Beruflich Dokumente

Kultur Dokumente

YANdoor Closer

Hochgeladen von

msyan1965Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

YANdoor Closer

Hochgeladen von

msyan1965Copyright:

Verfügbare Formate

IRO1 IRONMONGERY

MATERIALS

OVERHEAD DOOR CLOSERS

IRO1.M530.7 OVERHEAD DOOR CLOSERS

1. Submission Requirements:

a. At sample submission and approval stage, submit a sample of the proposed

overhead door closers complete with all accessories for CM's approval

together with all the following substantiation for CM's information:

i. Catalogue, brand name/model name and job reference of the material;

ii. Name, address and contact person of the local supplier;

iii. Name, address and contact person of the manufacturer;

iv. Where applicable, either the document from the manufacturer showing

his authorization for the supplier as the agent/distributor in Hong Kong;

or the document from the supplier showing the appointment of the

manufacturer and manufacturer's agreement for the production of the

proposed product;

v. When the overhead door closer is supplied for domestic blocks, except

for the ancillary facilities at lower floors, comply with the following

particular requirements:

- Two identical sample boards, with accessories mounted on boards,

similar to the one maintained by the Housing Department showing

the quality, components and internal construction for the overhead

door closers, for comparison of the standard of visual quality with

the benchmark samples maintained by the Housing Department;

- Original or a certified true copy each of the certification to ISO

9001 and ISO 14001 for the manufacturing plant. If a copy of the

ISO certificate is submitted, it shall be certified true by the

certification bodies or by the QCM. The certification bodies shall

be as follows:

ISO Certification Body

ISO 9001 The certification body shall either be accredited by

the Hong Kong Accreditation Service (HKAS) or

an accreditation body which has entered into a

mutual recognition agreement with HKAS.

ISO 14001 The certification body shall be accredited by the

Hong Kong Accreditation Service (HKAS), or the

China National Accreditation Service (CNAS), or

an accreditation body which has entered into a

mutual recognition agreement with HKAS.

b. Submit original or certified true copy (issued or certified by the laboratory

that complies with PRE.B9.570) of the test reports showing full compliance

with the requirements of sub-clause (2)(c) for CM's information:

i. The date of the test shall be generally within three years prior to the

notified date for commencement of the Works or at an earlier date for

domestic blocks subject to CM's consideration on the track records as

maintained by the Housing Department;

ii. The test reports shall either be submitted at the sample submission and

approval stage as mentioned in sub-clause (1)(a), or at a time not later

than the delivery of the material as mentioned in sub-clause (3)(a);

iii. In the event that no test report has been submitted for CM's information

when the materials are delivered to Site, remove all delivered materials

off Site, bear all associated costs and no extension of time will be

allowed.

2. Quality Requirements:

a. Overhead door closer to BS EN 1154:1997 except clause 7.2 and to comply

with the following:

i. To the product range as IRO1.M040;

ii. Horizontal pattern with regular arm unless otherwise required or

scheduled;

iii. Capable of being fitted to door handing and of closing door positively;

iv. With one or more control valves to regulate closing speed;

v. Latch control to BS EN 1154:1997 sub-clause 5.2.12;

vi. Select the appropriate sizes of overhead door closers as scheduled on

Drawings and to select Size 4 closers for those door closers of parallel

arm installation type;

vii. Finish:

- Where closers supplied with separate covers, the covers are to be

rust proof steel plated or finished to the approval of CM.

viii.Barrier free access requirements for door closers to be used for doors to

exit staircases, protected lobbies and common areas:

- Closing period: for interior doors, a period of at least 3 seconds

measured from an open position of 70 degrees to a point 75 mm

from the closed position measured from the leading edge of the

edge of the door;

- Opening force: shall allow exterior and interior doors to be opened

with forces of not more than 30 N and 22 N respectively;

- Fire rated doors installed along accessible route shall be opened

with horizontal force of not more than 30N.

b. Classification according to BS EN 1154:1997:

i. Category of use: Grade 3 for closing doors from at least 105 open and

Grade 4 for closing doors from 180 open;

ii. Durability: Grade 8, tested to 500,000 test cycles;

iii. Door closer power size:

- According to Table 1 of BS EN 1154:1997 as tabulated below;

- Power size of 3 for door required to have fire resistance period

installed along accessible route;

Door leaf width and closing moment:

Door Recommended Test Closing moment

closer door leaf width door

power mass Between 0 and 4 Between Any other

size 88 and 92 angle of

opening

mm max. kg N.m min. N.m max. N.m min. N.m min.

1 <750 20 9 <13 3 2

2 850 40 13 <18 4 3

3 950 60 18 <26 6 4

4 1100 80 26 <37 9 6

5 1250 100 37 <54 12 8

6 1400 120 54 <87 18 11

7 1600 160 87 <140 29 18

Opening moment and efficiency:

Door Opening moment Door closer efficiency between 0 and

closer between 0 and 60 4

power

size N.m max. % min.

1 26 50

2 36 50

3 47 55

4 62 60

5 83 65

6 134 65

7 215 65

iv. Fire resistance: Grade 1, identified as suitable for use on fire/smoke

door assemblies, or to comply BS 476:Part22:1987;

v. Safety: Grade 1, met the Essential Requirements of safety in use;

vi. Corrosion resistance: Grade 2 with moderate resistance for the closers

installed at domestic flats and public areas.

c. Performance requirements as follows:

i. For the test Sample B as stated in BS EN 1154:1997, comply with the

mechanical performance and durability as follows (two samples at

maximum and minimum strength for adjustable strength closers):

Items Reference in Acceptance Standards

(BS EN 1154 Clause 7.3) BS EN 1154:1997

Set test door to required 7.3.1 para. 1 -

mass for strength of closer

on test.

Open door to determine 7.3.1 para. 2; The test door shall be opened:

maximum opening angle. 5.2.7 - Grade 3 - from at least 105

open

- Grade 4 - from 180 open.

The door closer shall control the

door from a minimum angle of

70, down to the closed position.

Cycle opening to 90 and 7.3.2; -

allowing to close to 0, in a 7.3.3.1

time of 3 to 7 seconds, 5000

times.

Measure torques and 7.3.4.1; Measure the closing moments and

calculate efficiency over 7.3.4.2; opening moments to meet

region 0 to 4. 5.2.3 - 5.2.5 requirements in the Table of sub-

clause (2)(b). Calculate the door

closer efficiency and verify that

the value is in accordance with

the Table in sub-clause (2)(b).

For door closer with a range of

power sizes, the power size used

for the testing shall be stated in

the test report.

Measure closing time. 7.3.4.3; Verify that the closing time from

5.2.6 90 is capable of adjustment to

between 3 seconds and 20

seconds.

Closing overload test set 7.3.4.4; Able to withstand the closing

abuse weight to value in 5.2.8 overload test.

table, set weight to be

arrested at door position 15.

Set closer to close from 90

in 10 seconds. Allow weight

to close door from 90 for 10

times.

All closers cycle for a total 7.3.5.1; The door closer shall be rejected

of 500000 cycles. Measure 7.3.6.1 if closing time from 90 to the

closing time. fully closed position is more than

2 times, or less than 0.7 times the

value after 5000 test cycles.

Calculate efficiency over 7.3.6.2; 7.3.4.1; Measure the closing moments and

region 0 to 4. 7.3.4.2; opening moments to meet

5.2.3 - 5.2.5 requirements in the Table of sub-

clause (2)(b). Calculate the door

closer efficiency and verify that

the value is in accordance with

the Table in sub-clause (2)(b).

For door closer with a range of

power sizes, the power size used

for the testing shall be stated in

the test report.

Measure closing time. 7.3.6.3 Verify that the closing time from

90 open to fully close is not less

than 20 seconds.

Closing overload test set 7.3.6.4; 7.3.4.4; Able to withstand the closing

abuse weight to value in 5.2.8 overload test.

table, set weight to be

arrested at door position 15.

Set closer to close from 90

in 10 seconds. Allow weight

to close door from 90 for 10

times.

Note: There shall be no fluid leakage or damage (that would adversely affect the

performance) to the door closer throughout the tests.

ii. For the test Sample C as stated in BS EN 1154:1997, comply with the

corrosion resistance as follows (one sample set to minimum strength for

adjustable closers):

Items Reference in Acceptance Standards

(BS EN 1154:1997 Clause 7.4) BS EN 1154:1997

Set test door to required mass. 7.4.1 -

Measure opening and closing 7.4.2 Measure the closing

torques. moments to meet the

requirements in the Table

of sub-clause (2)(b).

Expose to neutral salt spray in 7.4.3 Refer clause 5.7 of BS EN

accordance with BS EN 1670:1998 1670:1998.

Grade 0 no exposure

Grade 1 24 hours exposure

Grade 2 48 hours exposure

Grade 3 96 hours exposure

Grade 4 240 hours exposure

Measure closing moments 7.4.4; The closing moments of

7.4.2; the door closer shall be not

5.2.17 less than 80% of the

closing moments measured

prior to the test.

3. On Site Delivery Verification:

a. At delivery stage, submit the following documents:

i. Written confirmation that the material delivered to Site conforms with

the Approved sample submitted under sub-clause (1)(a);

ii. Original or certified true copy of Certificate of Origin for every batch of

delivery. One batch being the material quantity covered under each

delivery note;

iii. Delivery notes for all material delivered to site.

b. Carry out and submit report on the following verifications for overhead door

closers upon delivery on Site. Prior to carrying out the verifications, inform

CM's representatives who may present to witness the verifications:

i. Method:

Verification Items Method Acceptance Standards

Surface Quality Visual No discolouration, no

damage, no staining, no

blemish

Logo and label Visual Same as CM's Approval

check sample

ii. Frequency:

Test Items Sampling Frequency Representative Batch

Surface Quality 1 sample for each Same batch of material

delivery delivered to Site under

one Delivery Note

Logo and label 1 sample for each Same batch of material

check delivery delivered to Site under

one Delivery Note

c. Where any of the verifications fail to meet the acceptance standards, either:

i. Remove the representative batch off Site; or

ii. When agreed by the CM, repeat all verification items on three separate

samples selected by the CM. In case of failure of any verification to any

one sample, remove the representative batch off Site, bear all associated

costs, and no extension of time will be allowed.

Das könnte Ihnen auch gefallen

- A. Design Considerations: Best Practice SectionDokument1 SeiteA. Design Considerations: Best Practice Sectionmsyan1965Noch keine Bewertungen

- A. Design Considerations: Best Practice SectionDokument1 SeiteA. Design Considerations: Best Practice Sectionmsyan1965Noch keine Bewertungen

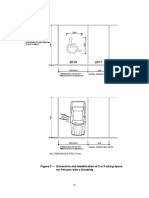

- BFA 2008-English 31Dokument1 SeiteBFA 2008-English 31msyan1965Noch keine Bewertungen

- Figure 6B - Typical Tactile Guide Path Junction: Positional Tiles/ BlocksDokument1 SeiteFigure 6B - Typical Tactile Guide Path Junction: Positional Tiles/ Blocksmsyan1965Noch keine Bewertungen

- Figure 5 - Parking Space Indication SignageDokument1 SeiteFigure 5 - Parking Space Indication Signagemsyan1965Noch keine Bewertungen

- BFA 2008-English 25Dokument1 SeiteBFA 2008-English 25msyan1965Noch keine Bewertungen

- Figure 6A - Tactile Guide Paths at Building Entrances Linking Up With Initial Access On The Lot Boundary and Interior FacilitiesDokument1 SeiteFigure 6A - Tactile Guide Paths at Building Entrances Linking Up With Initial Access On The Lot Boundary and Interior Facilitiesmsyan1965Noch keine Bewertungen

- BFA 2008-English 28Dokument1 SeiteBFA 2008-English 28msyan1965Noch keine Bewertungen

- Division 2 - Hotels, Hostels and Guesthouses: Performance Objectives 7. Guest RoomsDokument1 SeiteDivision 2 - Hotels, Hostels and Guesthouses: Performance Objectives 7. Guest Roomsmsyan1965Noch keine Bewertungen

- Figure 2 - Typical Guest Room Layout: All Dimensions Are in MMDokument1 SeiteFigure 2 - Typical Guest Room Layout: All Dimensions Are in MMmsyan1965Noch keine Bewertungen

- Division 3 - CARPARKS: Mandatory SectionDokument1 SeiteDivision 3 - CARPARKS: Mandatory Sectionmsyan1965Noch keine Bewertungen

- BFA 2008-English 24Dokument1 SeiteBFA 2008-English 24msyan1965Noch keine Bewertungen

- Obligatory Design Requirements (Cont'd) : Best Practice SectionDokument1 SeiteObligatory Design Requirements (Cont'd) : Best Practice Sectionmsyan1965Noch keine Bewertungen

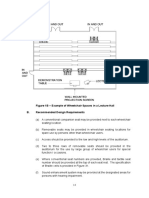

- Figure 1B - Example of Wheelchair Spaces in A Lecture Hall B. Recommended Design RequirementsDokument1 SeiteFigure 1B - Example of Wheelchair Spaces in A Lecture Hall B. Recommended Design Requirementsmsyan1965Noch keine Bewertungen

- 2.1 Extent of Application (Cont'D) TABLE 2 (Cont'd) Extent of Application of Additional Assistive Provisions To Various Uses of BuildingsDokument1 Seite2.1 Extent of Application (Cont'D) TABLE 2 (Cont'd) Extent of Application of Additional Assistive Provisions To Various Uses of Buildingsmsyan1965Noch keine Bewertungen

- "Y" Denotes "Applicable" "-" Denotes "Not Applicable": 2.1 Extent of Application (Cont'D) Table 2Dokument1 Seite"Y" Denotes "Applicable" "-" Denotes "Not Applicable": 2.1 Extent of Application (Cont'D) Table 2msyan1965Noch keine Bewertungen

- BFA 2008-English 15Dokument1 SeiteBFA 2008-English 15msyan1965Noch keine Bewertungen

- BFA 2008-English 17Dokument1 SeiteBFA 2008-English 17msyan1965Noch keine Bewertungen

- BFA 2008-English 16Dokument1 SeiteBFA 2008-English 16msyan1965Noch keine Bewertungen

- BFA 2008-English 14Dokument1 SeiteBFA 2008-English 14msyan1965Noch keine Bewertungen

- BFA 2008-English 8Dokument1 SeiteBFA 2008-English 8msyan1965Noch keine Bewertungen

- BFA 2008-English 11Dokument1 SeiteBFA 2008-English 11msyan1965Noch keine Bewertungen

- BFA 2008-English 10Dokument1 SeiteBFA 2008-English 10msyan1965Noch keine Bewertungen

- BFA 2008-English 7Dokument1 SeiteBFA 2008-English 7msyan1965Noch keine Bewertungen

- BFA 2008-English 4Dokument1 SeiteBFA 2008-English 4msyan1965Noch keine Bewertungen

- BFA 2008-English 9Dokument1 SeiteBFA 2008-English 9msyan1965Noch keine Bewertungen

- BFA 2008-English 5Dokument1 SeiteBFA 2008-English 5msyan1965Noch keine Bewertungen

- BFA 2008-English 6Dokument1 SeiteBFA 2008-English 6msyan1965Noch keine Bewertungen

- BFA 2008-English 3Dokument1 SeiteBFA 2008-English 3msyan1965Noch keine Bewertungen

- Design Manual Barrier Free Access 2008Dokument1 SeiteDesign Manual Barrier Free Access 2008msyan1965Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- OSHA's General Duty ClauseDokument4 SeitenOSHA's General Duty ClauseGray Fox GarcíaNoch keine Bewertungen

- GPPB 2013-2014 Updates and Latest IssuancesDokument166 SeitenGPPB 2013-2014 Updates and Latest Issuancesztirf_278737100% (1)

- Case Study Let There Be LightDokument26 SeitenCase Study Let There Be LightfeechooNoch keine Bewertungen

- Tax Law Rev Notes - Q and ADokument107 SeitenTax Law Rev Notes - Q and AJohnNoch keine Bewertungen

- Short-Term Rentals PresentationDokument47 SeitenShort-Term Rentals PresentationThe Globe and MailNoch keine Bewertungen

- Contracts of AffreightmentDokument53 SeitenContracts of AffreightmentEstefanía Gonzalez100% (2)

- Clearfield Doctrine Us Incorporated in Florida July 15,%Dokument2 SeitenClearfield Doctrine Us Incorporated in Florida July 15,%lee sandsNoch keine Bewertungen

- India Business Law DirectoryDokument41 SeitenIndia Business Law DirectoryVidya AdsuleNoch keine Bewertungen

- UK YPRAC ManosDokument1 SeiteUK YPRAC ManoseschizasNoch keine Bewertungen

- Iec 60601-2-49 (2001) (INDIA)Dokument48 SeitenIec 60601-2-49 (2001) (INDIA)estebanNoch keine Bewertungen

- Regulatory Compliance Guide Chaper 3800Dokument101 SeitenRegulatory Compliance Guide Chaper 3800Ava0% (1)

- Tripartite Agreement Between Stock Broker, Subbroker and ClientDokument7 SeitenTripartite Agreement Between Stock Broker, Subbroker and ClientKrishnamurthy HegdeNoch keine Bewertungen

- 1Dokument8 Seiten1motors_josep6203Noch keine Bewertungen

- Living Will SampleDokument6 SeitenLiving Will SampleFelicia Daniels100% (2)

- 2020 Draft HSE Plan Ucd CampDokument17 Seiten2020 Draft HSE Plan Ucd Campbilo198450% (2)

- Social ResponsibilityDokument24 SeitenSocial ResponsibilityAnuj DubeyNoch keine Bewertungen

- Anime d20 SRD v1.0 - Chap01Dokument3 SeitenAnime d20 SRD v1.0 - Chap01Rémy TrepanierNoch keine Bewertungen

- G.R. No. 162090Dokument6 SeitenG.R. No. 162090Mariaanna ReyesNoch keine Bewertungen

- SRO 483 17042018 - Amendments Cos Inc. Reg. 2017Dokument17 SeitenSRO 483 17042018 - Amendments Cos Inc. Reg. 2017MUNIR HUSSAINNoch keine Bewertungen

- Analysis of Sale of Goods Act and Statute of Fraud in NigeriaDokument11 SeitenAnalysis of Sale of Goods Act and Statute of Fraud in NigeriaJohn O. Ichie100% (1)

- MCIAA vs. MarcosDokument2 SeitenMCIAA vs. MarcosKing BadongNoch keine Bewertungen

- PED Certification RequirementsDokument10 SeitenPED Certification RequirementsDheeraj Chowdary DhanekulaNoch keine Bewertungen

- TOLENTINO vs. Sec of FinanceDokument3 SeitenTOLENTINO vs. Sec of FinanceMark Pelobello Malhabour100% (4)

- Concept Paper: ON Limited Liability Partnership (LLP) in PakistanDokument19 SeitenConcept Paper: ON Limited Liability Partnership (LLP) in PakistanshaddydagerNoch keine Bewertungen

- Central Excise DutyDokument19 SeitenCentral Excise DutyGurneet Kaur GujralNoch keine Bewertungen

- 2 Brahmastra Audit Revision by PK SA 200 SeriesDokument32 Seiten2 Brahmastra Audit Revision by PK SA 200 Seriesaaditya mehtaNoch keine Bewertungen

- Business PlanDokument5 SeitenBusiness Planjenefer100% (2)

- SkyHigh Liability WaiverDokument1 SeiteSkyHigh Liability WaiverZach HunterNoch keine Bewertungen

- Case Digest ANG PUE vs. SECRETARYDokument1 SeiteCase Digest ANG PUE vs. SECRETARYHannahboi G DesckyNoch keine Bewertungen

- Submission To Procurement Review Committee: Building / Construction / Roads and Bridges Only (Otherwise Delete)Dokument3 SeitenSubmission To Procurement Review Committee: Building / Construction / Roads and Bridges Only (Otherwise Delete)dileep2000100% (1)