Beruflich Dokumente

Kultur Dokumente

Bioethanol - Fuel or Feedstock

Hochgeladen von

Adamu OnakpaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bioethanol - Fuel or Feedstock

Hochgeladen von

Adamu OnakpaCopyright:

Verfügbare Formate

Journal of Chemical Technology and Biotechnology J Chem Technol Biotechnol 82:329333 (2007)

Perspective

Bioethanol: fuel or feedstock?

Jeppe Rass-Hansen, Hanne Falsig, Betina Jrgensen and Claus H Christensen

Center for Sustainable and Green Chemistry, Department of Chemistry, NanoDTU, Technical University of Denmark, DK-2800 Kgs. Lyngby,

Denmark

Abstract: Increasing amounts of bioethanol are being produced from fermentation of biomass, mainly to counteract

the continuing depletion of fossil resources and the consequential escalation of oil prices. Today, bioethanol is

mainly utilized as a fuel or fuel additive in motor vehicles, but it could also be used as a versatile feedstock

in the chemical industry. Currently the production of carbon-containing commodity chemicals is dependent on

fossil resources, and more than 95% of these chemicals are produced from non-renewable carbon resources. The

question is: what will be the optimal use of bioethanol in a longer perspective?

2007 Society of Chemical Industry

Keywords: bioethanol; fuel; feedstock

SETTING A NEW SCENE high-value commodity chemicals and fuels currently

Growing demands for CO2 -neutral transportation available from fossil resources. There could even

fuels and the desire to achieve a reduced dependence be some advantages using biomass compared to

on fossil resources have been the major driving fossil fuels as a feedstock, e.g., for production of

forces for the substantial increase in the amounts certain oxygenated chemicals since introduction of

of bioethanol produced by fermentation of biomass. oxygen functionalities into hydrocarbons can be rather

An interesting question is whether the optimal use of difficult, whereas many products derived from biomass

bioethanol is as a fuel, or as a feedstock for producing already contain some oxygen.4 However, this also

higher-value chemical products. entails an increase in production costs for some of the

The vast majority of all fuels and carbon-containing non-oxygen-containing products, such as gasoline.

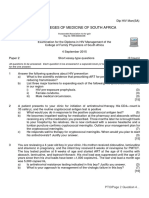

chemicals are produced from fossil resources. Studies Figure 1 illustrates that, in relative terms, it is

predict that most kinds of fossil resources will be possible to produce some chemicals more easily and in

depleted within the next century.1 Furthermore the fewer steps from biomass than from fossil resources,

combustion of fossil fuels causes elevated levels of whereas others are less readily available.5 Thus, fossil

greenhouse gases (GHG) in the atmosphere, which and renewable resources are not necessarily equally

could possibly lead to global warming.2,3 As a useful starting materials for all possible products. In

consequence, society must gradually change from an this context, it is particularly important to note that

economy based on fossil resources to one based on

sustainable resources. Here, biomass could have a

significant role to play. In Fig. 1, the price for a range

of selected fuels and chemicals produced from fossil

or renewable resources are indicated. Obviously, the

costs of the raw materials, both fossil and renewable,

depend on many factors and therefore the scale is

only approximate. From these raw materials it is

possible to produce all the chemicals needed in society.

The relevant transformations are typically catalytic

reactions, and the cost of the various fuels and

chemicals is largely governed by the cost of the raw Figure 1. Indication of relative prices for a range of selected

chemicals produced from either renewable or fossil resources. The

material and the efficiency of the involved processes. raw materials are shown in italics and the remaining fuels and

It is noteworthy that with the proper technology it chemicals are typically produced in one or more process steps

is possible to convert biomass to essentially all the starting from fossil or renewable resources.

Correspondence to: Claus H Christensen, Center for Sustainable and Green Chemistry, Department of Chemistry, NanoDTU, Technical University of Denmark,

DK-2800 Kgs. Lyngby, Denmark

E-mail: chc@kemi.dtu.dk

(Received 9 October 2006; revised version received 18 November 2006; accepted 23 November 2006)

DOI: 10.1002/jctb.1665

2007 Society of Chemical Industry. J Chem Technol Biotechnol 02682575/2007/$30.00

Jeppe Rass-Hansen et al.

RENEWABLE FUELS

In many countries, ethanol is used as an additive to

gasoline. In particular, Brazil and the United States

have invested significant resources in using blends of

ethanol and gasoline as a fuel for motor vehicles (with

internal combustion engines). Today, around 2% of

the total transportation fuels are covered by bioethanol

in the United States.7 The US Department of Energy

has set a goal of replacing 30% of transportation

fuels with bioethanol and biodiesel by 2025.7 Many

other countries are also producing or planning to

produce ethanol from biomass for use as a motor

fuel. The European Union has established a goal

of 5.75% biomass-derived transportation fuels by

December 2010.7 The use of fuel ethanol has been

quite successful in Brazil, where it is produced at a very

Figure 2. Corn/oil price ratio during in the last part of the 20th

century (data from www.eia.doe.gov or www.lefflercom.com).

low cost by fermentation of sugarcane. In the United

States corn is the dominant biomass feedstock for

production of ethanol, and in the EU straw and other

agricultural wastes are the preferred types of biomass

for ethanol production. It is, however, somewhat more

the figure does not show the amount of each chemical

difficult to obtain a high conversion to ethanol from

produced. For instance, it is not currently possible to

these types of biomass, resulting in much higher

produce the worlds need for ethylene from biomass,

production costs of bioethanol in Europe.

because the production of ethylene is about three times

The renewable energy content for production of

as high as the production of bioethanol, which would bioethanol from corn with current technology was

be the most likely feedstock for ethylene production in recently estimated to be between 5% and 26%, where

a renewable economy. the non-renewable energy used in the production

In an evaluation of the usefulness of renewable was mainly contributed by coal and natural gas.8

resources compared to fossil resources as possible However, currently the energy balance for bioethanol

sources of fuels and chemicals, the cost of the production is quite controversial. Anyhow, an increase

feedstocks plays a central role. Therefore, it is in the renewable energy content and a significant

very interesting to note that the price of biomass reduction in GHG emissions can be expected by use

relative to oil has decreased more than 10 times of gene-modified starch-rich non-food biomass and/or

over the last 60 years, as shown in Fig. 2 (data from second-generation fermentation plants with improved

www.eia.doe.gov or www.lefflercom.com). The prices conversion of lignocellulose. First-generation plants

of the products derived from renewable resources use only the sugar and the starch in the biomass

are sensitive to technological improvements of the material and are therefore only highly effective with

production process, probably more so than those in starch-rich materials like sugarcane. On the other

the fossil economy, since here the involved processes hand, second-generation fermentation plants can

have been improved through significant efforts over also convert most of the lignocellulose (cellulose,

many years. One key improvement would be to find hemicellulose and lignin) to useful chemicals, which

more efficient routes for conversion of biomass to is necessary when, for instance, straw is the biomass

fuels or chemicals. If the decrease in the corn/oil feedstock.9 Thus these new improved technologies for

price ratio continues and the technology improves, the biomass conversion uses less non-renewable energy

relative cost for biomass-derived chemicals and fuels and give both a higher CO2 reduction and a higher

will decrease, making it more feasible to switch to ethanol yield than first-generation plants due to a

biomass. higher utilization of the feedstock.10,11 Moreover, the

In addition, it could be important that the use of feedstocks for second-generation plants are cheaper

biomass as a sustainable resource for production of (agricultural waste etc.) and do not give the same

fuels and commodity chemicals should offer improved ethical concerns when using potential food resources

security in supply, since biomass can be grown in most for energy production. In the second-generation

parts of the world. This is in contrast to oil resources, biorefinery, the highest CO2 reduction is reached by

which are limited by being located in few and, for co-producing other valuable products. In the Danish

some, unstable areas of the world. bioenergy concept this is achieved by co-producing

Ethanol is one chemical that can be readily obtained methane and hydrogen.12 Another significant issue

from biomass by fermentation. The total world is that abundant coal resources are the primary

production of bioethanol is constantly increasing and source of non-renewable energy in conversion of

was estimated to reach more than 46 billion liters per biomass into ethanol. In that way, a premium liquid

year in 2005.6 transportation fuel is produced from a less valuable

330 J Chem Technol Biotechnol 82:329333 (2007)

DOI: 10.1002/jctb

Perspective

energy resource, which further reduces the need for alternative to produce these chemicals is to use

import of petroleum.13 biomass and biomass-derived molecules as feedstocks.

The environmental impact of using blends of The chemical industry is enormous, and a signif-

ethanolgasoline depends on the actual fraction of icant reduction in GHG emissions could therefore

ethanol in the blend. A recent review by Niven be achieved by a change to renewable CO2 -neutral

questions whether the use of ethanol as a fuel resources. Bioethanol production is already imple-

additive has any environmental advantage compared mented in many places around the world and in

to using pure gasoline.15 A fuel blend of 10 vol% progress in many other places. This means that the

ethanol offers little reduction in GHG emissions or amount of bioethanol available most likely will keep

improvement in energy efficiency, with the drawback increasing for several years. Studies suggest a yearly

of increasing risk and severity of soil and groundwater increase of approximately 6.5% until 2020, leading to

contamination. Increasing the ethanol fraction to 85 an annual production of more than 120 billion liters

vol% decreases emissions of GHG, but may cause in 2020.20 With this amount of bioethanol available,

significant air pollution in the form of NOx and there is great promise in partly converting the chemical

organic compounds.14 However, if 85 vol% ethanol industry to one based on renewable resources.

is the goal, alterations to existing combustion engines Instead of using bioethanol for transportation fuel

are necessary, and different car exhaust catalysts purposes where it has a relatively low value, it could

could probably reduce the emissions of NOx and instead be used as feedstock for other important

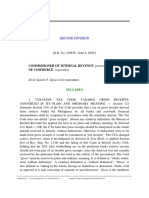

organic compounds. When 10 vol% mixtures are used, chemical products with a much higher value. Figure 3

ethanol works as an octane enhancer and improves illustrates some possible uses of biomass-derived

combustion, which reduces CO and ground-level ethanol. Besides its use for hydrogen production

ozone emissions.13 Ethanol is also less poisonous to by steam reforming or the direct use as a fuel

the environment than other octane boosters such as or fuel additive, it could be utilized for producing

lead and methyl tert-butyl ether (MTBE). acetaldehyde, ethylene, butadiene and acetic acid,

Another possible future use of bioethanol to supply among others. The annual amount of these chemicals

a sustainable/green transportation fuel is catalytic produced worldwide is around 1.4, 120, 7.5 and

steam reforming for production of H2 . Many consider 8.5 million tons, respectively.21 Today, the annual

hydrogen to be a future energy source, especially production of bioethanol is around 45 million tons,

for the transportation sector and mobile devices.15 which means that it could replace a significant

Today most hydrogen is produced from steam amount of these petrochemical products. For this to

reforming of natural gas. However, this is not a be economically viable, the products produced from

solution to substantially decrease emissions of GHG bioethanol must obviously be more valuable than the

to the atmosphere. There are two primary reasons bioethanol itself. Moreover, it is necessary to keep the

as to why conversion of bioethanol to hydrogen is conversion processes inexpensive.

promising. First, direct combustion of ethanol used The production costs for bioethanol is on average

for transportation is estimated to have an energy around 250 US $ per ton, for ethylene it is around 700

efficiency of approximately 20%, whereas utilizing US $ per ton, and for acetic acid it is around 650 US

hydrogen in a fuel cell has an energy efficiency of $ per ton.5 Looking into the amounts and production

up to 60%.16 Therefore, even though the conversion costs of the respective chemicals, it seems realistic to

of ethanol to hydrogen requires some energy input, produce, for example, acetic acid from bioethanol with

it may be possible to capture more than 50% of the proper catalytic reaction pathway. Such a reaction

the energy from photosynthesis as electricity from was recently proposed, where ethanol is oxidized with

autothermal reforming of ethanol.17 Secondly, the air in an aqueous-phase reaction over a gold catalyst.22

most expensive step in using bioethanol directly as Moreover, analysis of the reaction indicates that it is

a fuel is removal of the water. With steam reforming of competitive both economically and environmentally to

ethanol to hydrogen, it is not necessary to remove

the conventional petrochemical production of acetic

water, making the process considerably cheaper.

acid by the Monsanto process. With regard to CO2

Ethanol can also be used directly in a fuel cell.

emission, the Monsanto process produces around 0.7

However, the efficiency of the current direct ethanol

fuel cell is quite inadequate.18 The catalytic chemical

reactions for steam reforming of bioresources are very

complex. Specific information about the intermediates

can, however, be provided by computational methods

and thereby help pinpoint where to set in catalytic

modifications to improve this viable route to large-

scale hydrogen production.19

FEEDSTOCK

More than 95% of all carbonaceous chemicals are Figure 3. Possible uses of bioethanol as a fuel or as a feedstock for

produced from fossil resources. The only existing important bulk chemicals.

J Chem Technol Biotechnol 82:329333 (2007) 331

DOI: 10.1002/jctb

Jeppe Rass-Hansen et al.

tons of CO2 for every ton of acetic acid, whereas the greatest economic promise. Thus, the optimal use

production from bioethanol is almost CO2 neutral. of bioethanol, in terms of efficiency, could well be

Thus, production of chemicals from bioethanol can to incorporate it into high-value materials otherwise

actually lead to higher CO2 savings than by using produced from fossil resources and eventually burn

it as a fuel. At the moment, it is not possible to the resulting waste in a thermal power station for heat

produce all the required ethylene from bioethanol, generation.

because ethylene is produced in much greater amounts The central point is that all available resources, both

than bioethanol. This, though, is likely to change fossil and renewable, are limited and it is essential that

in the future with increasing production capacity of we carefully consider how each is best used. This

bioethanol and eventually with increasing oil prices. is a future key challenge for chemical research and

However, in the foreseeable future, the production development.

of bioethanol will most likely be smaller than the

production of the most important carbon-containing

commodity chemicals, and therefore it could easily be REFERENCES

1 BP Statistical Review of World Energy, June 2005

an important feedstock for several of these.

(www.bp.com).

2 Huybrechts P, Kuhn M, Lambeck K, Nhuan MT, Qin D,

Woodworth PL, Changes in sea level, in Climate Change

THE FUTURE 2001: The Scientific Basis, ed. by Douglas BC and Ramirez A.

Cambridge University Press, Cambridge, UK, pp. 639693

During the previous century, petroleum became an (2001).

essential source for energy and commodity chemicals. 3 Wigley TML, The climate change commitment. Science

One future goal is to convert biomass into products 307:17661769 (2005).

that can compete with corresponding products derived 4 Dale BE, Greening the chemical industry: research and

development priorities for biobased industrial products.

from fossil resources with a focus on sustainability,

J Chem Technol Biotechnol 78:10931103 (2003).

resource availability and supply reliability. The aim 5 Kosaric N, Duvnjak Z, Farkas A, Sahm H, Bringer-Meyer S,

for the US Department of Energy is to replace Goebel O, et al., Ethanol in Ullmanns Encyclopedia of

25% of carbonaceous chemicals with biomass-derived Industrial Chemistry (7th edn). Wiley, Chichester (2006.).

chemicals by 2025.7 To achieve this goal, there is Additional data from www.icispricing.com, www.eia.doe.gov

and www.dft.gov.uk.

a need for some manageable oxygenated molecules.

6 Biofuels Strategy: Key Facts and Figures. MEMO/06/05 European

With its large-scale production ethanol is an obvious Commission, Brussels (2005).

choice for such a molecule, but other easily available 7 Ragauskas AJ, Williams CK, Davison BH, Britovsek G, Cair-

molecules from biomass, like glucose and fructose, ney J, Eckert CA, et al., The path forward for biofuels and

could also be very important for attaining this and biomaterials. Science 311:484489 (2006).

8 Farrell AE, Plevin RJ, Turner BT, Jones AD, OHare M and

further ambitions.

Kammen DM, Ethanol can contribute to energy and

The most energy-efficient utilization of dry biomass environmental goals. Science 311:506508 (2006).

is to use it in a combined heat and power plant, where 9 Haagesen F, Torry-Smith M and Ahring BK, Fermentation of

it directly substitutes fossil fuels on a 1:1 basis, and biomass to alcohols, in Biofuels for Fuel Cells: Renewable Energy

yields energy efficiencies above 90%. Furthermore, from Biomass Fermentation, ed. by Lens P, Westermann P,

Haberbauer M and Moreno A. IWA Publishing, London,

a 50% increased CO2 reduction can be achieved

pp. 169190 (2005).

if biomass is used for combined heat and power 10 Biofuels for Transport: An International Perspective. International

production instead of production of bioethanol using Energy Agency, Paris (2004). (www.iea.org).

first-generation technologies.23 11 Hammerschlag R, Ethanols energy return on investment: a

Recently, it was estimated for the European Union survey of the literature 1990present. Environ Sci Technol

40:17441750 (2006).

that around 20% of the total energy consumption in 12 Westermann P and Ahring B, The biorefinery for production of

the future could be covered from the use of biomass, multiple biofuels, in Biofuels for Fuel Cells: Renewable Energy

without compromising the need for food. Thus, from Biomass Fermentation, ed. by Lens P, Westermann P,

biomass cannot alone cover the energy demands.24 Haberbauer M and Moreno A. IWA Publishing, London,

The main motivation for producing ethanol has pp. 194205 (2005).

13 Shapouri H, Duffield JA and Wang M, The energy balance of

so far been the need for transportation fuels. The corn ethanol revisited. Trans ASAE 46:959968 (2003).

consumption of transportation fuels alone in the 14 Niven RK, Ethanol in gasoline: environmental impacts and

United States is over 530 billion liters per year, whereas sustainability review article. Renew Sust Energ Rev 9:535555

US bioethanol production was only about 15 billion (2005).

liters in 2005.25 Bioethanol will most certainly have 15 Jacobson MZ, Colella WG and Golden DM, Cleaning the air

and improving health with hydrogen fuel-cell vehicles. Science

some positive influence on CO2 emissions from the 308:19011905 (2005).

transportation sector, but it might prove possible to 16 Larminie J and Dicks A, Fuel Cell Systems Explained (2nd edn).

achieve an even better environmental effect by using Wiley, Chichester (2005).

it as a feedstock for the chemical industry. Finding 17 Deluga GA, Salge JR, Schmidt LD and Verykios XE, Renew-

effective catalytic reaction pathways for producing able hydrogen from ethanol by autothermal reforming. Science

303:993997 (2004).

commodity or specialty chemicals from bioethanol 18 Lamy C, Belgsir EM and Leger J-M, Electrocatalytic oxidation

rather than using it to substitute the least expensive of aliphatic alcohols: application to the direct alcohol fuel cell

fossil products, such as the fuels, will most likely hold (DAFC). J Appl Electrochem 31:799809 (2001).

332 J Chem Technol Biotechnol 82:329333 (2007)

DOI: 10.1002/jctb

Perspective

19 Nrskov JK and Christensen CH, Toward efficient hydrogen 23 Nielsen PH and Wenzel H, Environmental assessment of

production at surfaces. Science 312:13221323 (2006). ethanol produced from corn starch and used as an alterna-

20 Biofuel Market Worldwide (2006), RNCOS, 1 July (2006). tive to conventional gasoline for car driving. IPU Pruduktion

(www.rncos.com). (2005). (http://www.ipu.dk/IPU-Produktion/Publikationer/bio-

21 Weissermel K and Arpe H-J, Industrial Organic Chemistry (4th ethanol-report,-d-,pdf.aspx.).

edn). Wiley-VCH, Weinheim (2003). 24 Ericsson K and Nilsson LJ, Assessment of the potential biomass

22 Christensen CH, Jrgensen B, Rass-Hansen J, Egeblad K, supply in Europe using a resource-focused approach. Biomass

Madsen R, Klitgaard SK, et al, Formation of acetic acid by Bioenerg 30:115 (2006).

aqueous-phase oxidation of ethanol with air in the pres- 25 Editorial, Bioethanol needs biotech now. Nature Biotechnol

ence of a heterogeneous gold catalyst. Angew Chem Int Ed 24:725 (2006).

45:46484651 (2006).

J Chem Technol Biotechnol 82:329333 (2007) 333

DOI: 10.1002/jctb

Das könnte Ihnen auch gefallen

- Metal Pollution Status in Zhelin Bay Surface Sediments Inferred From A Sequential Extraction Technique, South China Sea PDFDokument6 SeitenMetal Pollution Status in Zhelin Bay Surface Sediments Inferred From A Sequential Extraction Technique, South China Sea PDFAdamu OnakpaNoch keine Bewertungen

- Dielectric Spectroscopy of Biodegradable Poly (3-Hydroxybutyrate-co-3-Hydroxyhexanoate) FilmsDokument8 SeitenDielectric Spectroscopy of Biodegradable Poly (3-Hydroxybutyrate-co-3-Hydroxyhexanoate) FilmsAdamu OnakpaNoch keine Bewertungen

- Domestic Borehole Water Quality Assessment and Treatment MethodsDokument11 SeitenDomestic Borehole Water Quality Assessment and Treatment MethodsAdamu OnakpaNoch keine Bewertungen

- Cloud Point Extraction and Flame Atomic Absorption Spectrometry Analysis of Palladium, Platinum, and Gold Ions From Industrial Polluted SoilDokument5 SeitenCloud Point Extraction and Flame Atomic Absorption Spectrometry Analysis of Palladium, Platinum, and Gold Ions From Industrial Polluted SoilAdamu OnakpaNoch keine Bewertungen

- Chapter 24Dokument10 SeitenChapter 24manurihimalshaNoch keine Bewertungen

- Biodegradation of P(3HB,4HB)/PLA Blends in Real SoilDokument11 SeitenBiodegradation of P(3HB,4HB)/PLA Blends in Real SoilAdamu OnakpaNoch keine Bewertungen

- Potentiometric Measurements Galvanic or Voltaic Cell: ElectrolyticDokument21 SeitenPotentiometric Measurements Galvanic or Voltaic Cell: ElectrolyticAmr GamalNoch keine Bewertungen

- A Rapid Gas Chromatographic Method For The Determination of Poly Hydroxybutyric Acid in Microbial Biomass PDFDokument9 SeitenA Rapid Gas Chromatographic Method For The Determination of Poly Hydroxybutyric Acid in Microbial Biomass PDFAdamu OnakpaNoch keine Bewertungen

- Atomic Spectroscopy - A Guide To Selecting The Appropriate Technique and System PDFDokument16 SeitenAtomic Spectroscopy - A Guide To Selecting The Appropriate Technique and System PDFAdamu OnakpaNoch keine Bewertungen

- Chiral Separations by Liquid Chromatography Theory and ApplicationsDokument376 SeitenChiral Separations by Liquid Chromatography Theory and ApplicationsAdamu Onakpa100% (1)

- A Rapid Gas Chromatographic Method For The Determination of Poly Hydroxybutyric Acid in Microbial BiomassDokument9 SeitenA Rapid Gas Chromatographic Method For The Determination of Poly Hydroxybutyric Acid in Microbial BiomassAdamu OnakpaNoch keine Bewertungen

- A Possible Role of Poly-3-Hydroxybuiyric Acid in Antibiotic Production in StreptomycesDokument4 SeitenA Possible Role of Poly-3-Hydroxybuiyric Acid in Antibiotic Production in StreptomycesAdamu OnakpaNoch keine Bewertungen

- The Utilization of Agriculturally Derived Lignin As An Antioxidant in Asphalt BinderDokument94 SeitenThe Utilization of Agriculturally Derived Lignin As An Antioxidant in Asphalt BinderAdamu OnakpaNoch keine Bewertungen

- Biodegradability of PlasticsDokument21 SeitenBiodegradability of PlasticsPhuong NguyenNoch keine Bewertungen

- Increased Recovery and Improved Purity of PHA From Recombinat Cupriavidus Necator PDFDokument5 SeitenIncreased Recovery and Improved Purity of PHA From Recombinat Cupriavidus Necator PDFAdamu OnakpaNoch keine Bewertungen

- Effects of Lignosulfonate and Temperature On Compressive Strength of CementDokument3 SeitenEffects of Lignosulfonate and Temperature On Compressive Strength of CementAdamu OnakpaNoch keine Bewertungen

- Biodegradable Plastics and PolymersDokument8 SeitenBiodegradable Plastics and PolymersMarius GedgaudasNoch keine Bewertungen

- A Rapid Gas Chromatographic Method For The Determination of Poly Hydroxybutyric Acid in Microbial Biomass PDFDokument9 SeitenA Rapid Gas Chromatographic Method For The Determination of Poly Hydroxybutyric Acid in Microbial Biomass PDFAdamu OnakpaNoch keine Bewertungen

- Chiral Chromatography 1998 - Scott & BeesleyDokument552 SeitenChiral Chromatography 1998 - Scott & Beesleytutuncucanan100% (1)

- Base-Catalyzed Depolymerization of Solid Lignin-Rich Streams Enables Microbial ConversionDokument10 SeitenBase-Catalyzed Depolymerization of Solid Lignin-Rich Streams Enables Microbial ConversionAdamu OnakpaNoch keine Bewertungen

- LIGNIN Biomass RecalcitraneDokument63 SeitenLIGNIN Biomass RecalcitraneIsroi.comNoch keine Bewertungen

- The Secondary Effects of Lignosulfonate Cement Retarded On Cement Slurry Properties PDFDokument7 SeitenThe Secondary Effects of Lignosulfonate Cement Retarded On Cement Slurry Properties PDFTran Huynh NamNoch keine Bewertungen

- About Nitrito and NitroDokument1 SeiteAbout Nitrito and NitroSare GomezNoch keine Bewertungen

- Akta 514 Akta Keselamatan Dan Kesihatan Pekerjaan 1994Dokument48 SeitenAkta 514 Akta Keselamatan Dan Kesihatan Pekerjaan 1994nazrics100% (9)

- About Nitrito and NitroDokument11 SeitenAbout Nitrito and NitroAdamu OnakpaNoch keine Bewertungen

- Chapter 9: Structure and Bonding - Fundamental Concepts........................... 2Dokument30 SeitenChapter 9: Structure and Bonding - Fundamental Concepts........................... 2Adamu OnakpaNoch keine Bewertungen

- Waterford Tender DesignDokument35 SeitenWaterford Tender DesignAdamu OnakpaNoch keine Bewertungen

- Waterford Tender DesignDokument35 SeitenWaterford Tender DesignAdamu OnakpaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- UdyogAadharRegistrationCertificate PDFDokument1 SeiteUdyogAadharRegistrationCertificate PDFRajit KumarNoch keine Bewertungen

- C.J. Yulo & Sons Inc. vs. Roman Catholic Archbishop donation disputeDokument2 SeitenC.J. Yulo & Sons Inc. vs. Roman Catholic Archbishop donation disputeheyoooNoch keine Bewertungen

- Analitika Data Dan Komputasi AwanDokument12 SeitenAnalitika Data Dan Komputasi AwanBigsmakivan OliviaNoch keine Bewertungen

- q3 1Dokument26 Seitenq3 1api-321469925Noch keine Bewertungen

- Latino Information and Resource Network, Et Al. v. City of West Sacramento ComplaintDokument9 SeitenLatino Information and Resource Network, Et Al. v. City of West Sacramento ComplaintKristin LamNoch keine Bewertungen

- Robert Bogan and Scott Bogan v. Austin E. Hodgkins, JR., Northwestern Mutual Life Insurance Company, 166 F.3d 509, 2d Cir. (1999)Dokument11 SeitenRobert Bogan and Scott Bogan v. Austin E. Hodgkins, JR., Northwestern Mutual Life Insurance Company, 166 F.3d 509, 2d Cir. (1999)Scribd Government DocsNoch keine Bewertungen

- Calculate business interruption costs of GSU transformer failuresDokument4 SeitenCalculate business interruption costs of GSU transformer failuressevero97Noch keine Bewertungen

- Role of MediatorDokument23 SeitenRole of MediatorIzyan IsmailNoch keine Bewertungen

- Dip HIV Man (SA) Past Papers - 2015 2nd Semester 24-1-2017Dokument2 SeitenDip HIV Man (SA) Past Papers - 2015 2nd Semester 24-1-2017matentenNoch keine Bewertungen

- Kurukshetra UniversityDokument2 SeitenKurukshetra UniversityANKUSH 87205312Noch keine Bewertungen

- Natural Health EncycDokument956 SeitenNatural Health EncycHarold WongNoch keine Bewertungen

- MAN305 Employee Scheduling ProblemDokument4 SeitenMAN305 Employee Scheduling ProblemgülraNoch keine Bewertungen

- 1 s2.0 S0959652622032954 MainDokument18 Seiten1 s2.0 S0959652622032954 MainAlexia Parra SanchezNoch keine Bewertungen

- GR No. 149636 - June 8, 2005 Double Taxation FWT - GRTDokument4 SeitenGR No. 149636 - June 8, 2005 Double Taxation FWT - GRTMonica SorianoNoch keine Bewertungen

- The Trinitarian Theology of Saint Gregory The TheologianDokument27 SeitenThe Trinitarian Theology of Saint Gregory The Theologianakimel100% (1)

- PCNC Accreditation For NGODokument2 SeitenPCNC Accreditation For NGOalexjalecoNoch keine Bewertungen

- Gulahmed MagazineDokument179 SeitenGulahmed MagazineFarhad Ali100% (1)

- Putsch Flume Water Treatment SystemDokument28 SeitenPutsch Flume Water Treatment Systemguillo tapiaNoch keine Bewertungen

- Adjusting Entries (Depreciation)Dokument2 SeitenAdjusting Entries (Depreciation)Mark Johnson LeeNoch keine Bewertungen

- Eicher Motors ESOP Statement 2021-22Dokument5 SeitenEicher Motors ESOP Statement 2021-22Srikesav SivakumarNoch keine Bewertungen

- AuintermoDokument132 SeitenAuintermoworm48Noch keine Bewertungen

- Accounting for partnership profitsDokument19 SeitenAccounting for partnership profitsየሞላ ልጅNoch keine Bewertungen

- Counseling and Psychotherapy Theories and Interventions 6th Edition Ebook PDFDokument28 SeitenCounseling and Psychotherapy Theories and Interventions 6th Edition Ebook PDFmargaret.hernandez8120% (1)

- GameChange Solar OverviewDokument35 SeitenGameChange Solar OverviewBen LauNoch keine Bewertungen

- Na IstamDokument1 SeiteNa IstamVijay THALAPATHYNoch keine Bewertungen

- It Modernize Data Architecture Phase 1 Develop A DA VisionDokument25 SeitenIt Modernize Data Architecture Phase 1 Develop A DA VisionMARIA SELES TELES SOUSANoch keine Bewertungen

- Lesson 14 - Financial Literacy ReflectionDokument1 SeiteLesson 14 - Financial Literacy Reflectionapi-456827469Noch keine Bewertungen

- BEDOYA, Soledad (1999) - La Ecología Política y La Crítica Al DesarrolloDokument25 SeitenBEDOYA, Soledad (1999) - La Ecología Política y La Crítica Al DesarrolloCARLOS AARÓN HERZ ZACARÍASNoch keine Bewertungen

- BCEA Deep DiveDokument50 SeitenBCEA Deep Diveharikateja100% (1)

- Event ContractDokument3 SeitenEvent ContractEniola SunmonuNoch keine Bewertungen