the COMPUTE button at the bottom and see the

selected. The differential methods require the height and the results in the simple isotherm plot in the upper right-hand

length of the computational region. The codes here are all corner. The tabular output is in the window in the lower right-

based on untransformed and unmapped forms of the equations hand corner. The tabular output can also be easily copied into

for simplicity. Thus, cartesian grids are used throughout. For EXCEL for printing and plotting. Below that window, one can

heat conduction problems, the computational region must be at see the number of iterations required to obtain a converged

least as large as the body of interest in all dimensions. The solution. One can change the initial guess for the temperature

grid spacing dx and dy must be selected so that the geometry in the interior and see how that affects the iterations required.

and the variations in the boundary conditions can be It is very easy to change the temperatures on the

accurately represented. In the interests of simplicity, we have boundary and recompute the temperature distribution. To

allowed only geometries where the boundaries fall on grid change the grid spacing and/or the geometry, it is necessary

points. It is possible to adequately represent very complicated for the user to create an input file working offline. An EXCEL

geometries within that restriction by employing a fine grid. spreadsheet is very convenient for that task. One can then cut

For the integral methods for heat convection included here, and paste the new input data into the input panel.

2 Copyright 1999 by ASME

PROGRAM UNSTDYCOND Spalding (1958) for a description of the technique. The

Here, we solve UNSTeaDY CONDuction heat transfer method is limited to flows with constant thermophysical

problems in two spatial directions by a numerical method. The properties and a constant wall temperature. It can treat cases

thermal conductivity is taken as constant. Central finite with sharp or blunt leading edges, planar or axisymmetric

differences are used to replace the spatial differentials in the geometries and arbitrary inviscid velocity variations.

2D Heat Equation, which governs such problems. The time A default input set is included for the following flow

derivative is approximated with an implicit finite difference problem.

representation. Refer to Holman (1986) or White (1988) for Example Laminar Integral Method Problem: Consider 2D

details of the general approach. laminar flow of a fluid with a kinematic viscosity = 1.6x10-5

The user can specify either temperature or heat flux as a m2/s, cp = 1005 J/kg/K, = 1.2 kg/m3 and Prandtl number Pr =

boundary condition at each grid point on the boundary. Since 0.72 at Uinf = 2.0 m/s over a surface that is a flat plate from the

these cases are unsteady, an initial temperature distribution at leading edge to x = 1.0 m. At that station, a ramp begins that

every grid point on the boundary and in the interior must be produces an inviscid velocity distribution Ue(x) = 2.1 - x/10, m/s.

given. This is an adverse pressure gradient, since Ue is decreasing so

A default input set is included for the problem described that p increases. Choose the wall to freestream temperature

below. difference, Tw - Te = 20C. Calculate the boundary layer

Example Unsteady, 2D Heat Conduction Problem: Let us development over this surface up to x = 2.0 m. Does the flow

consider an unsteady equivalent of the steady problem treated separate? Note how the dimensionless wall shear, Cf, and

above. The problem is now unsteady heat conduction in a 2X1 dimensionless heat transfer, Nu, vary in the constant pressure and

ellipse of aluminum. The temperature over the whole region is varying pressure regions along the surface.

100C at time t = 0. For t > 0, the temperature on the top half Solution:

of the boundary is held fixed at 100C, and that on the bottom We must provide input data for the kinematic viscosity as

half is set to 50C. What is the temperature pattern in the = 1.6e-5, Prandtl number Pr = 0.72, cp = 1005, = 1.2 and the

interior as a function of time? How long does it take to freestream velocity as Uinf = 2.0. Select NMAX = 41 to give dx =

approach steady state? 0.05.

Solution: The body thickness distribution, r(x), can be specified. The

In this case, the thermophysical properties are needed, code will then calculate the surface distance along the body. The

because the thermal diffusivity, k/cp, enters into the Heat default is r(x) = 0.0. Also, one must choose either a planar or

Equation. The values for aluminum at about 75C are shown in axisymmetric geometry.

the column at the lower left of Fig. 2. The geometry and Finally, the inviscid velocity distribution is required. Since

boundary conditions are given in the panel to the left in the this case has a bi-linear edge velocity variation, velocities at only

same format as for the steady calculation above. The region a few points including xinit and xfin need to be specified to define

and the grid are displayed above the input panel. the distribution. The wall to edge temperature distribution Tw Te

Push the RUN button at the bottom and watch the results is specified in the same way.

develop as a function of time in the simple isotherm plot in the The window in Fig. 3 shows the input information for the

upper right-hand corner. The tabular output is in the window default case. On the left are two panels containing the input data

in the lower right-hand corner. The elapsed time is shown in for this case. The input data in the far left panel can be changed

the line below the output table. The results shown in Fig. 2 are by selecting the item to be changed with the menu button,

for a time well before steady state is reached for this problem. entering the new value in the slot below and pushing SET. The

The FORWARD button at the bottom advances the solution input data in the next panel to the right can be changed in a

one time step at a time. similar manner. One might wish to change the dimensionless

There is an analogy between iterations to find a steady edge velocity distribution, Ue/Uinf , the body shape and/or the

solution as in the sample problem above and time steps in an temperature difference. All that is required is to enter or modify

unsteady problem approaching a steady-state solution as in sets of values for x, r, Ue/Uinf and Tw-Te in the panel below and

this case. If the initial guess used in obtaining the steady push SET. The code will fit a spline through the points used as

solution is the same as the initial condition for the unsteady input.

problem, the correspondence is close and one could watch the Then, press the START button and watch the integral

solutions develop iteration-by-iteration or time step by time quantities and the skin friction and heat transfer results develop

step and compare the behavior. in the graphs on the right. Use the panel in the upper right hand

corner to select which sets of results are displayed. The window

PROGRAM WALZHT given in Fig. 3 shows the results at the end of the calculation.

This program is an implementation of the Thwaites- Tabular values of the output can be accessed in the panel

WALZ and Smith-Spalding integral methods for indicated. One can scroll up and down in the table with the slider

incompressible, laminar boundary layer flows with Heat bar and left and right with the cursor. Some browsers display the

Transfer. Refer to Sec. 2-3-2 in Schetz (1993) and Smith and table starting at the bottom, so it may be necessary to scroll up to

3 Copyright 1999 by ASME

see the column headers. The tabular output can also be easily program so that the student can plot them in a presentable

copied into EXCEL for printing and plotting. form.

This compatibility with the 'clipboard' and other native

PROGRAM MOSESHT applications is a very important element of the programs, since

Here, we present a code for the MOSES integral method for 2D, it largely overcomes the limitation of JAVA programs not

incompressible, turbulent boundary layers extended to include being able to read or write files on the hard disk. It also opens

Heat Transfer with the approximate integral energy equation up the possibility of developing a suite of applets that the

method of Ambrok as described in Kays and Crawford (1980). student can use in combination to investigate the solution to

Refer to Sec. 7-7 in Schetz (1993) for the theory behind the more general problems. For example, we are in the process of

original Moses method. developing a panel code applet and an applet to determine

The method is limited to flows with constant transition location given laminar boundary layer parameters as

thermophysical properties. It can treat cases with arbitrary a function of streamwise distance. Given a geometry in the

inviscid velocity and wall temperature variations. form of a paneling scheme, the panel code will provide edge

Example Turbulent Integral Method Problem: Consider 2D velocity and coordinates as table output, and these may then

turbulent flow of a fluid with a kinematic viscosity = 1.0x10-5 be pasted into the WALZHT program and a laminar boundary

m2/s, Prandtl number Pr = 5, cp = 4187, = 1.2 at Uinf = 10.0 m/s layer computed. Results from WALZHT may then be pasted

over a surface that is a flat plate from x = 0.0 to 5.0 m. Calculate into the transition calculator whose output is used to initialize

the boundary layer to x = 7.0 m assuming a simple inviscid one of the turbulent boundary layer applets.

velocity distribution Ue(x) = 10 m/s = constant. The temperature The current suite of codes can be found under Heat

difference is 10K; what is the heat transfer? Transfer Applets at: http://www.engapplets.vt.edu. Primary

Solution: candidates for upgrades and further codes in the near future are

We must input = 1e-5, Pr = 5, cp = 4187, and = 1.2. the addition of heat generation to the conduction codes new

Since the first part of the flow is over a flat plate, the simple codes for numerical solution of compressible, laminar and

integral solution (see Sec. 7-7 in Schetz, 1993) can be used turbulent boundary layers and one for radiation heat transfer.

giving = 0.0857 m. Take St = 6.89e-4 at the initial station.

Also, at the initial station the pressure gradient parameter = 0. ACKNOWLEDGEMENT

Pick NMAX = 21 corresponding to dx = 0.10 m, which is William Devenport acknowledges the support of the

about the size of the initial boundary layer thickness. National Science Foundation under grant DUE-9752311

This case has a simple edge velocity variation, so velocities

and temperature differences can be specified at only two points,

at xinit and xfin. REFERENCES

The two panels on the left in Fig. 4 contain the input data Holman, J.P., 1986, Heat Transfer, McGraw-Hill, New York,

for this case. The input data in the far left panel can be changed NY.

by selecting the item with the menu button, entering the new Kays, W.M. and Crawford, M.E., 1980, Convective Heat and

value in the slot below and pushing SET. The input data in the Mass Transfer, McGraw-Hill, New York, NY.

next panel to the right can be changed in a similar manner. The Schetz, J.A., 1993, Boundary Layer Analysis, Prentice Hall,

user can modify the dimensionless edge velocity distribution, Englewood Cliffs, NJ.

Ue/Uinf and/or the temperature difference, Tw-Te. All that is Smith, A.G. and Spalding, D.B., 1958, Heat Transfer in a

necessary is to enter or modify sets of values for x and Ue/Uinf Laminar Boundary Layer with Constant Properties and

and Tw-Te in the panel below and push SET. Constant Wall Temperature, Journal of the Royal

Now, press the START button and watch the integral Aeronautical Society, Vol. 62, pp. 60-64.

quantities and the skin friction, heat transfer develop in the White, F.M., 1988, Heat and Mass Transfer, Addison-Wesley

graphs on the right. Use the panel in the upper right hand corner Publishing Co., Reading, MA.

to select which sets of results are displayed. The window in Fig.

4 shows the results at the end of the sample calculation. Again,

tabular values of the output can be accessed in the panel

indicated, and one can scroll up and down in the table with the

slider bar and left and right with the cursor.

DISCUSSION

All of these programs make use of tabular input (of edge

velocity and coordinates) and tabular output (of boundary

layer parameters and profiles). Data may be copied into or out

of these tables using standard cut/paste/copy operations. For

example, results may be pasted into EXCEL or a similar

4 Copyright 1999 by ASME

Figure 1. Sample input and output for the default case from the STDYCOND code.

Figure 2. Sample input and output for the default case from the UNSTDYCOND code.

5 Copyright 1999 by ASME

Figure 3. Sample input and output for the default case from the WALZHT code.

Figure 4. Sample input and output for the default case from the MOSESHT code.

6 Copyright 1999 by ASME

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Internet Phone Services Simplified (VoIP)Dokument176 SeitenInternet Phone Services Simplified (VoIP)sumanth83137Noch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Plant Management TafskillsDokument4 SeitenPlant Management TafskillsTHEOPHILUS ATO FLETCHERNoch keine Bewertungen

- 13 Ways The Coronavirus Pandemic Could Forever Change The Way We WorkDokument20 Seiten13 Ways The Coronavirus Pandemic Could Forever Change The Way We WorkAbidullahNoch keine Bewertungen

- 5 - Sales PlanningDokument26 Seiten5 - Sales PlanningSaba Amir GondalNoch keine Bewertungen

- Kumara SwamiyamDokument21 SeitenKumara SwamiyamVijey KumarNoch keine Bewertungen

- 04 HSE Inspection ChecklistDokument2 Seiten04 HSE Inspection ChecklistAjay Hazarika100% (2)

- ENGR 243 Course Outline-Summer 2017Dokument7 SeitenENGR 243 Course Outline-Summer 2017abdallah samadNoch keine Bewertungen

- Polyimide Insulated Flexible Heaters Data SheetDokument4 SeitenPolyimide Insulated Flexible Heaters Data Sheetabdallah samadNoch keine Bewertungen

- Fortran To MATLAB Conversion BenefitsDokument1 SeiteFortran To MATLAB Conversion Benefitsabdallah samadNoch keine Bewertungen

- Introduction To FT N 95Dokument45 SeitenIntroduction To FT N 95Guilherme Leal0% (1)

- Introduction To FT N 95Dokument11 SeitenIntroduction To FT N 95abdallah samadNoch keine Bewertungen

- We Freeze To Please A History of NASA's Icing Research TunnelDokument202 SeitenWe Freeze To Please A History of NASA's Icing Research Tunnelabdallah samadNoch keine Bewertungen

- Final Crash Booklet Engr251Dokument8 SeitenFinal Crash Booklet Engr251abdallah samadNoch keine Bewertungen

- Concordia Guide For Food HandlersDokument18 SeitenConcordia Guide For Food Handlersabdallah samadNoch keine Bewertungen

- Concordia Guide For Food HandlersDokument18 SeitenConcordia Guide For Food Handlersabdallah samadNoch keine Bewertungen

- Numerical Simulations For Ice Accretion On Rotors Using New Three-Dimensional Icing ModelDokument15 SeitenNumerical Simulations For Ice Accretion On Rotors Using New Three-Dimensional Icing Modelabdallah samadNoch keine Bewertungen

- STB9NK60Z, STP9NK60Z, STP9NK60ZFPDokument19 SeitenSTB9NK60Z, STP9NK60Z, STP9NK60ZFPyokonakagimaNoch keine Bewertungen

- 100 Free Fonts PDFDokument61 Seiten100 Free Fonts PDFzackiNoch keine Bewertungen

- April 24, 2008Dokument80 SeitenApril 24, 2008Reynaldo EstomataNoch keine Bewertungen

- 4th Party LogisticsDokument3 Seiten4th Party Logisticsch_salmanNoch keine Bewertungen

- Assessment Task 1: Written Questions 1. Identify and Describe Five Common Components of A Business PlanDokument6 SeitenAssessment Task 1: Written Questions 1. Identify and Describe Five Common Components of A Business PlanJoanne Navarro AlmeriaNoch keine Bewertungen

- Manual de Serviços QQ PDFDokument635 SeitenManual de Serviços QQ PDFLéo Nunes100% (1)

- Penn State: The Dickinson School of LawDokument88 SeitenPenn State: The Dickinson School of LawHafiz UmmarNoch keine Bewertungen

- BA Trolley AMC PO Vijay Sabre Cont - PrintDokument7 SeitenBA Trolley AMC PO Vijay Sabre Cont - PrintParag ChandankhedeNoch keine Bewertungen

- Contracts Act, 2010Dokument59 SeitenContracts Act, 2010Sam KNoch keine Bewertungen

- How To Use The R Software: July 2019Dokument28 SeitenHow To Use The R Software: July 2019Paul GokoolNoch keine Bewertungen

- Variance of A SinusoidDokument22 SeitenVariance of A SinusoidrzalshNoch keine Bewertungen

- Edu 637 Lesson Plan Gallivan TerryDokument11 SeitenEdu 637 Lesson Plan Gallivan Terryapi-161680522Noch keine Bewertungen

- Transportation Problem 2Dokument11 SeitenTransportation Problem 2Chasity WrightNoch keine Bewertungen

- Solution: Wireshark Lab: HTTPDokument7 SeitenSolution: Wireshark Lab: HTTPHaoTian YangNoch keine Bewertungen

- Mystique-1 Shark Bay Block Diagram: Project Code: 91.4LY01.001 PCB (Raw Card) : 12298-2Dokument80 SeitenMystique-1 Shark Bay Block Diagram: Project Code: 91.4LY01.001 PCB (Raw Card) : 12298-2Ion PetruscaNoch keine Bewertungen

- Power GREPDokument392 SeitenPower GREPCeles NubesNoch keine Bewertungen

- 17 Farley Fulache Vs ABS-CBN G.R. No. 183810Dokument7 Seiten17 Farley Fulache Vs ABS-CBN G.R. No. 183810SDN HelplineNoch keine Bewertungen

- Debugging With The PL/SQL Debugger: PhilippDokument51 SeitenDebugging With The PL/SQL Debugger: PhilippBenjytox BenjytoxNoch keine Bewertungen

- Asap 2020Dokument21 SeitenAsap 2020KarenNoch keine Bewertungen

- 10 Me 42 BDokument144 Seiten10 Me 42 BdineshNoch keine Bewertungen

- 04 Handout 1 (Midterms)Dokument14 Seiten04 Handout 1 (Midterms)Emmanuel DelarosaNoch keine Bewertungen

- Report On PesoDokument10 SeitenReport On PesoAerish RioverosNoch keine Bewertungen

- 4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactDokument48 Seiten4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactAlfred TsuiNoch keine Bewertungen

- 8 - Surface Mining - Wire - RopeDokument11 Seiten8 - Surface Mining - Wire - RopeSuelen Barbosa Sdrill do BrasilNoch keine Bewertungen