Beruflich Dokumente

Kultur Dokumente

Tensile Stress, Thread Root & Thread Stripping Areas

Hochgeladen von

tedOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tensile Stress, Thread Root & Thread Stripping Areas

Hochgeladen von

tedCopyright:

Verfügbare Formate

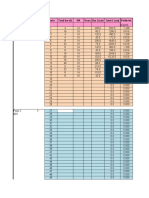

3358 I Fastener Technical Reference I

Tensile Stress, Thread Root & Thread Stripping Areas

Nominal Size Coarse Thread 8 Thread Series Fine Thread

Thread Tensile Stress Thread Root Int Thread Stripping Thread Tensile Thread Root Int Thread Stripping Thread Tensile Stress Thread Root Int Thread Stripping

Pitch Area Area Area Asn Pitch Stress Area Area Asn Pitch Area Area Area Asn

Area

(tpi) (sq in.) (sq in) sq in per in of (tpi) (sq in.) (sq in) sq in per in of (tpi) (sq in) (sq in) sq in per in of

engagement engagement engagement

0 0.060 80 0.0018 0.00150 0.106

1 0.073 64 0.00262 0.00218 0.133 72 0.00278 0.00237 0.130

2 0.086 56 0.00370 0.00310 0.162 64 0.00394 0.00339 0.156

3 0.099 48 0.00487 0.00406 0.191 56 0.00523 0.00451 0.186

4 0.112 40 0.00604 0.00496 0.221 48 0.00661 0.00566 0.216

5 0.125 40 0.00796 0.00672 0.248 44 0.00831 0.00716 0.246

6 0.138 32 0.00909 0.00745 0.281 40 0.01015 0.00874 0.274

8 0.164 32 0.0140 0.0120 0.334 36 0.0147 0.01285 0.331

10 0.190 24 0.0175 0.0145 0.401 32 0.02 0.01752 0.389

12 0.216 24 0.0242 0.0206 0.458 28 0.0258 0.02258 0.450

1/4 0.250 20 0.0318 0.0269 0.539 28 0.0364 0.03255

For additional products, visit

Fasteners

0.521

5/16 0.313 18 0.0525 0.0455 0.682 24 0.0581 0.05262 0.663

3/8 0.375 16 0.0775 0.0678 0.828 24 0.0878 0.08084 0.800

7/16 0.438 14 0.106 0.094 0.981 20 0.119 0.10927 0.908

1/2 0.500 13 0.142 0.126 1.12 20 0.160 0.14862 1.08

9/16 0.563 12 0.182 0.162 1.27 18 0.203 0.18917 1.23

5/8 0.625 11 0.226 0.202 1.42 18 0.256 0.23999 1.37

3/4 0.750 10 0.335 0.302 1.72 16 0.373 0.35125 1.66

7/8 0.875 9 0.462 0.419 2.03 14 0.510 0.48047 1.96

1 1.000 8 0.606 0.551 2.33 12 UNF 0.663 0.62445 2.27

1 1.000 14 UNS 0.680 0.64631 2.23

1 1/8 1.125 7 0.763 0.693 2.65 8 0.791 0.728 2.63 12 0.856 0.81180 2.54

1 1/4 1.250 7 0.969 0.890 2.94 8 1.000 0.929 3.27 12 1.073 1.02369 2.83

fastenal.com or contact your local store.

1 3/8 1.375 6 1.155 1.054 3.27 8 1.234 1.160 3.21 12 1.315 1.26013 3.11

1 1/2 1.500 6 1.406 1.294 3.57 8 1.492 1.410 3.5 12 1.581 1.52111 3.39

The 1-12 is the standard inch series fine thread to the Unified screw thread system. The 1-14 is considered a UNS (Unified Special). However, the majority of all 1-in fine threads manufactured are 1-14 (UNS).

Tensile Stress Area = 0.7854 (D - 0.9743/n)2

D = nominal thread diameter

n = threads per inch

Thread Root Area = 0.7854(D - 1.3/n)2

D = nominal thread diameter

n = threads per inch

Int Thread Stripping Area per inch of Engagement = 3.1416 x Dsmin x n [(1/2n)+0.57735(Dsmin - Enmax)]

The values listed are for 2B internal threads

n = threads per inch

Dsmin = minimum major diameter of external thread

Enmax = maximum pitch diameter of internal thread

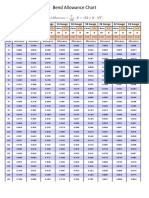

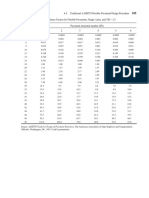

Metric (SI) System Thread Tensile Torque Values for A2 or A4 Metric

Stress Area (As) Stainless Steel Fasteners

Metric (SI) System Thread Tensile Stress Area (As)

Coarse Thread Fine Thread Bolt Torque (N-m) Torque (in-lbs. through

Nom Thread Tensile Thread Tensile Dia M10; M12 & over ft-lbs.)

Dia. Pitch Stress Area Pitch Stress Area (mm) Dry Lubricated Dry Lubricated

(mm) (mm) (mm sq.) (mm) (mm sq.) 3 1 0.9 8.9 in-lbs. 8.0 in-lbs.

3 0.5 5.03 4 2.6 2.3 23 20.7

3.5 0.6 6.78 5 5.1 4.6 45.1 40.6

4 0.7 8.78 6 8.7 7.8 77 69.3

5 0.8 14.2

8 21.2 19.1 188 169

6 1 20.1

10 42 38 372 335

12 73 66 54 ft-lbs. 48 ft-lbs.

7 1 28.9

14 118 106 87 78

8 1.25 36.6 1 39.2

16 180 162 133 119

10 1.5 58 1.25 61.2

18 258 232 190 171

12 1.75 84.3 1.25 92.1 20 370 333 273 246

14 2 115 1.5 125 22 485 437 358 322

16 2 157 1.5 167 24 603 543 445 400

18 2.5 192 1.5 216

20 2.5 245 1.5 272

22 2.5 303 1.5 333 Suggested Maximum Torquing Values - a guide based upon actual lab

24 3 353 2 384 testing on dry or near dry fasteners wiped clean. The lubricated values

27 3 459 2 496 were calculated at 90% of the dry condition test results. Values listed in

30 3.5 561 2 621 N-m; in-lbs. up through M10, and foot-pounds for M12 and over.

33 3.5 694 2 761

36 4 817 3 865 Note: stainless steel fasteners tend to gall while being tightened. The risk

39 4 976 3 1030 of galling or thread seizing can be reduced by:

Using lubrication

Tensile Stress Area= 0.7854[(d3+d2)/2] 2

Tighten fasteners with low RPMs without interruptions

Tensile Stress Area = 0.7854 [(d3=d2/2]2

d2=basic pitch diameter of the threads Apply only light pressure

D2= Basic Pitch Diameter

D3 = d3=minor diameter of the threads Avoid prevailing torque lock nuts when possible

Minor Diameter

Das könnte Ihnen auch gefallen

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesVon EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesBewertung: 5 von 5 Sternen5/5 (3)

- Particle Size Mesh ConversionDokument2 SeitenParticle Size Mesh ConversionmojicapNoch keine Bewertungen

- Typical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Dokument2 SeitenTypical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Mohammad TaherNoch keine Bewertungen

- Pitch Conversions Threads Per Inch TPI Pitch in Inches and Pitch in MM For Taps and DiesDokument3 SeitenPitch Conversions Threads Per Inch TPI Pitch in Inches and Pitch in MM For Taps and DiesChetan HinganeNoch keine Bewertungen

- Gauge Weight ChartDokument4 SeitenGauge Weight ChartLandel SmithNoch keine Bewertungen

- Bolts WeightDokument1 SeiteBolts WeightMysara MohsenNoch keine Bewertungen

- Mounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingsDokument1 SeiteMounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingssureshNoch keine Bewertungen

- Mounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingsDokument1 SeiteMounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingssureshNoch keine Bewertungen

- Mounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingsDokument1 SeiteMounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingssureshNoch keine Bewertungen

- Mesh To Micron Conversion ChartDokument2 SeitenMesh To Micron Conversion ChartKovarthanan EzhumalaiNoch keine Bewertungen

- Member Name Member # Steel N Total Bar (#) HA Doux Bar L (CM) Total L (CM) Poids/mLDokument269 SeitenMember Name Member # Steel N Total Bar (#) HA Doux Bar L (CM) Total L (CM) Poids/mLYoumna ShatilaNoch keine Bewertungen

- Mesh Sizing Chart For StrainersDokument3 SeitenMesh Sizing Chart For StrainersMalik DaniyalNoch keine Bewertungen

- Sheet Metal Thickness ChartDokument1 SeiteSheet Metal Thickness CharttylerstearnsNoch keine Bewertungen

- Gauge and Weight ChartDokument2 SeitenGauge and Weight ChartUsman AzamNoch keine Bewertungen

- Mesh Size PDFDokument1 SeiteMesh Size PDFuntoroNoch keine Bewertungen

- Mesh Size PDFDokument1 SeiteMesh Size PDFuntoroNoch keine Bewertungen

- Informe 4 (Datos)Dokument5 SeitenInforme 4 (Datos)Zaira Camila CriolloNoch keine Bewertungen

- Folga Radial de RolamentoDokument1 SeiteFolga Radial de RolamentoDavid Lima de freitasNoch keine Bewertungen

- P1 6 KG P1 12 KG P1 24 KG Beban Tegangan Normal: B C D E F G H I J K L 2Dokument17 SeitenP1 6 KG P1 12 KG P1 24 KG Beban Tegangan Normal: B C D E F G H I J K L 2DelaNoch keine Bewertungen

- Mesh To Micron Conversion ChartDokument2 SeitenMesh To Micron Conversion ChartMayur Agarwal100% (1)

- Comparison of Wire GaugesDokument6 SeitenComparison of Wire GaugesshrishkapsiNoch keine Bewertungen

- Benfard's LawDokument5 SeitenBenfard's LawMoises PedrazaNoch keine Bewertungen

- Aggregate ClaimsDokument3 SeitenAggregate ClaimsEdgar Alexander Hernández RebolledoNoch keine Bewertungen

- Aceleraox ForçaDokument6 SeitenAceleraox ForçaRaquel AzevedoNoch keine Bewertungen

- Triangular Grooves: Parker O-Ring HandbookDokument1 SeiteTriangular Grooves: Parker O-Ring Handbookbcanilkumar007Noch keine Bewertungen

- Evaluacion de La Integral de Duhamel para Cargas SismicasDokument6 SeitenEvaluacion de La Integral de Duhamel para Cargas SismicasAngela Odría RubioNoch keine Bewertungen

- Commercial Sieve Mesh DimensionsDokument9 SeitenCommercial Sieve Mesh DimensionsMuhammad MuneebNoch keine Bewertungen

- HA8 HA10 HA12 Nbre L (M) LT (M) Nbre L (M) LT (M) Nbre L (M) LT (M)Dokument3 SeitenHA8 HA10 HA12 Nbre L (M) LT (M) Nbre L (M) LT (M) Nbre L (M) LT (M)Mahdi MahdiNoch keine Bewertungen

- SWG - Standard Wire GaugeDokument1 SeiteSWG - Standard Wire GaugeSachin PrajapatiNoch keine Bewertungen

- Tabla Normal y T EstudentDokument2 SeitenTabla Normal y T EstudentPaty YalanquispeNoch keine Bewertungen

- Heave Acceleration ChartDokument1 SeiteHeave Acceleration Chartakash808099Noch keine Bewertungen

- EstadisticaDokument2 SeitenEstadisticaJuan BonifazNoch keine Bewertungen

- Mesh To Micron Conversion Chart Ecologix SystemsDokument1 SeiteMesh To Micron Conversion Chart Ecologix SystemsSantosh JayasavalNoch keine Bewertungen

- Let DESCRIBE Me For Futher Explaination in Detail (Near Future)Dokument30 SeitenLet DESCRIBE Me For Futher Explaination in Detail (Near Future)AntenasmNoch keine Bewertungen

- Gauge and Weight Chart - In-MmDokument7 SeitenGauge and Weight Chart - In-Mmmodulor3dNoch keine Bewertungen

- Sheet Metal Thickness GaugesDokument1 SeiteSheet Metal Thickness Gaugesting.draganNoch keine Bewertungen

- Clase 04-10-2019Dokument12 SeitenClase 04-10-2019KIKA CONTENTONoch keine Bewertungen

- Bend AllowanceDokument2 SeitenBend AllowancewentropremNoch keine Bewertungen

- Bend Allowance Chart: 8 Gauge 10 Gauge 12 Gauge 14 Gauge 16 Gauge 18 Gauge 20 Gauge 22 Gauge 24 GaugeDokument2 SeitenBend Allowance Chart: 8 Gauge 10 Gauge 12 Gauge 14 Gauge 16 Gauge 18 Gauge 20 Gauge 22 Gauge 24 GaugeGowrish SarvanaNoch keine Bewertungen

- Bend AllowanceDokument2 SeitenBend AllowancemorohiNoch keine Bewertungen

- Bend AllowanceDokument2 SeitenBend AllowancehixomiNoch keine Bewertungen

- Bend AllowanceDokument2 SeitenBend AllowancemorohiNoch keine Bewertungen

- Bend Allowance Chart: 8 Gauge 10 Gauge 12 Gauge 14 Gauge 16 Gauge 18 Gauge 20 Gauge 22 Gauge 24 GaugeDokument2 SeitenBend Allowance Chart: 8 Gauge 10 Gauge 12 Gauge 14 Gauge 16 Gauge 18 Gauge 20 Gauge 22 Gauge 24 Gaugemanoj983@gmail.comNoch keine Bewertungen

- Bend Deduction PDFDokument1 SeiteBend Deduction PDFChetan DalviNoch keine Bewertungen

- CBWWWWWWDokument1 SeiteCBWWWWWWDiego Vargas SalcedoNoch keine Bewertungen

- Indexing Techniques For Cubic Materials - Limbaga, Laguna, Heramis, Silas, JabienDokument24 SeitenIndexing Techniques For Cubic Materials - Limbaga, Laguna, Heramis, Silas, JabienEDISON LIMBAGANoch keine Bewertungen

- ZP1 ZP2 AnalysisDokument983 SeitenZP1 ZP2 AnalysisHelena Muñoz GalanNoch keine Bewertungen

- US Standard Sieve Openings: Sieve Number Opening, MM Wire Diameter, MMDokument2 SeitenUS Standard Sieve Openings: Sieve Number Opening, MM Wire Diameter, MMHosein EltimimiNoch keine Bewertungen

- Material Name Elastic Modulus Ultimate Strength Yield Strength Strain at BreakDokument3 SeitenMaterial Name Elastic Modulus Ultimate Strength Yield Strength Strain at Breakkrishnakant gargNoch keine Bewertungen

- Discharge Vs Minning ConstantDokument3 SeitenDischarge Vs Minning ConstantJohnn DoeNoch keine Bewertungen

- American Wire Gauge To Square MM Cross Sectional Area Chart 1.3.15.10 PDFDokument2 SeitenAmerican Wire Gauge To Square MM Cross Sectional Area Chart 1.3.15.10 PDFrahul.yerrawarNoch keine Bewertungen

- Spectru ProiectareDokument27 SeitenSpectru ProiectareHoria Ionut MihneaNoch keine Bewertungen

- Spectru ProiectareDokument27 SeitenSpectru ProiectareHoria Ionut MihneaNoch keine Bewertungen

- Sheet Metal Bom: Sr. No Itemid Revision No Description MaterialcodeDokument3 SeitenSheet Metal Bom: Sr. No Itemid Revision No Description MaterialcoderamNoch keine Bewertungen

- MQDokument4 SeitenMQJOMARY AGALEDNoch keine Bewertungen

- Table 4.1 Axle-Load Equivalency Factors For Flexible Pavements, Single Axles, and TSI 2.5Dokument6 SeitenTable 4.1 Axle-Load Equivalency Factors For Flexible Pavements, Single Axles, and TSI 2.5fadi eidNoch keine Bewertungen

- TablasDokument3 SeitenTablasVictor Sulca PucaNoch keine Bewertungen

- The Engineering Toolbox: Compressed Air - Pressure Drop in PipelinesDokument6 SeitenThe Engineering Toolbox: Compressed Air - Pressure Drop in Pipelineskrunal panchalNoch keine Bewertungen

- At 1cm Mmeter ReadingDokument5 SeitenAt 1cm Mmeter ReadingSandeep KesharavaniNoch keine Bewertungen

- Mesh SizesDokument1 SeiteMesh SizesSohan SinghNoch keine Bewertungen

- Absorption of GasesDokument10 SeitenAbsorption of GasestedNoch keine Bewertungen

- PING) ) ) ™ Ultrasonic Distance Sensor (#28015) : Features Key SpecificationsDokument12 SeitenPING) ) ) ™ Ultrasonic Distance Sensor (#28015) : Features Key SpecificationsIc MicNoch keine Bewertungen

- Acoustic Transducers by Donald P. Massa 110603Dokument18 SeitenAcoustic Transducers by Donald P. Massa 110603rakialiasNoch keine Bewertungen

- Horn-Type Piezoelectric Ultrasonic Transducer: Modelling and ApplicationsDokument25 SeitenHorn-Type Piezoelectric Ultrasonic Transducer: Modelling and ApplicationstedNoch keine Bewertungen

- HC SR04Users ManualDokument10 SeitenHC SR04Users ManualJuan HernándezNoch keine Bewertungen

- A Lok Tube FittingsDokument88 SeitenA Lok Tube FittingsCesarNoch keine Bewertungen

- Absorption of GasesDokument10 SeitenAbsorption of GasestedNoch keine Bewertungen

- Absorption of GasesDokument10 SeitenAbsorption of GasestedNoch keine Bewertungen

- HRSG-14 IAPWS Guidance Documents - DooleyDokument22 SeitenHRSG-14 IAPWS Guidance Documents - DooleytedNoch keine Bewertungen

- HRSG-12 CUI On Penetrations - ChiassonDokument23 SeitenHRSG-12 CUI On Penetrations - ChiassontedNoch keine Bewertungen

- HRSG-14 IAPWS Guidance Documents - DooleyDokument22 SeitenHRSG-14 IAPWS Guidance Documents - DooleytedNoch keine Bewertungen

- HRSG-12 CUI On Penetrations - ChiassonDokument23 SeitenHRSG-12 CUI On Penetrations - ChiassontedNoch keine Bewertungen

- HRSG-16 Control Valves For Turbine Bypass - GeelhartDokument41 SeitenHRSG-16 Control Valves For Turbine Bypass - GeelharttedNoch keine Bewertungen

- HRSG-09 Wholistic Approach To HRSG Inspections - TurnerDokument149 SeitenHRSG-09 Wholistic Approach To HRSG Inspections - Turnerted100% (1)

- HRSG-05A Ice Blasting Benefits - WilliamsDokument56 SeitenHRSG-05A Ice Blasting Benefits - WilliamstedNoch keine Bewertungen

- HRSG-10 Modeling With PlantTrack - OzboyaDokument29 SeitenHRSG-10 Modeling With PlantTrack - OzboyatedNoch keine Bewertungen

- HRSG-07 Update On Cycle Chemistry Control and FAC - DooleyDokument22 SeitenHRSG-07 Update On Cycle Chemistry Control and FAC - DooleytedNoch keine Bewertungen

- HRSG-07 Update On Cycle Chemistry Control and FAC - DooleyDokument22 SeitenHRSG-07 Update On Cycle Chemistry Control and FAC - DooleytedNoch keine Bewertungen

- How To EQ Vocals in Six Easy Steps - Behind The Mixer PDFDokument21 SeitenHow To EQ Vocals in Six Easy Steps - Behind The Mixer PDFtedNoch keine Bewertungen

- HRSG-08 Thermal Assessments - AndersonDokument6 SeitenHRSG-08 Thermal Assessments - AndersontedNoch keine Bewertungen

- HRSG-06 Physical Flow Modeling - OSullivanDokument21 SeitenHRSG-06 Physical Flow Modeling - OSullivantedNoch keine Bewertungen

- Parker Pgi Gauge SiphonsDokument2 SeitenParker Pgi Gauge SiphonstedNoch keine Bewertungen

- HRSG-05B Heat Tube Extraction - DaviesDokument23 SeitenHRSG-05B Heat Tube Extraction - DaviestedNoch keine Bewertungen

- ORD 5700 Parker O-Ring HandbookDokument292 SeitenORD 5700 Parker O-Ring Handbookcalaverilandia100% (1)

- 10 SzyszkaDokument16 Seiten10 SzyszkatedNoch keine Bewertungen

- ASME B16.5 Pipe Flanges and Flanged Fittings Published InterpretationsDokument71 SeitenASME B16.5 Pipe Flanges and Flanged Fittings Published InterpretationsAymen HileliNoch keine Bewertungen

- 5D FilterHousing VFL Ver2 2010 FancyPaperDokument1 Seite5D FilterHousing VFL Ver2 2010 FancyPapertedNoch keine Bewertungen

- Cfdesign Manual PDFDokument586 SeitenCfdesign Manual PDFted100% (1)

- Hazardous Zone, Class, DivisionDokument26 SeitenHazardous Zone, Class, DivisionHạo Nam-Born To WinNoch keine Bewertungen

- Chapter 5: Current and Resistance: 5.1 The Motion of Electric ChargeDokument11 SeitenChapter 5: Current and Resistance: 5.1 The Motion of Electric Chargeayunna ayunniNoch keine Bewertungen

- You'Re My Everything - Glenn FredlyDokument2 SeitenYou'Re My Everything - Glenn FredlyTommy Juliansyah MarsenoNoch keine Bewertungen

- TOPIC 2 - Fans, Blowers and Air CompressorDokument69 SeitenTOPIC 2 - Fans, Blowers and Air CompressorCllyan ReyesNoch keine Bewertungen

- HP 6940 Manual CompleteDokument150 SeitenHP 6940 Manual CompletepaglafouNoch keine Bewertungen

- Kaibigan, Kabarkada, Kaeskwela: Pinoy Friendships and School LifeDokument47 SeitenKaibigan, Kabarkada, Kaeskwela: Pinoy Friendships and School LifeGerald M. LlanesNoch keine Bewertungen

- Vehicles 6-Speed PowerShift Transmission DPS6 DescriptionDokument3 SeitenVehicles 6-Speed PowerShift Transmission DPS6 DescriptionCarlos SerapioNoch keine Bewertungen

- Laminar Premixed Flames 6Dokument78 SeitenLaminar Premixed Flames 6rcarpiooNoch keine Bewertungen

- Weather Prediction Using Machine Learning TechniquessDokument53 SeitenWeather Prediction Using Machine Learning Techniquessbakiz89Noch keine Bewertungen

- The Frozen Path To EasthavenDokument48 SeitenThe Frozen Path To EasthavenDarwin Diaz HidalgoNoch keine Bewertungen

- Burj Khalifa: Engineer Abdul MananDokument29 SeitenBurj Khalifa: Engineer Abdul MananabdulmananNoch keine Bewertungen

- Assignment OSDokument11 SeitenAssignment OSJunaidArshadNoch keine Bewertungen

- JSSC JDLCCE 2021 (Civil Engineering) Official Pape 230615 233342Dokument39 SeitenJSSC JDLCCE 2021 (Civil Engineering) Official Pape 230615 233342Bhuban KumbhakarNoch keine Bewertungen

- Nursing Care Plan TemplateDokument3 SeitenNursing Care Plan TemplateJeffrey GagoNoch keine Bewertungen

- BPI - I ExercisesDokument241 SeitenBPI - I Exercisesdivyajeevan89Noch keine Bewertungen

- E WiLES 2021 - BroucherDokument1 SeiteE WiLES 2021 - BroucherAshish HingnekarNoch keine Bewertungen

- 2019 Auto Truck Key Blank Reference PDFDokument188 Seiten2019 Auto Truck Key Blank Reference PDFAlbert RodaNoch keine Bewertungen

- Artificial Intelligence and Expert Systems: Management Information Systems, 4 EditionDokument27 SeitenArtificial Intelligence and Expert Systems: Management Information Systems, 4 Editionabhi7219Noch keine Bewertungen

- A Database For Handwritten Text Recognition ResearchDokument5 SeitenA Database For Handwritten Text Recognition Researchtweety492Noch keine Bewertungen

- R07 SET-1: Code No: 07A6EC04Dokument4 SeitenR07 SET-1: Code No: 07A6EC04Jithesh VNoch keine Bewertungen

- Elad Shapira - Shall We Play A Game - Lessons Learned While Playing CoreWars8086Dokument61 SeitenElad Shapira - Shall We Play A Game - Lessons Learned While Playing CoreWars8086james wrightNoch keine Bewertungen

- Oxygenation - NCPDokument5 SeitenOxygenation - NCPCazze SunioNoch keine Bewertungen

- Test Bank For Global Marketing Management 6th Edition Masaaki Mike Kotabe Kristiaan HelsenDokument34 SeitenTest Bank For Global Marketing Management 6th Edition Masaaki Mike Kotabe Kristiaan Helsenfraught.oppugnerp922o100% (43)

- Good Manufacturing Practices in Postharvest and Minimal Processing of Fruits and VegetablesDokument40 SeitenGood Manufacturing Practices in Postharvest and Minimal Processing of Fruits and Vegetablesmaya janiNoch keine Bewertungen

- Vermicomposting Learning ModulesDokument6 SeitenVermicomposting Learning ModulesPamara Prema Khannae100% (1)

- Notes 3 Mineral Dressing Notes by Prof. SBS Tekam PDFDokument3 SeitenNotes 3 Mineral Dressing Notes by Prof. SBS Tekam PDFNikhil SinghNoch keine Bewertungen

- Alliance For ProgressDokument19 SeitenAlliance For ProgressDorian EusseNoch keine Bewertungen

- Revised Exam PEDokument3 SeitenRevised Exam PEJohn Denver De la Cruz0% (1)

- Hydrotest Test FormatDokument27 SeitenHydrotest Test FormatRähûl Prätäp SïnghNoch keine Bewertungen

- Cooperative LinuxDokument39 SeitenCooperative Linuxrajesh_124Noch keine Bewertungen

- Training Structure - Thinkific Plus TemplateDokument7 SeitenTraining Structure - Thinkific Plus TemplateQIONG WUNoch keine Bewertungen