Beruflich Dokumente

Kultur Dokumente

JHA ConcretePlacingOperation

Hochgeladen von

Anonymous XJ9663C6N4Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

JHA ConcretePlacingOperation

Hochgeladen von

Anonymous XJ9663C6N4Copyright:

Verfügbare Formate

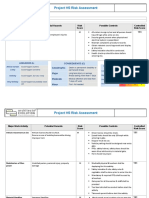

JOB HAZARD ANALYSIS

Reference: 29 CFR 1926 Subpart Q, Concrete and masonry construction. OSHA Standard

Job Description Hazard Identification Hazard Controls

Concrete Placing

Laying out footing forms

a. Saw operators and adjacent workers will

1. Cutting form lumber with circular saw 1. High pitched noise can damage hearing wear hearing and eye protection when

operating saws.

b. All power saws will have manufacturer-

2. Setting and securing form lumber in 2. Saw blades cut whatever they come in

supplied guards in place and operational at

place contact with

all times

3. Driving/securing stakes in ground 3. Electrical Shock c. Inspect and test equipment and cords.

4. Sledge hammer can send particles of d. Power tools not in use shall be

wood/metal flying disconnected from their power source.

e. All workers will wear eye protection.

f. Person using sledge hammer will make

sure everyone else is clear before swinging.

Installing Rebar

a. Rebar cutters will wear safety glasses,

1. Grinder wheel throws off sparks and hot

1. Cutting rebar gloves, hearing protection, safety vest, and

bits of metal

hardhats.

2. Accidental contact with grinder wheel b. Workers will ensure the grinders guard

2. Setting and tying rebar

can cause bad cuts is in place and fully operational before use.

3. Mill scale, sharp/sheared ends of tie wire c. Workers tying rebar will wear safety

can injure eyes glasses.

d. Debris should be removed from work

4. Tripping and/or falling

areas on a regular basis.

e. Rebar should be properly stacked.

Stacks stored beneath overhead power

5. Impalement hazard lines shall first be moved forward and away

from the power lines before being lifted, to

eliminate contacting power lines.

f. All protruding ends of steel rebar shall be

guarded with rebar caps or wooden

6. Accidental contact with overhead power

troughs, or bent so that exposed ends no

lines

longer create an impalement hazard. Refer

to OSHA 1926.701(b)

Scaffolding

1. Scaffold set up 1. Pinch Points a. Ensure hard hats, safety glasses, and

2. Ladder set up 2. Slips, trips, and falls safety vests are worn.

3. Getting to the scaffold platform a. Ensure scaffold is secure and stable.

a. Ensure that top rail, mid-rail, and toe

4. Using scaffold components

boards are in place.

JHA - Concrete Placing Operation.xls 1

b. Use ladders or stairs to reach platforms

that are more than 2 feet above or below

the access point.

c. Dont use damaged scaffold

components; repair or replace them

immediately.

d. Make sure a competent person inspects

the components before each work shift.

e. Dont modify components.

Placing Concrete

a. While heavy equipment is operating, all

1. Positioning concrete pumper and redi- 1. Workers run over/backed into by

workers on the ground will wear hi-

mix trucks equipment

visibility vests and hardhats.

2. Placing concrete as it comes from the 2. Air in line causing high-speed burst of b. Concrete pumpers and redi-mix trucks

hose concrete will always have spotters while backing up.

c. Equipment idling longer than 3 minutes

shall be turned off.

d. Only trained workers will handle the

whip-hose.

e. Whip-hose operator and others will

coordinate on signals with pump operator.

Instructions for employees

Actions for forming

Clear debris from area on a regular basis

Wear hardhat, eye protection

Inspect and test equipment prior to use

Actions for installing rebar

Wear safety glasses, gloves, hearing protection, safety vest and hardhats

Inspect and test equipment prior to use

Clear debris from area on a regular basis

Properly stack rebar

All protruding ends of rebar should be capped

Actions for scaffolding

Wear hardhats, safety glasses, and safety vests

Ensure that scaffold is secure and stable

Ensure that top rail, mid-rail and toe boards are in place

Ensure that ladder is installed properly and in a stable place

A competent person must inspect components of scaffold prior to each shift

Actions for concrete placement operation

While heavy equipment is operating, all ground workers will wear hardhats and safety vests

Pumpers and redi-mix trucks will use spotters

Equipment idling more than 3 minutes will be shut off

Only trained workers will use the whip-hose

Whip-hose operator and others will coordinate signals with pump operator

JHA - Concrete Placing Operation.xls 2

Have all crew members sign here to acknowledge their understanding of the JHA.

Manager / Supervisor Signature: ______________________________ Date: ____________________

NOTE TO MANAGER, SUPERVISOR OR FOREMAN: WORK MUST NOT START UNTIL CONTROLS ARE

IN PLACE AND THIS HAS BEEN DISCUSSED AND ALL SIGNATURES ARE OBTAINED.

JHA - Concrete Placing Operation.xls 3

Das könnte Ihnen auch gefallen

- Demolition PDFDokument2 SeitenDemolition PDFvinothNoch keine Bewertungen

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDokument3 SeitenGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- Excavation and TrenchingDokument2 SeitenExcavation and TrenchingvikasNoch keine Bewertungen

- Jsa Working at Height (Maintenance & Cleaning)Dokument2 SeitenJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (1)

- Rohan Abuilders (India) PVT - LTD: Job Hazard AnalysisDokument2 SeitenRohan Abuilders (India) PVT - LTD: Job Hazard AnalysisMc Evans Magallanes100% (1)

- Job Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9Dokument4 SeitenJob Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9OGBONNAYA MARTINSNoch keine Bewertungen

- Risk AssessmentDokument3 SeitenRisk AssessmentAkinbami Olorunnifemi100% (1)

- Excavations JSA Final 2015Dokument5 SeitenExcavations JSA Final 2015jithin shankarNoch keine Bewertungen

- Job Hazard Analysis of Site SURVEYINGDokument1 SeiteJob Hazard Analysis of Site SURVEYINGYogesh Gowda100% (1)

- Jha RebarsDokument7 SeitenJha RebarsJaycee QuinNoch keine Bewertungen

- 01 JSA For Earthworks at Corridor ADokument32 Seiten01 JSA For Earthworks at Corridor AHilbrecht De Pedro100% (1)

- Concrete Pouring JSaDokument12 SeitenConcrete Pouring JSaTheo Vidallon BautistaNoch keine Bewertungen

- Risk Assessment - Concrete CastingDokument3 SeitenRisk Assessment - Concrete Castingdnmule50% (2)

- Concrete Surface Coating JSA-027Dokument5 SeitenConcrete Surface Coating JSA-027shivgovind pal100% (1)

- Jha RoofingDokument4 SeitenJha Roofingahmadhatake100% (1)

- JSA PlumberDokument2 SeitenJSA PlumberSyed Yousuf AliNoch keine Bewertungen

- Concreting and ShutteringDokument3 SeitenConcreting and ShutteringAnuj Kjoy0% (1)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDokument3 SeitenNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNoch keine Bewertungen

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDokument6 Seitenjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNoch keine Bewertungen

- Concrete Cutting JsaDokument4 SeitenConcrete Cutting JsaMohammad Irfan Kiki IsmailNoch keine Bewertungen

- TBT-Driving in FogDokument2 SeitenTBT-Driving in FogImran KhanNoch keine Bewertungen

- RA-for Glass Installation 30-04-2022Dokument6 SeitenRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDokument5 SeitenRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNoch keine Bewertungen

- New Pta Complex: Jsa For Reinforcing Steel BarsDokument12 SeitenNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNoch keine Bewertungen

- Project HS Risk AssessmentDokument8 SeitenProject HS Risk AssessmentParasNoch keine Bewertungen

- Jsa006-Construction of Retaining WallDokument5 SeitenJsa006-Construction of Retaining WallWan Muhammad Faiz100% (1)

- JSA Ladders Working at Heights 001Dokument2 SeitenJSA Ladders Working at Heights 001Anonymous voA5Tb0Noch keine Bewertungen

- Risk Assessment of Cantilever ScaffoldDokument1 SeiteRisk Assessment of Cantilever ScaffoldGyanendra Srivastava100% (1)

- Block Work MS (Sample)Dokument18 SeitenBlock Work MS (Sample)jones100% (1)

- Risk Assisment For Fence WorkDokument2 SeitenRisk Assisment For Fence Workashishakare100% (1)

- Job Safety Analysis (JSA) - CONCRETE WORKS - DateDokument2 SeitenJob Safety Analysis (JSA) - CONCRETE WORKS - DatenabeelNoch keine Bewertungen

- Risk Assessmen For-Excavation-And-BackfillingDokument4 SeitenRisk Assessmen For-Excavation-And-BackfillingEngrHazrat Maaz100% (1)

- Job Safety Analysis - Civil WorksDokument7 SeitenJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- JSA FOR Concerate PlacementDokument1 SeiteJSA FOR Concerate Placementwahyu nugrohoNoch keine Bewertungen

- Risk Assessment For Anti Termite WorksDokument7 SeitenRisk Assessment For Anti Termite WorksSaeed Ahmad100% (1)

- Jha of PaintingDokument3 SeitenJha of PaintingAllan Camacho Regalado100% (1)

- RS Concrete Pumping Risk AssessmentDokument8 SeitenRS Concrete Pumping Risk AssessmentLito PanchoNoch keine Bewertungen

- Risk Assess Plastering 2006 Tcm17 26368Dokument2 SeitenRisk Assess Plastering 2006 Tcm17 26368Anonymous QGHbz92uNoch keine Bewertungen

- JSA - Installation of U G PipingDokument11 SeitenJSA - Installation of U G PipingOws Anish100% (1)

- Excavation (Company Name) : Phase Hazard AnalysisDokument11 SeitenExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieNoch keine Bewertungen

- Risk Assessment - Lifting OperationsDokument3 SeitenRisk Assessment - Lifting Operationsdnmule100% (2)

- Job Activity Hazard Effect Control Measures: Project in ChargeDokument3 SeitenJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNoch keine Bewertungen

- Risk Assessment Template For Combo Roof Waterproofing Work.Dokument14 SeitenRisk Assessment Template For Combo Roof Waterproofing Work.Majaga MabhenaNoch keine Bewertungen

- JSA For HDPE Liner Fusion Welding2Dokument6 SeitenJSA For HDPE Liner Fusion Welding2Mohammed Minhaj100% (8)

- Risk Assessment: N C Tucker LTD Plastering 17/06/2019 NTDokument4 SeitenRisk Assessment: N C Tucker LTD Plastering 17/06/2019 NTAngela DaveyNoch keine Bewertungen

- 4.assembly & Erection of StructureDokument3 Seiten4.assembly & Erection of StructureFrancis Vinoj100% (1)

- Anchor Bolt Setting - Rev 01Dokument26 SeitenAnchor Bolt Setting - Rev 01Geherson AbustanNoch keine Bewertungen

- Risk Assesment For CompactionDokument12 SeitenRisk Assesment For CompactionAzhar MushtaqNoch keine Bewertungen

- Steel FixingDokument5 SeitenSteel Fixingrishanmulky88% (8)

- Job Safety Analysis: Manual ExcavationDokument2 SeitenJob Safety Analysis: Manual Excavationfdfddf dfsdfNoch keine Bewertungen

- Swms For Glass Partition FixingDokument6 SeitenSwms For Glass Partition FixingSiddharth PNoch keine Bewertungen

- JSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Dokument7 SeitenJSA For The Steel Fixing and Manual Conxrete Pouring at New Flare Line Phase 2 (Brown Area)Marvin BerrensteinNoch keine Bewertungen

- JSA For Plaster WorkDokument8 SeitenJSA For Plaster WorkZakeer ShaikhNoch keine Bewertungen

- Management Health and Safety Risk Assessment: ClientDokument3 SeitenManagement Health and Safety Risk Assessment: ClientMian100% (1)

- 11 - JSA (Tower Crane) 12-9-06Dokument11 Seiten11 - JSA (Tower Crane) 12-9-06sattiNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDokument2 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Job Hazard Analysis (Earth Mounted Tank)Dokument8 SeitenJob Hazard Analysis (Earth Mounted Tank)jay RNoch keine Bewertungen

- JSA For RCC, Foundation & Generator Installation (R-00)Dokument14 SeitenJSA For RCC, Foundation & Generator Installation (R-00)Suju RajanNoch keine Bewertungen

- Job Safety Analysis Light Bulb ReplacementDokument4 SeitenJob Safety Analysis Light Bulb Replacementshane.ramirez1980Noch keine Bewertungen

- Job Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or ProcedureDokument2 SeitenJob Hazard Analysis: Basic Job Steps Potential Hazards Recommended Actions or ProcedureBernard Christian DimaguilaNoch keine Bewertungen

- JHA - Clearing, Grubbing, Excavation, Backfilling and CompactionDokument11 SeitenJHA - Clearing, Grubbing, Excavation, Backfilling and Compactionmark jayson yabesNoch keine Bewertungen

- LUS-HSE-WG3-446-006.01 - Personal Protective Equipment (PPE)Dokument14 SeitenLUS-HSE-WG3-446-006.01 - Personal Protective Equipment (PPE)OgochukwuNoch keine Bewertungen

- Rigging Basic Learner Workbook Marking Guide ANSWERS SAMPLEDokument25 SeitenRigging Basic Learner Workbook Marking Guide ANSWERS SAMPLEMoha WlweeaNoch keine Bewertungen

- 25 Multiple Choice QuestionsDokument4 Seiten25 Multiple Choice QuestionsMaricar TeodoroNoch keine Bewertungen

- Ppe GuidelinesDokument25 SeitenPpe GuidelinesPaige Jones100% (1)

- Epp y Equipos SoldaduraDokument100 SeitenEpp y Equipos SoldaduraAlvaro Alexis Mendoza PradaNoch keine Bewertungen

- Job Safety Analysis Record SheetDokument23 SeitenJob Safety Analysis Record Sheetza8319712Noch keine Bewertungen

- Formwork and Steel Reinforcements Work Risk AssessmentDokument8 SeitenFormwork and Steel Reinforcements Work Risk AssessmentVC100% (1)

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Dokument11 SeitenJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNoch keine Bewertungen

- Hard Hat PDFDokument3 SeitenHard Hat PDFusama shehrozNoch keine Bewertungen

- Tle-10 Agri-Crop (Q1-Week 7)Dokument4 SeitenTle-10 Agri-Crop (Q1-Week 7)Juliet Alfaro SorianoNoch keine Bewertungen

- Gestamp Production System (GPS) Standards Gestamp Production System (GPS) StandardsDokument10 SeitenGestamp Production System (GPS) Standards Gestamp Production System (GPS) Standardsசிவ சங்கர்100% (1)

- JHA-welding Joint PaintingDokument9 SeitenJHA-welding Joint Paintingmansih457Noch keine Bewertungen

- 2017 Core PPE CatalogueDokument52 Seiten2017 Core PPE CatalogueMOHAMEDNoch keine Bewertungen

- JSA FOR Concerate PlacementDokument1 SeiteJSA FOR Concerate Placementwahyu nugrohoNoch keine Bewertungen

- Key Vocabulary For A Safe WorkplaceDokument109 SeitenKey Vocabulary For A Safe WorkplaceEva DiazNoch keine Bewertungen

- 0600-66-MC - ANSIZ89 - WhitePaper - EN PDFDokument1 Seite0600-66-MC - ANSIZ89 - WhitePaper - EN PDFAnonymous C4PJCOz6Noch keine Bewertungen

- Terex PT-110 Operation & Maintenance ManualDokument100 SeitenTerex PT-110 Operation & Maintenance ManualJoe ZhaoNoch keine Bewertungen

- 4194 Sirio Duplex 150 inDokument145 Seiten4194 Sirio Duplex 150 inIvan RalchevNoch keine Bewertungen

- Hard Hats Clips - Reference Designs and GuidelinesDokument5 SeitenHard Hats Clips - Reference Designs and GuidelinesasdNoch keine Bewertungen

- Work - Method - Statement - PPMC Reconstruction of Eroded Perimeter Fence Embarkment at ExcravosDokument14 SeitenWork - Method - Statement - PPMC Reconstruction of Eroded Perimeter Fence Embarkment at ExcravosImonieroGodspowerEfeNoch keine Bewertungen

- Msa Helmet Catalog PDFDokument9 SeitenMsa Helmet Catalog PDFRinto IrawanNoch keine Bewertungen

- Revised Risk Assessment-Concrete Coring-1Dokument5 SeitenRevised Risk Assessment-Concrete Coring-1riyazkader83% (12)

- Assignment 6 - Putri Arifa Nur'Aini - 464211052Dokument3 SeitenAssignment 6 - Putri Arifa Nur'Aini - 464211052Putri Arifa N.Noch keine Bewertungen

- Module 5Dokument7 SeitenModule 5sheynie penalosaNoch keine Bewertungen

- High Risk Job Safety Analysis: Contractor ArgonneDokument13 SeitenHigh Risk Job Safety Analysis: Contractor ArgonneVwoke OyibogareNoch keine Bewertungen

- Slide No 01 SF 06 Safety Awareness & PPEDokument59 SeitenSlide No 01 SF 06 Safety Awareness & PPETusharShuvroNoch keine Bewertungen

- Catalogo Herramientas CaterpillarDokument112 SeitenCatalogo Herramientas CaterpillarJorge Perez100% (2)

- HSE PLAN For UploadDokument18 SeitenHSE PLAN For UploadOladimeji Taiwo71% (7)

- Abc 123Dokument2 SeitenAbc 123BRSantanaNoch keine Bewertungen