Beruflich Dokumente

Kultur Dokumente

Measuring Engine Components Lesson Plan

Hochgeladen von

api-341297288Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Measuring Engine Components Lesson Plan

Hochgeladen von

api-341297288Copyright:

Verfügbare Formate

Course: Ag Mech & Tech

Unit: Small Engines

Lesson: Measuring Engine Components

Objectives:

Upon completion of this lesson, students should be able to:

1. Identify measuring and testing equipment for internal combustion engines.

2. Identify the specifications of an internal combustion engine.

3. Explain four major specifications to be checked on small engines.

4. Identify micrometer parts.

5. Determine micrometer reading.

Materials:

Measuring Engine Components Lesson Plan (2 copies)

Measuring Engine Components PPT

Micrometer Reading PPT

Smart Board & Computer

Paper & Pencil

Vocabulary:

Compression gage: helps in determining if there is a problem with the cylinder, piston rings,

valves, or gaskets. (lbs per square foot)

Dial indicator: recognizes the spacing between two surfaces and records readings of the dial

needle.

Flat feeler gage: recognizes the spacing between two surfaces.

Inside micrometer set: determines the inside of a cylinder.

Micrometer caliper: precision measuring tool for taking outside measurements.

Plastigage: a thin, plastic, threadlike material used to measure the clearance between the bearing

journal on a crankshaft and the bearing rod cap.

Round-wire gage: used in measuring the electrode gap of spark plugs.

Tachometers: used for reading revolutions per minute.

Telescoping gage: a tool used for measuring inside diameter.

Torque wrench: the hand tool used to measure the amount of torque which bolts and nuts must

be tightened to.

Situation:

There are 15 students in the 1st section of Ag Mech & Tech, with no IEPs or 504 plans.

Prior to this lesson, the students have learned the Engine Parts and have just taken a test over that

part of the unit. Today the students will be learning more in depth about measuring engine

components.

Review/ Interest Approach: (10 minutes)

To start the lesson, students will answer the bell-ringer question in their notebooks. The

question is:

The answer is:

As an addition to the interest approach, the class will review the tests they took yesterday.

We will go over the correct answers and discuss any questions the students may have.

Procedure: (30 minutes)

The first half of this lesson will be the Measuring Engine Components PPT.

1. Slides 1-20 are definitions that we will read through as a review the students completed

a worksheet over these terms one week ago.

2. Slide 21: Specifications

3. Slides 22-26: Major Specifications

a. Fuel use fuel that is recommended by the manufacturer if you put in the wrong

fuel, it could cause engine damage.

i. Carburetor adjustments can have less air or more air coming into the

carburetor and mixing with fuel.

b. Oxygen Need clean air in order for combustion to occur.

i. Debris and contaminants are bad for the engine.

c. Compression Serious problems if no compression. Why maybe bad valves,

bad head gasket, etc. What happens engine will not start without compression.

i. Test method pull the starter rope, no resistance = no compression.

ii. Test with a compression gage.

d. Ignition routinely check spark plugs; engine will not start if spark plugs arent

working.

4. 4. Slide 27: Setting the gap on a Spark Plug

a. Have to adjust the distance between the center and the side electrodes so that they

fire efficiently. Adjusting the distance is called gapping your spark plugs. Use a

feeler gage to get the right distance.

5. Slide 28: Review Questions

The second half of this lesson will be the Micrometer Reading PPT.

1. Slides 3-5: The parts to a micrometer

2. Slides 6-8: How to read the sleeve.

3. Slides 9-14: Examples for how to read the micrometer.

4. Slides 15-16: Quick Review.

Closure: (5 minutes)

The closure for this lesson will be addressing any student concerns or questions. I will also

review with them as time allows.

1. What are some of the instruments used for measuring internal combustion engines?

a. Micrometer caliper, inside micrometer, flat feeler gage, dial indicator, round-

wire gage, plastigage, torque wrench, compression gage, telescoping gage,

and tachometers.

2. What are four major specifications that are commonly checked on small engines?

a. Fuel, Oxygen, Compression, and Ignition.

Assessment:

Students will be asked questions throughout the lesson. The students will be formally assessed

over this at a later date.

Das könnte Ihnen auch gefallen

- Cyberpunk 2020 - Datafortress 2020 - AppleseedDokument30 SeitenCyberpunk 2020 - Datafortress 2020 - AppleseedGeraint BrownNoch keine Bewertungen

- Tle Eim10 Q4 M5Dokument11 SeitenTle Eim10 Q4 M5Ramil ObraNoch keine Bewertungen

- Documentation Matrix DS QMS 00 R2Dokument19 SeitenDocumentation Matrix DS QMS 00 R2DhinakaranNoch keine Bewertungen

- Underwater ROV Control SystemDokument20 SeitenUnderwater ROV Control SystemPhanNamNoch keine Bewertungen

- GRADES 1 To 12 Daily Lesson Log Monday Tuesday Wednesday Thursday FridayDokument5 SeitenGRADES 1 To 12 Daily Lesson Log Monday Tuesday Wednesday Thursday FridayReignz Giangan MosquedaNoch keine Bewertungen

- Science Year 6 (Chapter 1) - Protecting Endangered SpeciesDokument6 SeitenScience Year 6 (Chapter 1) - Protecting Endangered SpeciesTuisyen Dewan Hj AliNoch keine Bewertungen

- Cronasia Foundation College Inc.: TLE - IAEI7/8UT-0a-1Dokument9 SeitenCronasia Foundation College Inc.: TLE - IAEI7/8UT-0a-1noyNoch keine Bewertungen

- The Honest WoodcutterDokument7 SeitenThe Honest WoodcutterELANGNoch keine Bewertungen

- BS en 00054-1-2021Dokument26 SeitenBS en 00054-1-2021Mike DluNoch keine Bewertungen

- ExploraceDokument3 SeitenExploraceSya SyafiayatunNoch keine Bewertungen

- Floral Design Lesson PlanDokument7 SeitenFloral Design Lesson Planapi-341297288100% (1)

- DLL Grade 8 Metal WorksDokument2 SeitenDLL Grade 8 Metal WorksLinda Cudal RaguindinNoch keine Bewertungen

- War On Waste: Inawayan National High-School - Tibolo ExtensionDokument3 SeitenWar On Waste: Inawayan National High-School - Tibolo Extensionrenato roqueNoch keine Bewertungen

- Farm Layout RubricDokument1 SeiteFarm Layout Rubricapi-233392301Noch keine Bewertungen

- Security SY0 501 Study GuideDokument39 SeitenSecurity SY0 501 Study GuidereNoch keine Bewertungen

- ReactivepowerComp usingSTATCOMDokument126 SeitenReactivepowerComp usingSTATCOMsreddy4svuNoch keine Bewertungen

- Installation of A PCS7 Project 1Dokument115 SeitenInstallation of A PCS7 Project 1Mohammad HaiderNoch keine Bewertungen

- Module 5 - TechdrawingDokument92 SeitenModule 5 - Techdrawingarnoldalejado100% (1)

- Analytic Rubric For Diorama Making: Criteria Rating ScaleDokument1 SeiteAnalytic Rubric For Diorama Making: Criteria Rating ScaleSHANNEL ANN VILLUGANoch keine Bewertungen

- Motors - Generators and Transformers PDFDokument46 SeitenMotors - Generators and Transformers PDFYashodhaNoch keine Bewertungen

- Electric Motor Boat ProjectDokument2 SeitenElectric Motor Boat ProjectVinoth KumarNoch keine Bewertungen

- Activity 1 Straw TowersDokument3 SeitenActivity 1 Straw TowersPhillip Cook100% (1)

- Tasksheet 1.6 - Form 4.1. Self-Assessment CheckDokument4 SeitenTasksheet 1.6 - Form 4.1. Self-Assessment CheckAngelica AgaNoch keine Bewertungen

- SMAW BUTT JOINT Evaluation Rubric: Name: Matric NoDokument1 SeiteSMAW BUTT JOINT Evaluation Rubric: Name: Matric NoHairul Effendy Ab MaulodNoch keine Bewertungen

- DLP Tle 6Dokument3 SeitenDLP Tle 6Lyra Fe Grande0% (1)

- 1 - A Electronic CommunicationsDokument56 Seiten1 - A Electronic CommunicationsYui PhantomhiveNoch keine Bewertungen

- Activity On Measuring (Pull Push Rule)Dokument2 SeitenActivity On Measuring (Pull Push Rule)Robert Pugayan0% (1)

- Budget of Work Math 9 3rd QuarterDokument48 SeitenBudget of Work Math 9 3rd Quarterian razoNoch keine Bewertungen

- Ratio Lesson PlanDokument4 SeitenRatio Lesson Planapi-214658810Noch keine Bewertungen

- LRMDS - Evaluation Tool On The Use of Ict Based Lessons in Teaching Grade 8 ChemistryDokument6 SeitenLRMDS - Evaluation Tool On The Use of Ict Based Lessons in Teaching Grade 8 ChemistryKiara Camille RibanoNoch keine Bewertungen

- Rubrics Series and Parallel Circuit PresentartionDokument1 SeiteRubrics Series and Parallel Circuit PresentartionAnneka TugadoNoch keine Bewertungen

- Rubrik POPBLDokument5 SeitenRubrik POPBLludfiNoch keine Bewertungen

- Template - MTDC PitchingDokument20 SeitenTemplate - MTDC PitchingMuhamad Azlan ShahNoch keine Bewertungen

- Trolley Turning and Lifting Mechanism: Ayneendra B, Mohd Salman, Jimmy Thaddeus Ojyok Attari, Marvan EDokument8 SeitenTrolley Turning and Lifting Mechanism: Ayneendra B, Mohd Salman, Jimmy Thaddeus Ojyok Attari, Marvan ERahul PrasadNoch keine Bewertungen

- Practical Task 2Dokument15 SeitenPractical Task 2Kosigar Chelladorai100% (1)

- Electricity Lesson PlanDokument4 SeitenElectricity Lesson Planapi-509821131Noch keine Bewertungen

- Safety Measures in Performing Ignition TimingDokument2 SeitenSafety Measures in Performing Ignition TimingJestoniNoch keine Bewertungen

- Lessonplan Data HandlingDokument5 SeitenLessonplan Data HandlingNur Shahirah Mohd RadziNoch keine Bewertungen

- Lesson Plan (Electricity Bell)Dokument9 SeitenLesson Plan (Electricity Bell)Yolanita Septiana100% (1)

- Dial Kilowatt Hour Meter ReadingDokument18 SeitenDial Kilowatt Hour Meter ReadingGemaiNoch keine Bewertungen

- Preview PDFDokument62 SeitenPreview PDFlembert casinilloNoch keine Bewertungen

- Yearly Plan Science Form 5Dokument32 SeitenYearly Plan Science Form 5saizassr100% (7)

- The Learners Will Be Able To : A. Value Life and Preservation/care For God's CreationDokument3 SeitenThe Learners Will Be Able To : A. Value Life and Preservation/care For God's CreationRobert Carbayas100% (1)

- COT 1 Exemplary Dll-Template COT1Dokument3 SeitenCOT 1 Exemplary Dll-Template COT1Joanne CabangilNoch keine Bewertungen

- Cot in Tle 8Dokument2 SeitenCot in Tle 8AxelJohnBedanaNoch keine Bewertungen

- TLE ExamDokument3 SeitenTLE ExamJennNoch keine Bewertungen

- COT MATH 5 2nd ROUNDING Decimal For ShareDokument4 SeitenCOT MATH 5 2nd ROUNDING Decimal For ShareMary Grace Amador Corto-Villanueva100% (1)

- DLP 03-21Dokument4 SeitenDLP 03-21Jannah Palcis Lacdo-oNoch keine Bewertungen

- A Semi Detailed Lesson Plan in Fundamentals of Electricity IAE 102 I. ObjectivesDokument6 SeitenA Semi Detailed Lesson Plan in Fundamentals of Electricity IAE 102 I. ObjectivesChristian Lumactod EmbolodeNoch keine Bewertungen

- Fluid Mechanics 1Dokument10 SeitenFluid Mechanics 1cheongjiajunNoch keine Bewertungen

- Proposal Projek Cooling FanDokument13 SeitenProposal Projek Cooling FanNor Syafiqah Suhaimi100% (1)

- Department of Education: Learning Activity SheetDokument4 SeitenDepartment of Education: Learning Activity SheetDexter LouisNoch keine Bewertungen

- Lesson Plan InsulatorsconductorsDokument3 SeitenLesson Plan Insulatorsconductorsapi-2676811580% (1)

- O365 Distribution InstructionsDokument8 SeitenO365 Distribution InstructionsEthyle Morales LingbawanNoch keine Bewertungen

- Rubrics in 1st Performance TaskDokument1 SeiteRubrics in 1st Performance TaskCristina Dapetillo - AmistosoNoch keine Bewertungen

- Bridgewater College Teacher Education Program Lesson PlanDokument2 SeitenBridgewater College Teacher Education Program Lesson Planapi-317403302100% (1)

- Q1, Module 1, Lesson4Dokument11 SeitenQ1, Module 1, Lesson4Jerome A. Gomez100% (1)

- Signed ClusteRICE Guidelines IRRDokument30 SeitenSigned ClusteRICE Guidelines IRRren whahahhaNoch keine Bewertungen

- Request For TonnerDokument1 SeiteRequest For TonnerNag28rajNoch keine Bewertungen

- Form 6 Leave TeachersDokument1 SeiteForm 6 Leave TeachersEduardo Zoraida BeraniaNoch keine Bewertungen

- Grade-8 CarpentryDokument22 SeitenGrade-8 CarpentryEdvantic Applicant13Noch keine Bewertungen

- DLL - SCIENCE Grade 5Dokument8 SeitenDLL - SCIENCE Grade 5Donald Dann BuhayanNoch keine Bewertungen

- Photo Album Rubrics: Graphics/ PicturesDokument1 SeitePhoto Album Rubrics: Graphics/ PicturesJeannie DacionNoch keine Bewertungen

- Enhancing The Basic Computer Skills in Microsoft Office Programs of Grade 4 Learners Through ICT 101Dokument21 SeitenEnhancing The Basic Computer Skills in Microsoft Office Programs of Grade 4 Learners Through ICT 101Rox EstandaNoch keine Bewertungen

- MeasurementDokument23 SeitenMeasurementFunwith ScienceNoch keine Bewertungen

- Telling Time Math Lesson PlanDokument2 SeitenTelling Time Math Lesson Planapi-295565394Noch keine Bewertungen

- A6 3 Measuring Engine Components and SpecificationsDokument11 SeitenA6 3 Measuring Engine Components and Specificationscrwood415Noch keine Bewertungen

- Ael I ManualDokument29 SeitenAel I ManualNivedita kNoch keine Bewertungen

- Explaining A Soil Profile Lesson PlanDokument4 SeitenExplaining A Soil Profile Lesson Planapi-341297288100% (2)

- Intro To Ag - Course OutlineDokument5 SeitenIntro To Ag - Course Outlineapi-341297288Noch keine Bewertungen

- Food Additives Lesson PlanDokument7 SeitenFood Additives Lesson Planapi-341297288Noch keine Bewertungen

- Job Applications Interview SkillsDokument5 SeitenJob Applications Interview Skillsapi-341297288Noch keine Bewertungen

- 450 857 07 C44CL Memcom Otis REM6 Wiring Loom V02 MLDokument8 Seiten450 857 07 C44CL Memcom Otis REM6 Wiring Loom V02 MLsam11Noch keine Bewertungen

- Baker Campbell FormulaDokument3 SeitenBaker Campbell FormulaArkayan LahaNoch keine Bewertungen

- Oxygen Enters The Lungs and Then Is Passed On Into Blood. The Blood CarriesDokument9 SeitenOxygen Enters The Lungs and Then Is Passed On Into Blood. The Blood CarriesPranita PotghanNoch keine Bewertungen

- SAP MM-Step by Step Configuration of Split ValuationDokument18 SeitenSAP MM-Step by Step Configuration of Split Valuationjemss emailNoch keine Bewertungen

- Mechatronics Course OutlineDokument3 SeitenMechatronics Course OutlineRoss Mel Bautista LingonNoch keine Bewertungen

- Haxm-Windows v6 0 1Dokument3 SeitenHaxm-Windows v6 0 1Esteban David Ramírez EspinozaNoch keine Bewertungen

- Remotecontrol: Urc-A6Dokument47 SeitenRemotecontrol: Urc-A6Josue TrochezNoch keine Bewertungen

- Fusion Forecourt SystemDokument8 SeitenFusion Forecourt SystemOssama MarzoukNoch keine Bewertungen

- TIBCO BW Performance Best PracticesDokument48 SeitenTIBCO BW Performance Best PracticesSrinivasKannanNoch keine Bewertungen

- Audit Program TempleteDokument3 SeitenAudit Program TempleteKudakwashe ChiwunyaNoch keine Bewertungen

- Renub Research: Published: May, 2012Dokument12 SeitenRenub Research: Published: May, 2012api-114525849Noch keine Bewertungen

- M1GN1Dokument2 SeitenM1GN1isabelNoch keine Bewertungen

- Siemens 840D Programing Manual enDokument215 SeitenSiemens 840D Programing Manual enalejandro777_eNoch keine Bewertungen

- Unit01-Getting Started With .NET Framework 4.0Dokument40 SeitenUnit01-Getting Started With .NET Framework 4.0mgsumaNoch keine Bewertungen

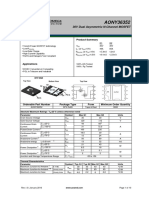

- AONY36352: 30V Dual Asymmetric N-Channel MOSFETDokument10 SeitenAONY36352: 30V Dual Asymmetric N-Channel MOSFETrobertjavi1983Noch keine Bewertungen

- Rajesh Vasa - PHD ThesisDokument252 SeitenRajesh Vasa - PHD Thesisrajeshvasa100% (1)

- M.Des IIT Delhi Brochure PDFDokument22 SeitenM.Des IIT Delhi Brochure PDFAnandu KBNoch keine Bewertungen

- Sag Tension (ACCC Casablanca)Dokument2 SeitenSag Tension (ACCC Casablanca)Subodh SontakkeNoch keine Bewertungen

- Boarding Pass (Web Check In) WWW - Goindigo.In: Ms Jasda Ramchandani Jaipur (T2) 6E 783 08 Aug 20Dokument1 SeiteBoarding Pass (Web Check In) WWW - Goindigo.In: Ms Jasda Ramchandani Jaipur (T2) 6E 783 08 Aug 20Kscsiddhant KscsiddhantNoch keine Bewertungen

- Agc 150 Designers Handbook 4189341188 UkDokument398 SeitenAgc 150 Designers Handbook 4189341188 UkMaicon ZagonelNoch keine Bewertungen

- Welcome To The Next Lecture On Design For Modularity. (Refer Slide Time: 00:18)Dokument19 SeitenWelcome To The Next Lecture On Design For Modularity. (Refer Slide Time: 00:18)SURESH SNoch keine Bewertungen

- State Management in React NativeDokument25 SeitenState Management in React NativeRüstem EleçNoch keine Bewertungen

- CN RecordDokument60 SeitenCN RecordAhmed JabriNoch keine Bewertungen