Beruflich Dokumente

Kultur Dokumente

20

Hochgeladen von

sebaversaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

20

Hochgeladen von

sebaversaCopyright:

Verfügbare Formate

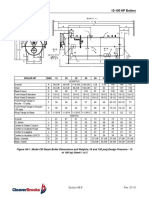

Model 4WI 100 800 HP Boilers

BOILER ALL DIMENSIONS IN INCHES

HP A B C D E

100 79.5 21.375 84.75 10 3

125 79.5 21.375 108.75 10 3

150 87.125 21.375 96.75 10 3

200 87.125 21.375 130.75 10 3

250 99 28.75 104.25 10 3

300 99 28.75 128.25 10 3

350 107.625 33.25 126 10 3

400 107.625 33.25 144 10 3

500 125.375 34.5 145 10 3

600 125.375 34.5 180 10 3

700-800 134.5 34.5 164 10 3

NOTE: A, B, and C dimensions may vary by 1 inch.

Table A2-10. Lifting Lug Locations

Section A2-12 Rev. 09-09

Model 4WI 100 800 HP Boilers

PERFORMANCE DATA

The Low Emission Option provides NOx reduction at current published and predicted

fuel-to-steam efficiencies. Refer to Table A2-12 and Table A2-13.

Specifying Boiler Efficiency

Cleaver-Brooks offers an industry leading fuel-to-steam boiler efficiency guarantee for

Promethean 4WI Firetube Boilers. The guarantee is based on the fuel-to-steam

efficiencies shown in the efficiency tables and the following conditions. The efficiency

percent number is only meaningful if the specific conditions of the efficiency calculations

are clearly stated in the specification (see Cleaver-Brooks publication CB-7768 for a

detailed description of efficiency calculations).

When specifying the efficiencies in the tables, be sure to include the specific guarantee

conditions to maximize the effectiveness of your efficiency specification. If you have any

questions regarding the efficiency specifications, please contact your local Cleaver-

Brooks authorized representative.

Efficiency Specification

The boiler manufacturer shall guarantee that, at the time of startup, the boiler will achieve

fuel-to-steam/water efficiency (as shown in Table A2-12 and Table A2-13) at 100% firing

rate (Reference efficiency guarantees at 25%, 50%, and 75% of rating, if required). If the

boiler(s) fail to achieve the corresponding guaranteed efficiency as published, the boiler

manufacturer will rebate, to the ultimate boiler owner, ten thousand dollars ($10,000) for

every full efficiency point (1.0%) that the actual efficiency is below the guaranteed level.

The specified boiler efficiency is based on the following conditions.

1. Fuel specification used to determine boiler efficiency:

Natural Gas

Carbon,% (wt) = 69.98

Hydrogen,% (wt) = 22.31

Sulfur,% (wt) = 0.0

Heating value, Btu/lb. = 21,830

No. 2 Oil

Carbon,% (wt) = 85.8

Hydrogen,% (wt) = 12.7

Sulfur,% (wt) = 0.2

Heating value, Btu/lb. = 19,420

No. 6 Oil

Carbon,% (wt) = 86.6

Hydrogen,% (wt) = 10.9

Sulfur,% (wt) = 2.09

Heating value, Btu/lb. = 18,830

2. Efficiencies are based on ambient air temperature of 80 F, relative humidity of 30%,

and 15% excess air in the exhaust flue gas.

3. Efficiencies are based on manufacturers published radiation and convection losses.

(For Cleaver-Brooks radiation and convection losses, see Boiler Efficiency Facts

Guide, publication number CB-7767).

4. Any efficiency verification testing will be based on the stack loss method.

For efficiencies and stack temperatures at operating pressures not listed, follow these

procedures:

Section A2-13 Rev. 09-09

Model 4WI 100 800 HP Boilers

When the operating steam pressure is between 10 psig and 125 psig, interpolate the

values from the efficiency tables.

When the operating steam pressure is above 125 psig, estimated efficiency can be

calculated as follows:

Example:

Boiler: 350 hp.

Fuel: natural gas.

Operating steam pressure: 200 psig.

Find the fuel-to-steam efficiency at 100% firing rate. From Table A2-12 a boiler operating

at 100% firing rate and an operating steam pressure of 125 psig, the efficiency is 82.1%.

Using Figure A2-3, note that the stack temperature increases 36 F at the higher

operating pressure. To estimate boiler efficiency, use this rule of thumb: For every 40 F

increase in stack temperature, efficiency decreases by 1%. Since the stack temperature

rise is 36 F, the decrease in the boiler efficiency at 200 psig operating pressure is

calculated as follows: 36/40 =.9%. Therefore, the boiler efficiency at 200 psig operating

pressure is 82.1 -.9 = 81.2%

Emissions

The emission data included in this section consists of typical emission levels for the 4WI

boiler equipped with 60 & 30 ppm reduction with natural gas or No. 2 oil.

Table A2-11. Firing Rates 4WI Boilers with Integral Burner

Natural Gas, 1000 Btu/hr No. 2 Oil, GPH

BHP Low High Low High

100 1021 4082 7.3 29.2

125 1276 5103 9.1 36.4

150 1531 6124 10.9 43.7

200 2041 8165 14.6 58.3

250 1021 10206 9.1 72.9

300 1225 12247 10.9 87.5

350 1428 14280 12.8 102.1

400 1633 16329 14.6 116.6

500 2042 20415 18.2 145.8

600 2449 24494 21.9 175

700 2858 28576 25.5 204.1

750 3062 30617 27.3 218.7

800 3266 32659 29.2 233.3

Notes:

Fuel input rates are based on nominal 82% efficiency.

No. 2 Oil = 140,000 Btu/Gal

Section A2-14 Rev. 09-09

Model 4WI 100 800 HP Boilers

Table A2-12. Predicted Fuel-to-Steam Efficiencies - Natural Gas - Model 4WI

OPERATING PRESSURE = 10 psig OPERATING PRESSURE = 125 psig

BHP % OF LOAD % OF LOAD

25% 50% 75% 100% 25% 50% 75% 100%

100 84.4 84.6 84.1 83.6 81.6 82.0 81.7 81.3

125 84.6 85.0 84.7 84.3 81.8 82.3 82.2 82.0

150 84.5 84.8 84.4 83.9 81.6 82.0 81.7 81.3

200 84.7 85.2 85.1 84.8 81.8 82.4 82.3 82.2

250 84.7 85.1 84.9 84.5 81.8 82.4 82.3 82.1

300 84.8 85.3 85.2 85.0 81.9 82.6 82.6 82.5

350 84.7 85.2 85.1 84.8 81.8 82.4 82.3 82.1

400 85.4 85.6 85.5 85.2 82.6 82.9 82.8 82.6

500 85.4 85.6 85.5 85.3 82.6 83.0 82.9 82.8

600 85.5 85.8 85.7 85.6 82.7 83.2 83.2 83.1

700 85.5 85.7 85.7 85.6 82.7 83.1 83.1 83.0

800 85.5 85.8 85.7 85.6 82.7 83.1 83.1 83.0

Note: Using the ultra low NOx burner (15-<9ppm) will result in a slight reduction of fuel-to-steam efficiency.

Figure A2-3. Predicted Stack Temperature Increase for Pressure Greater Than 125 psig - Model 4WI

Section A2-15 Rev. 09-09

Das könnte Ihnen auch gefallen

- Efficient 15-100 HP Boilers for BuildingsDokument5 SeitenEfficient 15-100 HP Boilers for BuildingssebaversaNoch keine Bewertungen

- Model CBL 900-1800 HP Boilers: Engineering DataDokument5 SeitenModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNoch keine Bewertungen

- Model CB 15-100 HP BoilersDokument5 SeitenModel CB 15-100 HP BoilerssebaversaNoch keine Bewertungen

- Model CB 15-100 HP BoilersDokument5 SeitenModel CB 15-100 HP BoilerssebaversaNoch keine Bewertungen

- Model CBL 900-1800 HP BoilersDokument5 SeitenModel CBL 900-1800 HP BoilerssebaversaNoch keine Bewertungen

- 15-100 HP Boilers Dimensions SpecsDokument5 Seiten15-100 HP Boilers Dimensions SpecssebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDokument5 SeitenModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDokument5 SeitenModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDokument5 SeitenModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNoch keine Bewertungen

- Features and Benefits: Model CB 15-100 HP BoilersDokument5 SeitenFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: Sound LevelDokument5 SeitenModel CB 15-100 HP Boilers: Sound LevelsebaversaNoch keine Bewertungen

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDokument5 Seiten900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDokument5 SeitenModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNoch keine Bewertungen

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDokument5 SeitenModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNoch keine Bewertungen

- 900-1800 HP Boiler SpecsDokument5 Seiten900-1800 HP Boiler SpecssebaversaNoch keine Bewertungen

- Section A5: Model CBL 900-1800 HP BoilersDokument5 SeitenSection A5: Model CBL 900-1800 HP BoilerssebaversaNoch keine Bewertungen

- Model CBR 125-800 HP Boilers: Front Feedwater TankDokument5 SeitenModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNoch keine Bewertungen

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDokument5 SeitenModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNoch keine Bewertungen

- 78Dokument5 Seiten78sebaversaNoch keine Bewertungen

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDokument5 SeitenModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNoch keine Bewertungen

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDokument5 SeitenModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNoch keine Bewertungen

- Model CBR 125-800 HP BoilersDokument5 SeitenModel CBR 125-800 HP BoilerssebaversaNoch keine Bewertungen

- 81Dokument5 Seiten81sebaversaNoch keine Bewertungen

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDokument5 Seiten125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNoch keine Bewertungen

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Dokument6 SeitenModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNoch keine Bewertungen

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDokument5 Seiten125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNoch keine Bewertungen

- 75Dokument5 Seiten75sebaversaNoch keine Bewertungen

- High-efficiency boiler specifications for 100-800 HP modelsDokument4 SeitenHigh-efficiency boiler specifications for 100-800 HP modelssebaversaNoch keine Bewertungen

- Model ICB 100-800 HP BoilersDokument4 SeitenModel ICB 100-800 HP BoilerssebaversaNoch keine Bewertungen

- General: Model ICB 100-800 HP BoilersDokument4 SeitenGeneral: Model ICB 100-800 HP BoilerssebaversaNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 1507704441084-Aug 2017 - Stock PDFDokument38 Seiten1507704441084-Aug 2017 - Stock PDFRakesh Singh0% (1)

- Cominox SterilClave 18-24 - User and Maintenance ManualDokument68 SeitenCominox SterilClave 18-24 - User and Maintenance ManualJose Tavares100% (2)

- Thermodynamics control volume analysisDokument6 SeitenThermodynamics control volume analysisLUISRONoch keine Bewertungen

- Chemical Supplies Company ListingDokument757 SeitenChemical Supplies Company ListingAmit Jage50% (4)

- 5-Speed Manual Transmission Parts and SpecificationsDokument24 Seiten5-Speed Manual Transmission Parts and SpecificationsAhmad Taha ZakiNoch keine Bewertungen

- PivsuexDokument7 SeitenPivsuextthenryNoch keine Bewertungen

- High-Performance Door RP2000 Machine ProtectionDokument2 SeitenHigh-Performance Door RP2000 Machine ProtectionRudolf GPNoch keine Bewertungen

- All Makes Filters Cross Reference GuidesDokument5 SeitenAll Makes Filters Cross Reference GuidesJafet Israel RojasNoch keine Bewertungen

- Emulsifying MachineDokument2 SeitenEmulsifying MachineSebas PerNoch keine Bewertungen

- Power Contactor 1250 A - HubbellDokument4 SeitenPower Contactor 1250 A - Hubbellmanuel99a2kNoch keine Bewertungen

- MIG Welding Guide - Processes, Principles & Applications of GMAWDokument23 SeitenMIG Welding Guide - Processes, Principles & Applications of GMAWAsad Bin Ala Qatari50% (2)

- Waste Paper Pulp Product Industry Project ReportDokument8 SeitenWaste Paper Pulp Product Industry Project ReportSukhvinder SinghNoch keine Bewertungen

- Total Water Management in Thermal Power StationsDokument8 SeitenTotal Water Management in Thermal Power StationsSarah FrazierNoch keine Bewertungen

- DS DT 02 Standard TraysDokument4 SeitenDS DT 02 Standard TraysAhmet Samet ÖzdilekNoch keine Bewertungen

- Understanding Defects in High Integrity Die Castings - EJ VinarcikDokument11 SeitenUnderstanding Defects in High Integrity Die Castings - EJ Vinarcikoğuz kağanNoch keine Bewertungen

- Teflon Research PaperDokument11 SeitenTeflon Research PaperluluazulNoch keine Bewertungen

- Catalogo Bepco Tractor PartsDokument266 SeitenCatalogo Bepco Tractor PartsGabriel Escarcena Robles100% (5)

- Overview of Pressure Vessel Design-Instructor's Guide (Carucci)Dokument137 SeitenOverview of Pressure Vessel Design-Instructor's Guide (Carucci)Kittipong PhakakarnNoch keine Bewertungen

- Level 9 - Mechanical TechnologyDokument17 SeitenLevel 9 - Mechanical TechnologyFajiza JuarezaNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument18 SeitenDisclosure To Promote The Right To InformationVedachalam ManiNoch keine Bewertungen

- C 71 - 00 - QzcxltawqqDokument5 SeitenC 71 - 00 - QzcxltawqqfekihassanNoch keine Bewertungen

- Factsheet SGT-700 enDokument2 SeitenFactsheet SGT-700 enAzril DahariNoch keine Bewertungen

- DistillationDokument15 SeitenDistillationRahul PalsNoch keine Bewertungen

- Stone Cladding Fixings Technical StandardsDokument6 SeitenStone Cladding Fixings Technical StandardsvtalexNoch keine Bewertungen

- Kiln Preheater Fan CoatingDokument6 SeitenKiln Preheater Fan CoatingVijay Bhan100% (1)

- Membrane LG CW 4040 SFDokument1 SeiteMembrane LG CW 4040 SFPT Deltapuro IndonesiaNoch keine Bewertungen

- 1059PTDokument1 Seite1059PTBastin John AntonyNoch keine Bewertungen

- GATIC Galvanised Mild Steel GMS Grating Data SheetDokument3 SeitenGATIC Galvanised Mild Steel GMS Grating Data Sheetiask5275Noch keine Bewertungen

- FAA 8083 30 - Ch09Dokument26 SeitenFAA 8083 30 - Ch09William LoNoch keine Bewertungen

- 2sc-Pco - Dual Solenoid Control ValveDokument3 Seiten2sc-Pco - Dual Solenoid Control Valveshan07011984Noch keine Bewertungen