Beruflich Dokumente

Kultur Dokumente

POLYTUNG-NICRBWC Datasheet

Hochgeladen von

rajeevkv4Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

POLYTUNG-NICRBWC Datasheet

Hochgeladen von

rajeevkv4Copyright:

Verfügbare Formate

Technical Datasheet

POLYTUNG NiCrBWC

Gas Metal Arc Welding Wire

April 2016

PRODUCT OVERVIEW

POLYTUNG NiCrBWCis a nickel chrome boron silicon matrix system, with 38-44% tungsten carbide particles. This combination

produces a superior microstructure when welded and has excellent fine particle erosion, corrosion and toughness. The low heat

input when welding POLYTUNG NiCrBWC reduces the amount of tungsten carbide particles going into solution. Deposits are not

machinable and can not be flame cut.

TYPICAL DEPOSIT CHARACTERISTICS: SPECIFICATION:

Abrasion Resistance Excellent Tungsten Carbides in a Nickel Chrome Boron Silicon

Matrix

Impact Resistance: Moderatehigh

Deposit Layers: 1-3 passes

Deposit Cross Checks: Yes

Magnetic: Yes

Hot Wear Hardness 900 F

Machineability: No

APPLICATION

Dredge cutter teeth & heads

Rotary bucket dredge teeth

Dozer end bits

Pipe & elbow ID slurry type application

Conveyor screws

stabilizers

Filter screens

NOMINAL CHEMICAL COMPOSITION (wt%)

W Cr Si B Ni

38-44 10.0 2.2 1.0 Bal

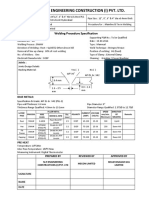

RECOMMENDED WELDING PARAMETERS:

Diameter Current Voltage Amperage Shielding Gas Wire Extension Position

.062 (1.6mm) DCEP 17-22* 90-150 75Ar25Co2 3/4 - 1 Flat

Use lowest possible heat input for best results

The properties listed are typical and not to be construed as guaranteed values. Actual properties may vary depending on customer operating conditions.

STANDARD SIZES & PACKAGING:

Diameter Packaging

.062 (1.6mm) 25# LWS

10073 Commerce Park Drive. Cincinnati, OH 45246 / Phone: 513-874-3586 / Fax: 513-874-2880

E-mail: sales@polymet.us

Das könnte Ihnen auch gefallen

- 501 Quantitative Comparison QuestionsDokument168 Seiten501 Quantitative Comparison Questionsjnanmol00793% (15)

- WPS Format For Asme Ix - Wps - Fcaw GmawDokument1 SeiteWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNoch keine Bewertungen

- Mathios Refractories Catalog Web EditionDokument102 SeitenMathios Refractories Catalog Web EditionEvangelos TentisNoch keine Bewertungen

- How To Passivate Stainless Steel PartsDokument11 SeitenHow To Passivate Stainless Steel Partsnqh2009Noch keine Bewertungen

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Dokument6 SeitenMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNoch keine Bewertungen

- Wire Rope Test CertificateDokument2 SeitenWire Rope Test CertificateDustin Xender50% (2)

- ElectroplatingDokument74 SeitenElectroplatingmp87_ing100% (4)

- 1 PBDokument7 Seiten1 PBANGELA MARIA VARGAS TABORDANoch keine Bewertungen

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantVon EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Mae Moh Lignite Mine and Environmental ManagementDokument11 SeitenMae Moh Lignite Mine and Environmental ManagementMaria Diamantopoulou100% (1)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Dokument6 SeitenMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNoch keine Bewertungen

- Welding Processes & InspectionDokument52 SeitenWelding Processes & InspectionKaung Htet Cho100% (1)

- NOTE CHAPTER 4 The Periodic Table of ElementsDokument24 SeitenNOTE CHAPTER 4 The Periodic Table of ElementsNur AfiqahNoch keine Bewertungen

- Proposed WPS For API 5LDokument1 SeiteProposed WPS For API 5LMecon HyderabadNoch keine Bewertungen

- Chapter 13 - Heat Treatment of SteelsDokument60 SeitenChapter 13 - Heat Treatment of SteelsRecep VatanseverNoch keine Bewertungen

- UK MOD (Issue 3 Publication Date 20 September 2009) - Code of Practice For Protective FinishesDokument48 SeitenUK MOD (Issue 3 Publication Date 20 September 2009) - Code of Practice For Protective FinishesLuis Gustavo PachecoNoch keine Bewertungen

- Sand Casting PresentationDokument40 SeitenSand Casting Presentationsiddiqsiddiq85Noch keine Bewertungen

- Sand Casting PresentationDokument40 SeitenSand Casting Presentationsiddiqsiddiq85Noch keine Bewertungen

- Company Presentation: AIA Engineering LimitedDokument26 SeitenCompany Presentation: AIA Engineering LimitedAl Amin Hossain SrabonNoch keine Bewertungen

- Polywear 60 GtawDokument1 SeitePolywear 60 GtawFlori MovNoch keine Bewertungen

- Polywear 50 Gtaw 1Dokument1 SeitePolywear 50 Gtaw 1Flori MovNoch keine Bewertungen

- Welding in Power SectorDokument50 SeitenWelding in Power SectoraadmaadmNoch keine Bewertungen

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Dokument1 SeiteAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNoch keine Bewertungen

- Tiginox 385: Classification: en Iso 14343-ADokument1 SeiteTiginox 385: Classification: en Iso 14343-AJagannath SahuNoch keine Bewertungen

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADokument1 SeiteAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNoch keine Bewertungen

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDokument3 SeitenConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390Noch keine Bewertungen

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Dokument1 SeiteAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNoch keine Bewertungen

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDokument2 SeitenTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNoch keine Bewertungen

- Merit S-G: Lincoln Electric China Gmaw Solid WireDokument2 SeitenMerit S-G: Lincoln Electric China Gmaw Solid Wiredev-nullNoch keine Bewertungen

- Wear Reducing Technology in Severe Pumping ServicesDokument29 SeitenWear Reducing Technology in Severe Pumping ServicesDaniel EsparzaNoch keine Bewertungen

- Diamondspark 52 MC: Seamless Metal-Cored WireDokument2 SeitenDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesNoch keine Bewertungen

- Miginox 347 / Tiginox 347: Classification: ApprovalsDokument1 SeiteMiginox 347 / Tiginox 347: Classification: ApprovalsJagannath SahuNoch keine Bewertungen

- Miginox 347si: Aws A/Sfa 5.9 EN ISO 14343-ADokument1 SeiteMiginox 347si: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNoch keine Bewertungen

- SK 900 Ni-G: ClassificationsDokument1 SeiteSK 900 Ni-G: ClassificationsYJ JangNoch keine Bewertungen

- CWC-BookletF1 15Dokument1 SeiteCWC-BookletF1 15satnamNoch keine Bewertungen

- Bronze C86300 SpecificationsDokument2 SeitenBronze C86300 SpecificationsDoss MartinNoch keine Bewertungen

- Welding Consumable DSMW-0024.1 - WokaDur - S80-Ni-TIG - ElectrodeDokument3 SeitenWelding Consumable DSMW-0024.1 - WokaDur - S80-Ni-TIG - ElectrodeJOLLY JAYA SENTOSANoch keine Bewertungen

- Asmeix Wps Fcawgmaw 191019041529 PDFDokument1 SeiteAsmeix Wps Fcawgmaw 191019041529 PDFvinod100% (1)

- item11-LNT NiCroMo 59.23Dokument1 Seiteitem11-LNT NiCroMo 59.23VVan TanNoch keine Bewertungen

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Dokument1 SeiteTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNoch keine Bewertungen

- X-Tract Electrical Submersible Pump CableDokument2 SeitenX-Tract Electrical Submersible Pump CableHarry RincónNoch keine Bewertungen

- Sandvik WeldingDokument3 SeitenSandvik WeldingRam KadamNoch keine Bewertungen

- CZ120 (CW612N) : Technical DatasheetDokument1 SeiteCZ120 (CW612N) : Technical DatasheetAmrut KanungoNoch keine Bewertungen

- UTP 655 32 SpecSheetDokument1 SeiteUTP 655 32 SpecSheetFadi HasnNoch keine Bewertungen

- ISO Standards On Mech Test of MetalsDokument1 SeiteISO Standards On Mech Test of MetalsKiran NikateNoch keine Bewertungen

- Datasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1Dokument3 SeitenDatasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1szystNoch keine Bewertungen

- Technical Datasheet: Engineering SteelDokument1 SeiteTechnical Datasheet: Engineering SteelKarimulla ShaikNoch keine Bewertungen

- Slip StreamDokument1 SeiteSlip StreamvietsdsNoch keine Bewertungen

- 1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBDokument1 Seite1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBRodrigo TeodoroNoch keine Bewertungen

- TDS Hardcarb 70 (#ET - EN - 20.1)Dokument2 SeitenTDS Hardcarb 70 (#ET - EN - 20.1)Jimit ShahNoch keine Bewertungen

- DSMTS-0010.6 ZN WireDokument4 SeitenDSMTS-0010.6 ZN WireMario Cortes FariasNoch keine Bewertungen

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Dokument1 SeiteAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNoch keine Bewertungen

- Technical Specification: B Em9henjDokument6 SeitenTechnical Specification: B Em9henjBartek HajaNoch keine Bewertungen

- Tube Alloy 240 oDokument2 SeitenTube Alloy 240 oelias667Noch keine Bewertungen

- CWC-BookletF1 24Dokument1 SeiteCWC-BookletF1 24Jagannath SahuNoch keine Bewertungen

- Merit S-6: Lincoln Electric China Gmaw Solid WireDokument2 SeitenMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62Noch keine Bewertungen

- Tronic-Cy (Liy-Cy) : Flexible, Colour Coded To DIN 47100, Screened, Meter Marking, EMC-preferred TypeDokument2 SeitenTronic-Cy (Liy-Cy) : Flexible, Colour Coded To DIN 47100, Screened, Meter Marking, EMC-preferred TypealexorigamiNoch keine Bewertungen

- Impact AR500 PlateDokument2 SeitenImpact AR500 PlateMario Diez100% (1)

- Maraging Steels For Aero Space ApplicationDokument33 SeitenMaraging Steels For Aero Space ApplicationKalikota Prasad100% (1)

- GBTDokument1 SeiteGBTRaviTeja BhamidiNoch keine Bewertungen

- Data MP35N Rev-2Dokument2 SeitenData MP35N Rev-2Nishant MehtaNoch keine Bewertungen

- TDS M30 REV2 Apr14 A4Dokument2 SeitenTDS M30 REV2 Apr14 A4dakidofdaboomNoch keine Bewertungen

- Chromcarb N6006: WeldingDokument2 SeitenChromcarb N6006: WeldingCasa de Adoración ConcepciónNoch keine Bewertungen

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Dokument1 SeiteAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNoch keine Bewertungen

- En 8Dokument1 SeiteEn 8Devendera TripathiNoch keine Bewertungen

- NZTM-Q29 - Roll Cage Tube SpecificationDokument1 SeiteNZTM-Q29 - Roll Cage Tube SpecificationDavid TurnerNoch keine Bewertungen

- Nicored 182 PDFDokument1 SeiteNicored 182 PDFDương Quang KhánhNoch keine Bewertungen

- Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-ADokument1 SeiteMiginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNoch keine Bewertungen

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDokument1 SeiteAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNoch keine Bewertungen

- Heavy Copper PCB Manufacturing and Design GuidelinesDokument15 SeitenHeavy Copper PCB Manufacturing and Design GuidelinesjackNoch keine Bewertungen

- Cab. Reg. No. 87 - Requirements For Steel Melting Equipment Etc.Dokument18 SeitenCab. Reg. No. 87 - Requirements For Steel Melting Equipment Etc.rajeevkv4Noch keine Bewertungen

- Identifying Casting DefectsDokument5 SeitenIdentifying Casting Defectsrajeevkv4Noch keine Bewertungen

- Casting Defects2Dokument10 SeitenCasting Defects2rajeevkv4Noch keine Bewertungen

- Ielts App FormDokument8 SeitenIelts App FormrafavandervaartNoch keine Bewertungen

- Electric Furnace SteelDokument9 SeitenElectric Furnace Steelrajeevkv4Noch keine Bewertungen

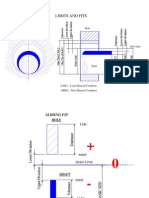

- Limits 10Dokument8 SeitenLimits 10rajeevkv4Noch keine Bewertungen

- Properties of The Transition Elements The Inner Transition Elements Highlights of Selected Transition Elements Coordination Compounds Theoretical Basis For The Bonding and Properties of ComplexesDokument91 SeitenProperties of The Transition Elements The Inner Transition Elements Highlights of Selected Transition Elements Coordination Compounds Theoretical Basis For The Bonding and Properties of ComplexesLuis VicenteNoch keine Bewertungen

- DENR Recognized Environmental Laboratories (062209) PDFDokument9 SeitenDENR Recognized Environmental Laboratories (062209) PDFRonel Lora DaduralNoch keine Bewertungen

- Research and Development Trends of Stainless SteelDokument11 SeitenResearch and Development Trends of Stainless SteelAndy S TjanNoch keine Bewertungen

- Perez, May M. BS PSY 1-6 STS ACTIVITY 1Dokument4 SeitenPerez, May M. BS PSY 1-6 STS ACTIVITY 1May PerezNoch keine Bewertungen

- Provisional Standards For Industrial Pollution Control in Ethiopia - 2Dokument35 SeitenProvisional Standards For Industrial Pollution Control in Ethiopia - 2Tewfic SeidNoch keine Bewertungen

- Valvula Kt585 BolaDokument1 SeiteValvula Kt585 BolaPaola LopezNoch keine Bewertungen

- Tatin CelikDokument52 SeitenTatin Celikgoran073Noch keine Bewertungen

- Lube Analyst Next Generation: Limit Guide ParametersDokument4 SeitenLube Analyst Next Generation: Limit Guide ParametersfrancisNoch keine Bewertungen

- Effect of Alloying Elements On Steel PropertiesDokument2 SeitenEffect of Alloying Elements On Steel PropertiesKARTHIGEYAN.RNoch keine Bewertungen

- HM Chemical Restrictions Part 3Dokument21 SeitenHM Chemical Restrictions Part 3THYAGUNoch keine Bewertungen

- Albalah Et al-2020-SN Applied SciencesDokument9 SeitenAlbalah Et al-2020-SN Applied SciencesDamra MustafaNoch keine Bewertungen

- Henk Alodine 1201 TdsDokument4 SeitenHenk Alodine 1201 TdstassawarNoch keine Bewertungen

- 137877-Article Text-368428-1-10-20160617 PDFDokument6 Seiten137877-Article Text-368428-1-10-20160617 PDFCARLOSALBERTONoch keine Bewertungen

- INDA Hotellerie 2019Dokument28 SeitenINDA Hotellerie 2019Srinivass AmirishettyNoch keine Bewertungen

- Astm E342 PDFDokument3 SeitenAstm E342 PDFMonir100% (1)

- Impact of Biomedical Waste On Environment and Human Health: Environmental Claims Journal May 2019Dokument26 SeitenImpact of Biomedical Waste On Environment and Human Health: Environmental Claims Journal May 2019Vaishnavi DangatNoch keine Bewertungen

- Alloy 308Dokument4 SeitenAlloy 308Branko FerenčakNoch keine Bewertungen

- Chapter 10/part The Application of Ionic Dyes To Ionic Fibers: Nylon, Silk and Wool and Their Sorption of AnionsDokument5 SeitenChapter 10/part The Application of Ionic Dyes To Ionic Fibers: Nylon, Silk and Wool and Their Sorption of AnionsSaurabhNoch keine Bewertungen

- Pinnacle Alloys E6013Dokument2 SeitenPinnacle Alloys E6013rahulNoch keine Bewertungen

- Alloy 316Dokument10 SeitenAlloy 316Branko FerenčakNoch keine Bewertungen

- H-E Parts Data Sheet PT-60 Chromium CarbideDokument1 SeiteH-E Parts Data Sheet PT-60 Chromium CarbideJorge VillalobosNoch keine Bewertungen

- Microbiological and Physicochemical Analyses of Top Soils Obtained From Four Municipal Waste Dumpsites in Benin City, NigeriaDokument8 SeitenMicrobiological and Physicochemical Analyses of Top Soils Obtained From Four Municipal Waste Dumpsites in Benin City, NigeriaInternational Network For Natural SciencesNoch keine Bewertungen